Carbide Inserts for Internal Profiling Carbide Insert Holders

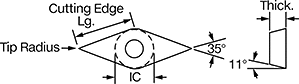

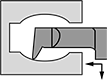

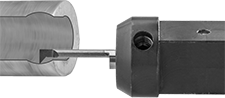

Combine a carbide insert with a compatible internal profiling holder to create a tool that can contour the interior wall of a hollow workpiece. When one edge of the insert dulls, just rotate it in the holder to use another side.

C3 carbide inserts are abrasion resistant and less likely to chip or crack than C6 carbide when cutting aluminum, brass, and bronze.

C6 carbide inserts hold up better than C3 carbide when making cuts in steel and stainless steel.

| Material | Finish | Insert Code | Inscribed Circle Dia. (IC) | Thick. | Cutting Edge Lg. | Tip Radius | For Cutting Operation | For Use On | Each | |

| C3 Carbide | Diamondlike Carbon (DLC) Coated | VPGT-2 | 1/4" | 1/8" | 0.43" | 0.004" | Finishing | Aluminum, Brass, Bronze | 0000000 | 000000 |

| C6 Carbide | Aluminum Titanium Chromium Nitride (AlTiCrN) Coated | VPGT-2 | 1/4" | 1/8" | 0.43" | 0.008" | Finishing | Stainless Steel, Steel | 0000000 | 00000 |

| Material | Finish | Insert Code | Inscribed Circle Dia. (IC) | Thick. | Cutting Edge Lg. | Tip Radius | For Cutting Operation | For Use On | Pkg. Qty. | Pkg. | |

| C3 Carbide | Diamondlike Carbon (DLC) Coated | VPGT-2 | 1/4" | 1/8" | 0.43" | 0.004" | Finishing | Aluminum, Brass, Bronze | 10 | 00000000 | 0000000 |

| C6 Carbide | Aluminum Titanium Chromium Nitride (AlTiCrN) Coated | VPGT-2 | 1/4" | 1/8" | 0.43" | 0.008" | Finishing | Stainless Steel, Steel | 10 | 00000000 | 000000 |

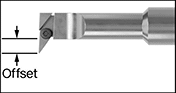

Internal Profiling Carbide Insert Holders

Contour the interior wall of a hollow workpiece when you pair a holder with a compatible insert (sold separately).

Holders | Replacement Torx Screws | Replacement Torx Keys | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

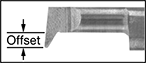

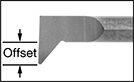

| Shank Dia. | Neck Dia. | Min. Hole Dia. | Max. Hole Dp. | Offset | O'all Lg. | Material | For Insert Code | Each | Each | Each | |||

Right Hand | |||||||||||||

| 5/8" | 0.438" | 0.76" | 1 3/4" | 0.292" | 5" | Steel | VPGT-2 | 0000000 | 0000000 | 000000000 | 00000 | 0000000 | 00000 |

| 3/4" | 0.563" | 0.88" | 2 1/4" | 0.292" | 5" | Steel | VPGT-2 | 0000000 | 000000 | 000000000 | 0000 | 0000000 | 0000 |

| 1" | 0.688" | 1.1" | 2 3/4" | 0.292" | 6" | Steel | VPGT-2 | 0000000 | 000000 | 000000000 | 0000 | 0000000 | 0000 |

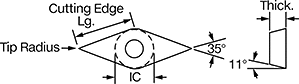

Combine a carbide insert with a compatible internal profiling holder to create a tool that can contour the interior wall of a hollow workpiece. When one edge of the insert dulls, just rotate it in the holder to use another side.

C3 carbide inserts are abrasion resistant and less likely to chip or crack than C6 carbide when cutting aluminum, brass, and bronze.

