Filter by

System of Measurement

Mount Type

Jaw Style

Mounting Hole Center-to-Center

Body Length

Overall Height

For Machine Type

Height

DFARS Specialty Metals

Export Control Classification Number (ECCN)

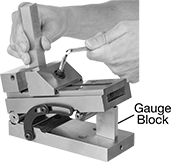

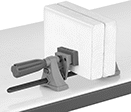

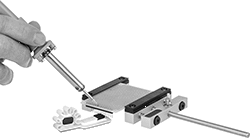

Sine Vises

With Flat Jaws

Jaw | Body | Mounting Holes | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Wd. | Ht. | Max. Opening | Material | Texture | Replaceable | Parallel Tolerance | Overall Ht. | Lg. | Material | Base/Bed Parallel Tolerance | Mount Type | Mounting Fasteners Included | No. of | Dia. | Ctr.-to-Ctr. | Features | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Fixed Base | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3" | 1 5/16" | 4 3/4" | Steel | Grooved | No | 0.0002" | 3 5/8" | 7 1/2" | Steel | 0.0002" | Bolt On | Yes | 4 | 5/16" | 3" | Fixed Dowel Locking Bar Movable Dowel | 0000000 | 000000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

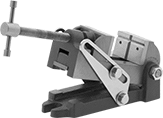

Drill-Press Vises

With Flat Jaws

Jaw | Body | Mounting Holes | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Wd. | Ht. | Max. Opening | Material | Texture | Replaceable | Overall Ht. | Lg. | Material | Mount Type | Mounting Fasteners Included | No. of | Dia. | Ctr.-to-Ctr. | Features | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Fixed Base | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 3/4" | 1" | 1 1/2" | Steel | Smooth, Grooved | Yes | 2" | 4 1/4" | Iron | Bolt On | No | 2 | 3/8" | 2 5/8" | Open Base | 000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3" | 1 1/8" | 3" | Steel | Smooth, Grooved | Yes | 2 1/2" | 6 5/8" | Iron | Bolt On | No | — | — | — | Open Base | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3" | 1 1/2" | 3" | Steel | Smooth, Grooved | Yes | 2 5/8" | 6 3/4" | Iron | Bolt On | No | 2 | 9/16" | 3 9/16" | Open Base | 000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4" | 1 3/4" | 4" | Steel | Smooth, Grooved | Yes | 2 7/8" | 7 5/8" | Iron | Bolt On | No | — | — | — | Open Base | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6" | 2" | 6" | Steel | Smooth, Grooved | Yes | 3 5/8" | 11" | Iron | Bolt On | No | — | — | — | Open Base | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8" | 2" | 8" | Steel | Smooth, Grooved | Yes | 3 5/8" | 15 1/2" | Iron | Bolt On | No | — | — | — | Open Base | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Bench Vises for Dremel

With Flat Jaws

|  |  |

Swivel Base | Swivel Base Removable Clamp | Swivel Base |

Jaw | Overall | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Wd. | Max. Opening | Material | Texture | Throat Dp. | Lg. | Wd. | Ht. | Wt., lb. | For Max. Mounting Surface Thk. | Body Material | Mount Type | For Mfr. Model No. | Features | Includes | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

360° Swivel Base | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7 1/2" | 7" | Rubber | Grooved | 2 1/4" | 13" | 4 1/4" | 13" | 2.7 | 2 1/2" | Plastic | Clamp On | 100, 100-N/7, 200, 285, 300, 395, 400, 800, 3000, 3000-1/24, 4000, 4000-2/30, 4200, 8100-N/21, 8200, 8220, 8220-1/28 | Removable Clamp | Tool Holder Ring | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

