About Sleeving

More

Corrugated Sleeving

Slide this sleeving over wire, cable, or hose before adding connectors or making electrical connections. The corrugated construction gives it impact and abrasion resistance similar to conduit, but with more flexibility. It’s ultra-flexible so it’s good for applications that require tight turns. Since it doesn’t have a slit, it keeps out more dust and debris than slit corrugated sleeving.

Steel sleeving is more impact resistant than stainless steel and aluminum sleeving, so it’s better for use in high traffic areas where equipment or people could bump into it.

| ID | OD | Temperature Range, °F | Lengths, ft. | Per Ft. | |

Steel | |||||

|---|---|---|---|---|---|

| 1/8" | 1/4" | -40° to 390° | 000000000 | 00000 | |

| 5/32" | 1/4" | -40° to 450° | 00000000 | 000 | |

| 3/16" | 9/32" | -40° to 450° | 00000000 | 0000 | |

| 7/32" | 5/16" | -40° to 450° | 00000000 | 0000 | |

| 1/4" | 11/32" | -40° to 450° | 00000000 | 0000 | |

| 5/16" | 13/32" | -40° to 450° | 00000000 | 0000 | |

| 3/8" | 1/2" | -40° to 450° | 00000000 | 0000 | |

| 1/2" | 5/8" | -40° to 450° | 00000000 | 0000 | |

| 5/8" | 3/4" | -40° to 390° | 000000000 | 0000 | |

| 3/4" | 31/32" | -40° to 450° | 00000000 | 0000 | |

| 1" | 1 1/8" | -40° to 390° | 000000000 | 0000 | |

| 1 1/2" | 1 3/4" | -40° to 390° | 000000000 | 0000 | |

| 2" | 2 1/4" | -40° to 390° | 000000000 | 0000 | |

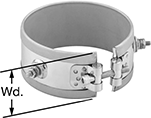

Heavy Duty Wrap-Around Heaters for Pails and Drums

For applications requiring high heat over long periods of time, these aluminized steel heaters warm up faster and are more durable than silicone rubber heaters. They wrap around containers to heat contents without direct contact. Heaters should be positioned at the base of the pail or drum. The spring-loaded clamp closure allows heaters to expand to fit around slightly larger container diameters. Heaters are not for use with flammable materials or in hazardous areas.

Heaters with three output settings have a dial to select low, medium, or high watt density.

Nonadjustable thermostat automatically turns the heater on when the temperature drops below the factory-set temperature and off when it rises above the factory-set temperature. The thermostat keeps the heater temperature at or below 165° F. Adjustable thermostats automatically turn the heater on when the temperature drops below your set temperature and off when it rises above your set temperature. Adjust the set temperature with the dial.

Time-cycle controllers constantly cycle on and off to maintain your set temperature with less fluctuation than thermostats. Turn the dial to adjust the ratio of on to off time. Controllers require a thermometer (sold separately) for calibration and temperature monitoring.

For Container | O'all | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cap., gal. | Dia. | Lg. | Wd. | Wattage, W | Watt Density, W/sq. in. | Voltage | Electrical Phase | Current, A | Thick. | NEMA Style | For Surface Material | Each | |

Nonadjustable Thermostat—With One Output Setting | |||||||||||||

165° F Max. Heat Output | |||||||||||||

| 55 | 22 1/2" | 67 5/8" | 9 1/4" | 800 | 1.71 | 120V AC | Single | 6.6 | 3/16" | 5-15 | Plastic | 0000000 | 0000000 |

