Reinforced Ceramic Inserts for Heat-Resistant Super Alloys

Made from heat-resistant ceramic, these inserts are reinforced with strands of silicon carbide to add strength and prevent chips or fractures. Also called whisker ceramic inserts, they last up to four times longer than carbide inserts when cutting nickel- or cobalt-based superalloys. Designed for semi-interrupted cutting, they're often used to machine imperfectly round workpieces, such as a shaft with a keyway. They’re tough enough for roughing, or quick material removal, but you can also use them for medium cutting and finishing.

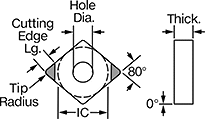

These negative-rake inserts are the first choice for most turning applications. They have cutting edges on both sides, so you can flip them over when the edges on one face wear out. Since they have a 0° lead angle, or neutral cut direction, they can cut from either right to left or left to right.

Inserts with a larger tip radius remove more material with each pass but cut less precisely than smaller inserts. Select the insert with the largest tip radius that still turns your workpiece to the desired shape.

Inserts sold individually come packed in a clear plastic case to protect cutting edges during shipment. Inserts sold in packs come factory sealed from the manufacturer for maximum traceability.

Each | Package | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Insert Code | Inscribed Circle Dia. (IC) | Tip Radius | Thick. | Hole Dia. | Cutting Edge Lg. | Rake Type | For Cutting Operation | Finish | Each | Pkg. Qty. | Pkg. | ||

CNGA Inserts—For DCLN, MCLN, PCLN Holders | |||||||||||||

For Semi-Interrupted Cutting Conditions | |||||||||||||

| CNGA-432 | 1/2" | 1/32" | 3/16" | 0.203" | 0.49" | Negative | Finishing, Medium, Roughing | Uncoated | 0000000 | 000000 | 10 | 0000000 | 0000000 |

| CNGA-433 | 1/2" | 3/64" | 3/16" | 0.203" | 0.49" | Negative | Finishing, Medium, Roughing | Uncoated | 0000000 | 00000 | 10 | 0000000 | 000000 |

| CNGA-434 | 1/2" | 1/16" | 3/16" | 0.203" | 0.49" | Negative | Finishing, Medium, Roughing | Uncoated | 0000000 | 00000 | 10 | 0000000 | 000000 |

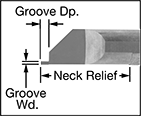

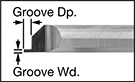

Face Grooving Lathe Tools

Machine circular grooves onto the end of a workpiece. Tools have flats on the shank for quick alignment.

Groove | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Wd. | Dp. | Min. Groove Dia. | Offset | Shank Dia. | Neck Relief | Overall Lg. | Material | For Use On | Each | |

| 0.015" | 0.04" | 0.135" | 0.005" | 1/8" | 0.4" | 1 1/2" | Micrograin Carbide | Aluminum, Brass, Bronze, Cast Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium | 0000000 | 000000 |

| 0.02" | 0.05" | 0.135" | 0.005" | 1/8" | 0.4" | 1 1/2" | Micrograin Carbide | Aluminum, Brass, Bronze, Cast Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium | 0000000 | 00000 |

| 0.021" | 0.05" | 0.26" | 0.006" | 1/4" | 3/4" | 2 1/2" | Micrograin Carbide | Aluminum, Brass, Bronze, Cast Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium | 0000000 | 00000 |

| 0.025" | 0.05" | 0.135" | 0.005" | 1/8" | 0.4" | 1 1/2" | Micrograin Carbide | Aluminum, Brass, Bronze, Cast Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium | 0000000 | 00000 |

| 0.03" | 0.06" | 0.135" | 0.005" | 1/8" | 0.4" | 1 1/2" | Micrograin Carbide | Aluminum, Brass, Bronze, Cast Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium | 0000000 | 00000 |

| 0.031" | 0.06" | 0.26" | 0.006" | 1/4" | 3/4" | 2 1/2" | Micrograin Carbide | Aluminum, Brass, Bronze, Cast Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium | 0000000 | 00000 |

| 0.031" | 0.06" | 0.32" | 0.007" | 5/16" | 1" | 2 1/2" | Micrograin Carbide | Aluminum, Brass, Bronze, Cast Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium | 0000000 | 00000 |

| 0.031" | 0.06" | 0.385" | 0.008" | 3/8" | 1 1/8" | 2 1/2" | Micrograin Carbide | Aluminum, Brass, Bronze, Cast Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium | 0000000 | 00000 |

