Filter by

Shaft Diameter

Mounted Bearing Type

Shaft Mount Type

ID

Center Height

Mounting Hole Center-to-Center

Width

Overall Length

Housing Material

Overall Height

Bearing Trade Number

Overall Width

DFARS Specialty Metals

Dynamic Radial Load Capacity

Maximum Rotation Speed

Static Radial Load Capacity

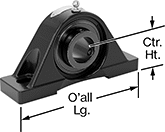

Mounted Ball Bearings

|

Mounted Bearings | Replacement Bearings | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Overall | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Shaft Dia. | Ctr. Ht. | Lg. | Wd. | Dynamic Radial Load Cap., lb. | Max. Rotation Speed, rpm | Bearing Material | Bearing Seal Type | Misalignment Capability | Manufacturer | Each | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Powder-Coated Cast Iron Housing | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Eccentric Lock | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8" | 1 1/16" | 5 15/32" | 1 1/2" | 2,150 | 9,500 | Steel | Sealed | 2° | SKF | 0000000 | 000000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | 1 1/4" | 5" | 1 19/32" | 2,850 | 8,500 | Steel | Sealed | 2° | SKF | 0000000 | 00000 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/8" | 1 5/16" | 5 1/2" | 1 43/64" | 3,150 | 7,000 | Steel | Sealed | 2° | SKF | 0000000 | 00000 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 1 5/16" | 5 1/2" | 1 43/64" | 3,150 | 7,000 | Steel | Sealed | 2° | SKF | 0000000 | 00000 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/8" | 1 9/16" | 6 1/2" | 1 59/64" | 4,350 | 6,300 | Steel | Sealed | 2° | SKF | 0000000 | 000000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 3/16" | 1 9/16" | 6 1/2" | 2 1/16" | 4,350 | 6,300 | Steel | Sealed | 2° | SKF | 0000000 | 000000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4" | 1 13/16" | 6 9/16" | 2 1/16" | 5,700 | 5,300 | Steel | Sealed | 2° | SKF | 0000000 | 000000 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 3/8" | 1 13/16" | 6 9/16" | 2 1/16" | 5,700 | 5,300 | Steel | Sealed | 2° | SKF | 0000000 | 000000 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 7/16" | 1 13/16" | 6 9/16" | 2 1/16" | 5,700 | 5,300 | Steel | Sealed | 2° | SKF | 0000000 | 00000 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 1 15/16" | 7 1/4" | 2 1/4" | 6,900 | 4,800 | Steel | Sealed | 2° | SKF | 0000000 | 000000 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 3/4" | 2 1/16" | 7 15/32" | 2 19/64" | 7,450 | 4,300 | Steel | Sealed | 2° | SKF | 0000000 | 000000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 15/16" | 2 3/16" | 8 1/8" | 2 3/8" | 7,850 | 4,000 | Steel | Sealed | 2° | SKF | 0000000 | 000000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 2 7/16" | 8 5/8" | 2 37/64" | 9,800 | 3,600 | Steel | Sealed | 2° | SKF | 0000000 | 000000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

One-Way-Locking Ball Bearings

Temp. Range, ° F | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Shaft Dia., mm | For Housing ID, mm | Wd., mm | ABEC Rating | Dynamic Radial Load Cap., lb. | Max. Rotation Speed, rpm | Max. Torque, ft·lbf | Min. | Max. | Inner Ring Type | Bearing Trade No. | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Shielded | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8 | 22 | 9 | 1 | 720 | 15,000 | 1.5 | -40 | 170 | Standard | 608-2Z | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12 | 32 | 10 | 1 | 1,150 | 10,000 | 6.5 | -40 | 170 | Standard | FZ 6201 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 15 | 35 | 11 | 1 | 1,160 | 9,400 | 15 | -40 | 170 | Standard | FZ 6202 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 17 | 40 | 12 | 1 | 1,270 | 8,200 | 23 | -40 | 170 | Standard | FZ 6203 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 20 | 47 | 14 | 1 | 1,540 | 6,800 | 64 | -40 | 170 | Standard | FZ 6204 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 | 52 | 15 | 1 | 1,620 | 5,600 | 70 | -40 | 170 | Standard | FZ 6205 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 30 | 62 | 16 | 1 | 1,730 | 4,000 | 165 | -40 | 170 | Standard | FZ 6206 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 35 | 72 | 17 | 1 | 1,830 | 3,600 | 240 | -40 | 170 | Standard | FZ 6207 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 40 | 80 | 22 | 1 | 2,010 | 3,000 | 305 | -40 | 170 | Standard | FZ 6208 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Sealed | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12 | 32 | 14 | 1 | 1,150 | 10,000 | 6.5 | -40 | 170 | Standard | FZ 6201 2RS | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 15 | 35 | 16 | 1 | 1,160 | 8,400 | 15 | -40 | 170 | Standard | FZ 6202 2RS | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 17 | 40 | 17 | 1 | 1,270 | 7,300 | 23 | -40 | 170 | Standard | FZ 6203 2RS | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 20 | 47 | 19 | 1 | 1,540 | 6,000 | 64 | -40 | 170 | Standard | FZ 6204 2RS | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 | 52 | 20 | 1 | 1,620 | 5,200 | 70 | -40 | 170 | Standard | FZ 6205 2RS | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 30 | 62 | 21 | 1 | 1,730 | 4,200 | 165 | -40 | 170 | Standard | FZ 6206 2RS | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 35 | 72 | 22 | 1 | 1,830 | 3,600 | 240 | -40 | 170 | Standard | FZ 6207 2RS | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 40 | 80 | 27 | 1 | 2,010 | 3,000 | 305 | -40 | 170 | Standard | FZ 6208 2RS | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

