Filter by

Thread Size

Handle Style

Handle Length

Stud Length

Stud Material

Maximum Temperature

DFARS Specialty Metals

Insert Material

Minimum Temperature

Knob Material

Handle Material

Tapered Lever Handles

|  |  |

Style 1 (Fixed) | Style 1 (Revolving/Folding) | Style 1 (Revolving, Phenolic) |

|  |  |

Style 1 (Revolving, Aluminum) | Style 2 | Style 3 (Fixed) |

|  | |

Style 3 (Revolving/Folding) | Style 4 |

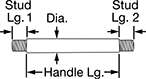

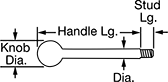

Style 1—Threaded Stud with Smooth Fixed Handle

| -1607697253-p9@halfx_637432724644783048.png?ver=ImageNotFound) |

Style 1 (Fixed) |

Dia. | Temp., ° F | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Thread Size | Stud Lg. | Handle Lg. | (A) | (B) | Stud Material | Min. | Max. | 1-9 | 10-Up | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Black Phenolic | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16"-18 | 1/2" | 3 7/8" | 1" | 5/8" | Steel | -30 | 400 | 00000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 1/2" | 3 7/8" | 1" | 5/8" | Steel | -30 | 400 | 00000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M5 × 0.8 mm | 7 mm | 50 mm | 15 mm | 11 mm | Steel | — | 230 | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M6 × 1 mm | 10 mm | 72 mm | 21 mm | 15 mm | Steel | — | 230 | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M8 × 1.25 mm | 10 mm | 90 mm | 25 mm | 17 mm | Steel | — | 230 | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M10 × 1.5 mm | 12 mm | 100 mm | 26 mm | 20 mm | Steel | — | 230 | 0000000 | 00000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M12 × 1.75 mm | 14 mm | 124 mm | 33 mm | 25 mm | Steel | — | 230 | 0000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Style 1—Threaded Stud with Smooth Revolving Handle

Dia. | Temp., ° F | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Thread Size | Stud Lg. | Handle Lg. | (A) | (B) | Stud Material | Min. | Max. | 1-9 | 10-Up | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Black Phenolic | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-20 | 1/2" | 1 9/16" | 0.688" | 9/16" | Steel | -30 | 325 | 0000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-20 | 1/2" | 2" | 0.813" | 11/16" | Steel | -30 | 325 | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16"-18 | 9/16" | 2 9/16" | 0.938" | 3/4" | Steel | -30 | 325 | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 5/8" | 3 1/8" | 1" | 13/16" | Steel | -30 | 325 | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 5/8" | 3 9/16" | 1 1/8" | 13/16" | Steel | -30 | 325 | 0000000 | 00000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-13 | 13/16" | 4" | 1 1/4" | 1" | Steel | -30 | 325 | 0000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M6 × 1 mm | 13 mm | 40 mm | 18 mm | 15 mm | Steel | -30 | 325 | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M6 × 1 mm | 13 mm | 50 mm | 21 mm | 17 mm | Steel | -30 | 325 | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M8 × 1.25 mm | 15 mm | 65 mm | 23 mm | 19 mm | Steel | -30 | 325 | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M10 × 1.5 mm | 17 mm | 80 mm | 26 mm | 21 mm | Steel | -30 | 325 | 0000000 | 00000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M10 × 1.5 mm | 17 mm | 90 mm | 28 mm | 22 mm | Steel | -30 | 325 | 0000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M12 × 1.75 mm | 20 mm | 102 mm | 31 mm | 25 mm | Steel | -30 | 325 | 0000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Aluminum | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10-24 | 3/8" | 1 1/8" | 0.438" | 3/8" | Steel | — | — | 00000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-20 | 7/16" | 1 9/16" | 5/8" | 1/2" | Steel | — | — | 00000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16"-18 | 1/2" | 2" | 7/8" | 9/16" | Steel | — | — | 00000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 1/2" | 2 1/2" | 1" | 3/4" | Steel | — | — | 00000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-13 | 1/2" | 2 7/8" | 1 1/8" | 15/16" | Steel | — | — | 00000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-13 | 1/2" | 3 1/4" | 1 1/4" | 15/16" | Steel | — | — | 00000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M5 × 0.8 mm | 9 mm | 28 mm | 11 mm | 9 mm | Steel | — | — | 00000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M6 × 1 mm | 11 mm | 39 mm | 16 mm | 13 mm | Steel | — | — | 00000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M8 × 1.25 mm | 13 mm | 50 mm | 22 mm | 14 mm | Steel | — | — | 00000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M10 × 1.5 mm | 13 mm | 63 mm | 25 mm | 19 mm | Steel | — | — | 00000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M12 × 1.75 mm | 13 mm | 72 mm | 28 mm | 23 mm | Steel | — | — | 00000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M12 × 1.75 mm | 13 mm | 82 mm | 31 mm | 23 mm | Steel | — | — | 00000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Style 1—Threaded Stud with Smooth Revolving/Folding Handle