| 0.035" | 0.07" | 0.195" | 0.006" | 3/16" | 1/2" | 2" | Micrograin Carbide | Aluminum, Brass, Bronze, Cast Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium | 0000000 | 00000 |

| 0.04" | 0.08" | 0.195" | 0.006" | 3/16" | 1/2" | 2" | Micrograin Carbide | Aluminum, Brass, Bronze, Cast Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium | 0000000 | 00000 |

| 0.041" | 0.08" | 0.26" | 0.006" | 1/4" | 3/4" | 2 1/2" | Micrograin Carbide | Aluminum, Brass, Bronze, Cast Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium | 0000000 | 00000 |

| 0.041" | 0.08" | 0.32" | 0.007" | 5/16" | 1" | 2 1/2" | Micrograin Carbide | Aluminum, Brass, Bronze, Cast Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium | 0000000 | 00000 |

| 0.045" | 0.09" | 0.195" | 0.006" | 3/16" | 1/2" | 2" | Micrograin Carbide | Aluminum, Brass, Bronze, Cast Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium | 0000000 | 00000 |

| 0.05" | 0.1" | 0.195" | 0.006" | 3/16" | 1/2" | 2" | Micrograin Carbide | Aluminum, Brass, Bronze, Cast Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium | 0000000 | 00000 |

| 0.051" | 0.1" | 0.26" | 0.006" | 1/4" | 3/4" | 2 1/2" | Micrograin Carbide | Aluminum, Brass, Bronze, Cast Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium | 0000000 | 00000 |

| 0.051" | 0.1" | 0.32" | 0.007" | 5/16" | 1" | 2 1/2" | Micrograin Carbide | Aluminum, Brass, Bronze, Cast Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium | 0000000 | 00000 |

| 0.063" | 0.13" | 0.32" | 0.007" | 5/16" | 1" | 2 1/2" | Micrograin Carbide | Aluminum, Brass, Bronze, Cast Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium | 0000000 | 00000 |

| 0.063" | 0.13" | 0.385" | 0.008" | 3/8" | 1 1/8" | 2 1/2" | Micrograin Carbide | Aluminum, Brass, Bronze, Cast Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium | 0000000 | 00000 |

| 0.063" | 0.13" | 0.51" | 0.009" | 1/2" | 1 1/4" | 3" | Micrograin Carbide | Aluminum, Brass, Bronze, Cast Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium | 0000000 | 00000 |

| 0.063" | 0.13" | 0.635" | 0.01" | 5/8" | 1 1/2" | 3 1/2" | Micrograin Carbide | Aluminum, Brass, Bronze, Cast Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium | 0000000 | 000000 |

| 0.094" | 0.19" | 0.385" | 0.008" | 3/8" | 1 1/8" | 2 1/2" | Micrograin Carbide | Aluminum, Brass, Bronze, Cast Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium | 0000000 | 00000 |

| 0.094" | 0.19" | 0.51" | 0.009" | 1/2" | 1 1/4" | 3" | Micrograin Carbide | Aluminum, Brass, Bronze, Cast Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium | 0000000 | 00000 |

| 0.094" | 0.19" | 0.76" | 0.012" | 3/4" | 1 3/4" | 4" | Micrograin Carbide | Aluminum, Brass, Bronze, Cast Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium | 0000000 | 000000 |

| 0.125" | 1/4" | 0.51" | 0.009" | 1/2" | 1 1/4" | 3" | Micrograin Carbide | Aluminum, Brass, Bronze, Cast Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium | 0000000 | 00000 |

| 0.126" | 1/4" | 0.385" | 0.008" | 3/8" | 1 1/8" | 2 1/2" | Micrograin Carbide | Aluminum, Brass, Bronze, Cast Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium | 0000000 | 00000 |

| 0.126" | 1/4" | 0.635" | 0.01" | 5/8" | 1 1/2" | 3 1/2" | Micrograin Carbide | Aluminum, Brass, Bronze, Cast Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium | 0000000 | 000000 |

| 0.126" | 1/4" | 0.76" | 0.012" | 3/4" | 1 3/4" | 4" | Micrograin Carbide | Aluminum, Brass, Bronze, Cast Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium | 0000000 | 000000 |

| 0.157" | 0.31" | 0.51" | 0.009" | 1/2" | 1 1/4" | 3" | Micrograin Carbide | Aluminum, Brass, Bronze, Cast Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium | 0000000 | 00000 |

