Filter by

For Use On

Military Specification

Container Type

DFARS Specialty Metals

Specifications Met

Export Control Classification Number (ECCN)

Visibility

Solution Type

Length

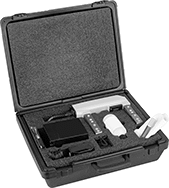

Plug-In Magnetic Particle Flaw Detection Kits

Electrical | |||||||||

|---|---|---|---|---|---|---|---|---|---|

For Use On | Includes | Connection | No. of Blades | Voltage, V AC | Specs. Met | Mil. Spec. | Each | ||

| Cast Iron, Stainless Steel, Steel | One 1-lb. Bottle of Gray Powder, One 1-lb. Bottle of Red Powder | Straight Blade | 3 | 120 | ASTM E1444 | MIL-STD-2132, MIL-STD-271 | 000000 | 0000000 | |

Magnetic Particles for Flaw Detection

Container | Application Temp. Range, ° F | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Use On | Visibility | Color | Net Wt. | Type | Particle Size, μm | Min. | Max. | Features | Specs. Met | Mil. Spec. | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Powder | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Cobalt, Iron, Nickel, Stainless Steel, Steel | Natural Light | Gray | 10 lb. | Pail | 80 | Not Rated | 750 | — | ASTM E1444 | MIL-STD-2132, MIL-STD-271, NAVSEA 250-1500-1, NAVSEA T9074-AS-GIB-010/271 | 00000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Cobalt, Iron, Nickel, Stainless Steel, Steel | Natural Light | Red | 10 lb. | Pail | 80 | Not Rated | 600 | — | ASTM E1444, ISO 9934 | MIL-STD-2132, MIL-STD-271, NAVSEA 250-1500-1, NAVSEA T9074-AS-GIB-010/271 | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Cobalt, Iron, Nickel, Stainless Steel, Steel | Natural Light | Yellow | 10 lb. | Pail | 80 | Not Rated | 500 | — | ASTM E1444, ISO 9934 | MIL-STD-2132, MIL-STD-271, NAVSEA 250-1500-1, NAVSEA T9074-AS-GIB-010/271 | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Oil-Based Spray | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Cobalt, Iron, Nickel, Stainless Steel, Steel | Natural Light | Black | 10.5 oz. | Aerosol Can | 2 | 45 | 120 | 360° Sprayer | ASTM E1444, ISO 9934 | MIL-STD-2132, NAVSEA 250-1500-1, NAVSEA T9074-AS-GIB-010/271 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Cobalt, Iron, Nickel, Stainless Steel, Steel | Ultraviolet | Fluorescent Light Green | 10.5 oz. | Aerosol Can | 6 | 55 | 120 | — | ASTM E1444, ISO 9934 | MIL-STD-2132, MIL-STD-271, NAVSEA 250-1500-1, NAVSEA T9074-AS-GIB-010/271 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Water-Based Spray | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Cobalt, Iron, Nickel, Stainless Steel, Steel | Natural Light | Black | 12.2 oz. | Aerosol Can | 2 | 25 | 120 | — | ISO 9934 | MIL-STD-2132, NAVSEA 250-1500-1, NAVSEA T9074-AS-GIB-010/271 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

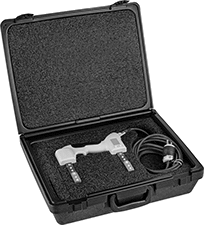

Battery-Powered Magnetic Particle Flaw Detection Kits

For Use On | Includes | Battery Voltage, V DC | Batteries Included | Battery Charger Included | Specs. Met | Each | ||

|---|---|---|---|---|---|---|---|---|

| Cobalt, Iron, Nickel, Stainless Steel, Steel | One 1-lb. Bottle of Gray Powder | 6 | Yes | Yes | ASTM E1444 | 0000000 | 000000000 |

Plug-In Magnetic Yokes

Yokes | Test Weights | LED Light Attachments | Replacement Cords | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Voltage, V AC | Features | For Use On | Power Source | Cord Lg., ft. | Ht. | Lg. | Wt., lb. | Specs. Met | Each | Each | Each | Each | |||||

| 120 | — | Cobalt, Iron, Nickel, Stainless Steel, Steel | Electric | 12 | 7 1/2" | 12" | 6 | ASTM E1444 | 0000000 | 0000000 | 0000000 | 0000000 | 0000000 | 0000000 | 0000000 | 0000000 | |

| 120 | AC/DC Switch | Cobalt, Iron, Nickel, Stainless Steel, Steel | Electric | 12 | 7 1/2" | 12" | 8 | ASTM E1444 | 0000000 | 00000000 | 0000000 | 000000 | ——— | 0 | ——— | 0 | |

Contrast Paint for Magnetic-Particle Flaw Detection

Container | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Net Wt., oz. | Type | Solution Type | Overall Dry Time, min. | Application Temp. Range, ° F | For Use On | Color | Features | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Spray | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12 | Aerosol Can | Solvent Based | 1 | 45 to 120 | Cast Iron, Cobalt, Nickel, Steel, Stainless Steel, Iron | White | 360° Sprayer | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||