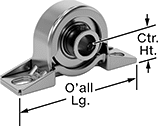

Light Duty Mounted Ball Bearings

|

Overall | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Shaft Dia. | Ctr. Ht. | Lg. | Wd. | Dynamic Radial Load Cap., lb. | Max. Rotation Speed, rpm | Bearing Material | Bearing Seal Type | Misalignment Capability | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel Housing | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Eccentric Lock | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 7/8" | 3 3/8" | 31/32" | 2,100 | 5,500 | Steel | Sealed | 3° | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8" | 7/8" | 3 3/8" | 31/32" | 2,100 | 5,500 | Steel | Sealed | 3° | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | 1" | 3 27/32" | 1 1/4" | 2,850 | 5,500 | Steel | Sealed | 3° | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/8" | 1 1/8" | 4 1/4" | 1 1/4" | 3,100 | 5,000 | Steel | Sealed | 3° | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 15/16" | 1 1/8" | 4 1/4" | 1 1/4" | 3,100 | 5,000 | Steel | Sealed | 3° | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 1 1/8" | 4 1/4" | 1 1/4" | 3,100 | 5,000 | Steel | Sealed | 3° | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/8" | 1 15/16" | 4 19/32" | 1 1/2" | 4,300 | 4,000 | Steel | Sealed | 3° | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 3/16" | 1 15/16" | 4 19/32" | 1 1/2" | 4,300 | 4,000 | Steel | Sealed | 3° | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4" | 1 15/16" | 4 19/32" | 1 1/2" | 4,300 | 4,000 | Steel | Sealed | 3° | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Food-and-Beverage Permanently Lubricated Mounted Ball Bearings with Two-Bolt Flange

|

Mounted Bearings | Closed Caps | Open Caps | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Overall | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

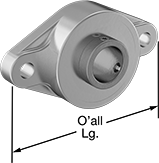

For Shaft Dia. | Lg. | Wd. | Flange Thk. | Dynamic Radial Load Cap., lb. | Max. Rotation Speed, rpm | Bearing Material | Bearing Seal Type | Misalignment Capability | Enclosure Rating | Manufacturer | Each | Each | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

316 Stainless Steel Housing | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Clamp On | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | 4 13/32" | 2 17/64" | 7/16" | 2,600 | 3,000 | Steel | Sealed | 2° | IP69K | Sealmaster | 00000000 | 0000000 | 0000000 | 000000 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 4 7/8" | 2 7/16" | 17/32" | 2,800 | 2,000 | Steel | Sealed | 2° | IP69K | Sealmaster | 00000000 | 000000 | 0000000 | 00000 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 mm | 124 mm | 61.9 mm | 13.5 mm | 2,800 | 2,000 | Steel | Sealed | 2° | IP69K | Sealmaster | 00000000 | 000000 | 0000000 | 00000 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 50 mm | 189 mm | 78 mm | 14 mm | 7,850 | 1,500 | Steel | Sealed | 2° | IP69K | Sealmaster | 00000000 | 000000 | 0000000 | 00000 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Tapped-Base Mounted Ball Bearings

|

Mounted Bearings | Replacement Bearings | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Overall | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

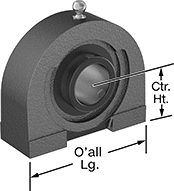

For Shaft Dia. | Ctr. Ht. | Lg. | Wd. | Dynamic Radial Load Cap., lb. | Max. Rotation Speed, rpm | Bearing Material | Bearing Seal Type | Misalignment Capability | Manufacturer | Each | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Powder-Coated Cast Iron Housing | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Set Screw | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 mm | 36.5 mm | 76.2 mm | 38.1 mm | 2,800 | 6,350 | Steel | Sealed | 2° | Sealmaster | 00000000 | 0000000 | 00000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Clamp On | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 7/16" | 1 7/8" | 4 1/4" | 1 7/8" | 5,780 | 6,500 | Steel | Sealed | 2° | Sealmaster | 00000000 | 000000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 15/16" | 2 1/4" | 5 1/2" | 2" | 7,880 | 5,000 | Steel | Sealed | 2° | Sealmaster | 00000000 | 000000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 2 1/4" | 5 1/2" | 2" | 7,880 | 5,000 | Steel | Sealed | 2° | Sealmaster | 00000000 | 000000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 30 mm | 42.9 mm | 101.6 mm | 38.1 mm | 4,380 | 5,450 | Steel | Sealed | 2° | Sealmaster | 00000000 | 000000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||