Dia. | Temp., ° F | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Thread Size | Stud Lg. | Handle Lg. | (A) | (B) | Stud Material | Min. | Max. | 1-9 | 10-Up | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Black Nylon | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 1/2" | 3 3/8" | 0.91" | 3/4" | Steel | -50 | 200 | 00000000 | 000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-13 | 9/16" | 4" | 1.02" | 0.83" | Steel | -50 | 200 | 00000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8"-11 | 13/16" | 4 1/2" | 1.1" | 0.91" | Steel | -50 | 200 | 00000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M8 × 1.25 mm | 13 mm | 86 mm | 23 mm | 19 mm | Steel | -50 | 200 | 00000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M10 × 1.5 mm | 14 mm | 102 mm | 26 mm | 21 mm | Steel | -50 | 200 | 00000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M12 × 1.75 mm | 20 mm | 114 mm | 28 mm | 23 mm | Steel | -50 | 200 | 00000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

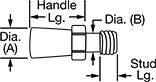

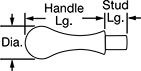

Style 2—Threaded Stud with Ribbed Fixed Handle

| -1607697253-p9@halfx_637432724644783048.png?ver=ImageNotFound) |

Style 2 |

Dia. | Temp., ° F | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Thread Size | Stud Lg. | Handle Lg. | (A) | (B) | Stud Material | Min. | Max. | 1-9 | 10-Up | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Black Phenolic | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-20 | 3/8" | 3 7/8" | 1 1/8" | 3/4" | Steel | -30 | 400 | 00000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16"-18 | 3/8" | 3 7/8" | 1 1/8" | 3/4" | Steel | -30 | 400 | 00000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 1/2" | 3 7/8" | 1 1/8" | 3/4" | Steel | -30 | 400 | 00000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 3/4" | 4 15/16" | 1 3/8" | 1" | Steel | -30 | 400 | 00000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Style 3—Threaded Hole with Smooth Fixed Handle

Thread | Dia. | Temp., ° F | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Size | Dp. | Handle Lg. | (A) | (B) | Insert Material | Min. | Max. | 1-9 | 10-Up | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Black Phenolic | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-20 | 3/8" | 2 5/8" | 7/8" | 5/8" | Brass | -30 | 400 | 00000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16"-18 | 3/4" | 2 5/8" | 7/8" | 5/8" | Brass | -30 | 400 | 00000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 5/8" | 3 7/8" | 1" | 5/8" | Brass | -30 | 400 | 00000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 2" | 3 7/8" | 1" | 5/8" | Brass | -30 | 400 | 00000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-24 | 5/8" | 3 7/8" | 1" | 5/8" | Brass | -30 | 400 | 00000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-24 | 2" | 3 7/8" | 1" | 5/8" | Brass | -30 | 400 | 00000000 | 00000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M5 × 0.8 mm | 14 mm | 27 mm | 13 mm | 11 mm | — | 0 | 300 | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M6 × 1 mm | 25 mm | 50 mm | 21 mm | 17 mm | — | 0 | 300 | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M8 × 1.25 mm | 25 mm | 50 mm | 21 mm | 17 mm | — | 0 | 300 | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M8 × 1.25 mm | 30 mm | 65 mm | 25 mm | 20 mm | — | 0 | 300 | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M10 × 1.5 mm | 30 mm | 65 mm | 25 mm | 20 mm | — | 0 | 300 | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M12 × 1.75 mm | 30 mm | 65 mm | 25 mm | 20 mm | — | 0 | 300 | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M12 × 1.75 mm | 40 mm | 112 mm | 29 mm | 22 mm | — | 0 | 300 | 0000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Style 3—Threaded Hole with Smooth Revolving/Folding Handle

