Filter by

Grit Rating

For Polishing Step

Abrasive Grain Size

Abrasive Material

DFARS Specialty Metals

Export Control Classification Number (ECCN)

Sold As

Hardness Rating

Tumbler Motion

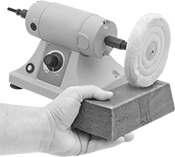

Buffing and Polishing Compounds

4 oz. | 6 oz. | 1 lb. | 2 lb. | 3 lb. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Abrasive Material | Abrasive Grain Size, μm | For Finish | Color | Vegetable Based | Each | Each | Each | Each | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Steel and Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Cutting | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Aluminum Oxide | 40 | Extra Smooth | Gray | No | ——— | 0 | 0000000 | 00000 | 0000000 | 00000 | ——— | 0 | 000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Aluminum Oxide | 40 | Extra Smooth | Gray | Yes | ——— | 0 | ——— | 0 | ——— | 0 | 000000 | 000000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Coloring | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Chrome Oxide | 1 | Polished | Green | No | ——— | 0 | 00000000 | 0000 | 00000000 | 00000 | ——— | 0 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Chrome Oxide | 1 | Polished | Green | Yes | ——— | 0 | ——— | 0 | ——— | 0 | ——— | 0 | 000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Cutting/Coloring | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Calcined Alumina | 5 | Polished | Yellow | No | ——— | 0 | 0000000 | 0000 | 0000000 | 0000 | ——— | 0 | 000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Chrome, Steel, Stainless Steel, and Iron | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Cutting/Coloring | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Calcined Alumina | 4 | Polished | White | No | ——— | 0 | ——— | 0 | ——— | 0 | ——— | 0 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Calcined Alumina | 5 | Polished | White | No | ——— | 0 | ——— | 0 | ——— | 0 | ——— | 0 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Steel, Stainless Steel, Aluminum, Brass, Bronze, and Copper | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Coloring | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Calcined Alumina | 2 | Polished | White | Yes | ——— | 0 | ——— | 0 | ——— | 0 | 000000 | 00000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Calcined Alumina | 3 | Polished | White | No | ——— | 0 | 0000000 | 0000 | 0000000 | 00000 | ——— | 0 | 000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Cutting/Coloring | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Calcined Alumina | 4 | Polished | Yellow | Yes | ——— | 0 | ——— | 0 | ——— | 0 | 000000 | 00000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Aluminum, Brass, Bronze, and Copper | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Coloring | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Calcined Alumina | 2 | Polished | Black | No | ——— | 0 | ——— | 0 | ——— | 0 | ——— | 0 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Silica | 15 | Polished | Brown Tripoli | Yes | ——— | 0 | ——— | 0 | ——— | 0 | 000000 | 00000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Cutting/Coloring | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Silica | 35 | Extra Smooth | Brown Tripoli | No | ——— | 0 | 0000000 | 0000 | 0000000 | 0000 | ——— | 0 | 000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Silica | 35 | Extra Smooth | Brown Tripoli | Yes | ——— | 0 | ——— | 0 | ——— | 0 | 000000 | 00000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Silica | 50 | Extra Smooth | Brown Tripoli | No | ——— | 0 | 0000000 | 0000 | 0000000 | 0000 | ——— | 0 | 000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Brass, Bronze, and Copper | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Coloring | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Iron Oxide | 0.5 | Polished | Red Rouge | No | ——— | 0 | 0000000 | 0000 | ——— | 0 | ——— | 0 | 000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Fiberglass | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Coloring | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Calcined Alumina | 1 | Polished | White | No | ——— | 0 | 0000000 | 0000 | 0000000 | 00000 | ——— | 0 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Plastic and Rubber | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Cutting | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Silica | 45 | Extra Smooth | Beige | No | ——— | 0 | 0000000 | 0000 | 0000000 | 0000 | ——— | 0 | 000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Coloring | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Quartz | 15 | Polished | Tan | No | ——— | 0 | ——— | 0 | 00000000 | 0000 | ——— | 0 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Cutting/Coloring | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Silica | 35 | Extra Smooth | Brown | No | 00000000 | 00000 | ——— | 0 | 00000000 | 00000 | ——— | 0 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