Adjustable Thermostat—With Three Output Settings | |||||||||||||

200° to 400° F Temp. Control Range | |||||||||||||

| 5 | 11 1/4" | 33 3/8" | 5" | 1,500 | 3 6 12 | 120V AC | Single | 12.5 | 11/16" | 5-15 | Metal | 0000000 | 000000 |

| 16 | 14 1/2" | 43 1/2" | 5" | 1,500 | 2.35 4.69 9.38 | 120V AC | Single | 12.5 | 11/16" | 5-15 | Metal | 0000000 | 000000 |

| 30 | 18 1/2" | 54 7/8" | 5" | 1,920 | 2.4 4.8 9.6 | 120V AC | Single | 16 | 11/16" | 5-20 | Metal | 0000000 | 000000 |

| 55 | 22 1/2" | 67 5/8" | 5" | 1,750 | 1.69 3.37 6.73 | 120V AC | Single | 14.6 | 11/16" | 5-15 | Metal | 0000000 | 000000 |

| 55 | 22 1/2" | 67 5/8" | 5" | 1,920 | 1.85 3.7 7.4 | 120V AC | Single | 16 | 11/16" | 5-20 | Metal | 0000000 | 000000 |

| 55 | 22 1/2" | 67 5/8" | 5" | 3,000 | 2.88 5.77 11.54 | 240V AC | Single | 12.5 | 11/16" | 6-15 | Metal | 0000000 | 000000 |

60° to 250° F Temp. Control Range | |||||||||||||

| 5 | 11 1/4" | 33 3/8" | 5" | 1,500 | 3 6 12 | 120V AC | Single | 12.5 | 11/16" | 5-15 | Metal | 0000000 | 000000 |

| 16 | 14 1/2" | 43 1/2" | 5" | 1,500 | 2.35 4.69 9.38 | 120V AC | Single | 12.5 | 11/16" | 5-15 | Metal | 0000000 | 000000 |

| 30 | 18 1/2" | 54 7/8" | 5" | 1,920 | 2.4 4.8 9.6 | 120V AC | Single | 16 | 11/16" | 5-20 | Metal | 0000000 | 000000 |

| 55 | 22 1/2" | 67 5/8" | 5" | 1,750 | 1.69 3.37 6.73 | 120V AC | Single | 14.6 | 11/16" | 5-15 | Metal | 0000000 | 000000 |

| 55 | 22 1/2" | 67 5/8" | 5" | 1,920 | 1.85 3.7 7.4 | 120V AC | Single | 16 | 11/16" | 5-20 | Metal | 0000000 | 000000 |

| 55 | 22 1/2" | 67 5/8" | 5" | 3,000 | 2.88 5.77 11.54 | 240V AC | Single | 12.5 | 11/16" | 6-15 | Metal | 0000000 | 000000 |

Time-Cycle Controller—With Three Output Settings | |||||||||||||

500° F Max. Heat Output | |||||||||||||

| 5 | 11 1/4" | 33 3/8" | 5" | 1,500 | 3 6 12 | 120V AC | Single | 12.5 | 11/16" | 5-15 | Metal | 0000000 | 000000 |

| 16 | 14 1/2" | 43 1/2" | 5" | 1,500 | 2.35 4.69 9.38 | 120V AC | Single | 12.5 | 11/16" | 5-15 | Metal | 0000000 | 000000 |

| 30 | 18 1/2" | 54 7/8" | 5" | 1,750 | 2.18 4.38 8.75 | 120V AC | Single | 14.6 | 11/16" | 5-20 | Metal | 0000000 | 000000 |

| 55 | 22 1/2" | 67 5/8" | 5" | 1,750 | 1.68 3.36 6.73 | 120V AC | Single | 14.6 | 11/16" | 5-20 | Metal | 0000000 | 000000 |

| 55 | 22 1/2" | 67 5/8" | 5" | 3,000 | 2.88 5.77 11.54 | 240V AC | Single | 12.5 | 11/16" | 6-15 | Metal | 0000000 | 000000 |

Noncontact Wrap-Around Heaters for Pails and Drums

To prevent hot spots that can damage heat-sensitive materials such as adhesives, sealants, and food, these heaters warm the air around containers without touching them. They provide uniform heat to 80% of the container. An adjustable thermostat automatically turns the heater on when the temperature drops below your set temperature and off when it rises above your set temperature. Adjust the set temperature with the dial. Do not use these heaters with flammable materials or in hazardous areas.

Heaters for 5-gallon containers do not open; set containers in from the top.