| 0.157" | 0.31" | 0.76" | 0.012" | 3/4" | 1 3/4" | 4" | Micrograin Carbide | Aluminum, Brass, Bronze, Cast Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium | 0000000 | 000000 |

| 0.188" | 3/8" | 0.635" | 0.01" | 5/8" | 1 1/2" | 3 1/2" | Micrograin Carbide | Aluminum, Brass, Bronze, Cast Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium | 0000000 | 000000 |

| 0.188" | 3/8" | 0.76" | 0.012" | 3/4" | 1 3/4" | 4" | Micrograin Carbide | Aluminum, Brass, Bronze, Cast Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium | 0000000 | 000000 |

| 0.251" | 1/2" | 0.76" | 0.012" | 3/4" | 1 3/4" | 4" | Micrograin Carbide | Aluminum, Brass, Bronze, Cast Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium | 0000000 | 000000 |

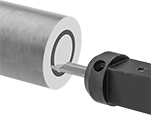

Quick-Change Lathe Tools and Holders

Reduce tooling setup time—install the holder once and alternate between applications by switching out the bit. Once the holder has been aligned with the centerline of the lathe, the locking system ensures alignment repeatability from tool to tool.

Face grooving tools machine circular grooves onto the end of a workpiece.

Groove | ||||||

|---|---|---|---|---|---|---|

| Wd. | Dp. | Min. Dia. | Material | For Use On | Each | |

3/16" Shank Dia. | ||||||

| 0.02" | 0.05" | 0.19" | Micrograin Carbide | Aluminum, Brass, Bronze, Cast Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium | 0000000 | 000000 |

| 0.03" | 0.05" | 0.19" | Micrograin Carbide | Aluminum, Brass, Bronze, Cast Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium | 0000000 | 00000 |

1/4" Shank Dia. | ||||||

| 0.02" | 0.05" | 0.24" | Micrograin Carbide | Aluminum, Brass, Bronze, Cast Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium | 0000000 | 00000 |

| 0.03" | 0.05" | 0.24" | Micrograin Carbide | Aluminum, Brass, Bronze, Cast Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium | 0000000 | 00000 |

| 0.03" | 0.05" | 0.26" | Micrograin Carbide | Aluminum, Brass, Bronze, Cast Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium | 0000000 | 00000 |

5/16" Shank Dia. | ||||||

| 0.03" | 0.05" | 0.322" | Micrograin Carbide | Aluminum, Brass, Bronze, Cast Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium | 0000000 | 00000 |

| 0.04" | 0.05" | 0.322" | Micrograin Carbide | Aluminum, Brass, Bronze, Cast Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium | 0000000 | 00000 |

| 0.062" | 0.1" | 0.322" | Micrograin Carbide | Aluminum, Brass, Bronze, Cast Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium | 0000000 | 00000 |

3/8" Shank Dia. | ||||||

| 0.062" | 0.1" | 0.385" | Micrograin Carbide | Aluminum, Brass, Bronze, Cast Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium | 0000000 | 00000 |

| 0.078" | 0.1" | 0.385" | Micrograin Carbide | Aluminum, Brass, Bronze, Cast Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium | 0000000 | 00000 |

| 0.093" | 0.1" | 0.385" | Micrograin Carbide | Aluminum, Brass, Bronze, Cast Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium | 0000000 | 00000 |

| 0.118" | 0.15" | 0.385" | Micrograin Carbide | Aluminum, Brass, Bronze, Cast Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium | 0000000 | 00000 |

| 1/8" | 0.15" | 0.385" | Micrograin Carbide | Aluminum, Brass, Bronze, Cast Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium | 0000000 | 00000 |

1/2" Shank Dia. | ||||||

| 0.062" | 0.1" | 0.48" | Micrograin Carbide | Aluminum, Brass, Bronze, Cast Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium | 0000000 | 00000 |

| 0.078" | 0.1" | 1/2" | Micrograin Carbide | Aluminum, Brass, Bronze, Cast Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium | 0000000 | 00000 |

| 0.093" | 0.1" | 0.48" | Micrograin Carbide | Aluminum, Brass, Bronze, Cast Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium | 0000000 | 00000 |

| 0.118" | 0.15" | 1/2" | Micrograin Carbide | Aluminum, Brass, Bronze, Cast Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium | 0000000 | 00000 |

| 1/8" | 0.15" | 1/2" | Micrograin Carbide | Aluminum, Brass, Bronze, Cast Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium | 0000000 | 00000 |