Filter by

Overall Length

For Use With

Keying

For Plug Width

Overall Width

Specifications Met

Message

Length

Export Control Classification Number (ECCN)

DFARS Specialty Metals

Width

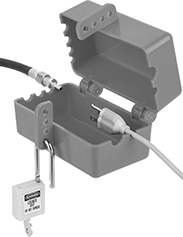

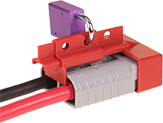

Electrical Plug Lockouts

For Plug | Overall | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Max. No. of Padlocks | For Max. Padlock Shackle Dia. | For Maximum Cord Diameter | No. of Holes | Max. Lg. | Wd. | Lg. | Wd. | Ht. | Dia. | Temp. Range, ° F | Message | Specs. Met | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Yellow Plastic with Adjustable-Fit Closure | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 5/16" | 1 1/4" | 1 | 5 1/2" | 1 1/2" to 3" | 6 1/4" | — | — | 3 1/2" | 32 to 275 | — | OSHA Compliant 29 CFR 1910.147 | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Yellow Plastic | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 | 3/8" | 1 1/8" | 2 | 4 3/4" | 1 1/2" to 2 3/4" | 7 1/4" | — | — | 4 1/4" | -20 to 140 | — | OSHA Compliant 29 CFR 1910.147 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 | 3/8" | 1 7/16" | 2 | 10 1/4" | 1/2" to 4 1/2" | 12 1/2" | — | — | 5" | 0 to 175 | — | OSHA Compliant 29 CFR 1910.147 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Yellow Plastic (English/Spanish) with Adjustable-Fit Closure | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 | 9/16" | 1 1/4" | 1 | 5 1/2" | 1 1/2" to 3" | 7" | — | — | 3 3/4" | -25 to 200 | Danger—Do Not Plug In/No Conectar | OSHA Compliant 29 CFR 1910.147, UL ECVP 2809-2 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Red Plastic (English) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 11/32" | 1/2" | 2 | 3 1/8" | 1/2" to 1 5/8" | 3 1/2" | 3 1/8" | 2" | — | 0 to 175 | Danger—Locked Out—Do Not Remove | OSHA Compliant 29 CFR 1910.147 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 | 9/16" | 1/2" | 2 | 3" | 3/4" to 2" | 3 1/2" | — | — | 2 1/2" | -25 to 200 | Danger—Do Not Operate—Equipment Locked Out | OSHA Compliant 29 CFR 1910.147, UL ECVP 2809-2 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 | 9/32" | 1 1/8", 1", 1" | 5 | 6 3/4" | 1/2" to 2 1/2" | 7 1/4" | 4 1/4" | 3" | — | -40 to 300 | Danger—Do Not Operate—Equipment Locked Out | OSHA Compliant 29 CFR 1910.147, UL ECVP 2809-2 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

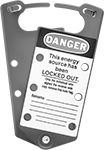

Lockout Hasps

Hasp Clearance | Overall | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Vertical | Horizontal | Hasp Thk. | For Max. No. of Padlocks | For Max. Padlock Shackle Dia. | Lg. | Wd. | Color | Specs. Met | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Aluminum | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Powder Coated | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 1" | 1/2" | 6 | 3/8" | 4 7/16" | 1 1/2" | Red | OSHA Compliant 29 CFR 1910.147, UL ECVP 2809-2 | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 1 1/2" | 1/2" | 6 | 3/8" | 5" | 2 1/16" | Red | OSHA Compliant 29 CFR 1910.147, UL ECVP 2809-2 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Vinyl Coated | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 1" | 1/4" | 6 | 7/16" | 4 3/8" | 1 1/2" | Red | OSHA Compliant 29 CFR 1910.147 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 1 1/2" | 1/4" | 6 | 7/16" | 4 7/8" | 1 1/2" | Red | OSHA Compliant 29 CFR 1910.147 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Powder Coated | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 1" | 1/4" | 12 | 3/8" | 6 1/2" | 1 1/2" | Red | OSHA Compliant 29 CFR 1910.147 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 1" | 1/4" | 24 | 1/4" | 10 3/8" | 1 1/2" | Red | OSHA Compliant 29 CFR 1910.147 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Vinyl Coated | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 1" | 3/8" | 6 | 3/8" | 4 1/2" | 1 3/4" | Red | OSHA Compliant 29 CFR 1910.147 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 1 1/2" | 3/8" | 6 | 3/8" | 5" | 2 3/8" | Red | OSHA Compliant 29 CFR 1910.147 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Epoxy Coated | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 1" | 3/8" | 6 | 3/8" | 5 1/16" | 1 3/4" | Yellow | OSHA Compliant 29 CFR 1910.147 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 1 1/2" | 3/8" | 6 | 3/8" | 5 1/16" | 2 1/4" | Yellow | OSHA Compliant 29 CFR 1910.147 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