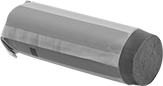

Aggressive Buffing and Polishing Compounds

Abrasive Material | Abrasive Grain Size, μm | Grit (For Finish) | Color | Dia. | Lg. | Wt., lb. | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Steel, Stainless Steel, Aluminum, Brass, Bronze, and Copper | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Cutting | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Aluminum Oxide | 38 | 400 (Extra Smooth) | Black | 2 1/2" | 10 1/2" | 3 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Aluminum Oxide | 40 | 280 (Extra Smooth) | Black | 2 1/2" | 10 1/2" | 3 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Aluminum Oxide | 60 | 240 (Extra Smooth) | Red | 2 1/2" | 10 1/2" | 3 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Aluminum Oxide | 80 | 180 (Smooth) | Red | 2 1/2" | 10 1/2" | 3 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Aluminum Oxide | 100 | 150 (Smooth) | Red | 2 1/2" | 10 1/2" | 3 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Aluminum Oxide | 120 | 120 (Smooth) | Red | 2 1/2" | 10 1/2" | 3 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Aluminum Oxide | 173 | 80 (Rough) | Red | 2 1/2" | 10 1/2" | 3 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

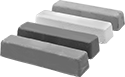

Buffing and Polishing Compound Assortments

|

No. of Pieces | Includes | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Cutting, Coloring, and Cutting/Coloring | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 | One 4 oz. Smooth-Finish Gray Cutting Compound One 4 oz. Extra-Smooth-Finish Brown Cutting/Coloring Compound One 4 oz. Polished-Finish White Rouge Coloring Compound One 4 oz. Polished-Finish Red Rouge Coloring Compound | 000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 | One 1 lb. Extra-Smooth-Finish Brown Cutting/Coloring Compound One 1 lb. Extra-Smooth-Finish Tan Cutting Compound One 1 lb. Polished-Finish White Rouge Coloring Compound One 1 lb. Polished-Finish Yellow Cutting/Coloring Compound One 1 lb. Polished-Finish White Coloring Compound One 1 lb. Polished-Finish Red Coloring Compound | 000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Polishing Bob and Compound Kits

