Filter by

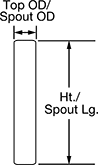

Top OD

Height

Spout Length

Capacity

Filter Material

Fitting Connection

Environment

Flame Arrester Material

Export Control Classification Number (ECCN)

DFARS Specialty Metals

Maximum Temperature

Drum Style

Strainer Type

Metal Funnels

|  |  |  |

Style A | Style B | Style C | Style D |

Style B

Spout | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Cap. | Top OD | Ht. | OD | Lg. | Autoclavable | Features | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

304 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 1/4 fl. oz. | 3" | 3 3/4" | 1/2" | 1 1/2" | Yes | Vented Spout, Hanging Eyelet | 000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 1/4 fl. oz. | 4 1/8" | 4 7/8" | 1/2" | 1 1/2" | Yes | Vented Spout, Hanging Eyelet | 000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 13 fl. oz. | 5 1/8" | 5 5/8" | 1/2" | 1 1/2" | Yes | Vented Spout, Hanging Eyelet | 000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 22 fl. oz. | 6 1/4" | 6 5/8" | 1/2" | 1 1/2" | Yes | Vented Spout, Hanging Eyelet | 000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 32 fl. oz. | 7" | 8 3/8" | 7/8" | 2 5/8" | Yes | Vented Spout, Hanging Eyelet | 000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 64 fl. oz. | 8 3/8" | 9 1/2" | 7/8" | 2 5/8" | Yes | Vented Spout, Hanging Eyelet | 000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Style C

|

Spout | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Cap. | Top OD | Ht. | OD | Lg. | Autoclavable | Features | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

304 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 fl. oz. | 2" | 2" | 5/16" | 1" | No | Hanging Eyelet | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Style D

|

Spout | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Cap. | Top OD | Ht. | OD | Lg. | Autoclavable | Features | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

304 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 19 fl. oz. | 5 1/2" | 2 3/4" | 2 1/4" | 1/2" | No | Handle | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Metal Funnels with Filter

|  |  |

Style A | Style B | Style C |

|  |  |

Style D | Style E | Style F |

|  |  |

Style G | Style H | Style J |

Style B

Spout | Filter | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Cap. | Top OD | Ht. | OD | Lg. | Permanence | Material | Strainer Type | Mesh Size | Autoclavable | Features | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Galvanized Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 gal. | 12 3/8" | 9 1/2" | 1" | 3 3/4" | Removable | Brass | Mesh | 50 × 50 | No | Quick-Drain Ridges | 000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Style C

Spout | Filter | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Cap. | Top OD | Ht. | OD | Lg. | Permanence | Material | Strainer Type | Mesh Size | Autoclavable | Features | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Galvanized Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 1/4 gal. | 12 1/2" | 12" | 1 1/8" | 3 3/4" | Removable | Brass | Mesh | 50 × 50 | No | Quick-Drain Ridges, Vented Spout | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Style D

Spout | Filter | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Cap. | Top OD | Ht. | OD | Lg. | Permanence | Material | Strainer Type | Mesh Size | Autoclavable | Features | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Galvanized Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 gal. | 9 5/8" | 11 7/8" | 1 1/8" | 3 3/4" | Removable | Brass | Mesh | 50 × 50 | No | Quick-Drain Ridges, Spill-Resistant Rim, Vented Spout | 000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 gal. | 11 3/8" | 12 1/8" | 1 1/8" | 3 3/4" | Removable | Brass | Mesh | 50 × 50 | No | Quick-Drain Ridges, Spill-Resistant Rim, Vented Spout | 000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Style E

Spout | Filter | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Cap. | Top OD | Ht. | OD | Lg. | Permanence | Material | Strainer Type | Mesh Size | Autoclavable | Features | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Galvanized Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 gal. | 9 5/8" | 11 7/8" | 1 1/8" | 3 3/4" | Removable | Brass | Mesh | 50 × 50 | No | Quick-Drain Ridges, Spill-Resistant Rim, Stabilizing Ring, Vented Spout | 000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 gal. | 11 3/8" | 12 1/8" | 1 1/8" | 3 3/4" | Removable | Brass | Mesh | 50 × 50 | No | Quick-Drain Ridges, Spill-Resistant Rim, Stabilizing Ring, Vented Spout | 000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Style F