304 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Vinyl Coated | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 1" | 1/4" | 6 | 7/16" | 4 7/16" | 1 1/2" | Red | OSHA Compliant 29 CFR 1910.147 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4" | 1 1/4" | 1/4" | 6 | 5/16" | 4 9/16" | 1 1/2" | Red | OSHA Compliant 29 CFR 1910.147 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Pry-Resistant Interlocking-Hasp Lockouts

Hasp Clearance | Overall | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Vertical | Horizontal | Hasp Thk. | For Max. No. of Padlocks | For Max. Padlock Shackle Dia. | Lg. | Wd. | Color | Label Included | Specs. Met | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Lockout Hasp | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Powder-Coated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 1" | 1/2" | 6 | 3/8" | 4 1/2" | 1 1/2" | Red | No | OSHA Compliant 29 CFR 1910.147, UL ECVP 2809-2 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 1 1/2" | 1/2" | 6 | 3/8" | 5" | 1 1/2" | Red | No | OSHA Compliant 29 CFR 1910.147, UL ECVP 2809-2 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Vinyl-Coated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 1" | 1/8" | 6 | 3/8" | 4 1/2" | 1 1/2" | Red | No | OSHA Compliant 29 CFR 1910.147 | 00000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 1 1/2" | 1/8" | 6 | 3/8" | 5" | 1 1/2" | Red | No | OSHA Compliant 29 CFR 1910.147 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

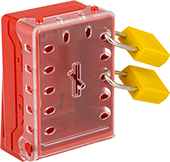

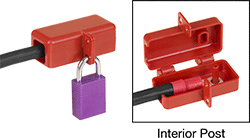

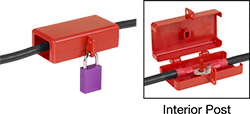

Plug-In Electrical Plug Lockouts

Overall | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Keying | Key No. | No. of Keys Included | Lg. | Wd. | Dp. | For No. of Blades | Temp. Range, ° F | Color | Label Included | Specs. Met | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Lockout Cover | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Plastic-Coated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Keyed Alike | 4001 | 2 | 1 3/4" | 1 1/4" | 3/4" | 2, 3 | -40 to 194 | Red | No | OSHA Compliant 29 CFR 1910.147 | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Keyed Differently | — | 2 | 1 3/4" | 1 1/4" | 3/4" | 2, 3 | -40 to 194 | Red | No | OSHA Compliant 29 CFR 1910.147 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Nonconductive Lockout Hasps

|  |  |  | |

Style A | Style B | Style C | Style D | Style E |

Hasp Clearance | Overall | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Style | Vertical | Horizontal | Hasp Thk. | For Max. No. of Padlocks | For Max. Padlock Shackle Dia. | Lg. | Wd. | Color | Label Included | Specs. Met | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Lockout Hasp | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Plastic | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 1" | 1" | 3/8" | 6 | 3/8" | 5" | 1 1/2" | Red | No | OSHA Compliant 29 CFR 1910.147, UL ECVP 2809-2 | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 1 1/2" | 1 1/2" | 3/8" | 6 | 3/8" | 4 1/2" | 1 1/2" | Red | No | OSHA Compliant 29 CFR 1910.147, UL ECVP 2809-2 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | 1 3/4" | 3/4" | 1" | 2 | 1 1/2" | 4 3/4" | 2 1/2" | Red | No | OSHA Compliant 29 CFR 1910.147 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| C | 1 15/16" | 1" | 1/4" | 3 | 1/4" | 8" | 1 3/4" | Red | Yes | OSHA Compliant 29 CFR 1910.147, UL ECVP 2809-2 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| D | 3 1/2" | 1 1/4" | 3/8" | 6 | 3/8" | 7" | 1 3/4" | Orange | No | OSHA Compliant 29 CFR 1910.147 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| E | 3 1/2" | 1 1/4" | 1/2" | 12 | 1/4" | 7 1/4" | 3 1/4" | Red | No | OSHA Compliant 29 CFR 1910.147 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Electrical Socket Lockouts

