About Track Rollers

Also known as cam followers, track rollers have a thick outer roller that runs directly on a flat surface.

More

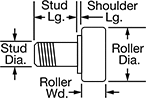

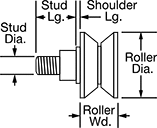

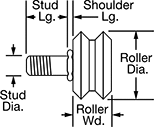

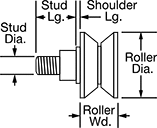

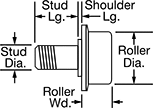

Threaded Track Rollers

Also known as cam followers, track rollers support loads while guiding and positioning work. Thread the stud directly into a component or secure with a nut for through-hole mounting.

Crowned rollers have a slight curve, which is invisible to the naked eye, to stay centered on surfaces that are not perfectly aligned and/or not perfectly flat.

Rollers with seal have end seals to protect rolling elements from dirt and contamination.

Track lubricators reduce friction and wear without shutting down equipment. Oil-infused resin distributes lubricant onto rollers, which transfer it to your track.

Track Rollers | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Roller, mm | Stud, mm | Thread | Shoulder, mm | Radial Load Cap., lbs. | Roller-Mount Track Lubricators | |||||||||||||

| Dia. | Wd. | Dia. | Lg. | Size | Pitch, mm | Lg., mm | Dia. | Lg. | Max. Speed, rpm | Static | Dynamic | Max. Temp., °F | Bearing Type | Includes | Each | Each | ||

Black-Oxide Steel Flat Rollers without Seal | ||||||||||||||||||

| 13 | 9 | 5 | 13 | M5 | 0.8 | 7.5 | 9 | 0.6 | 20,000 | 350 | 450 | 250° | Needle Roller | __ | 00000000 | 000000 | 0000000 | 000000 |

| 16 | 11 | 6 | 16 | M6 | 1 | 9 | 11 | 0.6 | 19,500 | 500 | 750 | 250° | Needle Roller | __ | 00000000 | 000000 | 0000000 | 00000 |

| 19 | 11 | 8 | 20 | M8 | 1.25 | 11 | 13 | 0.6 | 10,500 | 1,100 | 1,500 | 250° | Needle Roller | __ | 00000000 | 000000 | 0000000 | 00000 |

| 22 | 12 | 10 | 23 | M10 | 1 | 12 | 15 | 0.6 | 9,000 | 2,300 | 1,700 | 250° | Needle Roller | __ | 00000000 | 000000 | 0000000 | 00000 |

| 26 | 12 | 10 | 23 | M10 | 1 | 12 | 15 | 0.6 | 9,000 | 2,300 | 1,700 | 250° | Needle Roller | __ | 00000000 | 000000 | 0000000 | 00000 |

| 30 | 14 | 12 | 25 | M12 | 1.5 | 14 | 19 | 0.6 | 9,600 | 1,800 | 1,500 | 250° | Needle Roller | __ | 00000000 | 000000 | 0000000 | 00000 |

| 35 | 18 | 16 | 32.5 | M16 | 1.5 | 18 | 24 | 0.8 | 6,300 | 3,500 | 2,400 | 250° | Needle Roller | __ | 00000000 | 000000 | 000000 | 00 |

| 47 | 24 | 20 | 40.5 | M20 | 1.5 | 21 | 30 | 0.8 | 3,900 | 6,700 | 3,900 | 250° | Needle Roller | __ | 00000000 | 000000 | 000000 | 00 |

| 90 | 35 | 30 | 63 | M30 | 1.5 | 32 | 68 | 1 | 2,200 | 19,000 | 10,000 | 250° | Needle Roller | __ | 00000000 | 000000 | 000000 | 00 |

Black-Oxide Steel Flat Rollers with Seal | ||||||||||||||||||

| 13 | 9 | 5 | 13 | M5 | 0.8 | 7.5 | 9 | 0.6 | 20,000 | 350 | 450 | 250° | Needle Roller | __ | 00000000 | 00000 | 0000000 | 00000 |

| 16 | 11 | 6 | 16 | M6 | 1 | 9 | 11 | 0.6 | 19,500 | 500 | 750 | 250° | Needle Roller | __ | 00000000 | 00000 | 0000000 | 00000 |

| 19 | 11 | 8 | 20 | M8 | 1.25 | 11 | 13 | 0.6 | 10,500 | 1,100 | 1,500 | 250° | Needle Roller | __ | 00000000 | 000000 | 0000000 | 00000 |

| 22 | 12 | 10 | 23 | M10 | 1 | 12 | 15 | 0.6 | 9,000 | 2,300 | 1,700 | 250° | Needle Roller | __ | 00000000 | 000000 | 0000000 | 00000 |

| 26 | 12 | 10 | 23 | M10 | 1 | 12 | 15 | 0.6 | 9,000 | 2,300 | 1,700 | 250° | Needle Roller | __ | 00000000 | 000000 | 0000000 | 00000 |

| 30 | 14 | 12 | 25 | M12 | 1.5 | 14 | 19 | 0.6 | 6,400 | 3,400 | 2,400 | 250° | Needle Roller | __ | 00000000 | 000000 | 0000000 | 00000 |

| 32 | 14 | 12 | 25 | M12 | 1.5 | 14 | 21 | 0.6 | 9,600 | 1,800 | 1,500 | 250° | Needle Roller | __ | 00000000 | 000000 | 000000 | 00 |

| 35 | 18 | 16 | 32.5 | M16 | 1.5 | 18 | 24 | 0.8 | 6,300 | 3,500 | 2,400 | 250° | Needle Roller | __ | 00000000 | 000000 | 000000 | 00 |

| 40 | 20 | 18 | 36.5 | M18 | 1.5 | 19 | 27 | 0.8 | 3,300 | 7,200 | 4,300 | 250° | