About Glove Sizing

More

Electrical-Protection Gloves

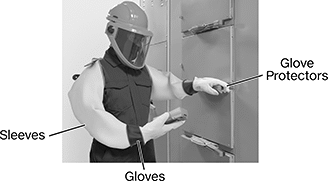

Rated to ASTM D120 standards for handling live electrical equipment, these gloves come tested and marked with the test date. You have one year from the test date to put gloves into service before they must be retested. Once in use, gloves should be tested every six months. To comply with ASTM safety standards, protectors (sold separately) must be worn over gloves when working with live electrical equipment.

ASTM defines voltage classes for rubber insulating gloves. Make sure the gloves you use are rated for the voltage class of your equipment.

Gloves with taper cuffs are shorter on the inside of the elbow than the outside, so you can bend your arm easily. Gloves with flare cuffs widen at the end to fit over electrical protection sleeves or thick coats. Wear-indicating gloves have a colored inner layer that shows through the coating as it wears off, making it easy to inspect them for signs of damage.

Use an inspection pump (sold separately) to check Class 1-4 gloves for damage. Purchase an adapter (sold separately) to use the inspection pump with Class 00 and 0 gloves.

Available Sizes | |

|---|---|

| Size | Glove Size |

| S | 7 |

| M | 8 |

| L | 9 |

| XL | 10 |

| 2XL | 11 |

| 3XL | 12 |

| Lg. | Material | Color | Specifications Met | Choose a Size | Pair | |

Class 00 (500V AC Max. Use) | ||||||

|---|---|---|---|---|---|---|

Straight Cuff | ||||||

| 11" | Natural Rubber | Black | OSHA Compliant 29 CFR 1910.137, ASTM D120 | 0000000 | 000000 | |

| 11" | Natural Rubber | Orange | OSHA Compliant 29 CFR 1910.137, ASTM D120 | 00000000 | 00000 | |

| 11" | Natural Rubber | Red | OSHA Compliant 29 CFR 1910.137, ASTM D120 | 0000000 | 00000 | |

| 14" | Natural Rubber | Black | OSHA Compliant 29 CFR 1910.137, ASTM D120 | 0000000 | 00000 | |

| 14" | Natural Rubber | Yellow | OSHA Compliant 29 CFR 1910.137, ASTM D120 | 00000000 | 00000 | |

Class 0 (1,000V AC Max. Use) | ||||||

Straight Cuff | ||||||

| 11" | Natural Rubber | Black | OSHA Compliant 29 CFR 1910.137, ASTM D120 | 0000000 | 00000 | |

| 11" | Natural Rubber | Orange | OSHA Compliant 29 CFR 1910.137, ASTM D120 | 00000000 | 00000 | |

| 11" | Natural Rubber | Red | OSHA Compliant 29 CFR 1910.137, ASTM D120 | 0000000 | 00000 | |

| 14" | Natural Rubber | Black | OSHA Compliant 29 CFR 1910.137, ASTM D120 | 0000000 | 00000 | |

| 14" | Natural Rubber | Yellow | OSHA Compliant 29 CFR 1910.137, ASTM D120 | 00000000 | 000000 | |

Straight Cuff with Wear Indicator | ||||||

| 11" | Natural Rubber | Black | OSHA Compliant 29 CFR 1910.137, ASTM D120 | 00000000 | 000000 | |

Class 1 (7,500V AC Max. Use) | ||||||

Straight Cuff | ||||||

| 14" | Natural Rubber | Black | OSHA Compliant 29 CFR 1910.137, ASTM D120 | 0000000 | 000000 | |

| 14" | Natural Rubber | Orange | OSHA Compliant 29 CFR 1910.137, ASTM D120 | 00000000 | 000000 | |

Straight Cuff with Wear Indicator | ||||||

| 14" | Natural Rubber | Black | OSHA Compliant 29 CFR 1910.137, ASTM D120 | 0000000 | 000000 | |

| 16" | Natural Rubber | Black | OSHA Compliant 29 CFR 1910.137, ASTM D120 | 00000000 | 000000 | |

Taper Cuff with Wear Indicator | ||||||

| 18" | Natural Rubber | Black | OSHA Compliant 29 CFR 1910.137, ASTM D120 | 00000000 | 000000 | |

Class 2 (17,000V AC Max. Use) | ||||||

Straight Cuff | ||||||

| 14" | Natural Rubber | Black | OSHA Compliant 29 CFR 1910.137, ASTM D120 | 0000000 | 000000 | |

Straight Cuff with Wear Indicator | ||||||

| 14" | Natural Rubber | Black | OSHA Compliant 29 CFR 1910.137, ASTM D120 | 0000000 | 000000 | |

| 16" | Natural Rubber | Black | OSHA Compliant 29 CFR 1910.137, ASTM D120 | 0000000 | 000000 | |

Flare Cuff with Wear Indicator | ||||||

| 16" | Natural Rubber | Black | OSHA Compliant 29 CFR 1910.137, ASTM D120 | 00000000 | 000000 | |

Class 3 (26,500V AC Max. Use) | ||||||

Straight Cuff with Wear Indicator | ||||||

| 16" | Natural Rubber | Black | OSHA Compliant 29 CFR 1910.137, ASTM D120 | 0000000 | 000000 | |

Class 4 (36,000V AC Max. Use) | ||||||

Straight Cuff with Wear Indicator | ||||||

| 18" | Natural Rubber | Black | OSHA Compliant 29 CFR 1910.137, ASTM D120 | 0000000 | 000000 | |

Protectors should be the same size as the gloves they will be worn over. To comply with ASTM standards, the cuff of the glove should extend past the end of the protector. For Class 00 and Class 0 ratings, the gloves must be at least 1/2" longer than the protector. For all other classes, the number of inches that the glove extends past the protector should match the class number. For example, Class 1 gloves should be 1" longer than their protector.

Those that cannot be sold to Canada are restricted due to import regulations.

| Lg. | Material | Lining Material | Arc Rating, cal/cm2 | Arc Rated PPE Category | ANSI Cut Rating | ANSI Puncture Rating | Color | Specifications Met | Cannot Be Sold To | Choose a Size | Pair | |

For Class 00, Class 0 Straight Cuff Gloves | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

Adjustable Strap | ||||||||||||

| 10" | Goatskin Leather | __ | 25 | 3 | __ | 3 | Yellow | ANSI/ISEA 105, ASTM F696, NFPA 70E | Canada | 0000000 | 000000 | |

| 10" | Goatskin Leather | Kevlar Fabric | 36 | 3 | A3 | 4 | Yellow | ANSI/ISEA 105, ASTM F696, NFPA 70E | Canada | 0000000 | 00000 | |

| 13" | Goatskin Leather | __ | 25 | 3 | __ | 3 | Yellow | ANSI/ISEA 105, ASTM F696, NFPA 70E | __ | 0000000 | 00000 | |

| 13" | Goatskin Leather | Kevlar Fabric | 36 | 3 | A3 | 4 | Yellow | ANSI/ISEA 105, ASTM F696, NFPA 70E | Canada | 0000000 | 00000 | |

For Class 1, Class 2, Class 3, Class 4 Straight and Flare Cuff Gloves | ||||||||||||

Adjustable Strap | ||||||||||||

| 12" | Cowhide Leather | __ | 32 | 3 | __ | 5 | Beige/Orange | ANSI/ISEA 105, ASTM F696, NFPA 70E | __ | 0000000 | 00000 | |

| 12" | Cowhide Leather | Kevlar Fabric | 48 | 4 | A3 | 5 | Beige/Orange | ANSI/ISEA 105, ASTM F696, NFPA 70E | __ | 0000000 | 00000 | |

| 14" | Cowhide Leather | __ | 32 | 3 | __ | 5 | Beige/Orange | ANSI/ISEA 105, ASTM F696, NFPA 70E | __ | 0000000 | 00000 | |

| 14" | Cowhide Leather | Kevlar Fabric | 48 | 4 | A3 | 5 | Beige/Orange | ANSI/ISEA 105, ASTM F696, NFPA 70E | __ | 0000000 | 00000 | |