Overall | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

IEC Connector Type | For Max. No. of Padlocks | For Max. Padlock Shackle Dia. | Lg. | Wd. | Ht. | Temp. Range, ° F | Color | Label Included | Specs. Met | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Lockout Cover | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Plastic | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| C13 | 1 | 1/4" | 3 1/2" | 1 1/8" | 7/8" | 0 to 245 | Orange | No | OSHA Compliant 29 CFR 1910.147 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

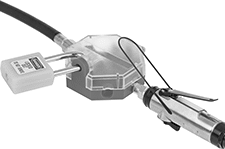

Air Hose Lockouts

|  |  |

Style A (Padlock Not Included) | Style B (Padlock Not Included) | C (Padlock Not Included) |

|  | |

Style D (Padlock Not Included) | Style E (Padlock Not Included) |

For Plug | Overall | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Style | For Coupling Size | For Fitting Connection | For Quick-Disconnect Component | For Max. No. of Padlocks | For Max. Padlock Shackle Dia. | For Max. Cord Dia. | Max. Lg. | Wd. | Lg. | Wd. | Ht. | Temp. Range, ° F | Color | Label Included | Message | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Lockout Cover | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Plastic | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 1/4 | Quick Disconnect | Plug | 1 | 9/32" | — | — | — | 1 1/2" | 1" | 1" | -30 to 200 | Red | Yes | Pneumatic Tool Lockout | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | 1/4, 3/8, 1/2 | Quick Disconnect | Plug | 2 | 1/4" | — | — | — | 3" | 3" | 7/8" | — | Red | No | — | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| C | 1/8, 1/4, 3/8 | Quick Disconnect | Plug, Socket | 1 | 9/32" | — | — | — | 3 1/4" | 3 7/8" | 1 7/8" | -30 to 200 | Red | No | — | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| D | 1/8 | Quick Disconnect | Plug | 4 | 1/4" | 1/4" | 5" | 2" to 3 1/2" | 6 1/4" | 4 1/2" | 3 3/4" | 0 to 175 | Red | Yes | Lockout Device—Do Not Plug In | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Lockout Hasp | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| E | 1/4, 5/16, 3/8, 7/16, 1/2, 9/16, 13/16 | Quick Disconnect | Plug | 2 | 9/32" | — | — | — | 7 3/4" | 1 3/8" | — | -30 to 183 | — | No | — | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

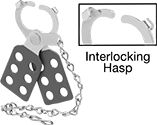

Lockout Hasps with Chain

Hasp Clearance | Overall | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Vertical | Horizontal | Hasp Thk. | For Max. No. of Padlocks | For Max. Padlock Shackle Dia. | Lg. | Wd. | Color | Label Included | Specs. Met | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Lockout Hasp | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Vinyl-Coated Aluminum | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 1" | 1/4" | 6 | 7/16" | 4 3/8" | 1 1/2" | Red | No | OSHA Compliant 29 CFR 1910.147 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 1 1/2" | 1/4" | 6 | 7/16" | 4 7/8" | 1 1/2" | Red | No | OSHA Compliant 29 CFR 1910.147 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Choose-a-Color Lockout Hasps with Label

Hasp Clearance | Overall | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Vertical | Horizontal | Hasp Thk. | For Max. No. of Padlocks | For Max. Padlock Shackle Dia. | Lg. | Wd. | Label Included | Language | Message | Specs. Met | Choose a Color | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Lockout Hasp | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Anodized Aluminum | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/16" | 1 3/8" | 3/16" | 6 | 5/16" | 7 3/8" | 3" | Yes | English | Danger—Do Not Operate | OSHA Compliant 29 CFR 1910.147 | Blue , Green , Red | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Electrical, Valve, and Air Hose Lockout Sets with Padlocks

For Use With | For Valve Control Type | Includes | Specs. Met | Each | ||

|---|---|---|---|---|---|---|

| Air Hose, Circuit Breakers, Electrical Panels, Electrical Plugs, Push Buttons, Valves, Wall Switches | Hand Wheel, Handle | 1 Each: Wall Switch Lockout 2 Each: Plug Lockouts 2 Valve Wheel Lockouts (1 Each that fits 1"-2 1/2" and 2 1/2"-5" Diameter Wheels) 3 Each: Circuit Breaker Lockouts 1 Each: Cable Lockout 2 Each: Lockout Hasps 1 Each: Air Hose Lockout 1 Each: Push Button Lockout 1 Each: Valve Handle Lockout (Fits 3/8 to 1 Pipe Size) 2 Each: 1/4" Shackle Diameter Keyed Differently Padlocks with Labels 5 Each: Cable Ties 5 Each: Tags Carrying Case | OSHA Compliant 29 CFR 1910.147 | 0000000 | 0000000 |

