About Heat-Shrink Tubing

More

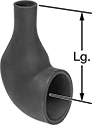

Tapered Heat-Shrink Tubing

- Material: Polyolefin Plastic

- Shrink Ratio: See Table

- Dielectric Strength: 200 V/mil

- Shrink Temperature: 250° F

- Temperature Range: -65° to 275° F

A different shrink ratio on each end allows this tubing to fit over cable assemblies and wire harnesses with large connections, or around connectors with a 90° elbow. An adhesive lining melts when the tubing is heated and bonds to the underlying surface, creating a water-resistant seal. The tubing length listed is after shrinking; the length before shrinking is 20-25% shorter.

Lipped tubing has a ridge on the inside of one opening for better retention than non-lipped tubing. It’s often used with grooved adapters—upon shrinking, the lip grips onto the groove.

Dielectric strength is the maximum voltage a material can handle before it starts to breakdown.

Tapered End | Non-Tapered End | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Style | ID Before Shrinking | Min. ID After Shrinking | Shrink Ratio | ID Before Shrinking | Min. ID After Shrinking | Shrink Ratio | Min. Wall Thick. After Shrinking | Color | End Style | Lg. | Each | |

| D | 1.25" | 0.28" | 4.5:1 | 1.25" | 0.75" | 1.7:1 | 0.09" | Black | Lipped | 1.4" | 0000000 | 000000 |

| D | 1.25" | 0.28" | 4.5:1 | 1.25" | 0.75" | 1.7:1 | 0.09" | Black | Non Lipped | 1.4" | 0000000 | 00000 |

| D | 1.5" | 0.33" | 4.5:1 | 1.5" | 0.75" | 2:1 | 0.1" | Black | Lipped | 1.7" | 0000000 | 00000 |

| D | 1.5" | 0.33" | 4.5:1 | 1.5" | 0.75" | 2:1 | 0.1" | Black | Non Lipped | 1.7" | 0000000 | 00000 |

| D | 1.75" | 0.38" | 4.6:1 | 1.75" | 1.1" | 1.6:1 | 0.13" | Black | Lipped | 2.1" | 0000000 | 00000 |

| D | 1.75" | 0.38" | 4.6:1 | 1.75" | 1.1" | 1.6:1 | 0.13" | Black | Non Lipped | 2.1" | 0000000 | 00000 |

| D | 2" | 0.62" | 3.2:1 | 2" | 1.6" | 1.3:1 | 0.13" | Black | Non Lipped | 3" | 0000000 | 00000 |

| E | 3" | 0.86" | 3.5:1 | 3" | 1.41" | 2.1:1 | 0.18" | Black | Non Lipped | 5" | 0000000 | 000000 |