Flame-Resistant Backing and Adjustable Strap | ||||||||||||

| 12" | Cowhide Leather, Acrylic/Cotton/Aramid Fabric Blend | Kevlar Fabric | 29 | 3 | A5 | 3 | Blue/Beige/Fluorescent Orange | ANSI/ISEA 105, ASTM F3258, ASTM F696, NFPA 70E | __ | 00000000 | 000000 | |

| 14" | Cowhide Leather, Acrylic/Cotton/Aramid Fabric Blend | Kevlar Fabric | 29 | 3 | A5 | 3 | Blue/Beige/Fluorescent Orange | ANSI/ISEA 105, ASTM F3258, ASTM F696, NFPA 70E | __ | 00000000 | 000000 | |

For Class 1, Class 2, Class 3, Class 4 Taper Cuff Gloves | ||||||||||||

Adjustable Strap | ||||||||||||

| 16" | Cowhide Leather | __ | 32 | 3 | __ | 5 | Beige/Orange | ANSI/ISEA 105, ASTM F696, NFPA 70E | __ | 00000000 | 00000 | |

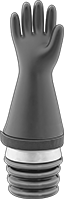

Strap your glove to the pump and inflate to reveal cracks, pinholes, and other signs of wear.

| For ASTM Voltage Rating | Each | |

| Class 1, Class 2, Class 3, Class 4 | 0000000 | 0000000 |

| For ASTM Voltage Rating | Each | |

| Class 00, Class 0 | 0000000 | 0000000 |

Bags for Electrical-Protection Gloves

Prevent damage to gloves in storage. Attach the bag to your belt with the quick-release snap hook. Grommets on the bottom provide ventilation and drainage.

Protectors for Electrical-Protection Gloves

Wear these protectors over electrical-protection gloves to meet ASTM standards when working with live electrical equipment. They also protect your gloves from scrapes and tears. All have an arc rating, which measures a protector’s ability to insulate the wearer from burns. The higher the rating, the greater the flame resistance. They meet NFPA 70E for arc-flash protection as well as ANSI/ISEA 105 for resistance to cuts or punctures. Higher cut or puncture ratings mean more protection.

Choose protectors that are the same size as the gloves they will be worn over. To comply with ASTM standards, the cuff of the glove should extend past the end of the protector. For Class 00 and Class 0 ratings, the gloves must be at least 1/2" longer than the protector. For all other classes, the number of inches that the glove extends past the protector should match the class number. For example, Class 1 gloves should be 1" longer than their protector.

Protectors that cannot be sold to Canada are restricted due to import regulations.

Available Sizes | |

|---|---|

| Size | Glove Size |

| S | 7 |

| M | 8 |

| L | 9 |

| XL | 10 |

| 2XL | 11 |

| 3XL | 12 |

| Lg. | Material | Lining Material | Arc Rating, cal/cm2 | Arc Rated PPE Category | ANSI Cut Rating | ANSI Puncture Rating | Color | Specifications Met | Cannot Be Sold To | Choose a Size | Pair | |

For Class 00, Class 0 Straight Cuff Gloves | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

Adjustable Strap | ||||||||||||

| 10" | Goatskin Leather | __ | 25 | 3 | __ | 3 | Yellow | ANSI/ISEA 105, ASTM F696, NFPA 70E | Canada | 0000000 | 000000 | |

| 10" | Goatskin Leather | Kevlar Fabric | 36 | 3 | A3 | 4 | Yellow | ANSI/ISEA 105, ASTM F696, NFPA 70E | Canada | 0000000 | 00000 | |

| 13" | Goatskin Leather | __ | 25 | 3 | __ | 3 | Yellow | ANSI/ISEA 105, ASTM F696, NFPA 70E | __ | 0000000 | 00000 | |

| 13" | Goatskin Leather | Kevlar Fabric | 36 | 3 | A3 | 4 | Yellow | ANSI/ISEA 105, ASTM F696, NFPA 70E | Canada | 0000000 | 00000 | |

