Filter by

For Polishing Step

Grit Rating

Abrasive Grain Size

Abrasive Material

Sold As

Export Control Classification Number (ECCN)

DFARS Specialty Metals

Hardness Rating

Tumbler Motion

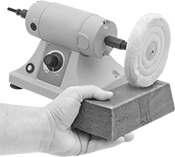

Buffing and Polishing Compounds

Abrasive Material | Abrasive Grain Size, μm | For Finish | Color | Vegetable Based | Wt. | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Steel and Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Cutting | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Aluminum Oxide | 40 | Extra Smooth | Gray | No | 6 oz. | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Aluminum Oxide | 40 | Extra Smooth | Gray | No | 1 lb. | 0000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Aluminum Oxide | 40 | Extra Smooth | Gray | No | 3 lb. | 000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Aluminum Oxide | 40 | Extra Smooth | Gray | Yes | 2 lb. | 000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Coloring | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Chrome Oxide | 1 | Polished | Green | No | 6 oz. | 00000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Chrome Oxide | 1 | Polished | Green | No | 1 lb. | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Chrome Oxide | 1 | Polished | Green | No | 3 lb. | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Chrome Oxide | 1 | Polished | Green | Yes | 3 lb. | 000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Cutting/Coloring | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Calcined Alumina | 5 | Polished | Yellow | No | 6 oz. | 0000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Calcined Alumina | 5 | Polished | Yellow | No | 1 lb. | 0000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Calcined Alumina | 5 | Polished | Yellow | No | 3 lb. | 000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Chrome, Steel, Stainless Steel, and Iron | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Cutting/Coloring | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Calcined Alumina | 4 | Polished | White | No | 3 lb. | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Calcined Alumina | 5 | Polished | White | No | 3 lb. | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Steel, Stainless Steel, Aluminum, Brass, Bronze, and Copper | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Coloring | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Calcined Alumina | 2 | Polished | White | Yes | 2 lb. | 000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Calcined Alumina | 3 | Polished | White | No | 6 oz. | 0000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Calcined Alumina | 3 | Polished | White | No | 1 lb. | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Calcined Alumina | 3 | Polished | White | No | 3 lb. | 000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Cutting/Coloring | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Calcined Alumina | 4 | Polished | Yellow | Yes | 2 lb. | 000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Aluminum, Brass, Bronze, and Copper | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Coloring | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Calcined Alumina | 2 | Polished | Black | No | 3 lb. | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Silica | 15 | Polished | Brown Tripoli | Yes | 2 lb. | 000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Cutting/Coloring | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Silica | 35 | Extra Smooth | Brown Tripoli | No | 6 oz. | 0000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Silica | 35 | Extra Smooth | Brown Tripoli | No | 1 lb. | 0000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Silica | 35 | Extra Smooth | Brown Tripoli | No | 3 lb. | 000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Silica | 35 | Extra Smooth | Brown Tripoli | Yes | 2 lb. | 000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Silica | 50 | Extra Smooth | Brown Tripoli | No | 6 oz. | 0000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Silica | 50 | Extra Smooth | Brown Tripoli | No | 1 lb. | 0000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Silica | 50 | Extra Smooth | Brown Tripoli | No | 3 lb. | 000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Brass, Bronze, and Copper | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Coloring | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Iron Oxide | 0.5 | Polished | Red Rouge | No | 6 oz. | 0000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Iron Oxide | 0.5 | Polished | Red Rouge | No | 3 lb. | 000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Fiberglass | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Coloring | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Calcined Alumina | 1 | Polished | White | No | 6 oz. | 0000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Calcined Alumina | 1 | Polished | White | No | 1 lb. | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Calcined Alumina | 1 | Polished | White | No | 3 lb. | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Plastic and Rubber | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Cutting | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Silica | 45 | Extra Smooth | Beige | No | 6 oz. | 0000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Silica | 45 | Extra Smooth | Beige | No | 1 lb. | 0000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Silica | 45 | Extra Smooth | Beige | No | 3 lb. | 000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Coloring | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Quartz | 15 | Polished | Tan | No | 1 lb. | 00000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Quartz | 15 | Polished | Tan | No | 3 lb. | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Cutting/Coloring | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Silica | 35 | Extra Smooth | Brown | No | 4 oz. | 00000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Silica | 35 | Extra Smooth | Brown | No | 1 lb. | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