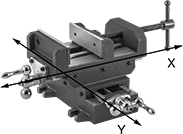

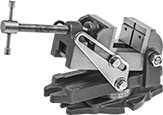

Cross-Slide Drill-Press Vises

With Flat Jaws

Jaw | Max. Travel | Base | Mounting Holes | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Wd. | Ht. | Max. Opening | Material | Texture | Replaceable | X-Axis | Y-Axis | Adjustment Dial Graduations | Overall Ht. | Lg. | Wd. | Body Material | Mount Type | Mounting Fasteners Included | No. of | Dia. | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Fixed Base | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3" | 1 3/8" | 3" | Steel | Smooth, Grooved | Yes | 5" | 5" | 0.002" | 5 7/8" | 8 3/8" | 4 5/8" | Iron | Bolt On | No | 5 | 1/2" | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6" | 2" | 6" | Steel | Smooth, Grooved | Yes | 8" | 8" | 0.001" | 7 3/8" | 12 1/8" | 7 1/8" | Iron | Bolt On | No | 5 | 5/8" | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8" | 2" | 8" | Steel | Smooth, Grooved | Yes | 8" | 8" | 0.001" | 7 3/8" | 12 1/8" | 7 1/8" | Iron | Bolt On | No | 5 | 5/8" | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

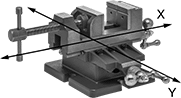

High-Precision Cross-Slide Drill-Press Vises

With Flat Jaws

Jaw | Max. Travel | Base | Mounting Holes | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Wd. | Ht. | Max. Opening | Material | Texture | Replaceable | Parallel Tolerance | X-Axis | Y-Axis | Adjustment Dial Graduations | Overall Ht. | Lg. | Wd. | Body Material | Mount Type | Mounting Fasteners Included | No. of | Dia. | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Fixed Base | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3" | 1 3/4" | 3" | Steel | Smooth, Grooved | Yes | 0.001" | 4" | 4" | 0.001" | 5 1/2" | 7 1/2" | 6 1/4" | Iron | Bolt On | No | 4 | 5/8" | 00000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Any-Orientation Drill-Press Vises

With Flat Jaws

Jaw | Body | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Wd. | Ht. | Max. Opening | Material | Texture | Replaceable | Overall Ht. | Lg. | Material | Mount Type | Features | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Fixed Base | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 1" | 1 1/2" | Steel | Smooth, Grooved | Yes | 1 7/8" | 5 1/8" | Iron | Clamp On | Open Base | 000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 7/16" | 1 1/2" | 3" | Steel | Smooth, Grooved | Yes | 2 5/8" | 7 1/2" | Iron | Clamp On | Open Base | 000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4" | 1 3/4" | 4" | Steel | Smooth, Grooved | Yes | 3 1/4" | 10 3/4" | Iron | Clamp On | Open Base | 000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6" | 2" | 6" | Steel | Smooth, Grooved | Yes | 3 1/2" | 11 3/8" | Iron | Clamp On | Open Base | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Hand Vises

With Flat Jaws

Jaw | Overall | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Style | Wd. | Max. Opening | Material | Texture | Throat Dp. | Lg. | Ht. | Body Material | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Rectangular Jaws | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| C | 1 1/4" | 1" | Steel | Grooved | 1/2" | 6 1/4" | 3" | Wood | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Ultra-Precision Machine Vises

With Flat Jaws

Jaw | Body | Mounting Holes | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Wd. | Ht. | Max. Opening | Material | Texture | Replaceable | Parallel Tolerance | Overall Ht. | Lg. | Material | Base/Bed Parallel Tolerance | Mount Type | Mounting Fasteners Included | No. of | Dia. | Ctr.-to-Ctr. | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Fixed Base | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 1" | 3 1/4" | Steel | Smooth, Grooved | Yes | 0.0002" | 2" | 5 7/8" | Steel | 0.0002" | Bolt On | No | 4 | 5/16" | 1" | 0000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3" | 1 5/16" | 4 3/4" | Steel | Smooth, Grooved | No | 0.0002" | 2 5/8" | 7 1/2" | Steel | 0.0002" | Bolt On, Clamp On | No | 4 | 5/16" | — | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

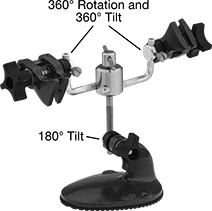

Any-Angle Tilting-Head Bench Vises

With Flat Jaws

Jaw | Overall | Mounting Holes | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

