About Hex Head Screws and Bolts

More

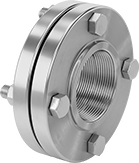

Stainless Steel Hex Screw and Nut Kits for Pipe Flanges

Shown Installed |  Stainless Steel |

Stainless Steel with Blue PTFE-Coated Nuts |

Join standard-sized stainless steel and aluminum pipe flanges in corrosive conditions. These kits come with the right size and number of screws and nuts for the bolt holes in each pipe size. For a tight seal, you’ll also need a gasket between the flanges. All screws and nuts meet ASTM and ASME standards or DIN standards for material quality and dimensions. They may be mildly magnetic. Screw length is measured from under the head.

18-8 stainless steel fasteners resist corrosion from mild chemicals and water. They are ideal for wet environments.

316 stainless steel fasteners are more corrosion resistant than 18-8 stainless steel fasteners and have excellent resistance to chemicals and salt water.

Kits with blue PTFE-coated nuts thread together with the screws smoothly thanks to the slippery coating on the nut. The coating also resists chemicals, so it doesn't compromise their corrosion resistance.

Screw | Nut | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| For Pipe Size | Lg. | Min. Thread Lg. | Head Wd. | Head Ht. | Tensile Strength, psi | Wd. | Ht. | No. of Screws Included | No. of Nuts Included | Each | |

18-8 Stainless Steel | |||||||||||

3/4"-10 | |||||||||||

| 8 | 3 1/2" | 1 3/4" | 1 1/8" | 1/2" | 80,000 | 1 1/8" | 41/64" | 8 | 8 | 000000000 | 000000 |

316 Stainless Steel | |||||||||||

3/4"-10 | |||||||||||

| 8 | 3 1/2" | 1 3/4" | 1 1/8" | 1/2" | 80,000 | 1 1/8" | 41/64" | 8 | 8 | 000000000 | 00000 |

316 Stainless Steel with Blue PTFE-Coated Nuts | |||||||||||

3/4"-10 | |||||||||||

| 8 | 3 1/2" | 1 3/4" | 1 1/8" | 1/2" | 80,000 | 1 1/8" | 41/64" | 8 | 8 | 000000000 | 00000 |

Screw | Nut | 18-8 Stainless Steel | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| For Pipe Size | Lg. | Min. Thread Lg. | Head Wd. | Head Ht. | Tensile Strength, psi | Wd. | Ht. | No. of Screws Included | No. of Nuts Included | Each | |

7/8"-9 | |||||||||||

| 8 | 4 1/2" | 2" | 1 5/16" | 37/64" | 80,000 | 1 5/16" | 3/4" | 12 | 12 | 000000000 | 0000000 |

Stainless Steel Heavy Hex Screw and Nut Kits for Pipe Flanges

Connect standard-size stainless steel or aluminum pipe flanges with these kits—they come with screws and nuts in the right size and number to match the bolt holes. The screw heads and nuts are 10% wider than standard hex fasteners, so they spread force over a larger area, and you can tighten with more torque. Made from 316 stainless steel, the fasteners in these kits have excellent resistance to chemicals and salt water. They may also be mildly magnetic. For a complete connection, you’ll also need a gasket. Screw length is measured from under the head.

All screws and nuts meet ASTM A193 or A194 standards for high-pressure and high-temperature applications. They also meet ASME B18.2.1 standards for dimensions.

Screw | Nut | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| For Pipe Size | Lg. | Min. Thread Lg. | Head Wd. | Head Ht. | Tensile Strength, psi | Wd. | Ht. | No. of Screws Included | No. of Nuts Included | Each | |

ASTM Grade B8M 316 Stainless Steel for Class 125/150 Pipe Flanges | |||||||||||

3/4"-10 | |||||||||||

| 8 | 3 1/2" | 1 3/4" | 1 1/4" | 1/2" | 75,000 | 1 1/4" | 47/64" | 8 | 8 | 000000000 | 000000 |

Steel Hex Screw and Nut Kits for Pipe Flanges

Connect standard-sized steel and cast iron pipe flanges. These kits come with the right size and number of screws and nuts for the bolt holes in each pipe size. For a tight seal, you’ll also need a gasket between the flanges. All screws and nuts meet ASTM and ASME standards or DIN standards for material quality and dimensions. Screw length is measured from under the head.

Zinc-plated fasteners resist corrosion in wet environments.

Hot-dipped galvanized fasteners are 10 times more corrosion resistant than zinc-plated fasteners.

Hex Head Screw, Nut, and Washer Kits for Plastic Pipe Flanges

Use these kits to connect plastic pipe flanges—they’re sized for Class 150 flanges made to ASME B16.5 dimensions. They come with screws, nuts, and washers that match the size and number of bolt holes for each pipe size. For a complete connection, you’ll also need a gasket. All screws and nuts meet ASTM specifications for material quality and ASME specifications for dimensions. Washers distribute the pressure from a tightened nut over the surface of the flange, which helps prevent damage. Screw length is measured from under the head.

Zinc-plated steel fasteners resist corrosion in wet environments.

18-8 stainless steel fasteners are more corrosion resistant than zinc-plated steel fasteners and ideal for wet and outdoor environments. They have good chemical resistance and may be mildly magnetic.

Screw | Nut | Washer | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Pipe Size | Lg. | Min. Thread Lg. | Head Wd. | Head Ht. | Tensile Strength, psi | Wd. | Ht. | ID | OD | Thick. | No. of Screws Included | No. of Nuts Included | No. of Washers Included | Each | |

Zinc-Plated Steel for Class 150 Plastic Flanges | |||||||||||||||

3/4"-10 | |||||||||||||||

| 8 | 4 1/2" | 1 3/4" | 1 1/8" | 15/32" | 60,000 | 1 1/8" | 21/32" | 0.812" | 2" | 0.156" | 8 | 8 | 16 | 000000000 | 000000 |

18-8 Stainless Steel for Class 150 Plastic Flanges | |||||||||||||||

3/4"-10 | |||||||||||||||

| 8 | 4 1/2" | 1 3/4" | 1 1/8" | 15/32" | 85,000 | 1 1/8" | 21/32" | 0.812" | 1 7/8" | 0.109" | 8 | 8 | 16 | 000000000 | 00000 |