Spout | Filter | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Cap. | Top OD | Ht. | OD | Lg. | Permanence | Material | Strainer Type | Mesh Size | Autoclavable | Features | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Galvanized Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2 gal. | 10 5/8" | 11 5/8" | 1" | 3 3/4" | Removable | Brass | Mesh | 50 × 50 | No | Offset Spout | 000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Style G

Spout | Filter | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Cap. | Top OD | Ht. | OD | Lg. | Permanence | Material | Strainer Type | Mesh Size | Autoclavable | Features | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Galvanized Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 32 fl. oz. | 6 3/8" | 19" | 1/2" | 14" | Removable | Brass | Mesh | 40 × 60 | No | Flexible Spout | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 48 fl. oz. | 6" | 18" | 1/2" | 13 1/4" | Removable | Stainless Steel | Mesh | 40 × 40 | No | Flexible Spout | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 64 fl. oz. | 7" | 28" | 9/16" | 17" | Removable | Brass | Mesh | 50 × 50 | No | Flexible Spout | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Style H

Spout | Filter | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Cap. | Top OD | Ht. | OD | Lg. | Permanence | Material | Strainer Type | Filter Opening Size | Autoclavable | Features | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12 fl. oz. | 5" | 4 1/2" | 5/8" | 2 1/8" | Removable | Stainless Steel | Perforated | 0.079" | No | Vented Spout, Handle | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 20 fl. oz. | 5 3/4" | 4 7/8" | 5/8" | 2 1/8" | Removable | Stainless Steel | Perforated | 0.079" | No | Vented Spout, Handle | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Style J

Spout | Filter | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Cap. | Top OD | Ht. | OD | Lg. | Permanence | Material | Strainer Type | Filter Opening Size | Autoclavable | Features | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 17 fl. oz. | 5 5/8" | 2 5/8" | 2 1/4" | 1/2" | Removable | Silicone Rubber | Perforated | 0.098" | No | Handle | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

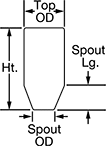

Sanitary Metal Hopper-Style Funnels

Funnels | Lids | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Spout | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Cap. | For Tube OD | Top OD | Ht. | OD | Lg. | Autoclavable | Each | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

304 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 16 fl. oz. | 1 1/2" | 4 3/8" | 5 7/8" | 1 1/2" | 1" | No | 00000000 | 0000000 | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 96 fl. oz. | 1 1/2" | 7 1/4" | 9 1/2" | 1 1/2" | 1" | No | 00000000 | 000000 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2 gal. | 1 1/2" | 10" | 10 1/8" | 1 1/2" | 1" | No | 00000000 | 000000 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 7/8 gal. | 1 1/2" | 13" | 17" | 1 1/2" | 1" | No | 00000000 | 000000 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 3/8 gal. | 1 1/2" | 15 1/8" | 17 5/8" | 1 1/2" | 1" | No | 00000000 | 000000 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7 1/4 gal. | 1 1/2" | 17 1/4" | 17 1/8" | 1 1/2" | 1" | No | 00000000 | 000000 | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 14 5/8 gal. | 1 1/2" | 21 1/4" | 21 7/8" | 1 1/2" | 1" | No | 00000000 | 000000 | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 33 gal. | 1 1/2" | 32" | 28 1/8" | 1 1/2" | 1" | No | 00000000 | 00000000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 51 gal. | 1 1/2" | 36" | 31 5/8" | 1 1/2" | 1" | No | 00000000 | 00000000 | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