No. of Vise Heads | Wd. | Max. Opening | Material | Texture | Replaceable | Throat Dp. | Lg. | Wd. | Ht. | Wt., lb. | Body Material | Mount Type | Mounting Fasteners Included | No. of | Dia. | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Fixed Base | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 1 1/2" | 11/16" | Aluminum | Grooved | No | 3/8" | 5" | 4" | 6 1/2" | 3 | Aluminum | Bolt On | No | 2 | 3/16" | 00000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

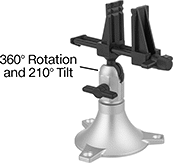

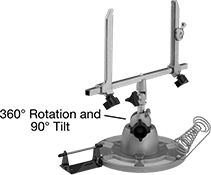

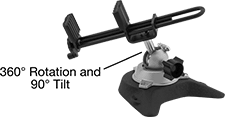

Tilting-Head Circuit Board Vises

With Flat Jaws

|  |

Fixed Base 2 7/8" Maximum Jaw Opening | Fixed Base 10" Maximum Jaw Opening |

Jaw | Mounting Holes | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Wd. | Max. Opening | Material | Texture | Replaceable | Body Material | For Max. Circuit Board Thk. | Max. Range of Motion | Tilt Range of Motion | Mount Type | Mounting Fasteners Included | No. of | Dia. | Ctr.-to-Ctr. | Features | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Fixed Base | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 2 7/8" | Plastic | Grooved | Yes | Zinc | 5/16" | 360° | 210° | Bolt On | No | 3 | 5/16" | 2 1/2" | — | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 1/4" | 10" | Aluminum | Grooved | Yes | Zinc | 5/32" | 360° | 90° | Bolt On | No | 3 | 5/16" | 3 3/4" | Six Compartment Tray Base Solder Spool Holder Soldering Iron Holder | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Machine Vises

With Flat Jaws

|  |

Jaw | Body | Mounting Holes | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Wd. | Ht. | Max. Opening | Material | Texture | Replaceable | Overall Ht. | Lg. | Material | Base/Bed Parallel Tolerance | Mount Type | Mounting Fasteners Included | No. of | Dia. | Ctr.-to-Ctr. | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Fixed Base | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4" | 1 3/4" | 4" | Steel | Smooth, Grooved | Yes | 3 3/8" | 8 3/4" | Iron | 0.001" | Bolt On | No | 2 | 9/16" | 4 5/8" | 000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6" | 2" | 6" | Steel | Smooth, Grooved | Yes | 3 7/8" | 11 1/2" | Iron | 0.001" | Bolt On | No | 2 | 5/8" | 6 1/2" | 000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Clamp-On Bench Vises

With Flat Jaws

Vises | Replacement Flat Jaws | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Jaw | Overall | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Wd. | Max. Opening | Material | Texture | Replaceable | Throat Dp. | Lg. | Wd. | Ht. | Wt., lb. | For Max. Mounting Surface Thk. | Body Material | Mount Type | Features | Each | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

45° Swivel Base | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 1/2" | 2 1/8" | Steel | Grooved | Yes | 1 3/4" | 10" | 10 1/4" | 5 1/2" | 11 | 3" | Iron | Clamp On | Anvil | 000000 | 0000000 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4" | 2 1/4" | Steel | Grooved | Yes | 2" | 10" | 10 1/4" | 5 1/2" | 18 | 3" | Iron | Clamp On | Anvil | 000000 | 000000 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

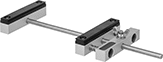

Quick-Clamp Drill-Press Vises

With Flat Jaws

Jaw | Body | Mounting Holes | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Wd. | Ht. | Max. Opening | Material | Texture | Replaceable | Overall Ht. | Lg. | Material | Mount Type | Mounting Fasteners Included | No. of | Dia. | Features | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Fixed Base | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Screw Jaw Lock | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3" | 1 1/2" | 3" | Steel | Smooth, Grooved | Yes | 2 5/8" | 9" | Steel | Bolt On | No | 4 | 1/2" | Stepped Jaws | 0000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4" | 1 1/2" | 6" | Steel | Smooth, Grooved | Yes | 3" | 13" | Steel | Bolt On | No | 4 | 1/2" | Stepped Jaws | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6" | 2" | 8" | Steel | Smooth, Grooved | Yes | 3 7/8" | 17" | Steel | Bolt On | No | 8 | 5/8" | Stepped Jaws | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8" | 3" | 10" | Steel | Smooth, Grooved | Yes | 5 1/2" | 21 3/4" | Steel | Bolt On | No | 8 | 7/8" | Stepped Jaws | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

