How to Install Helical Inserts

More

How to Install Key-Locking Inserts

More

About Nuts, Materials, and Finishes

More

Mil. Spec. Stainless Steel Key-Locking Inserts

These inserts are made to stringent military specifications. Drive the keys into the surrounding material for a more secure hold than thread-locking inserts. Use them to repair or change threads in soft metals such as aluminum. Inserts may be mildly magnetic. They’re comparable to Keensert® inserts. Installation requires a drill bit, a standard tap, an installation tool, and a hammer.

Inserts with a thin wall are often used in small holes or near the edge of a workpiece.

Choose inserts with a thick wall for greater strength than thin-wall inserts, or to fill a large hole.

Inserts | Installation Tools | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Thread Size | For Tap Thread Size | Installed Lg. | Drill Bit Size | For Max. Hole Dia. | No. of Locking Keys | Specifications Met | Each | Each | ||

18-8 Stainless Steel with Thin Wall | ||||||||||

| 4-40 | 12-24 | 1/4" | 14 | 0.183" | 2 | NAS1395C04 | 000000000 | 00000 | 000000000 | 000000 |

| 10-32 | 5/16"-18 | 5/16" | I | 0.276" | 2 | MS51830-201, NAS1394C3 | 000000000 | 0000 | 000000000 | 00000 |

| 1/4"-28 | 3/8"-16 | 3/8" | Q | 0.336" | 2 | MS51830-202, NAS1394C4 | 000000000 | 0000 | 000000000 | 00000 |

| 5/16"-24 | 7/16"-14 | 7/16" | X | 0.401" | 4 | MS51830-203, NAS1394C5 | 000000000 | 0000 | 000000000 | 00000 |

| 3/8"-24 | 1/2"-13 | 1/2" | 29/64" | 0.457" | 4 | MS51830-204, NAS1394C6 | 000000000 | 0000 | 000000000 | 00000 |

| 7/16"-20 | 9/16"-12 | 9/16" | 33/64" | 0.521" | 4 | MS51830-205, NAS1394C7 | 000000000 | 0000 | 000000000 | 00000 |

| 1/2"-20 | 5/8"-11 | 5/8" | 37/64" | 0.583" | 4 | MS51830-206, NAS1394C8 | 000000000 | 0000 | 000000000 | 00000 |

18-8 Stainless Steel with Thick Wall | ||||||||||

| 10-32 | 3/8"-16 | 5/16" | Q | 0.336" | 2 | MS51831-201, NAS1395C3 | 000000000 | 0000 | 000000000 | 00000 |

| 1/4"-28 | 7/16"-14 | 3/8" | X | 0.401" | 2 | MS51831-202, NAS1395C4 | 000000000 | 0000 | 000000000 | 00000 |

| 5/16"-24 | 1/2"-13 | 7/16" | 29/64" | 0.457" | 4 | MS51831-203, NAS1395C5 | 000000000 | 0000 | 000000000 | 00000 |

| 3/8"-24 | 9/16"-12 | 1/2" | 33/64" | 0.521" | 4 | MS51831-204, NAS1395C6 | 000000000 | 0000 | 000000000 | 00000 |

| 7/16"-20 | 5/8"-11 | 5/8" | 37/64" | 0.583" | 4 | MS51831-205, NAS1395C7 | 000000000 | 0000 | 000000000 | 00000 |

| 1/2"-20 | 11/16"-11 | 11/16" | 41/64" | 0.646" | 4 | MS51831-206, NAS1395C8 | 000000000 | 00000 | 000000000 | 00000 |

| 9/16"-18 | 13/16"-16 | 13/16" | 49/64" | 0.771" | 4 | MS51831-207, NAS1395C9 | 000000000 | 00000 | 000000000 | 00000 |

| 5/8"-18 | 7/8"-14 | 7/8" | 53/64" | 0.833" | 4 | MS51831-208, NAS1395C10 | 000000000 | 00000 | 000000000 | 00000 |

| 3/4"-16 | 1 1/8"-12 | 1 1/8" | 1 1/16" | 1.067" | 4 | MS51831-209 | 000000000 | 00000 | 000000000 | 000000 |

| 7/8"-14 | 1 1/4"-12 | 1 1/4" | 1 3/16" | 1.192" | 4 | MS51831-210 | 000000000 | 00000 | 000000 | 00 |

| 1"-12 | 1 3/8"-12 | 1 3/8" | 1 5/16" | 1.317" | 4 | MS51831-211 | 000000000 | 00000 | 000000000 | 000000 |

18-8 Stainless Steel with Extra Thick Wall | ||||||||||

| 10-32 | 7/16"-14 | 5/16" | X | 0.401" | 2 | MS51832-201 | 000000000 | 00000 | 000000000 | 00000 |

| 1/4"-28 | 1/2"-13 | 3/8" | 29/64" | 0.457" | 4 | MS51832-202 | 000000000 | 00000 | 000000000 | 00000 |

| 5/16"-24 | 9/16"-12 | 7/16" | 33/64" | 0.521" | 4 | MS51832-203 | 000000000 | 00000 | 000000000 | 00000 |

| 3/8"-24 | 5/8"-11 | 1/2" | 37/64" | 0.583" | 4 | MS51832-204 | 000000000 | 00000 | 000000000 | 00000 |

| 1/2"-20 | 13/16"-16 | 11/16" | 49/64" | 0.771" | 4 | MS51832-206 | 000000000 | 00000 | 000000000 | 00000 |

| 9/16"-18 | 7/8"-14 | 13/16" | 53/64" | 0.833" | 4 | MS51832-207 | 000000000 | 00000 | 000000000 | 00000 |

| 5/8"-18 | 1"-12 | 7/8" | 15/16" | 0.942" | 4 | MS51832-208 | 000000000 | 00000 | 000000000 | 00000 |

Mil. Spec. Alloy Steel Key-Locking Inserts

The strongest key-locking inserts we offer, these inserts are made to stringent military specifications. Drive the keys into the surrounding material for a more secure hold than thread-locking inserts. Use them to repair or change threads in soft metals such as aluminum. Inserts may be mildly magnetic. They’re comparable to Keensert® inserts. Installation requires a drill bit, a standard tap, an installation tool, and a hammer.

Inserts with a thin wall are often used in small holes or near the edge of a workpiece.

Choose inserts with a thick wall for greater strength than thin-wall inserts, or to fill a large hole.

Inserts | Installation Tools | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Thread Size | For Tap Thread Size | Installed Lg. | Drill Bit Size | For Max. Hole Dia. | No. of Locking Keys | Specifications Met | Each | Each | ||