316 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 16 fl. oz. | 1 1/2" | 4 3/8" | 5 7/8" | 1 1/2" | 1" | No | 0000000 | 00000000 | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 16 fl. oz. | 2" | 4 3/8" | 6" | 2" | 1 1/8" | No | 00000000 | 00000000 | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 96 fl. oz. | 1 1/2" | 7 1/4" | 9 1/2" | 1 1/2" | 1" | No | 00000000 | 00000000 | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 96 fl. oz. | 2" | 7 1/4" | 9 5/8" | 2" | 1 1/8" | No | 0000000 | 00000000 | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2 gal. | 1 1/2" | 10" | 10 1/8" | 1 1/2" | 1" | No | 00000000 | 00000000 | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2 gal. | 2" | 10" | 10 1/4" | 2" | 1 1/8" | No | 00000000 | 00000000 | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 7/8 gal. | 1 1/2" | 13" | 17" | 1 1/2" | 1" | No | 00000000 | 00000000 | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 7/8 gal. | 2" | 13" | 17 1/8" | 2" | 1 1/8" | No | 00000000 | 00000000 | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 3/8 gal. | 1 1/2" | 15 1/8" | 17 5/8" | 1 1/2" | 1" | No | 00000000 | 00000000 | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 3/8 gal. | 2" | 15 1/8" | 17 3/4" | 2" | 1 1/8" | No | 00000000 | 00000000 | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7 1/4 gal. | 1 1/2" | 17 1/4" | 17 1/8" | 1 1/2" | 1" | No | 00000000 | 00000000 | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7 1/4 gal. | 2" | 17 1/4" | 17 1/4" | 2" | 1 1/8" | No | 00000000 | 00000000 | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 14 5/8 gal. | 1 1/2" | 21 1/4" | 21 7/8" | 1 1/2" | 1" | No | 00000000 | 00000000 | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 14 5/8 gal. | 2" | 21 1/4" | 22" | 2" | 1 1/8" | No | 00000000 | 00000000 | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

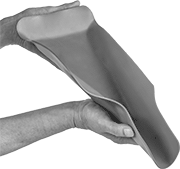

Moldable Rubber-Coated Aluminum Funnels

Style B

| |

B (Shown Flat) |

Spout | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Top OD | Ht. | OD | Lg. | Color | Autoclavable | Max. Temp., ° F | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Buna-N-Coated Aluminum | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5" | 29" | 5" | 29" | Green | Yes | 425 | 000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Plastic Funnels with Filter

|  |  |

Style A | Style B | Style C |

Style A

Spout | Filter | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Cap. | Top OD | Ht. | OD | Lg. | Color | Permanence | Material | Strainer Type | Filter Opening Size | Autoclavable | Max. Temp., ° F | Features | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

HDPE | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 19 fl. oz., 560 ml | 4 3/4" | 6" | 1/2" | 2" | Red | Permanent | Stainless Steel | Perforated | 0.0025" | No | 212 | Hanging Eyelet | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 64 fl. oz., 1,895 ml | 6 3/4" | 8 1/2" | 1 1/16" | 2 1/2" | Red | Permanent | Stainless Steel | Perforated | 0.0025" | No | 212 | Hanging Eyelet | 00000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 192 fl. oz., 5,680 ml | 8 1/2" | 10 1/2" | 1 5/16" | 1 1/2" | Red | Permanent | Stainless Steel | Perforated | 0.0025" | No | 212 | Hanging Eyelet | 00000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Style B

Spout | Filter | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Cap. | Top OD | Ht. | OD | Lg. | Color | Permanence | Material | Strainer Type | Mesh Size | Autoclavable | Max. Temp., ° F | Features | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Polyethylene | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 16 fl. oz., 475 ml | 4 3/4" | 20" | 5/8" | 15" | Red | Permanent | Brass | Mesh | 60 × 60 | No | 170 | Hanging Eyelet, Flexible Spout | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Style C

Spout | Filter | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Cap. | Top OD | Ht. | OD | Lg. | Color | Permanence | Material | Strainer Type | Filter Opening Size | Autoclavable | Max. Temp., ° F | Features | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Polyethylene | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 24 fl. oz., 710 ml | 6" | 6 1/2" | 5/8" | 2" | White | Removable | Stainless Steel | Perforated | 0.0059" | Yes | 212 | Hanging Eyelet, Splash Guard | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 144 fl. oz., 4,260 ml | 9 1/4" | 10 1/2" | 1 1/8" | 3 1/2" | White | Removable | Stainless Steel | Perforated | 0.0059" | Yes | 212 | Hanging Eyelet, Splash Guard | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Safety Pail Funnels

Flame Arrester | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Cap. | Top OD | Ht. | Color | Autoclavable | Ht. | Material | Certification | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Galvanized Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

2 NPT Male | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 32 fl. oz. | 4 1/2" | 4 1/2" | Red | No | 1" | Stainless Steel | FM Approved | 0000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Food and Beverage Metal Funnels

|  |

Hanging Eyelet |

Spout | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Cap. | Top OD | Ht. | OD | Lg. | Autoclavable | Food Industry Std. | Features | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