Heaters for 55-gallon containers close around containers. They are mounted on casters.

| For Container Dia. | O'all Ht. | Wattage, W | Watt Density, W/sq. in. | Voltage | Electrical Phase | Current, A | OD | Max. Heat Output, °F | NEMA Style | Cord Lg., ft. | For Surface Material | Housing Material | Insulation Material | Each | |

For 5-Gallon Containers | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

60° to 250° F Temp. Control Range | |||||||||||||||

| 12" | 13" | 1,350 | 81 | 120V AC | Single | 12 | 22" | 250° | 5-15 | 8 | Metal | Steel | Fiberglass | 0000000 | 000000000 |

100° to 550° F Temp. Control Range | |||||||||||||||

| 12" | 13" | 1,350 | 81 | 120V AC | Single | 12 | 22" | 550° | 5-15 | 8 | Metal | Steel | Fiberglass | 0000000 | 00000000 |

| 12" | 13" | 1,350 | 81 | 240V AC | Single | 6 | 22" | 550° | L6-20 | 8 | Metal | Steel | Fiberglass | 0000000 | 00000000 |

For 55-Gallon Containers | |||||||||||||||

60° to 250° F Temp. Control Range | |||||||||||||||

| 23 3/4" | 30 1/2" | 1,500 | 92 | 120V AC | Single | 15 | 35" | 250° | L5-15 | 8 | Metal | Steel | Fiberglass | 0000000 | 00000000 |

| 23 3/4" | 30 1/2" | 4,400 | 270 | 240V AC | Three | 12 | 35" | 250° | L15-20 | 8 | Metal | Steel | Fiberglass | 0000000 | 00000000 |

| 23 3/4" | 30 1/2" | 4,400 | 270 | 480V AC | Three | 6 | 35" | 250° | L16-20 | 8 | Metal | Steel | Fiberglass | 0000000 | 00000000 |

| 23 3/4" | 30 1/2" | 4,400 | 337 | 240V AC | Single | 20 | 35" | 250° | L6-20 | 8 | Metal | Steel | Fiberglass | 0000000 | 00000000 |

100° to 550° F Temp. Control Range | |||||||||||||||

| 23 3/4" | 30 1/2" | 4,400 | 270 | 240V AC | Three | 12 | 35" | 550° | L15-20 | 8 | Metal | Steel | Fiberglass | 000000 | 00000000 |

| 23 3/4" | 30 1/2" | 4,400 | 270 | 480V AC | Three | 6 | 35" | 550° | L16-20 | 8 | Metal | Steel | Fiberglass | 000000 | 00000000 |

| 23 3/4" | 30 1/2" | 4,400 | 337 | 240V AC | Single | 20 | 35" | 550° | L6-20 | 8 | Metal | Steel | Fiberglass | 000000 | 00000000 |

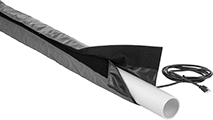

Insulating Wrap-Around Heaters for Propane Tanks

Keep gas flowing even when the temperature drops—also known as heat blankets, these heaters wrap around propane tanks to safely warm liquefied gas so it can vaporize. They’re insulated with foam, so they retain heat even in chilly environments. Their built-in thermostat heats up to 90° F, then automatically adjusts the power output to keep your tank consistently warm. Because you can’t adjust the thermostat, there’s no risk of accidentally changing the set temperature. These heaters are sized to fit industry-standard propane tanks. Quickly install and remove them using the buckles or latches.

Made of heavy duty vinyl, these heaters stand up to scuffs, water, and UV rays, so they last even outdoors. The vinyl is NFPA rated for flame retardance; however, you shouldn’t use these heaters near combustible gases or dust. A GFCI is built into the power cord to prevent electrical shocks.