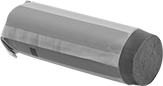

Aggressive Buffing and Polishing Compounds

Abrasive Material | Abrasive Grain Size, μm | Grit (For Finish) | Color | Dia. | Lg. | Wt., lb. | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Steel, Stainless Steel, Aluminum, Brass, Bronze, and Copper | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Cutting | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Aluminum Oxide | 38 | 400 (Extra Smooth) | Black | 2 1/2" | 10 1/2" | 3 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Aluminum Oxide | 40 | 280 (Extra Smooth) | Black | 2 1/2" | 10 1/2" | 3 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Aluminum Oxide | 60 | 240 (Extra Smooth) | Red | 2 1/2" | 10 1/2" | 3 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Aluminum Oxide | 80 | 180 (Smooth) | Red | 2 1/2" | 10 1/2" | 3 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Aluminum Oxide | 100 | 150 (Smooth) | Red | 2 1/2" | 10 1/2" | 3 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Aluminum Oxide | 120 | 120 (Smooth) | Red | 2 1/2" | 10 1/2" | 3 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Aluminum Oxide | 173 | 80 (Rough) | Red | 2 1/2" | 10 1/2" | 3 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

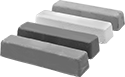

Buffing and Polishing Compound Assortments

|

No. of Pieces | Includes | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Cutting, Coloring, and Cutting/Coloring | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 | One 4 oz. Smooth-Finish Gray Cutting Compound One 4 oz. Extra-Smooth-Finish Brown Cutting/Coloring Compound One 4 oz. Polished-Finish White Rouge Coloring Compound One 4 oz. Polished-Finish Red Rouge Coloring Compound | 000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 | One 1 lb. Extra-Smooth-Finish Brown Cutting/Coloring Compound One 1 lb. Extra-Smooth-Finish Tan Cutting Compound One 1 lb. Polished-Finish White Rouge Coloring Compound One 1 lb. Polished-Finish Yellow Cutting/Coloring Compound One 1 lb. Polished-Finish White Coloring Compound One 1 lb. Polished-Finish Red Coloring Compound | 000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Polishing Bob and Compound Kits