Cadmium-Plated Alloy Steel with Thin Wall | ||||||||||

| 10-32 | 5/16"-18 | 5/16" | I | 0.272" | 2 | MS51830A201, NAS1394-3 | 000000000 | 00000 | 000000000 | 000000 |

| 1/4"-28 | 3/8"-16 | 3/8" | Q | 0.332" | 2 | MS51830A202, NAS1394-4 | 000000000 | 0000 | 000000000 | 00000 |

| 5/16"-24 | 7/16"-14 | 7/16" | X | 0.397" | 4 | MS51830A203, NAS1394-5 | 000000000 | 0000 | 000000000 | 00000 |

| 3/8"-24 | 1/2"-13 | 1/2" | 29/64" | 29/64" | 4 | MS51830A204, NAS1394-6 | 000000000 | 0000 | 000000000 | 00000 |

| 7/16"-20 | 9/16"-12 | 9/16" | 33/64" | 33/64" | 4 | MS51830A205, NAS1394-7 | 000000000 | 0000 | 000000000 | 00000 |

| 1/2"-20 | 5/8"-11 | 5/8" | 37/64" | 37/64" | 4 | MS51830A206, NAS1394-8 | 000000000 | 0000 | 000000000 | 00000 |

Cadmium-Plated Alloy Steel with Thick Wall | ||||||||||

| 10-32 | 3/8"-16 | 5/16" | Q | 0.332" | 2 | MS51831A201, NAS1395-3 | 000000000 | 00000 | 000000000 | 00000 |

| 1/4"-28 | 7/16"-14 | 3/8" | X | 0.397" | 2 | MS51831A202, NAS1395-4 | 000000000 | 0000 | 000000000 | 00000 |

| 5/16"-24 | 1/2"-13 | 7/16" | 29/64" | 29/64" | 4 | MS51831A203 | 000000000 | 0000 | 000000000 | 00000 |

| 3/8"-24 | 9/16"-12 | 1/2" | 33/64" | 33/64" | 4 | MS51831A204 | 000000000 | 0000 | 000000000 | 00000 |

| 7/16"-20 | 5/8"-11 | 5/8" | 37/64" | 37/64" | 4 | MS51831A205, NAS1395-7 | 000000000 | 0000 | 000000000 | 00000 |

| 1/2"-20 | 11/16"-11 | 11/16" | 41/64" | 41/64" | 4 | MS51831A206, NAS1395-8 | 000000000 | 0000 | 000000000 | 00000 |

| 9/16"-18 | 13/16"-16 | 13/16" | 49/64" | 49/64" | 4 | MS51831A207, NAS1395-9 | 000000000 | 00000 | 000000000 | 00000 |

| 5/8"-18 | 7/8"-14 | 7/8" | 53/64" | 53/64" | 4 | MS51831A208 | 000000000 | 00000 | 000000000 | 00000 |

| 3/4"-16 | 1 1/8"-12 | 1 1/8" | 1 1/16" | 1.062" | 4 | MS51831A209 | 000000000 | 00000 | 000000000 | 000000 |

High-Strength A286 Stainless Steel Key-Locking Inserts

The strongest and most corrosion-resistant stainless steel key-locking inserts we offer. Made of A286 stainless steel, these inserts stand up to salt water, harsh chemicals, and even high temperatures. Since you drive the keys into the surrounding material, these inserts also give you a more secure hold than thread-locking inserts. Use them to repair or add new, reusable threads to aluminum and other soft metal. They’re comparable to Keensert® inserts. Those that meet stringent military specifications or National Aerospace Standards have high-precision threads and tight tolerances.

Install them using a drill bit, a standard tap, an installation tool, and a hammer.