C6 carbide inserts hold up better than C3 carbide when making cuts in steel and stainless steel.

| Material | Finish | Insert Code | Inscribed Circle Dia. (IC) | Thick. | Cutting Edge Lg. | Tip Radius | For Cutting Operation | For Use On | Each | |

| C3 Carbide | Diamondlike Carbon (DLC) Coated | VPGT-2 | 1/4" | 1/8" | 0.43" | 0.004" | Finishing | Aluminum, Brass, Bronze | 0000000 | 000000 |

| C6 Carbide | Aluminum Titanium Chromium Nitride (AlTiCrN) Coated | VPGT-2 | 1/4" | 1/8" | 0.43" | 0.008" | Finishing | Stainless Steel, Steel | 0000000 | 00000 |

| Material | Finish | Insert Code | Inscribed Circle Dia. (IC) | Thick. | Cutting Edge Lg. | Tip Radius | For Cutting Operation | For Use On | Pkg. Qty. | Pkg. | |

| C3 Carbide | Diamondlike Carbon (DLC) Coated | VPGT-2 | 1/4" | 1/8" | 0.43" | 0.004" | Finishing | Aluminum, Brass, Bronze | 10 | 00000000 | 0000000 |

| C6 Carbide | Aluminum Titanium Chromium Nitride (AlTiCrN) Coated | VPGT-2 | 1/4" | 1/8" | 0.43" | 0.008" | Finishing | Stainless Steel, Steel | 10 | 00000000 | 000000 |

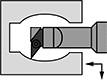

Internal Profiling Lathe Tools

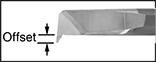

Contour the interior wall of a hollow workpiece. Tools have flats on the shank for quick alignment.

| Shank Dia. | Min. Hole Dia. | Max. Hole Dp. | Offset | Overall Lg. | Tip Radius | For Use On | Each | |

Right Hand | ||||||||

|---|---|---|---|---|---|---|---|---|

Micrograin Carbide | ||||||||

| 1/8" | 0.09" | 0.3" | 0.04" | 2" | 0.005" | Aluminum, Brass, Bronze, Cast Iron, Nickel, Stainless Steel, Steel | 0000000 | 000000 |

| 1/8" | 0.12" | 1/4" | 0.05" | 2" | 0.007" | Aluminum, Brass, Bronze, Cast Iron, Nickel, Stainless Steel, Steel | 0000000 | 00000 |

| 1/8" | 0.12" | 1/2" | 0.05" | 2" | 0.007" | Aluminum, Brass, Bronze, Cast Iron, Nickel, Stainless Steel, Steel | 0000000 | 00000 |

| 3/16" | 0.18" | 1/2" | 0.08" | 2 1/2" | 0.010" | Aluminum, Brass, Bronze, Cast Iron, Nickel, Stainless Steel, Steel | 0000000 | 00000 |

| 3/16" | 0.18" | 3/4" | 0.08" | 2 1/2" | 0.010" | Aluminum, Brass, Bronze, Cast Iron, Nickel, Stainless Steel, Steel | 0000000 | 00000 |

| 1/4" | 0.22" | 1/2" | 0.08" | 2 1/2" | 0.010" | Aluminum, Brass, Bronze, Cast Iron, Nickel, Stainless Steel, Steel | 0000000 | 00000 |

| 1/4" | 0.22" | 3/4" | 0.08" | 2 1/2" | 0.010" | Aluminum, Brass, Bronze, Cast Iron, Nickel, Stainless Steel, Steel | 0000000 | 00000 |

| 1/4" | 0.22" | 1" | 0.08" | 2 1/2" | 0.010" | Aluminum, Brass, Bronze, Cast Iron, Nickel, Stainless Steel, Steel | 0000000 | 00000 |

| 5/16" | 0.3" | 3/4" | 0.11" | 2 1/2" | 0.015" | Aluminum, Brass, Bronze, Cast Iron, Nickel, Stainless Steel, Steel | 0000000 | 00000 |

| 5/16" | 0.3" | 1" | 0.11" | 2 1/2" | 0.015" | Aluminum, Brass, Bronze, Cast Iron, Nickel, Stainless Steel, Steel | 0000000 | 00000 |

| 3/8" | 0.36" | 3/4" | 0.13" | 2 1/2" | 0.015" | Aluminum, Brass, Bronze, Cast Iron, Nickel, Stainless Steel, Steel | 0000000 | 00000 |

| 3/8" | 0.36" | 1" | 0.13" | 2 1/2" | 0.015" | Aluminum, Brass, Bronze, Cast Iron, Nickel, Stainless Steel, Steel | 0000000 | 00000 |

