Shape Shape |

|---|

| Sheet and Bar | Rod and Disc |

| Round Tube |

Material Material |

|---|

|

|

DFARS (Defense Acquisition Regulations Supplement) DFARS (Defense AcquisitionRegulations Supplement) |

|---|

Performance Properties Performance Properties |

|---|

|

REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) REACH (Registration,Evaluation, Authorization and Restriction of Chemicals) |

|---|

|

Flexibility Flexibility |

|---|

|

RoHS (Restriction of Hazardous Substances) RoHS (Restriction ofHazardous Substances) |

|---|

|

Tensile Strength Tensile Strength |

|---|

|

|

Impact Strength Impact Strength |

|---|

|

About Composites

More

About Plastic

More

Wear-Resistant Kevlar Sheets

- Color: Brown

- Max. Temperature: Not Rated

- Tensile Strength: 10,600 psi (Good)

- Impact Strength: 23.792 ft.-lbs./in. (Excellent)

- Hardness: Not Rated

- For Use Outdoors: Yes

Often used as rotor vanes in pumps and compressors, these sheets are made of Kevlar, a super-tough material that stands up to wear and abrasion.

For technical drawings and 3-D models, click on a part number.

Wear-Resistant Kevlar Tubes

- Color: Yellow

- Temperature Range: 0° F to 250° F

- Tensile Strength: Not Rated

- Impact Strength: Not Rated

- Hardness: Not Rated

- For Use Outdoors: No

These tubes are made of Kevlar, a super-tough material that stands up to wear and abrasion. Use them as sleeves to protect cords from cuts and gashes.

For technical drawings and 3-D models, click on a part number.

12" Lg. | 36" Lg. | ||||||

|---|---|---|---|---|---|---|---|

| OD | OD Tolerance | ID | ID Tolerance | Each | Each | ||

0.015" Wall Thick. (-0.012" to 0.012") | |||||||

| 0.655" | -0.012" to 0.012" | 5/8" | -0.006" to 0.006" | 0000000 | 0000000 | 0000000 | 0000000 |

| 0.78" | -0.012" to 0.012" | 3/4" | -0.006" to 0.006" | 0000000 | 000000 | 0000000 | 000000 |

| 1.53" | -0.012" to 0.012" | 1 1/2" | -0.006" to 0.006" | 0000000 | 000000 | 000000 | 00 |

| 2.03" | -0.02" to 0.02" | 2" | -0.01" to 0.01" | 0000000 | 000000 | 0000000 | 000000 |

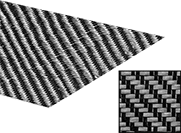

Composite Fabrics

Use these resin-free fabrics to reinforce or repair existing composites as well as create new composites. Mold custom-shaped composite parts by layering your choice of fabric with an epoxy. The epoxy (sold separately) is a two-part resin that begins to harden in 15 hours and reaches full strength in 4 days. Finished composite pieces withstand temperatures up to 250° or 350° F.

Fabrics with a plain, twill, or triaxial weave have fibers that are woven in alternating directions for uniform strength and rigidity in all directions. Easier to machine than fabrics with a unidirectional weave, their woven pattern holds the fibers together to limit splintering. Twill-weave fabrics are stronger than plain-weave fabrics. They’re also more flexible, making them easier to manipulate into complex shapes. They will not, however, retain their shape as well as plain-weave fabrics.

Kevlar fabrics are a super-tough material that offers excellent wear and abrasion resistance.

For technical drawings and 3-D models, click on a part number.

Impact-Resistant Ultra-Strength Carbon Fiber Sheets with Kevlar Core

- Color: Black

- Temperature Range: -100° to 190° F

- Tensile Strength: 177,000 psi (Excellent)

- Impact Strength: Not Rated

- Hardness: Not Rated

- For Use Outdoors: No

Often used to build frames and structures, these lightweight sheets combine the strength and stiffness of carbon fiber with the impact resistance of Kevlar. With carbon fiber on the outer layers, these sheets are extremely difficult to bend—they’re nearly as stiff as pure carbon fiber. The carbon fiber layers also provide good strength under tension, comparable to 6061 aluminum. Sandwiched between the carbon fiber layers of these sheets is a Kevlar core. Known for its toughness, the Kevlar core helps prevent sheets from failing under a variety of stresses, such as punctures, cuts, impact, and wear. The Kevlar core also has a lower density than carbon fiber, making these sheets even lighter than sheets made from carbon fiber alone.

Sheets with 0.09 in. thickness have thicker layers of carbon fiber, making them stiffer than those with 0.06 in. thickness.

For technical drawings and 3-D models, click on a part number.

Additives and Reinforcements for Composites

Mix these additives with melted plastic, epoxies, or adhesives to make parts stronger and more wear resistant without adding much weight. You can use them in batches to tackle repairs and small parts instead of machining your part from a sheet, bar, or other shape.

Kevlar

Choose these additives when your application is likely to wear down your finished part—they improve a part’s ability to stand up to corrosion, bangs, bumps, and scrapes. They’re also used to reinforce points where honeycomb cores connect to fabric. To start, mix in 1 part Kevlar to 15 parts composite.

Kevlar-Filled Wear-Resistant Nylon Rods

- Color: Yellow

- Temperature Range: -40° to 300° F

- Tensile Strength: 16,000 psi (Excellent)

- Impact Strength: 2.7 ft.-lbs./in. (Good)

- Hardness: Not Rated (Hard)

- For Use Outdoors: No

Often used for wear strips, bushings, and other parts that are continuously exposed to wear and abrasion, these nylon 6/6 rods are filled with Kevlar to last up to 20 times longer than unfilled nylon. They’re also stronger than glass-filled nylon and withstand higher temperatures. This material is frequently called Hydlar Z.

For technical drawings and 3-D models, click on a part number.

Kevlar-Filled Wear-Resistant Nylon Sheets

- Color: Yellow

- Temperature Range: -40° to 300° F

- Tensile Strength: 16,000 psi (Excellent)

- Impact Strength: 2.7 ft.-lbs./in. (Good)

- Hardness: Not Rated (Hard)

- For Use Outdoors: No

Designed for extreme wear resistance, these nylon 6/6 sheets are filled with Kevlar to last up to 20 times longer than unfilled nylon. They’re also stronger than glass-filled nylon and withstand higher temperatures. Known as Hydlar Z, this material is often used for parts that are continuously exposed to wear and abrasion, such as wear strips and bushings.

For technical drawings and 3-D models, click on a part number.