For Class 1, Class 2, Class 3, Class 4 Straight and Flare Cuff Gloves | ||||||||||||

Adjustable Strap | ||||||||||||

| 12" | Cowhide Leather | __ | 32 | 3 | __ | 5 | Beige/Orange | ANSI/ISEA 105, ASTM F696, NFPA 70E | __ | 0000000 | 00000 | |

| 12" | Cowhide Leather | Kevlar Fabric | 48 | 4 | A3 | 5 | Beige/Orange | ANSI/ISEA 105, ASTM F696, NFPA 70E | __ | 0000000 | 00000 | |

| 14" | Cowhide Leather | __ | 32 | 3 | __ | 5 | Beige/Orange | ANSI/ISEA 105, ASTM F696, NFPA 70E | __ | 0000000 | 00000 | |

| 14" | Cowhide Leather | Kevlar Fabric | 48 | 4 | A3 | 5 | Beige/Orange | ANSI/ISEA 105, ASTM F696, NFPA 70E | __ | 0000000 | 00000 | |

| 16" | Cowhide Leather | __ | 32 | 3 | __ | 5 | Beige/Orange | ANSI/ISEA 105, ASTM F696, NFPA 70E | __ | 0000000 | 00000 | |

Flame-Resistant Backing and Adjustable Strap | ||||||||||||

| 12" | Cowhide Leather, Acrylic/Cotton/Aramid Fabric Blend | Kevlar Fabric | 29 | 3 | A5 | 3 | Blue/Beige/Fluorescent Orange | ANSI/ISEA 105, ASTM F3258, ASTM F696, NFPA 70E | __ | 00000000 | 000000 | |

| 14" | Cowhide Leather, Acrylic/Cotton/Aramid Fabric Blend | Kevlar Fabric | 29 | 3 | A5 | 3 | Blue/Beige/Fluorescent Orange | ANSI/ISEA 105, ASTM F3258, ASTM F696, NFPA 70E | __ | 00000000 | 000000 | |

For Class 1, Class 2, Class 3, Class 4 Taper Cuff Gloves | ||||||||||||

Adjustable Strap | ||||||||||||

| 16" | Cowhide Leather | __ | 32 | 3 | __ | 5 | Beige/Orange | ANSI/ISEA 105, ASTM F696, NFPA 70E | __ | 00000000 | 00000 | |

Electrical-Protection Glove Kits

Everything you need to protect your hands when working with live electrical equipment. The gloves in this kit are rated to ASTM D120 standards, which means they come tested and marked with the test date. You have one year from the test date to put gloves into service before they must be retested. Once in use, gloves should be tested every six months. To comply with ASTM safety standards, protectors must be worn over gloves when working with live electrical equipment.

Gloves with a wear indicator have a colored inner layer that shows through as the coating wears down. This helps you spot cracks, pinholes, and other signs of damage.

Use an inspection pump to check Class 1-2 gloves for damage. Strap your glove to the pump and inflate to reveal cracks, pinholes, and other signs of wear. Purchase an adapter to use the inspection pump with Class 00 and 0 gloves.