No. of Pieces | Hardness Rating | For Polishing Step | Includes | Container Type | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Wool Felt | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 20 | Medium, Hard | Cutting, Coloring | One Medium Cylinder with Flat Tip Polishing Bob—1/2" Head Dia. × 1/2" Head Lg. × 1/8" Shank Dia. One Medium Cylinder with Round Tip Polishing Bob—1/2" Head Dia. × 1" Head Lg. × 1/8" Shank Dia. One Medium Ball Polishing Bob—1/2" Head Dia. × 1/2" Head Lg. × 1/8" Shank Dia. One Medium Oval Polishing Bob—1/2" Head Dia. × 1/2" Head Lg. × 1/8" Shank Dia. One Medium Pear Polishing Bob—1/2" Head Dia. × 3/4" Head Lg. × 1/8" Shank Dia. One Medium Cone with Flat Tip Polishing Bob—1/2" Head Dia. × 3/4" Head Lg. × 1/8" Shank Dia. One Medium Cone with Round Tip Polishing Bob—1/2" Head Dia. × 1" Head Lg. × 1/8" Shank Dia. Four Medium Flat-Edge Buffing Wheels—3/4" Dia. × 1/8" Thick. Four Hard Tapered-Edge Buffing Wheels—3/4" Dia. × 1/8" Thick. One 1/8" Dia. Shank for Buffing Wheels One 1/2 oz. Polished-Finish Black Cutting Compound One 1/2 oz. Extra-Smooth-Finish Brown Tripoli Cutting Compound One 1/2 oz. Polished-Finish Red Rouge Coloring Compound One 1/2 oz. Polished-Finish White Coloring Compound | Plastic Case | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 55 | Hard, Extra Hard | Cutting, Coloring | Three Extra-Hard Cylinder with Flat Tip Polishing Bobs—1/4" Head Dia. × 1/4" Head Lg. × 1/8" Shank Dia. Three Hard Cylinder with Flat Tip Polishing Bobs—1/4" Head Dia. × 1/4" Head Lg. × 1/8" Shank Dia. Four Extra-Hard Cylinder with Flat Tip Polishing Bobs—3/8" Head Dia. × 1/2" Head Lg. × 1/8" Shank Dia. Four Hard Cylinder with Flat Tip Polishing Bobs—3/8" Head Dia. × 1/2" Head Lg. × 1/8" Shank Dia. Four Extra-Hard Cylinder with Flat Tip Polishing Bobs—1/2" Head Dia. × 1/2" Head Lg. × 1/8" Shank Dia. Four Hard Cylinder with Flat Tip Polishing Bobs—1/2" Head Dia. × 1/2" Head Lg. × 1/8" Shank Dia. Four Extra-Hard Ball with Round Tip Polishing Bobs—1/2" Head Dia. × 1/2" Head Lg. × 1/8" Shank Dia. Four Hard Ball with Round Tip Polishing Bobs—1/2" Head Dia. × 1/2" Head Lg. × 1/8" Shank Dia. Three Extra-Hard Ball with Round Tip Polishing Bobs—3/4" Head Dia. × 3/4" Head Lg. × 1/4" Shank Dia. Three Hard Ball with Round Tip Polishing Bobs—3/4" Head Dia. × 3/4" Head Lg. × 1/4" Shank Dia. Four Extra-Hard Cone with Round Tip Polishing Bobs—1/2" Head Dia. × 1" Head Lg. × 1/8" Shank Dia. Four Hard Cone with Round Tip Polishing Bobs—1/2" Head Dia. × 1" Head Lg. × 1/8" Shank Dia. Three Extra-Hard Cone with Round Tip Polishing Bobs—3/4" Head Dia. × 1 1/2" Head Lg. × 1/4" Shank Dia. Three Hard Cone with Round Tip Polishing Bobs—3/4" Head Dia. × 1 1/2" Head Lg. × 1/4" Shank Dia. Three Hard Flat-Edge Buffing Wheels—1" Dia. × 1/4" Thk. One 1/2 oz. Polished-Finish Black Cutting Compound One 1/2 oz. Polished-Finish White Coloring Compound | Plastic Case | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 57 | Soft, Medium | Cutting, Coloring | Four Medium Cylinder with Flat Tip Polishing Bobs—1/4" Head Dia. × 1/4" Head Lg. × 1/8" Shank Dia. Four Soft Cylinder with Flat Tip Polishing Bobs—1/4" Head Dia. × 1/4" Head Lg. × 1/8" Shank Dia. Four Medium Cylinder with Flat Tip Polishing Bobs—3/8" Head Dia. × 1/2" Head Lg. × 1/8" Shank Dia. Four Soft Cylinder with Flat Tip Polishing Bobs—3/8" Head Dia. × 1/2" Head Lg. × 1/8" Shank Dia. Four Medium Cylinder with Flat Tip Polishing Bobs—1/2" Head Dia. × 1/2" Head Lg. × 1/8" Shank Dia. Four Soft Cylinder with Flat Tip Polishing Bobs—1/2" Head Dia. × 1/2" Head Lg. × 1/8" Shank Dia. Four Medium Ball with Round Tip Polishing Bobs—1/2" Head Dia. × 1/2" Head Lg. × 1/8" Shank Dia. Four Soft Ball with Round Tip Polishing Bobs—1/2" Head Dia. × 1/2" Head Lg. × 1/8" Shank Dia. Three Medium Ball with Round Tip Polishing Bobs—3/4" Head Dia. × 3/4" Head Lg. × 1/4" Shank Dia. Three Soft Ball with Round Tip Polishing Bobs—3/4" Head Dia. × 3/4" Head Lg. × 1/4" Shank Dia. Four Medium Cone with Round Tip Polishing Bobs—1/2" Head Dia. × 1" Head Lg. × 1/8" Shank Dia. Four Soft Cone with Round Tip Polishing Bobs—1/2" Head Dia. × 1" Head Lg. × 1/8" Shank Dia. Three Medium Cone with Round Tip Polishing Bobs—3/4" Head Dia. × 1 1/2" Head Lg. × 1/4" Shank Dia. Three Soft Cone with Round Tip Polishing Bobs—3/4" Head Dia. × 1 1/2" Head Lg. × 1/4" Shank Dia. Three Medium Flat-Edge Buffing Wheels—1" Dia. × 1/4" Thk. One 1/2 oz. Extra-Smooth-Finish Brown Tripoli Cutting Compound One 1/2 oz. Polished-Finish White Coloring Compound | Plastic Case | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 59 | Soft, Medium, Hard, Extra Hard | Cutting, Coloring | Three Extra-Hard Cylinder with Flat Tip Polishing Bobs—1/4" Head Dia. × 1/4" Head Lg. × 1/8" Shank Dia. Three Hard Cylinder with Flat Tip Polishing Bobs—1/4" Head Dia. × 1/4" Head Lg. × 1/8" Shank Dia. Three Medium Cylinder with Flat Tip Polishing Bobs—1/4" Head Dia. × 1/4" Head Lg. × 1/8" Shank Dia. Three Soft Cylinder with Flat Tip Polishing Bobs—1/4" Head Dia. × 1/4" Head Lg. × 1/8" Shank Dia. Four Extra-Hard Cylinder with Flat Tip Polishing Bobs—1/2" Head Dia. × 1/2" Head Lg. × 1/8" Shank Dia. Four Hard Cylinder with Flat Tip Polishing Bobs—1/2" Head Dia. × 1/2" Head Lg. × 1/8" Shank Dia. Four Medium Cylinder with Flat Tip Polishing Bobs—1/2" Head Dia. × 1/2" Head Lg. × 1/8" Shank Dia. Four Soft Cylinder with Flat Tip Polishing Bobs—1/2" Head Dia. × 1/2" Head Lg. × 1/8" Shank Dia. Four Extra-Hard Cone with Round Tip Polishing Bobs—1/2" Head Dia. × 1" Head Lg. × 1/8" Shank Dia. Four Hard Cone with Round Tip Polishing Bobs—1/2" Head Dia. × 1" Head Lg. × 1/8" Shank Dia. Four Medium Cone with Round Tip Polishing Bobs—1/2" Head Dia. × 1" Head Lg. × 1/8" Shank Dia. Four Soft Cone with Round Tip Polishing Bobs—1/2" Head Dia. × 1" Head Lg. × 1/8" Shank Dia. Three Extra-Hard Cone with Round Tip Polishing Bobs—3/4" Head Dia. × 1 1/2" Head Lg. × 1/4" Shank Dia. Three Hard Cone with Round Tip Polishing Bobs—3/4" Head Dia. × 1 1/2" Head Lg. × 1/4" Shank Dia. Three Medium Cone with Round Tip Polishing Bobs—3/4" Head Dia. × 1 1/2" Head Lg. × 1/4" Shank Dia. Three Soft Cone with Round Tip Polishing Bobs—3/4" Head Dia. × 1 1/2" Head Lg. × 1/4" Shank Dia. One 1/2 oz. Extra-Smooth-Finish Brown Tripoli Cutting Compound One 1/2 oz. Polished-Finish Black Cutting Compound One 1/2 oz. Polished-Finish White Coloring Compound | Plastic Case | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Tumbling Media for Aluminum, Brass, and Soft Metals