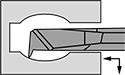

Long-Reach Internal Profiling Lathe Tools

An extra-long shank provides additional reach for contouring the interior wall of deep holes. All have flats on the shank for quick alignment.

| Shank Dia. | Min. Hole Dia. | Max. Hole Dp. | Offset | Overall Lg. | Tip Radius | For Use On | Each | |

Right Hand | ||||||||

|---|---|---|---|---|---|---|---|---|

Micrograin Carbide | ||||||||

| 1/4" | 0.36" | 3 3/8" | 0.1" | 4 3/8" | 0.010" | Aluminum, Brass, Bronze, Cast Iron, Nickel, Stainless Steel, Steel | 0000000 | 000000 |

| 5/16" | 0.42" | 3 3/8" | 0.1" | 4 3/8" | 0.015" | Aluminum, Brass, Bronze, Cast Iron, Nickel, Stainless Steel, Steel | 0000000 | 00000 |

| 3/8" | 0.48" | 5 3/8" | 0.1" | 6 3/8" | 0.015" | Aluminum, Brass, Bronze, Cast Iron, Nickel, Stainless Steel, Steel | 0000000 | 000000 |

| 1/2" | 0.615" | 5 3/8" | 0.11" | 6 3/8" | 0.015" | Aluminum, Brass, Bronze, Cast Iron, Nickel, Stainless Steel, Steel | 0000000 | 000000 |

| 5/8" | 3/4" | 5 3/8" | 1/8" | 6 3/8" | 0.020" | Aluminum, Brass, Bronze, Cast Iron, Nickel, Stainless Steel, Steel | 0000000 | 000000 |

Quick-Change Lathe Tools and Holders

Reduce tooling setup time—install the holder once and alternate between applications by switching out the bit. Once the holder has been aligned with the centerline of the lathe, the locking system ensures alignment repeatability from tool to tool.

Internal profiling tools contour the interior wall of a hollow workpiece.

| Min. Hole Dia. | Max. Hole Dp. | Offset | Tip Radius | Material | For Use On | Each | |

3/16" Shank Dia. | |||||||

|---|---|---|---|---|---|---|---|

| 0.07" | 1/2" | 0.025" | 0.005" | Micrograin Carbide | Aluminum, Brass, Bronze, Cast Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium | 000000 | 000000 |

| 0.12" | 3/4" | 0.05" | 0.008" | Micrograin Carbide | Aluminum, Brass, Bronze, Cast Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium | 000000 | 00000 |

| 0.16" | 1" | 0.05" | 0.008" | Micrograin Carbide | Aluminum, Brass, Bronze, Cast Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium | 000000 | 00000 |

1/4" Shank Dia. | |||||||

| 0.18" | 1/2" | 0.08" | 0.008" | Micrograin Carbide | Aluminum, Brass, Bronze, Cast Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium | 000000 | 00000 |

| 0.18" | 1" | 0.08" | 0.008" | Micrograin Carbide | Aluminum, Brass, Bronze, Cast Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium | 000000 | 00000 |

5/16" Shank Dia. | |||||||

| 0.23" | 1 1/4" | 0.08" | 0.008" | Micrograin Carbide | Aluminum, Brass, Bronze, Cast Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium | 0000000 | 00000 |

3/8" Shank Dia. | |||||||

| 0.36" | 1" | 0.13" | 0.008" | Micrograin Carbide | Aluminum, Brass, Bronze, Cast Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium | 0000000 | 00000 |

| 0.36" | 1 1/4" | 0.13" | 0.008" | Micrograin Carbide | Aluminum, Brass, Bronze, Cast Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium | 0000000 | 00000 |