Style 4—Threaded Hole with Ribbed Fixed Handle

Thread | Dia. | Temp., ° F | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Size | Dp. | Handle Lg. | (A) | (B) | Insert Material | Min. | Max. | 1-9 | 10-Up | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Black Phenolic | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-20 | 1/2" | 3" | 1 1/8" | 5/8" | Brass | -30 | 400 | 00000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-20 | 1/2" | 3 7/8" | 1 1/8" | 3/4" | Brass | -30 | 400 | 00000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 3/4" | 4 15/16" | 1 3/8" | 1" | Brass | -30 | 400 | 00000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-13 | 1" | 4 15/16" | 1 3/8" | 1" | Brass | -30 | 400 | 00000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Black Polypropylene | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-20 | 1/2" | 2 5/8" | 7/8" | 5/8" | Brass | -15 | 125 | 00000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 1/2" | 2 5/8" | 7/8" | 5/8" | Brass | -15 | 125 | 00000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

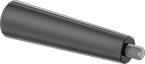

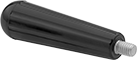

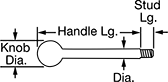

Lever Handles

Threaded Stud with Fixed Handle

| |

Knob | Temp., ° F | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Thread Size | Stud Lg. | Handle Lg. | Dia. | Dia. | Material | Color | Stud Material | Min. | Max. | 1-9 | 10-Up | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Black-Oxide Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10-32 | 3/8" | 1 1/2" | 1/4" | 3/4" | Phenolic | Black | Steel | -70 | 200 | 000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10-32 | 3/8" | 3" | 1/4" | 3/4" | Phenolic | Black | Steel | -70 | 200 | 000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-20 | 3/8" | 2 1/2" | 1/4" | 3/4" | Phenolic | Black | Steel | -70 | 200 | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-20 | 3/8" | 3 1/2" | 1/4" | 3/4" | Phenolic | Black | Steel | -70 | 200 | 000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-20 | 1/2" | 6" | 3/8" | 1" | Phenolic | Black | Steel | -70 | 200 | 000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16"-18 | 1/2" | 2 1/2" | 3/8" | 1" | Phenolic | Black | Steel | -70 | 200 | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16"-18 | 1/2" | 4" | 3/8" | 1" | Phenolic | Black | Steel | -70 | 200 | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16"-18 | 1/2" | 6" | 3/8" | 1" | Phenolic | Black | Steel | -70 | 200 | 000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 1/2" | 2 1/2" | 1/2" | 1 3/8" | Phenolic | Black | Steel | -70 | 200 | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 1/2" | 4" | 1/2" | 1 3/8" | Phenolic | Black | Steel | -70 | 200 | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 1/2" | 8" | 1/2" | 1 3/8" | Phenolic | Black | Steel | -70 | 200 | 000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-13 | 5/8" | 6" | 5/8" | 1 7/8" | Phenolic | Black | Steel | -70 | 200 | 0000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-13 | 5/8" | 8" | 5/8" | 1 7/8" | Phenolic | Black | Steel | -70 | 200 | 0000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-13 | 5/8" | 10" | 5/8" | 1 7/8" | Phenolic | Black | Steel | -70 | 200 | 000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M6 × 1 mm | 9.5 mm | 76 mm | 7 mm | 19 mm | Phenolic | Black | Steel | -70 | 200 | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M8 × 1.25 mm | 12.5 mm | 152 mm | 10 mm | 26 mm | Phenolic | Black | Steel | -70 | 200 | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M10 × 1.5 mm | 12.5 mm | 203 mm | 13 mm | 35 mm | Phenolic | Black | Steel | -70 | 200 | 0000000 | 00000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M12 × 1.75 mm | 16 mm | 254 mm | 16 mm | 48 mm | Phenolic | Black | Steel | -70 | 200 | 0000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

