About Shaft Couplings

More

Metal-Detectable Flexible Shaft Couplings

Safely connect slightly misaligned shafts near food lines—the spider on these couplings contains metal, so it’ll trigger a metal detector if a piece frays off and contaminates your batch. The hubs are made of 303 stainless steel to resist rusting in wet conditions common to food plants. However, these couplings shouldn’t directly touch food, since they’re not FDA compliant. If the spider fails, the hubs will interlock, giving you time to shut down equipment before other components break. You don’t need to lubricate these couplings.

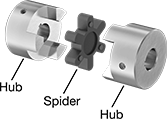

Also called Lovejoy® and jaw couplings, a complete coupling requires two hubs and one spider (all sold separately).

Hubs attach to the end of your shaft and have a set screw that bites into the shaft to hold the coupling in place.

Spiders cushion between the two hubs to reduce shocks and handle minor shaft misalignment. Metal-impregnated Buna-N spiders are the most commonly used and are good for applications that start, stop, and reverse often. They also dampen vibration and resist some chemicals. Metal-impregnated Hytrel spiders run at higher torque and resist chemicals better than Buna-N spiders. However, they shouldn’t be used in applications that start, stop, and reverse frequently.

Metal-Impregnated Buna-N Rubber Spiders | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

303 Stainless Steel Hubs | Misalignment Capability | ||||||||||

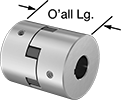

| O'all Lg. | OD | For Motion Type | For Shaft Dia. | Each | Max. Speed, rpm | Max.Torque, in.-lbs. | Parallel | Angular | Each | ||

| 2 1/8" | 1 3/4" | Continuous, Forward/Reverse, Start/Stop | 000000 | 000000 | 3,600 | 80 | 0.015" | 1° | 0000000 | 000000 | |

| 2 1/2" | 2 1/8" | Continuous, Forward/Reverse, Start/Stop | 00000000 | 000000 | 3,600 | 185 | 0.015" | 1° | 000000 | 00000 | |

| 3 1/2" | 2 17/32" | Continuous, Forward/Reverse, Start/Stop | 00000000 | 000000 | 3,600 | 415 | 0.015" | 1° | 0000000 | 00000 | |

| 54mm | 45mm | Continuous, Forward/Reverse, Start/Stop | 00000000 | 000000 | 3,600 | 80 | 0.015" | 1° | 0000000 | 00000 | |

| 64mm | 54mm | Continuous, Forward/Reverse, Start/Stop | 00000000 | 000000 | 3,600 | 185 | 0.015" | 1° | 000000 | 00000 | |

| 89mm | 65mm | Continuous, Forward/Reverse, Start/Stop | 00000000 | 000000 | 3,600 | 415 | 0.015" | 1° | 0000000 | 00000 | |

Metal-Impregnated Hytrel Rubber Spiders | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

303 Stainless Steel Hubs | Misalignment Capability | ||||||||||

| O'all Lg. | OD | For Motion Type | For Shaft Dia. | Each | Max. Speed, rpm | Max.Torque, in.-lbs. | Parallel | Angular | Each | ||

| 2 1/8" | 1 3/4" | Continuous, Forward/Reverse, Start/Stop | 000000 | 000000 | 3,600 | 240 | 0.015" | 1° | 0000000 | 000000 | |

| 2 1/2" | 2 1/8" | Continuous, Forward/Reverse, Start/Stop | 00000000 | 000000 | 3,600 | 565 | 0.015" | 1° | 0000000 | 000000 | |

| 3 1/2" | 2 17/32" | Continuous, Forward/Reverse, Start/Stop | 00000000 | 000000 | 3,600 | 1,245 | 0.015" | 1° | 0000000 | 000000 | |

| 54mm | 45mm | Continuous, Forward/Reverse, Start/Stop | 00000000 | 000000 | 3,600 | 240 | 0.015" | 1° | 0000000 | 00000 | |

| 64mm | 54mm | Continuous, Forward/Reverse, Start/Stop | 00000000 | 000000 | 3,600 | 565 | 0.015" | 1° | 0000000 | 000000 | |

| 89mm | 65mm | Continuous, Forward/Reverse, Start/Stop | 00000000 | 000000 | 3,600 | 1,245 | 0.015" | 1° | 0000000 | 000000 | |