Filter by

For Use With

Maximum Flow Rate

Maximum Pressure

Power Source

Maximum Temperature

Priming Type

Pump Type

Drive Direction

Maximum Feet of Head

Fixed Displacement Rate

Key Length

Electrical Phase

DFARS Specialty Metals

REACH

Constant-Flow-Rate Gear Pumps for Oil

Intake (NPT) | Discharge (NPT) | Overall | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Max. Flow Rate | Max. ft. of Head, ft. | Max. Pressure, psi | Max. Viscosity, cP | Temp. Range, ° F | Power, hp | Current | Pipe Size | Connection | Gender | Pipe Size | Connection | Gender | Lg. | Wd. | Ht. | Cannot Be Sold To | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

240V AC/460V AC, Three Phase—Without Thermal Overload Protection | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Hardwire | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 gpm | 577 | 250 | 880 | -20 to 240 | 1/2 | 2 amp/1 amp | 1/2 | Threaded | Female | 1/2 | Threaded | Female | 21 5/8" | 6 7/8" | 8 1/2" | Outside North America | 00000000 | 000000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

208V AC to 240V AC/460V AC, Three Phase—Without Thermal Overload Protection | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Hardwire | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10 gpm | 577 | 250 | 880 | -20 to 240 | 2 | 6.2 amp/3.1 amp | 3/4 | Threaded | Female | 3/4 | Threaded | Female | 24" | 6 7/8" | 8 1/2" | Outside North America | 00000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 20 gpm | 577 | 250 | 880 | -20 to 240 | 2 | 6.2 amp/3.1 amp | 1 | Threaded | Female | 1 | Threaded | Female | 24 1/2" | 6 7/8" | 8 1/2" | Outside North America | 00000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 30 gpm | 577 | 250 | 880 | -20 to 240 | 3 | 8.2 amp/4.1 amp | 1 | Threaded | Female | 1 | Threaded | Female | 25" | 6 7/8" | 8 1/2" | Outside North America | 00000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 40 gpm | 577 | 250 | 880 | -20 to 240 | 5 | 13.8 amp/6.9 amp | 1 1/2 | Threaded | Female | 1 1/2 | Threaded | Female | 28 1/8" | 11 7/8" | 8 1/2" | Outside North America | 00000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Hydraulic Gear Pumps

SAE 4F17—2" Mounting Hole Center-to-Center

|  |

Inlet Connection | Outlet Connection | Overall | Shaft | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Fixed Displacement Rate, in³/rev | Max. Flow Rate | Max. Pressure, psi | Max. Rotation Speed, rpm | Thread Size | Thread Type | Dash Size | Thread Size | Thread Type | Dash Size | Lg. | Ht. | Dia. | Lg. | Drive Direction | Each | |||

| 0.07 | 0.8 gpm | 3,000 | 4,000 | 9/16"-18 | UN/UNF (SAE Straight) | 06 | 9/16"-18 | UN/UNF (SAE Straight) | 06 | 4 5/8" | 3 7/16" | 1/2" | 1 3/8" | Clockwise, Counterclockwise | 0000000 | 0000000 | ||

| 0.13 | 1.7 gpm | 3,000 | 4,000 | 3/4"-16 | UN/UNF (SAE Straight) | 08 | 3/4"-16 | UN/UNF (SAE Straight) | 08 | 4 5/8" | 3 7/16" | 1/2" | 1 3/8" | Clockwise, Counterclockwise | 0000000 | 000000 | ||

| 0.39 | 5 gpm | 3,000 | 4,000 | 7/8"-14 | UN/UNF (SAE Straight) | 10 | 7/8"-14 | UN/UNF (SAE Straight) | 10 | 5 1/8" | 3 7/16" | 1/2" | 1 3/8" | Clockwise, Counterclockwise | 0000000 | 000000 | ||

| 0.71 | 5.4 gpm | 1,800 | 2,400 | 7/8"-14 | UN/UNF (SAE Straight) | 10 | 7/8"-14 | UN/UNF (SAE Straight) | 10 | 5 5/8" | 3 7/16" | 1/2" | 1 3/8" | Clockwise, Counterclockwise | 0000000 | 000000 | ||

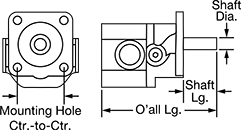

Constant-Flow-Rate Gear Pumps without Motor for Oil

Required hp, hp | Intake (NPT) | Discharge (NPT) | Overall | Shaft | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Max. Flow Rate @ 25 psi, gpm | Max. Flow Rate | Max. ft. of Head, ft. | Max. Pressure, psi | Max. Viscosity, cP | Temp. Range, ° F | @ 25 psi | @ 100 psi | Pipe Size | Connection | Gender | Pipe Size | Connection | Gender | Lg. | Wd. | Ht. | Dia. | Lg. | Ctr.-to-Base Lg. | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For 1,725 rpm Maximum Motor Speed | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8.9 | 9 gpm | 462 | 200 | 20,000 | -20 to 400 | 3/4 | 1 | 1/2 | Threaded | Female | 1/2 | Threaded | Female | 7 1/4" | 3 7/16" | 4 1/2" | 5/8" | 1 9/16" | 3" | 00000000 | 000000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||