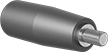

Threaded Stud with Revolving Handle

| |

Knob | Temp., ° F | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Thread Size | Stud Lg. | Handle Lg. | Dia. | Dia. | Material | Color | Stud Material | Min. | Max. | 1-9 | 10-Up | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Black Zinc-Plated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-20 | 7/16" | 1 1/2" | 3/8" | 1" | Phenolic | Black | Steel | 0 | 300 | 0000000 | 000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16"-18 | 1/2" | 1 7/8" | 1/2" | 1 1/4" | Phenolic | Black | Steel | 0 | 300 | 0000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 9/16" | 2 3/8" | 5/8" | 1 9/16" | Phenolic | Black | Steel | 0 | 300 | 0000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-13 | 13/16" | 3 1/16" | 13/16" | 2" | Phenolic | Black | Steel | 0 | 300 | 0000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M6 × 1 mm | 11 mm | 38 mm | 10 mm | 25 mm | Phenolic | Black | Steel | 0 | 300 | 00000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M8 × 1.25 mm | 13 mm | 48 mm | 13 mm | 32 mm | Phenolic | Black | Steel | 0 | 300 | 00000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M10 × 1.5 mm | 14 mm | 61 mm | 16 mm | 40 mm | Phenolic | Black | Steel | 0 | 300 | 00000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M12 × 1.75 mm | 21 mm | 78 mm | 20 mm | 50 mm | Phenolic | Black | Steel | 0 | 300 | 00000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Ball-Lever Shafts

Stud | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Thread Size | Lg. 1 | Lg. 2 | Handle Lg. | Dia. | Stud Material | 1-9 | 10-Up | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Threaded-Stud Mount | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Black-Oxide Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10-24 | 3/8" | 1/4" | 3/4" | 1/4" | Steel | 0000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10-24 | 3/8" | 1/4" | 2 1/4" | 1/4" | Steel | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10-32 | 3/8" | 1/4" | 3/4" | 1/4" | Steel | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10-32 | 3/8" | 1/4" | 2 1/4" | 1/4" | Steel | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-20 | 1/2" | 3/8" | 1 1/2" | 3/8" | Steel | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-20 | 1/2" | 3/8" | 5" | 3/8" | Steel | 0000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-28 | 3/8" | 1/4" | 1 3/4" | 3/8" | Steel | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-28 | 1/2" | 3/8" | 5" | 3/8" | Steel | 0000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16"-18 | 1/2" | 3/8" | 1 1/2" | 3/8" | Steel | 0000000 | 00000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16"-18 | 1/2" | 3/8" | 5" | 3/8" | Steel | 0000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16"-24 | 1/2" | 3/8" | 1 1/2" | 3/8" | Steel | 0000000 | 00000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16"-24 | 1/2" | 3/8" | 5" | 3/8" | Steel | 0000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 1/2" | 1/2" | 1 1/8" | 1/2" | Steel | 0000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 1/2" | 1/2" | 2 5/8" | 1/2" | Steel | 0000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 1/2" | 1/2" | 6 5/8" | 1/2" | Steel | 0000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-24 | 1/2" | 1/2" | 2 5/8" | 1/2" | Steel | 0000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-24 | 1/2" | 1/2" | 6 5/8" | 1/2" | Steel | 0000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-13 | 5/8" | 5/8" | 4 1/8" | 5/8" | Steel | 0000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-13 | 5/8" | 5/8" | 6 1/8" | 5/8" | Steel | 0000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-13 | 5/8" | 5/8" | 8 1/8" | 5/8" | Steel | 0000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-20 | 5/8" | 5/8" | 4 1/8" | 5/8" | Steel | 0000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-20 | 5/8" | 5/8" | 6 1/8" | 5/8" | Steel | 0000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8"-11 | 3/4" | 5/8" | 8" | 3/4" | Steel | 0000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8"-18 | 3/4" | 3/4" | 7 7/8" | 3/4" | Steel | 0000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M6 × 1 mm | 9.5 mm | 6.4 mm | 44 mm | 10 mm | Steel | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M8 × 1.25 mm | 12.7 mm | 9.5 mm | 38 mm | 10 mm | Steel | 0000000 | 00000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M10 × 1.5 mm | 12.7 mm | 12.7 mm | 29 mm | 13 mm | Steel | 0000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M12 × 1.75 mm | 15.9 mm | 15.9 mm | 105 mm | 16 mm | Steel | 0000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