Available Sizes | |

|---|---|

| Size | Glove Size |

| S | 7 |

| M | 8 |

| L | 9 |

| XL | 10 |

| 2XL | 11 |

| 3XL | 12 |

Gloves | Glove Protectors | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ASTM Voltage Rating | Max. Use Voltage | Material | Lg. | Cuff Shape | Cuff Style | Color | Features | Material | Lg. | Cuff Style | Color | Features | Includes | Specifications Met | Choose a Size | Each | |

| Class 00 | 500V AC | Dielectric Rubber | 11" | Straight | Open | Black | __ | Goatskin Leather | 10" | Open | Gray | __ | One Pair of Electrical-Protection Gloves, One Pair of Protectors for Electrical-Protection Gloves, One Bag for Electrical Protection Gloves | OSHA Compliant 29 CFR 1910.137, ASTM D120, NFPA 70E | 0000000 | 0000000 | |

| Class 0 | 1,000V AC | Dielectric Rubber | 11" | Straight | Open | Black | Wear Indicator | Goatskin Leather | 10" | Open | Gray | __ | One Pair of Electrical-Protection Gloves, One Pair of Protectors for Electrical-Protection Gloves, One Bag for Electrical Protection Gloves | OSHA Compliant 29 CFR 1910.137, ASTM D120, NFPA 70E | 0000000 | 000000 | |

| Class 1 | 7,500V AC | Dielectric Rubber | 14" | Straight | Open | Black | __ | Goatskin Leather | 12" | Open | Beige/Gray | Adjustable Strap | One Pair of Electrical-Protection Gloves, One Pair of Protectors for Electrical-Protection Gloves, One Bag for Electrical Protection Gloves | OSHA Compliant 29 CFR 1910.137, ASTM D120, NFPA 70E | 0000000 | 000000 | |

| Class 2 | 17,000V AC | Dielectric Rubber | 14" | Straight | Open | Black | Wear Indicator | Goatskin Leather | 12" | Open | Beige/Gray | Adjustable Strap | One Pair of Electrical-Protection Gloves, One Pair of Protectors for Electrical-Protection Gloves, One Bag for Electrical Protection Gloves | OSHA Compliant 29 CFR 1910.137, ASTM D120, NFPA 70E | 0000000 | 000000 | |

| For ASTM Voltage Rating | Each | |

| Class 1, Class 2, Class 3, Class 4 | 0000000 | 0000000 |

| For ASTM Voltage Rating | Each | |

| Class 00, Class 0 | 0000000 | 0000000 |

Electrical-Protection Sleeves

Pair these sleeves with electrical-protection gloves for full arm coverage when working near equipment running at 17,000V AC or higher. Rated to ASTM D1051 standards for handling live electrical equipment, these sleeves come tested and marked with the test date. You have one year from the test date to put sleeves into service before they must be retested. Once in use, sleeves should be tested every six months. All have a colored inner layer that shows through as the coating wears down, helping you spot cracks, pinholes, and other signs of damage.

ASTM defines voltage classes for rubber insulating sleeves. Make sure the sleeves and gloves you use are rated for the voltage class of your equipment.

Available Sizes | |

|---|---|

| Size | Upper Arm Circumference |

| S | 24 1/2" |

| M | 24 1/2" |

| L | 25 3/4" |

| XL | 25 3/4" |

| 2XL | 25 3/4" |

Sleeves | Replacement Straps | Replacement Buttons | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ASTM Voltage Rating | Max. Use Voltage | Lg. | Cuff Style | Color | Includes | Features | Specifications Met | Choose a Size | Pair | Each | Each | |||

Dielectric Rubber | ||||||||||||||

| Class 2 | 17,000V AC | 27" | Open | Yellow | Two Straps, Four Buttons | Wear Indicator | ASTM D1051 | 0000000 | 0000000 | 0000000 | 000000 | 0000000 | 00000 | |

| Class 3 | 26,500V AC | 27" | Open | Yellow | Two Straps, Four Buttons | Wear Indicator | ASTM D1051 | 0000000 | 000000 | 0000000 | 00000 | 0000000 | 0000 | |

| Class 4 | 36,000V AC | 27" | Open | Yellow | Two Straps, Four Buttons | Wear Indicator | ASTM D1051 | 0000000 | 00000000 | 0000000 | 00000 | 0000000 | 0000 | |