|

Granule |

10 lb. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Density, lb/ft³ | Recommended Media to Parts Ratio | Abrasion Type | Tumbling Condition | Material | Pkg. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Ultra Smooth Finish | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Granule | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 40 | 4:1 | None | Dry | Walnut Shell | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Polishing Bob and Compound Kits for Reciprocating Polishers

No. of Pieces | Hardness Rating | For Polishing Step | Includes | Container Type | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Wool Felt | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 26 | Medium, Hard | Cutting, Coloring | Four Medium Rectangle with Bevel Tip Polishing Bobs—1/4" Head Wd. × 1/4" Head Thk. × 1 1/2" Head Lg. × 1/8" Shank Dia. Four Hard Rectangle with Bevel Tip Polishing Bobs—1/4" Head Wd. × 1/4" Head Thk. × 1 1/2" Head Lg. × 1/8" Shank Dia. Four Medium Rectangle with Bevel Tip Polishing Bobs—3/8" Head Wd. × 3/8" Head Thk. × 1 1/2" Head Lg. × 1/8" Shank Dia. Four Hard Rectangle with Bevel Tip Polishing Bobs—3/8" Head Wd. × 3/8" Head Thk. × 1 1/2" Head Lg. × 1/8" Shank Dia. Four Medium Rectangle with Bevel Tip Polishing Bobs—1/2" Head Wd. × 1/2" Head Thk. × 1 1/2" Head Lg. × 1/8" Shank Dia. Four Hard Rectangle with Bevel Tip Polishing Bobs—1/2" Head Wd. × 1/2" Head Thk. × 1 1/2" Head Lg. × 1/8" Shank Dia. One 1/2 oz. Smooth-Finish Gray Cutting Compound One 1/2 oz. Polished-Finish White Coloring Compound | Plastic Case | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||