303 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10-24 | 3/8" | 1/4" | 3/4" | 1/4" | 303 Stainless Steel | 0000000 | 00000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10-24 | 3/8" | 1/4" | 2 1/4" | 1/4" | 303 Stainless Steel | 0000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10-32 | 3/8" | 1/4" | 3/4" | 1/4" | 303 Stainless Steel | 0000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10-32 | 3/8" | 1/4" | 2 1/4" | 1/4" | 303 Stainless Steel | 0000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-20 | 3/8" | 1/4" | 1 3/4" | 3/8" | 303 Stainless Steel | 0000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-20 | 1/2" | 3/8" | 5" | 3/8" | 303 Stainless Steel | 0000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-28 | 3/8" | 1/4" | 1 3/4" | 3/8" | 303 Stainless Steel | 0000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-28 | 1/2" | 3/8" | 5" | 3/8" | 303 Stainless Steel | 0000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16"-18 | 1/2" | 3/8" | 1 1/2" | 3/8" | 303 Stainless Steel | 0000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16"-18 | 1/2" | 3/8" | 5" | 3/8" | 303 Stainless Steel | 0000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16"-24 | 1/2" | 3/8" | 1 1/2" | 3/8" | 303 Stainless Steel | 0000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16"-24 | 1/2" | 3/8" | 5" | 3/8" | 303 Stainless Steel | 0000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 1/2" | 1/2" | 1 1/8" | 1/2" | 303 Stainless Steel | 0000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 1/2" | 1/2" | 2 5/8" | 1/2" | 303 Stainless Steel | 0000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 1/2" | 1/2" | 6 5/8" | 1/2" | 303 Stainless Steel | 0000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-24 | 1/2" | 1/2" | 2 5/8" | 1/2" | 303 Stainless Steel | 0000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-24 | 1/2" | 1/2" | 6 5/8" | 1/2" | 303 Stainless Steel | 0000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-13 | 5/8" | 5/8" | 4 1/8" | 5/8" | 303 Stainless Steel | 0000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-13 | 5/8" | 5/8" | 6 1/8" | 5/8" | 303 Stainless Steel | 0000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-13 | 5/8" | 5/8" | 8 1/8" | 5/8" | 303 Stainless Steel | 0000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-20 | 5/8" | 5/8" | 4 1/8" | 5/8" | 303 Stainless Steel | 0000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-20 | 5/8" | 5/8" | 6 1/8" | 5/8" | 303 Stainless Steel | 0000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8"-11 | 3/4" | 5/8" | 8" | 3/4" | 303 Stainless Steel | 0000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8"-18 | 3/4" | 3/4" | 7 7/8" | 3/4" | 303 Stainless Steel | 0000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M6 × 1 mm | 9.5 mm | 6.4 mm | 44 mm | 10 mm | 303 Stainless Steel | 0000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M8 × 1.25 mm | 12.7 mm | 9.5 mm | 38 mm | 10 mm | 303 Stainless Steel | 0000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M10 × 1.5 mm | 12.7 mm | 12.7 mm | 29 mm | 13 mm | 303 Stainless Steel | 0000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M12 × 1.75 mm | 15.9 mm | 15.9 mm | 105 mm | 16 mm | 303 Stainless Steel | 0000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Miniature Tapered Lever Handles

Push-On Tapered Lever Handles

|

Unthreaded Stud with Fixed Handle

Stud | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Dia. | Lg. | Handle Lg. | Dia. | 1-9 | 10-Up | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 7/16" | 1 5/16" | 7/16" | 0000000 | 000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 7/16" | 1 1/2" | 5/8" | 0000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16" | 7/16" | 1 3/4" | 3/4" | 0000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 9/16" | 2 1/8" | 7/8" | 0000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/16" | 11/16" | 2 3/4" | 1 1/8" | 0000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/16" | 11/16" | 3 1/4" | 1 3/16" | 0000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 15/16" | 4 1/16" | 1 3/8" | 0000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8" | 1 3/16" | 4 9/16" | 1 1/2" | 0000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Metal-Detectable Tapered Lever Handles

Threaded Hole

| --263ad7128161610655044-p9@halfx_637462302512265131.png?ver=ImageNotFound) |

Thread | Dia., mm | Temp., ° F | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Size | Dp., mm | Handle Lg., mm | (A) | (B) | Min. | Max. | Food Industry Std. | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Blue Nylon | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M10 × 1.5 mm | 55 | 80 | 26 | 21 | -20 | 110 | FDA Compliant 21 CFR 177.1500, FDA Compliant 21 CFR 178.3297 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Flow-Control Valve Handles

|  |  |  |

For ASC Engineered Solutions Valves | For Cipriani Valves | For Conbraco Valves | For Dixon Valve Valves |

|  | ||

For Milwaukee Valve Valves | For Nibco Valves | For RuB Valves |

Handle | For Stem | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Valve Mfr. Model No. | Mfr. Model No. | Material | Lg. | Wd. | Lg. | Color | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Lever Handle | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