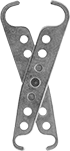

Dual-Jaw Lockout Hasps

Hasp Clearance | Overall | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Vertical | Horizontal | Hasp Thickness | For Max. No. of Padlocks | For Max. Padlock Shackle Dia. | Lg. | Wd. | Label Included | Specs. Met | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Lockout Hasp | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Zinc-Plated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" x 1" | 1/2" x 1" | 5/16" x 5/16" | 6 | 5/16" | 7 3/4" | 1 3/8" | No | OSHA Compliant 29 CFR 1910.147 | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Aluminum | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" x 1 1/2" | 1" x 1 1/2" | 1/4" x 1/4" | 8 | 9/32" | 5 7/8" | 2" | No | OSHA Compliant 29 CFR 1910.147 | 00000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Wall-Mount Electrical and Valve Lockout Sets with Padlocks

Mounting Holes | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Includes | Ht. | Wd. | Dp. | Fasteners Included | No. Of | Screw Size | Specs. Met | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Cabinet | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 Each: Gas Cylinder Lockout 1 Each: Wall Switch Lockout 2 Each: Plug Lockouts 2 Valve Wheel Lockouts (1 Each that fits 1"-2 1/2" and 2 1/2"-5" Diameter Wheels) 3 Each: Circuit Breaker Lockouts 4 Each: Lockout Hasps 4 Each: 1/4" Shackle Diameter Keyed Differently Padlocks with Labels 10 Each: Tags 10 Each: Cable Ties | 16" | 15 1/4" | 5 1/2" | No | 4 | No. 10 | OSHA Compliant 29 CFR 1910.147, UL ECVP 2809-2 | 00000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Case | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 Each: Plug Lockouts 1 Each: Cable Lockout 1 Each: Snap-On Lockout Hasp 2 Each: Lockout Hasps 2 Each: Valve Handle Lockouts (Fits 3/8 to 4 Pipe Size) 2 Each: Wall Switch Lockouts 4 Valve Wheel Lockouts (1 Each that fits 1"-3", 2"-5", 4"-6 1/2", and 6"-10" Diameter Wheels) 6 Each: 1/4" Shackle Diameter Keyed Differently Padlocks with Labels 8 Each: Circuit Breaker Lockouts 24 Each: Tags 24 Each: Cable Ties | 27" | 23 1/2" | 4 1/2" | No | 8 | No. 10 | OSHA Compliant 29 CFR 1910.147 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

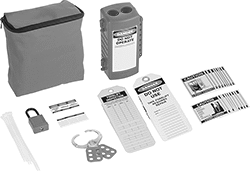

Electrical Lockout Sets with Padlocks

For Use With | Includes | Specs. Met | Each | ||

|---|---|---|---|---|---|

| Circuit Breakers, Electrical Plugs, Wall Switches | 1 Each: Wall Switch Lockout 10 Each: Tags 10 Each: Cable Ties 2 Each: Lockout Hasps 1 Each: Plug Lockout 5 Each: Circuit Breaker Lockouts 3 Each: 1/4" Shackle Diameter Keyed Differently Padlocks with Labels Plastic Box | OSHA Compliant 29 CFR 1910.147 | 00000000 | 000000 | |

| Circuit Breakers, Electrical Plugs | 2 Each: Plug Lockouts 2 Each: Lockout Hasps 2 Each: 1/4" Shackle Diameter Keyed Differently Padlocks with Labels 3 Each: Cable Ties 2 Each: Tags Carrying Case | OSHA Compliant 29 CFR 1910.147, UL ECVP 2809-2 | 00000000 | 00000 | |

| Circuit Breakers, Electrical Plugs | 2 Each: Lockout Hasps 3 Each: Cable Ties 4 each: Circuit Breaker Lockouts 1 Each: Plug Lockout 2 each: 1/4" Shackle Diameter Keyed Alike Padlocks with Labels 3 each: Tags Carrying Case | OSHA Compliant 29 CFR 1910.147 | 0000000 | 00000 |