No. of Pieces | Hardness Rating | For Polishing Step | Includes | Container Type | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Wool Felt | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 20 | Medium, Hard | Cutting, Coloring | One Medium Cylinder with Flat Tip Polishing Bob—1/2" Head Dia. × 1/2" Head Lg. × 1/8" Shank Dia. One Medium Cylinder with Round Tip Polishing Bob—1/2" Head Dia. × 1" Head Lg. × 1/8" Shank Dia. One Medium Ball Polishing Bob—1/2" Head Dia. × 1/2" Head Lg. × 1/8" Shank Dia. One Medium Oval Polishing Bob—1/2" Head Dia. × 1/2" Head Lg. × 1/8" Shank Dia. One Medium Pear Polishing Bob—1/2" Head Dia. × 3/4" Head Lg. × 1/8" Shank Dia. One Medium Cone with Flat Tip Polishing Bob—1/2" Head Dia. × 3/4" Head Lg. × 1/8" Shank Dia. One Medium Cone with Round Tip Polishing Bob—1/2" Head Dia. × 1" Head Lg. × 1/8" Shank Dia. Four Medium Flat-Edge Buffing Wheels—3/4" Dia. × 1/8" Thick. Four Hard Tapered-Edge Buffing Wheels—3/4" Dia. × 1/8" Thick. One 1/8" Dia. Shank for Buffing Wheels One 1/2 oz. Polished-Finish Black Cutting Compound One 1/2 oz. Extra-Smooth-Finish Brown Tripoli Cutting Compound One 1/2 oz. Polished-Finish Red Rouge Coloring Compound One 1/2 oz. Polished-Finish White Coloring Compound | Plastic Case | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 55 | Hard, Extra Hard | Cutting, Coloring | Three Extra-Hard Cylinder with Flat Tip Polishing Bobs—1/4" Head Dia. × 1/4" Head Lg. × 1/8" Shank Dia. Three Hard Cylinder with Flat Tip Polishing Bobs—1/4" Head Dia. × 1/4" Head Lg. × 1/8" Shank Dia. Four Extra-Hard Cylinder with Flat Tip Polishing Bobs—3/8" Head Dia. × 1/2" Head Lg. × 1/8" Shank Dia. Four Hard Cylinder with Flat Tip Polishing Bobs—3/8" Head Dia. × 1/2" Head Lg. × 1/8" Shank Dia. Four Extra-Hard Cylinder with Flat Tip Polishing Bobs—1/2" Head Dia. × 1/2" Head Lg. × 1/8" Shank Dia. Four Hard Cylinder with Flat Tip Polishing Bobs—1/2" Head Dia. × 1/2" Head Lg. × 1/8" Shank Dia. Four Extra-Hard Ball with Round Tip Polishing Bobs—1/2" Head Dia. × 1/2" Head Lg. × 1/8" Shank Dia. Four Hard Ball with Round Tip Polishing Bobs—1/2" Head Dia. × 1/2" Head Lg. × 1/8" Shank Dia. Three Extra-Hard Ball with Round Tip Polishing Bobs—3/4" Head Dia. × 3/4" Head Lg. × 1/4" Shank Dia. Three Hard Ball with Round Tip Polishing Bobs—3/4" Head Dia. × 3/4" Head Lg. × 1/4" Shank Dia. Four Extra-Hard Cone with Round Tip Polishing Bobs—1/2" Head Dia. × 1" Head Lg. × 1/8" Shank Dia. Four Hard Cone with Round Tip Polishing Bobs—1/2" Head Dia. × 1" Head Lg. × 1/8" Shank Dia. Three Extra-Hard Cone with Round Tip Polishing Bobs—3/4" Head Dia. × 1 1/2" Head Lg. × 1/4" Shank Dia. Three Hard Cone with Round Tip Polishing Bobs—3/4" Head Dia. × 1 1/2" Head Lg. × 1/4" Shank Dia. Three Hard Flat-Edge Buffing Wheels—1" Dia. × 1/4" Thk. One 1/2 oz. Polished-Finish Black Cutting Compound One 1/2 oz. Polished-Finish White Coloring Compound | Plastic Case | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 57 | Soft, Medium | Cutting, Coloring | Four Medium Cylinder with Flat Tip Polishing Bobs—1/4" Head Dia. × 1/4" Head Lg. × 1/8" Shank Dia. Four Soft Cylinder with Flat Tip Polishing Bobs—1/4" Head Dia. × 1/4" Head Lg. × 1/8" Shank Dia. Four Medium Cylinder with Flat Tip Polishing Bobs—3/8" Head Dia. × 1/2" Head Lg. × 1/8" Shank Dia. Four Soft Cylinder with Flat Tip Polishing Bobs—3/8" Head Dia. × 1/2" Head Lg. × 1/8" Shank Dia. Four Medium Cylinder with Flat Tip Polishing Bobs—1/2" Head Dia. × 1/2" Head Lg. × 1/8" Shank Dia. Four Soft Cylinder with Flat Tip Polishing Bobs—1/2" Head Dia. × 1/2" Head Lg. × 1/8" Shank Dia. Four Medium Ball with Round Tip Polishing Bobs—1/2" Head Dia. × 1/2" Head Lg. × 1/8" Shank Dia. Four Soft Ball with Round Tip Polishing Bobs—1/2" Head Dia. × 1/2" Head Lg. × 1/8" Shank Dia. Three Medium Ball with Round Tip Polishing Bobs—3/4" Head Dia. × 3/4" Head Lg. × 1/4" Shank Dia. Three Soft Ball with Round Tip Polishing Bobs—3/4" Head Dia. × 3/4" Head Lg. × 1/4" Shank Dia. Four Medium Cone with Round Tip Polishing Bobs—1/2" Head Dia. × 1" Head Lg. × 1/8" Shank Dia. Four Soft Cone with Round Tip Polishing Bobs—1/2" Head Dia. × 1" Head Lg. × 1/8" Shank Dia. Three Medium Cone with Round Tip Polishing Bobs—3/4" Head Dia. × 1 1/2" Head Lg. × 1/4" Shank Dia. Three Soft Cone with Round Tip Polishing Bobs—3/4" Head Dia. × 1 1/2" Head Lg. × 1/4" Shank Dia. Three Medium Flat-Edge Buffing Wheels—1" Dia. × 1/4" Thk. One 1/2 oz. Extra-Smooth-Finish Brown Tripoli Cutting Compound One 1/2 oz. Polished-Finish White Coloring Compound | Plastic Case | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 59 | Soft, Medium, Hard, Extra Hard | Cutting, Coloring | Three Extra-Hard Cylinder with Flat Tip Polishing Bobs—1/4" Head Dia. × 1/4" Head Lg. × 1/8" Shank Dia. Three Hard Cylinder with Flat Tip Polishing Bobs—1/4" Head Dia. × 1/4" Head Lg. × 1/8" Shank Dia. Three Medium Cylinder with Flat Tip Polishing Bobs—1/4" Head Dia. × 1/4" Head Lg. × 1/8" Shank Dia. Three Soft Cylinder with Flat Tip Polishing Bobs—1/4" Head Dia. × 1/4" Head Lg. × 1/8" Shank Dia. Four Extra-Hard Cylinder with Flat Tip Polishing Bobs—1/2" Head Dia. × 1/2" Head Lg. × 1/8" Shank Dia. Four Hard Cylinder with Flat Tip Polishing Bobs—1/2" Head Dia. × 1/2" Head Lg. × 1/8" Shank Dia. Four Medium Cylinder with Flat Tip Polishing Bobs—1/2" Head Dia. × 1/2" Head Lg. × 1/8" Shank Dia. Four Soft Cylinder with Flat Tip Polishing Bobs—1/2" Head Dia. × 1/2" Head Lg. × 1/8" Shank Dia. Four Extra-Hard Cone with Round Tip Polishing Bobs—1/2" Head Dia. × 1" Head Lg. × 1/8" Shank Dia. Four Hard Cone with Round Tip Polishing Bobs—1/2" Head Dia. × 1" Head Lg. × 1/8" Shank Dia. Four Medium Cone with Round Tip Polishing Bobs—1/2" Head Dia. × 1" Head Lg. × 1/8" Shank Dia. Four Soft Cone with Round Tip Polishing Bobs—1/2" Head Dia. × 1" Head Lg. × 1/8" Shank Dia. Three Extra-Hard Cone with Round Tip Polishing Bobs—3/4" Head Dia. × 1 1/2" Head Lg. × 1/4" Shank Dia. Three Hard Cone with Round Tip Polishing Bobs—3/4" Head Dia. × 1 1/2" Head Lg. × 1/4" Shank Dia. Three Medium Cone with Round Tip Polishing Bobs—3/4" Head Dia. × 1 1/2" Head Lg. × 1/4" Shank Dia. Three Soft Cone with Round Tip Polishing Bobs—3/4" Head Dia. × 1 1/2" Head Lg. × 1/4" Shank Dia. One 1/2 oz. Extra-Smooth-Finish Brown Tripoli Cutting Compound One 1/2 oz. Polished-Finish Black Cutting Compound One 1/2 oz. Polished-Finish White Coloring Compound | Plastic Case | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