304 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8 fl. oz., 20 ml | 2 1/8" | 2 1/2" | 1/4" | 1 1/8" | No | NSF/ANSI 2 | — | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 3/8 fl. oz., 100 ml | 3 11/16" | 4 3/4" | 1/2" | 2 1/4" | No | NSF/ANSI 2 | Hanging Eyelet | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8 1/2 fl. oz., 250 ml | 5" | 5 1/4" | 1/2" | 1 5/8" | No | NSF/ANSI 2 | Hanging Eyelet | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 13 1/2 fl. oz., 400 ml | 5 15/16" | 6 1/2" | 7/8" | 1 1/2" | No | NSF/ANSI 2 | Hanging Eyelet | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 33 1/2 fl. oz., 1,000 ml | 8 1/4" | 7 7/8" | 7/8" | 2 3/4" | No | NSF/ANSI 2 | Hanging Eyelet | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 68 fl. oz., 2,000 ml | 10" | 9" | 7/8" | 2 3/4" | No | NSF/ANSI 2 | Hanging Eyelet | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

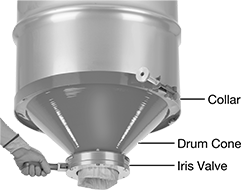

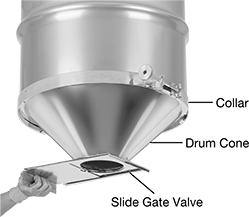

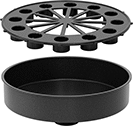

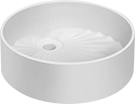

Drum Cones

|  |

Drum Cone Shown Installed with Collar and Iris Valve | Drum Cone Shown Installed with Collar and Slide Gate Valve |

|

Safety Drum Funnels

|  |  |  |

Style A | Style B | Style C | Style D |

Threaded Funnels for Closed-Head Drums

Spout | Flame Arrester | ||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Style | Cap., gal. | Top OD | Ht. | Pipe Size | Thread Type | Gender | OD | Lg. | Material | Color | Ht. | Material | Lock Type | For Max. Shackle Dia. | Max. Temp., ° F | Certification | Features | Includes | Each | ||

| A | 2 1/2 | 10 3/4" | 10" | 2 | NPT | Male | 2" | 6" | Galvanized Steel | Red | 6" | Brass | Padlockable | 5/16" | 165 | FM Approved | Self-Closing Lid | — | 0000000 | 0000000 | |

| B | 2 1/2 | 10 3/4" | 10" | 2 | NPT | Male | 2" | 6" | Galvanized Steel | Red | 6" | Brass | Padlockable | 5/16" | 165 | FM Approved | Self-Closing Lid, Ball Valve | Pressure-Relief Vent | 00000000 | 00000000 | |

| C | 2 1/2 | 10 3/4" | 10" | 2 | NPT | Male | 2" | 32" | Galvanized Steel | Red | 32" | Brass | Padlockable | 5/16" | 165 | FM Approved | Self-Closing Lid | — | 0000000 | 000000 | |

Floor Drain Funnels

Funneling Scoops

Bowl | Spout | Handles | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Wd. | Lg. | Wd. | Lg. | No. of | Lg. | Material | Material | Autoclavable | Food Industry Std. | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Flat Scoop Bottom | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8 1/4" | 8 1/4" | 4" | 4" | 2 | 4" | Plastic | 304 Stainless Steel | No | NSF/ANSI 2 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Drum Funnels

|  |  |

Style B (Drain Top Sold Separately) | Style C | Style E |

Threaded Funnels for Closed-Head Drums

Funnels | Drain Tops | |||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Spout | Filter | |||||||||||||||||||

Style | Cap., gal. | Top OD | Ht. | Pipe Size | Thread Type | Gender | OD | Lg. | Permanence | Material | Material | Color | Lock Type | For Max. Shackle Dia. | Max. Temp., ° F | Each | Each | |||

| B | 1 | 11 3/8" | 4 3/8" | 2 | NPT | Male | 2 1/2" | 1 1/2" | Permanent | Stainless Steel | Polypropylene | Black | — | — | 250 | 000000000 | 000000 | 000000000 | 000000 | |

| C | 1 | 9 1/8" | 8 1/2" | 2 | NPT | Male | 2" | 1 3/8" | Removable | Stainless Steel | Polypropylene | Red | Padlockable | 3/8" | 250 | 000000000 | 00000 | ——— | 0 | |