Inserts with a thin wall are often used in small holes or near the edge of a workpiece.

Choose inserts with a thick wall for large holes. They’re often used when you need to drill out damaged threads.

Inserts | Installation Tools | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Thread Size | For Tap Thread Size | Installed Lg. | Drill Bit Size | For Max. Hole Dia. | No. of Locking Keys | Specifications Met | Each | Each | ||

A286 Stainless Steel with Thin Wall | ||||||||||

| 1/4"-28 | 3/8"-16 | 3/8" | Q | 0.332" | 2 | MS51830CA202 | 000000000 | 000000 | 000000000 | 000000 |

| 5/16"-24 | 7/16"-14 | 7/16" | X | 0.397" | 4 | MS51830CA203 | 000000000 | 00000 | 000000000 | 00000 |

| 3/8"-24 | 1/2"-13 | 1/2" | 29/64" | 0.453" | 4 | MS51830CA204 | 000000000 | 00000 | 000000000 | 00000 |

| 1/2"-20 | 5/8"-11 | 5/8" | 37/64" | 0.578" | 4 | MS51830CA206 | 000000000 | 00000 | 000000000 | 00000 |

A286 Stainless Steel with Thick Wall | ||||||||||

| 10-32 | 3/8"-16 | 5/16" | Q | 0.332" | 2 | MS51831CA201 | 000000000 | 00000 | 000000000 | 00000 |

| 1/4"-28 | 7/16"-14 | 3/8" | X | 0.397" | 2 | MS51831CA202 | 000000000 | 00000 | 000000000 | 00000 |

| 5/16"-24 | 1/2"-13 | 7/16" | 29/64" | 0.453" | 4 | MS51831CA203 | 000000000 | 00000 | 000000000 | 00000 |

| 3/8"-24 | 9/16"-12 | 1/2" | 33/64" | 0.516" | 4 | MS51831CA204 | 000000000 | 00000 | 000000000 | 00000 |

| 5/8"-18 | 7/8"-14 | 7/8" | 53/64" | 0.828" | 4 | MS51831CA208 | 000000000 | 00000 | 000000000 | 00000 |

Mil. Spec. Rivet-Mount Nuts

Create threads in hard-to-work areas—where you can’t reach the back of a workpiece, or material is too thin to be tapped. For a strong grip, these nuts have distorted threads that increase friction with bolts. Because they mount with two rivets, they won’t spin when you’re tightening screws. However, these nuts do move inside their retainers, which lets you install bolts at a slight angle; use them to align with off-center parts. All meet military guidelines for dimensions and material.

Cadmium-plated nuts resist corrosion in industrial and saltwater environments, although will lose their corrosion resistance over 450° F. The cadmium plating also adds lubricity, making these nuts easy to install.

A286 stainless steel nuts are corrosion resistant. Silver-plated stainless steel nuts withstand temperatures up to 800° F. The silver plating also adds lubricity and prevents seizing caused by friction between nuts and bolts.

Lubricated nuts thread onto bolts smoothly.