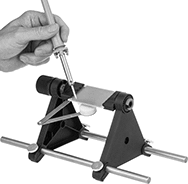

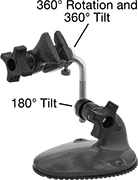

Static-Control Circuit Board Vises

With Flat Jaws

Jaw | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Wd. | Max. Opening | Material | Texture | Replaceable | Body Material | For Max. Circuit Board Thk. | Max. Range of Motion | Mount Type | Surface Resistance, ohm | Rod Material | Features | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Fixed Base | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 11/16" | 9 1/4" | Plastic | Grooved | No | Plastic | 5/16" | 360° | Freestanding | 1× 10^9 to 1× 10^11 | Steel | Positioning Arm | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Circuit Board Vises

With Flat Jaws

|  |  |

Shown with Component Positioning Stand (Sold Separately) | Electronic-Component Positioning Stands |

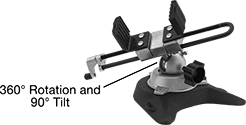

Extra-Wide-Opening Tilting-Head Bench Vises

With Flat Jaws

|  |

6" Max. Jaw Opening | 9" Max. Jaw Opening |

Vises | Clamp-On Base | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Jaw | Overall | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Wd. | Max. Opening | Material | Texture | Replaceable | Throat Dp. | Lg. | Wd. | Ht. | Wt., lb. | Body Material | Max. Range of Motion | Tilt Range of Motion | Mount Type | Base Wt., lb. | Features | Each | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Fixed Base | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 6" | Rubber | Serrated, Grooved | Yes | 1 7/8" | 11" | 5" | 7 1/4" | 7.6 | Aluminum | 360° | 90° | Freestanding | 5 | — | 0000000 | 0000000 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 9" | Rubber | Serrated, Grooved | Yes | 1 7/8" | 11 1/2" | 5" | 7 1/2" | 7.7 | Aluminum | 360° | 90° | Freestanding | 5 | Self-Centering Jaws | 0000000 | 000000 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Pivoting-Head Drill-Press Vises

With Flat Jaws

Jaw | Body | Mounting Holes | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Wd. | Ht. | Max. Opening | Material | Texture | Replaceable | Overall Ht. | Lg. | Material | Base Graduations | Mount Type | Mounting Fasteners Included | No. of | Dia. | Ctr.-to-Ctr. | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Fixed Base | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 7/8" | 1 1/2" | 2 1/2" | Steel | Smooth, Grooved | Yes | 3 7/8" | 9" | Iron | — | Bolt On | No | 2 | 1/2" | 6 11/16" | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

360° Swivel Base | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 7/8" | 1 1/2" | 2 1/2" | Steel | Smooth, Grooved | Yes | 4 5/8" | 8" | Iron | 5° | Bolt On | No | 4 | 1/2" | 6 13/16" | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4" | 1 3/4" | 4" | Steel | Smooth, Grooved | Yes | 6 1/4" | 12" | Iron | 1° | Bolt On | No | 2 | 1/2" | 7 7/8" | 000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Tilting-Head Bench Vises

Jaw | Overall | Mounting Holes | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Wd. | Max. Opening | Texture | Throat Dp. | Lg. | Wd. | Ht. | Wt., lb. | Mounting Fasteners Included | No. of | Dia. | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

With Flat Jaws | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Bolt On | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 11/16" | Grooved | 3/8" | 5" | 4" | 6 1/2" | 2 | No | 2 | 3/16" | 00000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||