ASC Engineered Solutions 50M76 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4351005840, 4351005860, 4351005880 | 4351006040 | Plastic-Coated Steel | 4 3/4" | 3/16" | 11/32" | Yellow | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4351005900 | 4351006060 | Plastic-Coated Steel | 5 5/8" | 1/4" | 13/32" | Yellow | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4351005920, 4351005940 | 4351006080 | Plastic-Coated Steel | 6 1/2" | 11/32" | 15/32" | Yellow | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4351005960, 4351005980 | 4351006100 | Plastic-Coated Steel | 8 1/2" | 13/32" | 5/8" | Yellow | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4351006000, 4351006020 | 4351006120 | Plastic-Coated Steel | 11 1/4" | 1/2" | 25/32" | Yellow | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Cipriani 100 Series | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| — | 7M10 | Stainless Steel | 6 5/8" | 5/16" | 7/8" | — | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| — | 7M5 | Plastic-Coated Stainless Steel | 6 5/8" | 5/16" | 7/8" | Black | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| — | 7M5/4 | Plastic-Coated Stainless Steel | 6 5/8" | 5/16" | 7/8" | Black | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Conbraco 70-100 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 70-101-01, 70-103-01 | W564000 | Plastic-Coated Steel | 4 1/4" | 7/32" | 3/8" | Yellow | 00000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 70-104-01, 70-105-01 | W564400 | Plastic-Coated Steel | 5 1/4" | 1/4" | 7/16" | Yellow | 00000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Dixon Valve BV2C | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| BV2CG-050CC-A, BV2CG-075CC-A, BV2CU-050CC-A, BV2CU-075CC-A, BV2CV-050CC-A, BV2CV-075CC-A | BV-23-HA050-075 | Plastic-Coated Stainless Steel | 4 15/16" | 3/8" | 13/32" | Blue | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| BV2CG-100CC-A, BV2CU-100CC-A, BV2CV-100CC-A | BV-23-HA100 | Plastic-Coated Stainless Steel | 5 3/8" | 7/16" | 13/32" | Blue | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| BV2CG-150CC-A, BV2CG-200CC-A, BV2CU-150CC-A, BV2CU-200CC-A, BV2CV-150CC-A, BV2CV-200CC-A | BV-23-HA150-200 | Plastic-Coated Stainless Steel | 9 5/16" | 9/16" | 19/32" | Blue | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| BV2CG-250CC-A, BV2CG-300CC-A, BV2CU-250CC-A, BV2CU-300CC-A, BV2CV-250CC-A, BV2CV-300CC-A | BV-23-HA-17 | Plastic-Coated Stainless Steel | 18" | 11/16" | 11/16" | Blue | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| BV2CG-400CC-A, BV2CU-400CC-A, BV2CV-400CC-A | BV-23-HA-22 | Plastic-Coated Stainless Steel | 18 1/4" | 7/8" | 29/32" | Blue | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Milwaukee Valve BA-475B | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| BA-475B 1/4 | 28996MV1/4 | Plastic-Coated Steel | 3 1/8" | 1/4" | 1/4" | Blue | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| BA-475B 1/2 | 28996MV1/2 | Plastic-Coated Steel | 3 1/8" | 1/4" | 1/4" | Blue | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| BA-475B 3/4 | 28997MV3/4 | Plastic-Coated Steel | 4 3/8" | 5/16" | 3/8" | Blue | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| BA-475B 1 | 28997MV1 | Plastic-Coated Steel | 4 3/8" | 5/16" | 3/8" | Blue | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Nibco T-585 Series | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| T58570-1/4 | T091761-1/4 | Plastic-Coated Steel | 3 15/16" | 3/16" | 5/16" | Blue | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| T58570-1/2 | T091761-1/2 | Plastic-Coated Steel | 3 15/16" | 3/16" | 5/16" | Blue | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| T58570-3/4 | T062696-3/4 | Plastic-Coated Steel | 4 11/16" | 1/4" | 3/8" | Blue | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

RuB S95 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| S95B41 | PLFG11 | Plastic-Coated Steel | 3 1/4" | 5/16" | 7/32" | Yellow | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| S95D41 | PLFG13 | Plastic-Coated Steel | 4" | 5/16" | 7/32" | Yellow | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| S95E41 | PLFG16 | Plastic-Coated Steel | 4 3/4" | 3/8" | 1/4" | Yellow | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| S95F41 | PLFG16 | Plastic-Coated Steel | 4 3/4" | 3/8" | 1/4" | Yellow | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||