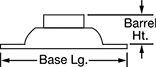

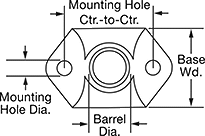

Base | Barrel | Mounting | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Thread Size | Lg. | Wd. | Thick. | Dia. | Ht. | No. of Holes | Hole Dia. | Hole Ctr.-to-Ctr. | Specifications Met | Each | |

Steel—Unlubricated | |||||||||||

| 10-32 | 47/64" | 13/32" | 3/32" | 0.234" | 5/32" | 2 | 0.098" | 1/2" | MS21075-3N | 000000000 | 00000 |

| 1/4"-28 | 51/64" | 1/2" | 3/32" | 0.313" | 3/16" | 2 | 0.098" | 9/16" | MS21075-4N | 000000000 | 0000 |

Cadmium-Plated Steel—Lubricated | |||||||||||

| 10-32 | 47/64" | 13/32" | 3/32" | 0.234" | 5/32" | 2 | 0.098" | 1/2" | MS21075L3N | 000000000 | 0000 |

| 1/4"-28 | 51/64" | 1/2" | 3/32" | 0.313" | 3/16" | 2 | 0.098" | 9/16" | MS21075L4N | 000000000 | 0000 |

Carbon Steel—Unlubricated | |||||||||||

| 10-32 | 61/64" | 13/32" | 1/32" | 0.234" | 7/32" | 2 | 0.098" | 11/16" | MS21059-3 | 000000000 | 0000 |

| 1/4"-28 | 1 19/64" | 33/64" | 1/32" | 0.313" | 1/4" | 2 | 0.098" | 1" | MS21059-4 | 000000000 | 0000 |

Cadmium-Plated Carbon Steel—Lubricated | |||||||||||

| 10-32 | 61/64" | 13/32" | 1/32" | 0.234" | 7/32" | 2 | 0.098" | 11/16" | MS21059L3 | 000000000 | 0000 |

| 1/4"-28 | 1 19/64" | 33/64" | 1/32" | 0.313" | 1/4" | 2 | 0.098" | 1" | MS21059L4 | 000000000 | 0000 |

| 5/16"-24 | 1 19/64" | 39/64" | 3/64" | 0.375" | 9/32" | 2 | 0.13" | 1" | MS21059L5 | 000000000 | 00000 |

| 3/8"-24 | 1 19/64" | 43/64" | 1/16" | 0.453" | 19/64" | 2 | 0.13" | 1" | MS21059L6 | 000000000 | 00000 |

A286 Stainless Steel—Lubricated | |||||||||||

| 10-32 | 47/64" | 13/32" | 3/32" | 0.234" | 5/32" | 2 | 0.098" | 1/2" | MS21076L3N | 000000000 | 0000 |

| 10-32 | 61/64" | 13/32" | 1/32" | 0.234" | 7/32" | 2 | 0.098" | 11/16" | MS21060L3 | 000000000 | 0000 |

| 1/4"-28 | 51/64" | 1/2" | 3/32" | 0.313" | 3/16" | 2 | 0.098" | 9/16" | MS21076L4N | 000000000 | 0000 |

| 1/4"-28 | 1 19/64" | 33/64" | 1/32" | 0.313" | 1/4" | 2 | 0.098" | 1" | MS21060L4 | 000000000 | 00000 |

| 5/16"-24 | 1 1/64" | 37/64" | 7/64" | 0.391" | 7/32" | 2 | 0.13" | 23/32" | MS21076L5N | 000000000 | 00000 |

| 5/16"-24 | 1 19/64" | 39/64" | 3/64" | 0.375" | 9/32" | 2 | 0.13" | 1" | MS21060L5 | 000000000 | 00000 |

| 3/8"-24 | 1 19/64" | 43/64" | 1/16" | 0.453" | 19/64" | 2 | 0.13" | 1" | MS21060L6 | 000000000 | 00000 |

Silver-Plated A286 Stainless Steel—Unlubricated | |||||||||||

| 10-32 | 47/64" | 13/32" | 3/32" | 0.234" | 5/32" | 2 | 0.098" | 1/2" | MS21076-3N | 000000000 | 0000 |

| 10-32 | 61/64" | 13/32" | 1/32" | 0.234" | 7/32" | 2 | 0.098" | 11/16" | MS21060-3 | 000000000 | 0000 |

| 1/4"-28 | 51/64" | 1/2" | 3/32" | 0.313" | 3/16" | 2 | 0.098" | 9/16" | MS21076-4N | 000000000 | 00000 |

| 1/4"-28 | 1 19/64" | 33/64" | 1/32" | 0.313" | 1/4" | 2 | 0.098" | 1" | MS21060-4 | 000000000 | 00000 |

| 5/16"-24 | 1 1/64" | 37/64" | 7/64" | 0.391" | 7/32" | 2 | 0.13" | 23/32" | MS21076-5N | 000000000 | 00000 |