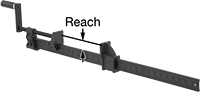

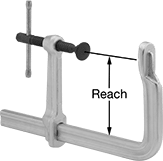

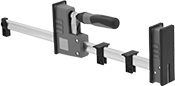

Heavy Duty Bar Clamps

Hold up to five times the capacity of standard bar clamps. Pull the lever to slide the clamping arm along the bar; release to lock in place. Use the handle for final tightening. These are also known as I-beam clamps.

Opening | ||||||

|---|---|---|---|---|---|---|

| Max. | Min. | Reach | Holding Capacity, lbs. | Body Material | Each | |

| 24" | 0" | 1 13/16" | 6,000 | Steel | 000000 | 000000 |

| 30" | 0" | 2" | 5,100 | Steel | 000000 | 00000 |

| 36" | 0" | 1 13/16" | 6,000 | Steel | 000000 | 00000 |

| 48" | 0" | 1 13/16" | 6,000 | Steel | 000000 | 00000 |

| 60" | 0" | 1 13/16" | 6,000 | Steel | 000000 | 00000 |

| 72" | 0" | 1 13/16" | 6,000 | Steel | 000000 | 000000 |

| 84" | 0" | 2" | 5,100 | Steel | 000000 | 00000 |

| 96" | 0" | 2" | 5,100 | Steel | 000000 | 00000 |

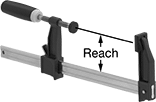

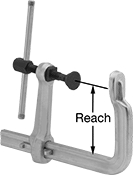

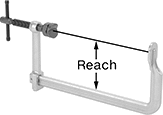

Bar Clamps

Pull the lever to slide the clamping arm along the bar; release to lock in place. Use the handle for final tightening.

Opening | ||||||

|---|---|---|---|---|---|---|

| Max. | Min. | Reach | Holding Capacity, lbs. | Body Material | Each | |

| 6" | 0" | 3" | 1,200 | Iron | 0000000 | 000000 |

| 12" | 0" | 3" | 1,000 | Steel | 0000000 | 00000 |

| 12" | 0" | 5" | 1,200 | Steel | 0000000 | 00000 |

| 18" | 0" | 3" | 1,000 | Steel | 0000000 | 00000 |

| 18" | 0" | 5" | 1,200 | Steel | 0000000 | 00000 |

| 24" | 0" | 3" | 1,000 | Steel | 0000000 | 00000 |

| 24" | 0" | 5" | 1,200 | Steel | 0000000 | 00000 |

| 30" | 0" | 3" | 1,000 | Steel | 0000000 | 00000 |

| 31 1/2" | 0" | 5 1/2" | 1,200 | Steel | 0000000 | 00000 |

| 36" | 0" | 3" | 1,000 | Steel | 0000000 | 00000 |

| 39 3/8" | 0" | 5 1/2" | 1,200 | Steel | 0000000 | 00000 |

| 59" | 0" | 5 1/2" | 1,200 | Steel | 0000000 | 00000 |

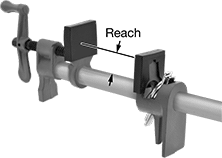

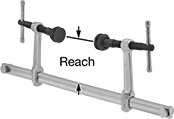

Any-Length Bar Clamps

Place the arms on a pipe that is threaded at one end and at least 12" long to create your own bar clamp. Turn the handle to tighten. The clamping surfaces have removable plastic pads that prevent damage to material. These are also known as pipe clamps.

Fast-Action Bar Clamps

The clamping arm slides freely along the bar for quick, one-handed positioning. Tighten the screw onto a workpiece and the arm locks in place. These clamps are also known as F- or L-clamps.

Opening | ||||||

|---|---|---|---|---|---|---|

| Max. | Min. | Reach | Holding Capacity, lbs. | Body Material | Each | |

| 4" | 0" | 2 1/4" | 400 | Zinc-Plated Steel | 0000000 | 000000 |

| 6" | 0" | 4 3/4" | 1,330 | Zinc-Plated Steel | 0000000 | 00000 |

| 8" | 0" | 5 1/2" | 2,660 | Zinc-Plated Steel | 0000000 | 00000 |

| 9" | 0" | 5 1/2" | 2,660 | Zinc-Plated Steel | 00000000 | 00000 |

| 10" | 0" | 4 3/4" | 1,000 | Zinc-Plated Steel | 00000000 | 00000 |

| 12" | 0" | 5 1/2" | 2,660 | Zinc-Plated Steel | 0000000 | 000000 |

| 12" | 0" | 8" | 1,700 | Zinc-Plated Steel | 0000000 | 000000 |

| 16" | 0" | 5 1/2" | 2,660 | Zinc-Plated Steel | 0000000 | 000000 |

| 18" | 0" | 4 3/4" | 1,980 | Zinc-Plated Steel | 00000000 | 000000 |

| 20" | 0" | 5 1/2" | 2,660 | Zinc-Plated Steel | 0000000 | 000000 |

| 24" | 0" | 5 1/2" | 2,660 | Zinc-Plated Steel | 0000000 | 000000 |

| 24" | 0" | 8" | 1,700 | Zinc-Plated Steel | 0000000 | 000000 |

| 36" | 0" | 5 1/2" | 2,800 | Zinc-Plated Steel | 0000000 | 000000 |

| 48" | 0" | 5 1/2" | 2,800 | Zinc-Plated Steel | 0000000 | 000000 |

| 60" | 0" | 5 1/2" | 2,800 | Zinc-Plated Steel | 0000000 | 000000 |

Heavy Duty Fast-Action Bar Clamps

These clamps have twice the capacity of standard fast-action bar clamps. The clamping arm slides freely along the bar for quick, one-handed positioning. Tighten the screw onto a workpiece and the arm locks in place. These are also known as F- or L-clamps.