Low-Profile Lockout Hasps with Label

Hasp Clearance | Overall | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Vertical | Horizontal | Hasp Thk. | For Max. No. of Padlocks | For Max. Padlock Shackle Dia. | Lg. | Wd. | Label Included | Language | Message | Specs. Met | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Lockout Hasp | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Nickel-Plated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 1 1/4" | 1/4" | 7 | 3/8" | 3" | 3" | Yes | English | Danger—Do Not Operate | OSHA Compliant 29 CFR 1910.145, OSHA Compliant 29 CFR 1910.147 | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Lockout Hasps with Label

Hasp Clearance | Overall | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Style | Vertical | Horizontal | Hasp Thk. | For Max. No. of Padlocks | For Max. Padlock Shackle Dia. | Lg. | Wd. | Color | Label Included | Language | Message | Specs. Met | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Lockout Hasp | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Vinyl-Coated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 1 1/8" | 2 1/16" | 3/16" | 6 | 5/16" | 5 7/16" | 3 7/16" | Red | Yes | English | Danger—Do Not Operate | OSHA Compliant 29 CFR 1910.147 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Anodized Aluminum | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | 1 1/2" | 1 1/2" | 3/16" | 6 | 9/32" | 7" | 2 3/4" | Red | Yes | English | Danger—Do Not Operate | OSHA Compliant 29 CFR 1910.147 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Battery Cable Connector Lockouts

|  |

Hinged Cover For 1 Battery Cable | Hinged Cover For 2 Battery Cables |

| |

Slide-On Cover |

For Max. Connector | Cable Opening | Overall | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Lg. | Wd. | Ht. | For No. of Battery Cables | Wd. | Ht. | Post Dia. | Lg. | Wd. | Ht. | For Max. No. of Padlocks | For Max. Padlock Shackle Dia. | Temp. Range, ° F | Color | Specs. Met | Flammability Rating | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Hinged Cover | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Plastic | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 5/8" | 1 1/2" | 1 1/4" | 1 | 1" | 1" | 1/4" | 3 3/4" | 2 7/8" | 1 3/8" | 2 | 5/16" | -40 to 212 | Red | OSHA Compliant 29 CFR 1910.147 | UL 94 HB | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 5/8" | 2 3/4" | 1 5/8" | 2 | 2" | 1 3/8" | 1/4" | 5 3/4" | 4 1/8" | 1 3/4" | 2 | 5/16" | -40 to 212 | Red | OSHA Compliant 29 CFR 1910.147 | UL 94 HB | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Slide-On Cover | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Plastic | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 1/2" | 2 7/8" | 1 3/8" | — | — | — | — | 5 1/4" | 3 1/8" | 2 1/2" | 2 | 5/16" | -40 to 212 | Red | OSHA Compliant 29 CFR 1910.147 | UL 94 HB | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

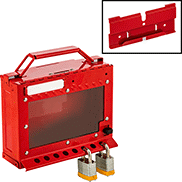

Portable Group Lockout Boxes

Style | Min. Padlock Vert. Shackle Clearance | For Max. No. of Padlocks | For Max. Padlock Shackle Dia. | Lg. | Wd. | Ht. | Color | No. of Windows | Window Material | Features | Specs. Met | Stackable | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Lockout Box | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Plastic | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 1 1/2" | 17 (Outside of Box) | 1/4" | 7 3/4" | 4" | 7 3/4" | Red | 1 | Polycarbonate | Handle, Key Slot | OSHA Compliant 29 CFR 1910.147 | No | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Powder-Coated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | 5/8" | 13 (Outside of Box) | 9/32" | 9" | 3 1/2" | 6" | Blue | — | — | Control-Lock Hole, Handle, Key Slot | OSHA Compliant 29 CFR 1910.147 | No | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | 5/8" | 13 (Outside of Box) | 9/32" | 9" | 3 1/2" | 6" | Red | — | — | Control-Lock Hole, Handle, Key Slot | OSHA Compliant 29 CFR 1910.147 | No | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | 3/4" | 13 (Outside of Box) | 5/16" | 10" | 4" | 6" | Yellow | — | — | Control-Lock Hole, Handle, Key Slot | OSHA Compliant 29 CFR 1910.147 | No | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | 1" | 7 (Outside of Box) | 5/16" | 4 1/4" | 4 1/4" | 6 1/4" | Red | — | — | Control-Lock Hole, Handle, Key Slot | OSHA Compliant 29 CFR 1910.147 | No | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| C | 1/2" | 21 (Outside of Box) | 5/16" | 12" | 8 1/4" | 9" | Red | 1 | Polycarbonate | Control-Lock Hole, Handle, Key Slot, Removable Key Cup | OSHA Compliant 29 CFR 1910.147 | Yes | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| C | 3/4" | 20 (Outside of Box) | 1/4" | 8" | 4 1/2" | 4 3/4" | Red | 2 | Polycarbonate | Handle, Key Slot | OSHA Compliant 29 CFR 1910.147 | No | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Powder-Coated Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| C | 3/4" | 19 (Outside of Box) | 3/8" | 12" | 6 1/2" | 5 3/4" | Red | 1 | Polycarbonate | Control-Lock Hole, Drain Holes, Handle, Key Slot, Removable Key Cup | OSHA Compliant 29 CFR 1910.147 | Yes | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Pry-Resistant Lockout Hasps