O'all | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Tank Cap., lbs. | Lg. | Wd. | Wattage, W | Watt Density, W/ft. | Voltage | Electrical Phase | Current, A | Thick. | NEMA Style | For Surface Material | Material | Closure Type | Each | |

Nonadjustable Thermostat | ||||||||||||||

90° F Max. Heat Output | ||||||||||||||

| 20 | 50" | 16" | 127 | 21 | 120V AC | Single | 1.02 | 0.7" | 5-15 | Aluminum, Steel | Vinyl Plastic | Latch | 0000000 | 0000000 |

| 30 | 50" | 20" | 127 | 17 | 120V AC | Single | 1.02 | 0.7" | 5-15 | Aluminum, Steel | Vinyl Plastic | Latch | 0000000 | 000000 |

| 40 | 50" | 25" | 127 | 14 | 120V AC | Single | 1.02 | 0.7" | 5-15 | Aluminum, Steel | Vinyl Plastic | Latch | 0000000 | 000000 |

| 100 | 59" | 43" | 316 | 16 | 120V AC | Single | 2.25 | 0.7" | 5-15 | Aluminum, Steel | Vinyl Plastic | Buckle | 0000000 | 000000 |

| 420 | 103" | 52" | 570 | 13 | 120V AC | Single | 4.7 | 0.7" | 5-15 | Aluminum, Steel | Vinyl Plastic | Buckle | 0000000 | 000000 |

Heaters for Extrusion- and Injection-Molding Barrels

Heat resins, raw materials, and food with these heaters that fit around extrusion and injection-molding barrels. All require a temperature switch or controller (sold separately) to regulate heat output.

Note: The heater must be sized to fit tightly around the barrel to prevent air gaps that lead to inefficient heating and premature failure.

| For Barrel OD | Wd. | Wattage, W | Max. Heat Output, °F | Wire Connection Type | Material | Current, A | Each | |

120V AC, Single Phase | ||||||||

|---|---|---|---|---|---|---|---|---|

With Mica Insulation | ||||||||

| 3" | 1 1/2" | 400 | 900° | Screw Terminals | Steel | 3.3 | 00000000 | 000000 |

| 3 1/2" | 1 1/2" | 500 | 900° | Screw Terminals | Steel | 4.2 | 00000000 | 00000 |

| 3 1/2" | 2" | 650 | 900° | Screw Terminals | Steel | 5.4 | 00000000 | 00000 |

| 4" | 1" | 400 | 900° | Screw Terminals | Steel | 3.3 | 00000000 | 00000 |

| 4" | 2" | 550 | 900° | Screw Terminals | Steel | 4.6 | 00000000 | 00000 |

| 4" | 4" | 1,250 | 900° | Screw Terminals | Steel | 10.4 | 00000000 | 000000 |

| 4 1/2" | 2 1/2" | 1,000 | 900° | Screw Terminals | Steel | 8.3 | 00000000 | 00000 |

| 5" | 1 1/2" | 700 | 900° | Screw Terminals | Steel | 5.8 | 00000000 | 00000 |

| 6" | 1 1/2" | 850 | 900° | Screw Terminals | Steel | 7.1 | 00000000 | 00000 |

| 6" | 2" | 1,200 | 900° | Screw Terminals | Steel | 10 | 00000000 | 000000 |

| 7" | 1 1/2" | 1,000 | 900° | Screw Terminals | Steel | 8.3 | 00000000 | 00000 |

| 8" | 2" | 1,500 | 900° | Screw Terminals | Steel | 12.5 | 00000000 | 000000 |

| 9" | 1 1/2" | 1,200 | 900° | Screw Terminals | Steel | 10 | 00000000 | 000000 |

| 10" | 1 1/2" | 1,300 | 900° | Screw Terminals | Steel | 10.8 | 00000000 | 000000 |

| 12" | 2" | 1,700 | 900° | Screw Terminals | Steel | 14.2 | 00000000 | 000000 |

| 14" | 1 1/2" | 1,600 | 900° | Screw Terminals | Steel | 13.3 | 00000000 | 000000 |