Opening | |||||||

|---|---|---|---|---|---|---|---|

| Max. | Min. | Reach | Holding Capacity, lbs. | Body Material | Swivel Range of Motion | Each | |

| 12" | 0" | 7" | 4,880 | Zinc-Plated Steel | 20° | 0000000 | 0000000 |

| 12" | 0" | 7" | 4,880 | Zinc-Plated Steel | 35° | 0000000 | 000000 |

| 18" | 0" | 7" | 4,880 | Zinc-Plated Steel | 20° | 0000000 | 000000 |

| 18" | 0" | 7" | 4,880 | Zinc-Plated Steel | 35° | 0000000 | 000000 |

| 36" | 0" | 7" | 4,880 | Zinc-Plated Steel | 20° | 0000000 | 000000 |

| 36" | 0" | 7" | 4,880 | Zinc-Plated Steel | 35° | 0000000 | 000000 |

Extra Heavy Duty Fast-Action Bar Clamps

For the most demanding jobs, these clamps have almost five times the capacity of standard fast-action bar clamps. The clamping arm slides freely along the bar for quick, one-handed positioning. Tighten the screw onto a workpiece and the arm locks in place. These are also known as F- or L-clamps.

Vibration-Resistant Fast-Action Bar Clamps

Pull the handle to lock the jaw in place and prevent loosening caused by vibration. The clamping arm slides freely along the bar for quick, one-handed positioning. These clamps are also known as F- or L-clamps.

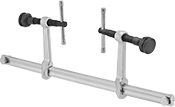

Parallel-Jaw Bar Clamps/Spreaders

The large, flat jaws remain parallel when clamping to apply even pressure without denting or marring the workpiece. Reverse the arms to use these clamps as spreaders. Pull the handle to lock or release the clamping arm.

Opening | Spreader Opening | |||||||

|---|---|---|---|---|---|---|---|---|

| Max. | Min. | Max. | Min. | Reach | Holding Capacity, lbs. | Body Material | Each | |

| 12" | 0" | 15 5/16" | 10 1/2" | 3 3/4" | 1,000 | Steel | 0000000 | 000000 |

| 18" | 0" | 21 1/2" | 10 1/2" | 3 3/4" | 1,000 | Steel | 0000000 | 00000 |

| 24" | 0" | 28 3/4" | 10 1/2" | 3 3/4" | 1,000 | Steel | 0000000 | 00000 |

| 40" | 0" | 44 1/2" | 10 1/2" | 3 3/4" | 1,000 | Steel | 0000000 | 00000 |

| 50" | 0" | 52 1/2" | 10 1/2" | 3 3/4" | 1,000 | Steel | 0000000 | 00000 |

Fast-Action Bar Clamps/Spreaders

Each arm slides freely for quick, one-handed positioning. They lock when the screws are tightened onto a workpiece. Reverse the arms to use these clamps as spreaders.

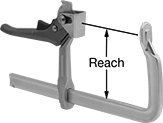

Bar Clamps for Recessed Areas

Also known as J-clamps, these provide additional clearance to reach around obstructions and clamp workpieces in recessed areas. The clamping arm slides freely along the bar for quick, one-handed positioning. Use the handle for final tightening.

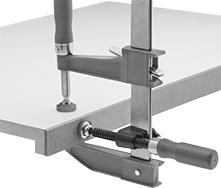

Edge-Clamping Adapters for Bar Clamps

Attach to your bar clamp to hold material on three sides. This adapter fits most standard bar clamps.

| For Max. Bar Thick. | Holding Capacity | Body Material | Each | |

| 1/2" | Not Rated | Powder-Coated Iron | 0000000 | 000000 |

Bar Clamps for Round and Angled Material

The swivel pad pivots to grip nearly any shape of material. The clamping arm slides freely along the bar for quick, one-handed positioning. Use the handle for final tightening.

Opening | ||||||

|---|---|---|---|---|---|---|

| Max. | Min. | Reach | Holding Capacity, lbs. | Body Material | Each | |

| 12" | 0" | 5 1/2" | 2,645 | Steel | 000000 | 000000 |

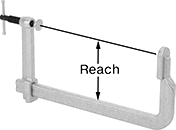

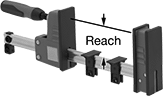

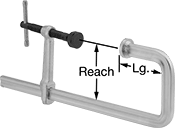

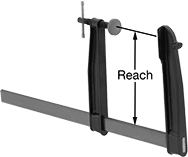

Extended-Reach Bar Clamps

Clamp much farther in from the edge of the workpiece than with standard bar clamps. The clamping arm slides freely along the bar for quick, one-handed positioning. Use the handle for final tightening.