Hasp Clearance | Overall | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Vertical | Horizontal | Hasp Thk. | For Max. No. of Padlocks | For Max. Padlock Shackle Dia. | Lg. | Wd. | Color | Label Included | Specs. Met | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Lockout Hasp | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Plastic | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/8" | 1" | 1/8" | 2 | 9/32" | 3 1/8" | 2 3/16" | Red | No | OSHA Compliant 29 CFR 1910.147 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Zinc-Plated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3" | 1" | 1/4" | 6 | 3/8" | 6 3/4" | 2 1/4" | — | No | OSHA Compliant 29 CFR 1910.147 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Vinyl-Coated Zinc-Plated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4" | 1" | 1/4" | 6 | 3/8" | 5" | 2 5/16" | Red | No | OSHA Compliant 29 CFR 1910.147 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Lockout Bags

Overall | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Max. No. of Padlocks | For Max. Padlock Shackle Dia. | Lg. | Wd. | Color | Label Included | Language | Message | Specs. Met | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Lockout Bag | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Canvas | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 9/32" | 18" | 9 3/4" | Yellow | Yes | English | Lock Out For Safety | OSHA Compliant 29 CFR 1910.147 | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Nylon | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 | 9/32" | 17" | 7" | Red | Yes | English, Spanish, French | Locked Out—Do Not Remove Cerrado—No Lo Quite Verrouille—Ne Pas Enlever | OSHA Compliant 29 CFR 1910.147 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 | 9/32" | 26" | 10" | Red | Yes | English, Spanish, French | Locked Out—Do Not Remove Cerrado—No Lo Quite Verrouille—Ne Pas Enlever | OSHA Compliant 29 CFR 1910.147 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Polyester Plastic | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 5/16" | 5" | 5" | Red | Yes | English | Locked Out—Do Not Operate | OSHA Compliant 29 CFR 1910.147 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Portable/Wall-Mount Group Lockout Boxes

Mounting Holes | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Style | Color | Lg. | Wd. | Ht. | For Max. No. of Padlocks | For Max. Padlock Shackle Dia. | No. of Key Hooks | Fasteners Included | No. Of | Screw Size | Mounting Location | Mount Type | No. of Windows | Features | Enclosure Rating | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Plastic Box with Polycarbonate Window | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | Red | 13" | 3 1/2" | 13" | 44 (Outside of Box) | 5/16" | 16 | No | 2 | 1/4" | Wall | Freestanding | 1 | Control-Lock Hole, Handle, Key Slot | — | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Powder-Coated Steel Box | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | Red | 6 3/8" | 3 1/2" | 12 3/4" | 14 (Outside of Box) | 9/32" | 12 | No | 4 | No. 8 | Wall | Freestanding | — | Handle, Key Slot | — | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | Yellow | 6 3/8" | 3 1/2" | 12 3/4" | 14 (Outside of Box) | 9/32" | 12 | No | 4 | No. 8 | Wall | Freestanding | — | Handle, Key Slot | — | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Powder-Coated Steel Box with Polycarbonate Window | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| C | Red | 10 1/2" | 3 1/2" | 6 1/8" | 12 (Outside of Box) | 5/16" | 6 | No | 2 | No. 8 | Wall | Freestanding | 1 | Handle, Key Slot | — | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Powder-Coated 430 Stainless Steel Box with Wall-Mount Bracket, Polycarbonate Window | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| D | Red | 8 3/8" | 4" | 6 7/8" | 8 (Outside of Box) | 3/8" | 4 | No | 3 | No. 10 | Wall | Freestanding | 1 | Dry Erase Label, Handle, Key Slot | — | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Powder-Coated 430 Stainless Steel Box with Document Display, Polycarbonate Window | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| E | Red | 12 1/8" | 4 3/4" | 31" | 12 (Outside of Box), 12 (Removable Lock Caddy) | 9/32" | 12 | No | 8 | No. 8 | Wall | — | 2 | Control-Lock Hole, Dry Erase Label, Handle, Key Slot, Removable Key Cup | IP03 | 000000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Forklift Lockout Sets with Padlock