240V AC, Single Phase | ||||||||

With Mica Insulation | ||||||||

| 3" | 1 1/2" | 400 | 900° | Screw Terminals | Steel | 1.7 | 00000000 | 00000 |

| 3 1/2" | 1 1/2" | 500 | 900° | Screw Terminals | Steel | 2.1 | 00000000 | 00000 |

| 3 1/2" | 2" | 650 | 900° | Screw Terminals | Steel | 2.7 | 00000000 | 00000 |

| 4" | 1" | 400 | 900° | Screw Terminals | Steel | 1.7 | 00000000 | 00000 |

| 4" | 2" | 550 | 900° | Screw Terminals | Steel | 2.3 | 00000000 | 00000 |

| 4" | 4" | 1,250 | 900° | Screw Terminals | Steel | 5.2 | 00000000 | 000000 |

| 4 1/2" | 2 1/2" | 1,000 | 900° | Screw Terminals | Steel | 4.2 | 00000000 | 00000 |

| 5" | 1 1/2" | 700 | 900° | Screw Terminals | Steel | 2.9 | 00000000 | 00000 |

| 6" | 1 1/2" | 850 | 900° | Screw Terminals | Steel | 3.5 | 00000000 | 00000 |

| 6" | 2" | 1,200 | 900° | Screw Terminals | Steel | 5 | 00000000 | 000000 |

| 7" | 1 1/2" | 1,000 | 900° | Screw Terminals | Steel | 4.2 | 00000000 | 00000 |

| 8" | 2" | 1,500 | 900° | Screw Terminals | Steel | 6.3 | 00000000 | 000000 |

| 9" | 1 1/2" | 1,800 | 900° | Screw Terminals | Steel | 7.5 | 00000000 | 000000 |

| 10" | 1 1/2" | 1,300 | 900° | Screw Terminals | Steel | 5.4 | 0000000 | 000000 |

| 12" | 2" | 2,300 | 900° | Screw Terminals | Steel | 9.6 | 00000000 | 000000 |

| 14" | 1 1/2" | 1,900 | 900° | Screw Terminals | Steel | 7.9 | 00000000 | 000000 |

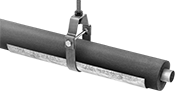

Insulating Wrap-Around Heaters for Pipe

Keep liquid in your pipes from freezing, maintain a specific viscosity, and prevent condensation in cold areas. Also known as heat blankets, these heaters wrap around your pipe to quickly warm the contents without direct contact. Their foam insulation retains heat, so your pipes will stay warm even in drafty areas. They’re self-regulating, so they automatically adjust their heat output to account for temperature differences along the length of the heater. They output high heat for sections of pipe exposed to the cold, and low heat for a section that’s in a warmer spot. There’s no need for a separate temperature switch or controller; just plug them in and they start heating. Do not use in hazardous areas.

O'all | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Pipe OD | Lg., ft. | Wd. | Wattage, W | Watt Density @ 30° F, W/ft. | Voltage | Electrical Phase | Current, A | Thick. | Max. Heat Output, °F | NEMA Style | For Surface Material | Material | Insulation Material | Each | |

With Self-Regulating Temp. Control | |||||||||||||||

| 3/4"-1 1/2" | 5 | 10" | 25 | 5 | 120V AC | Single | 0.2 | 4" | 80° | 5-15 | Fiberglass, Metal, Plastic, Steel | Vinyl Plastic | Foam | 0000000 | 0000000 |

| 3/4"-1 1/2" | 10 | 10" | 50 | 5 | 120V AC | Single | 0.41 | 4" | 80° | 5-15 | Fiberglass, Metal, Plastic, Steel | Vinyl Plastic | Foam | 0000000 | 000000 |

| 3/4"-1 1/2" | 25 | 10" | 125 | 5 | 120V AC | Single | 1.04 | 4" | 80° | 5-15 | Fiberglass, Metal, Plastic, Steel | Vinyl Plastic | Foam | 0000000 | 000000 |

| 2"-2 1/2" | 5 | 11" | 25 | 5 | 120V AC | Single | 0.2 | 4" | 80° | 5-15 | Fiberglass, Metal, Plastic, Steel | Vinyl Plastic | Foam | 0000000 | 000000 |