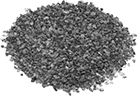

Tumbling Media for Aluminum, Brass, and Soft Metals

|

Granule |

10 lb. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Density, lb/ft³ | Recommended Media to Parts Ratio | Abrasion Type | Tumbling Condition | Material | Pkg. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Ultra Smooth Finish | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Granule | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 40 | 4:1 | None | Dry | Walnut Shell | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Polishing Bob and Compound Kits for Reciprocating Polishers

No. of Pieces | Hardness Rating | For Polishing Step | Includes | Container Type | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Wool Felt | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 26 | Medium, Hard | Cutting, Coloring | Four Medium Rectangle with Bevel Tip Polishing Bobs—1/4" Head Wd. × 1/4" Head Thk. × 1 1/2" Head Lg. × 1/8" Shank Dia. Four Hard Rectangle with Bevel Tip Polishing Bobs—1/4" Head Wd. × 1/4" Head Thk. × 1 1/2" Head Lg. × 1/8" Shank Dia. Four Medium Rectangle with Bevel Tip Polishing Bobs—3/8" Head Wd. × 3/8" Head Thk. × 1 1/2" Head Lg. × 1/8" Shank Dia. Four Hard Rectangle with Bevel Tip Polishing Bobs—3/8" Head Wd. × 3/8" Head Thk. × 1 1/2" Head Lg. × 1/8" Shank Dia. Four Medium Rectangle with Bevel Tip Polishing Bobs—1/2" Head Wd. × 1/2" Head Thk. × 1 1/2" Head Lg. × 1/8" Shank Dia. Four Hard Rectangle with Bevel Tip Polishing Bobs—1/2" Head Wd. × 1/2" Head Thk. × 1 1/2" Head Lg. × 1/8" Shank Dia. One 1/2 oz. Smooth-Finish Gray Cutting Compound One 1/2 oz. Polished-Finish White Coloring Compound | Plastic Case | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||