For Use With | Includes | Specs. Met | Each | ||

|---|---|---|---|---|---|

| Battery Cable Connectors, Electrical Plugs, Gas Cylinders | 10 Each: Cable Ties 1 Each: Plug Lockout 1 Each: 1/4" Shackle Diameter Keyed Differently Padlock with Label 1 Each: Lockout Hasp 10 Each: Forklift Inspection Tags 10 Each: Lockout Tags 20 Each: Safety Labels Carrying Case | OSHA Compliant 29 CFR 1910.147 | 0000000 | 0000000 |

Nonconductive Lockout Hasps with Tag Holder

Hasp Clearance | Overall | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Vertical | Horizontal | Hasp Thk. | For Max. No. of Padlocks | For Max. Padlock Shackle Dia. | Lg. | Wd. | Color | Tag Included | Features | Specs. Met | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Lockout Hasp | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Plastic | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 3/4" | 1 3/8" | 1/2" | 3 | 5/16" | 5 1/4" | 3" | Red | No | Tag Holder | OSHA Compliant 29 CFR 1910.147 | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Low-Profile Lockout Hasps

Hasp Clearance | Overall | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Vertical | Horizontal | Hasp Thk. | For Max. No. of Padlocks | For Max. Padlock Shackle Dia. | Lg. | Wd. | Label Included | Specs. Met | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Lockout Hasp | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Nickel-Plated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 1 1/4" | 1/4" | 7 | 3/8" | 3" | 3" | No | OSHA Compliant 29 CFR 1910.147 | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

304 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 1 1/4" | 1/4" | 7 | 3/8" | 3" | 3" | No | OSHA Compliant 29 CFR 1910.147 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Pry-Resistant Interlocking-Hasp Lockouts with Chain

Hasp Clearance | Overall | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Vertical | Horizontal | Hasp Thk. | For Max. No. of Padlocks | For Max. Padlock Shackle Dia. | Lg. | Wd. | Mounting Chain Lg. | Label Included | Specs. Met | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Lockout Hasp | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Vinyl-Coated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 1" | 1/8" | 6 | 3/8" | 4 1/2" | 1 1/2" | 8" | No | OSHA Compliant 29 CFR 1910.147 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 1 1/2" | 1/8" | 6 | 3/8" | 5" | 1 1/2" | 8" | No | OSHA Compliant 29 CFR 1910.147 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Wall-Mount Group Lockout Boxes

Mounting Holes | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Max. No. of Padlocks | For Max. Padlock Shackle Dia. | Lg. | Wd. | Ht. | Color | No. of Key Hooks | Fasteners Included | No. Of | Screw Size | No. of Windows | Window Material | Includes | Features | Specs. Met | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Lockout Box | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Plastic | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12 (Outside of Box) | 9/32" | 2 3/4" | 4" | 5 3/4" | Red | 3 | No | 3 | No. 4 | 1 | Polycarbonate | Wall-Mount Bracket | Key Slot | OSHA Compliant 29 CFR 1910.147 | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 26 (Outside of Box) | 15/32" | 4" | 13" | 11" | Red | 11 | No | 2 | No. 10 | 1 | Polycarbonate | — | Control-Lock Hole, Key Slot | OSHA Compliant 29 CFR 1910.147 | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Electrical and Valve Lockout Sets with Padlocks

Lockout Type | Includes | Specs. Met | Each | ||

|---|---|---|---|---|---|

| Cover, Cable, Hasp, Bag | 1 Each: Wall Switch Lockout 1 Each: Cable Lockout 1 Each: Plug Lockout 5 Each: Circuit Breaker Lockouts Plastic Box 1 Each: Adjustable Ball Valve Lockout 1 Each: Plug Prong Lockout 3 Valve Wheel Lockouts (1 Each that fits 1"-3", 2"-5", and 4"-6 1/2" Diameter Wheels) 1 Each: Hoist Cover 3 Each: Lockout Hasps 3 Each: 1/4" Shackle Diameter Keyed Alike Padlocks with Labels 6 Each: Tags 6 Cable Ties | OSHA Compliant 29 CFR 1910.147 | 0000000 | 0000000 | |