| 2"-2 1/2" | 10 | 11" | 50 | 5 | 120V AC | Single | 0.41 | 4" | 80° | 5-15 | Fiberglass, Metal, Plastic, Steel | Vinyl Plastic | Foam | 0000000 | 000000 |

| 2"-2 1/2" | 25 | 11" | 125 | 5 | 120V AC | Single | 1.04 | 4" | 80° | 5-15 | Fiberglass, Metal, Plastic, Steel | Vinyl Plastic | Foam | 0000000 | 000000 |

| 3"-3 1/2" | 5 | 12" | 25 | 5 | 120V AC | Single | 0.2 | 4" | 80° | 5-15 | Fiberglass, Metal, Plastic, Steel | Vinyl Plastic | Foam | 0000000 | 000000 |

| 3"-3 1/2" | 10 | 12" | 50 | 5 | 120V AC | Single | 0.41 | 4" | 80° | 5-15 | Fiberglass, Metal, Plastic, Steel | Vinyl Plastic | Foam | 0000000 | 000000 |

| 3"-3 1/2" | 25 | 12" | 125 | 5 | 120V AC | Single | 1.04 | 4" | 80° | 5-15 | Fiberglass, Metal, Plastic, Steel | Vinyl Plastic | Foam | 0000000 | 00000000 |

| 4"-4 1/2" | 5 | 13" | 25 | 5 | 120V AC | Single | 0.2 | 4" | 80° | 5-15 | Fiberglass, Metal, Plastic, Steel | Vinyl Plastic | Foam | 0000000 | 000000 |

| 4"-4 1/2" | 10 | 13" | 50 | 5 | 120V AC | Single | 0.41 | 4" | 80° | 5-15 | Fiberglass, Metal, Plastic, Steel | Vinyl Plastic | Foam | 0000000 | 000000 |

| 4"-4 1/2" | 25 | 13" | 125 | 5 | 120V AC | Single | 1.04 | 4" | 80° | 5-15 | Fiberglass, Metal, Plastic, Steel | Vinyl Plastic | Foam | 0000000 | 00000000 |

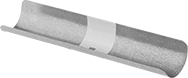

Pipe Cradles for Loop Hangers

Also known as pipe shields, these cradles provide additional support and prevent insulation from tearing when routing insulated pipe through loop hangers.

Adhesive-mount cradles have an adhesive strip that attaches the cradle to the pipe’s insulation.

ID | ||||||||

|---|---|---|---|---|---|---|---|---|

| Inch | Metric, mm | Lg. | Wd. | Ht. | Thick. | Temp. Range, °F | Each | |

Galvanized Steel | ||||||||

Adhesive Mount | ||||||||

| 1 7/8" | 48 | 12" | 2" | 1" | 1/32" | -150° to 500° | 0000000 | 00000 |

| 2 3/8" | 60 | 12" | 2 1/2" | 1 1/4" | 1/32" | -150° to 500° | 0000000 | 0000 |

| 2 7/8" | 73 | 12" | 3" | 1 1/2" | 1/32" | -150° to 500° | 0000000 | 0000 |

| 3 1/2" | 89 | 12" | 3 1/2" | 1 3/4" | 1/32" | -150° to 500° | 0000000 | 0000 |

| 4" | 102 | 12" | 4" | 2" | 1/32" | -150° to 500° | 0000000 | 0000 |

| 4 1/2" | 114 | 12" | 4 1/2" | 2 1/4" | 1/32" | -150° to 500° | 0000000 | 0000 |

| 5" | 127 | 12" | 5" | 2 1/2" | 1/32" | -150° to 500° | 0000000 | 0000 |

| 5 9/16" | 141 | 12" | 5 1/2" | 2 3/4" | 1/32" | -150° to 500° | 0000000 | 0000 |

| 6 1/8" | 156 | 12" | 6" | 3" | 1/16" | -150° to 500° | 0000000 | 0000 |