| Cover, Cable, Hasp, Bag | 1 Each: Wall Switch Lockout 2 Each: Plug Lockouts 1 Each: Cable Lockout 6 Each: 1/4" Shackle Diameter Keyed Differently Padlocks with Labels 12 Each: Tags 3 Valve Wheel Lockouts (1 Each that fits 1"-3", 2"-5", and 4"-6 1/2" Diameter Wheels) 11 Each: Circuit Breaker Lockouts 2 Each: Valve Lockouts 6 Each: Lockout Hasps 12 Cable Ties Carrying Case | OSHA Compliant 29 CFR 1910.147 | 0000000 | 000000 | |

| Cover, Hasp | 4 Each: Lockout Hasps 2 Each: 1/4" Shackle Diameter Keyed Differently Padlocks with Labels 5 Each: Tags 1 Each: Plug Lockout 1 Each: Circuit Breaker Lockout 1 Valve Wheel Lockout (fits 2 1/2"-5" Diameter Wheels) 5 Cable Ties Fanny Pack | OSHA Compliant 29 CFR 1910.147, UL ECVP 2809-2 | 00000000 | 000000 |

Pry-Resistant Lockout Hasps with Padlock Slot

Hasp Clearance | Overall | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Vertical | Horizontal | Hasp Thk. | For Max. No. of Padlocks | For Max. Padlock Shackle Dia. | Body Ht. | Lg. | Wd. | Label Included | Specs. Met | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Lockout Hasp | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Zinc-Plated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 1" | 1/8" | 5 | 5/16" | 2" | 3 1/4" | 2 1/4" | No | OSHA Compliant 29 CFR 1910.147 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 1" | 1/4" | 5 | 5/16" | 2" | 3 1/4" | 2 1/4" | No | OSHA Compliant 29 CFR 1910.147 | 00000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 1" | 3/8" | 6 | 7/16" | 3 1/2" | 5 3/8" | 2 1/2" | No | OSHA Compliant 29 CFR 1910.147 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3" | 1" | 1/8" | 9 | 5/16" | 3 1/2" | 6 5/8" | 2 1/4" | No | OSHA Compliant 29 CFR 1910.147 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3" | 1" | 1/4" | 9 | 5/16" | 3 1/2" | 6 3/4" | 2 1/4" | No | OSHA Compliant 29 CFR 1910.147 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 3/4" | 1 1/2" | 1/4" | 3 | 3/8" | 2" | 7" | 3" | No | OSHA Compliant 29 CFR 1910.147 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Wall-Mount Lockout Sets with Padlocks

Mounting Holes | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Includes | Ht. | Wd. | Dp. | Fasteners Included | No. Of | Screw Size | Specs. Met | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Board | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10 Each: Tags 2 Each: Lockout Hasps 16 Each: 1/4" Shackle Diameter Keyed Differently Padlocks with Labels | 13 1/2" | 14 1/2" | 3" | No | 4 | No. 10 | OSHA Compliant 29 CFR 1910.147 | 00000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10 Each: Tags 10 Each: Cable Ties 2 Each: Lockout Hasps 8 Each: 1/4" Shackle Diameter Keyed Differently Padlocks with Labels | 15" | 15" | 2 1/2" | No | 4 | No. 10 | OSHA Compliant 29 CFR 1910.147, UL ECVP 2809-2 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10 Each: Tags 10 Each: Cable Ties 2 Each: Lockout Hasps 12 Each: 1/4" Shackle Diameter Keyed Differently Padlocks with Labels | 23" | 15" | 2 1/2" | No | 4 | No. 10 | OSHA Compliant 29 CFR 1910.147, UL ECVP 2809-2 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 Each: Lockout Hasps 3 Each: Cable Ties 3 each: Tags 3 Each: 1/4" Shackle Diameter Keyed Differently Padlocks with Labels | 11" | 11" | 2 1/2" | No | 4 | No. 10 | OSHA Compliant 29 CFR 1910.147, UL ECVP 2809-2 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Case | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 Each: 1/4" Shackle Diameter Keyed Differently Padlocks with Labels 2 Each: Lockout Hasps 12 Each: Cable Ties 12 Each: Tags | 12 1/4" | 16" | 1 3/4" | No | 4 | No. 6 | OSHA Compliant 29 CFR 1910.147 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 Each: Lockout Hasps 24 Each: Tags 24 Each: Cable Ties 10 Each: 1/4" Shackle Diameter Keyed Differently Padlocks with Labels | 15 1/2" | 22" | 1 3/4" | No | 4 | No. 6 | OSHA Compliant 29 CFR 1910.147 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||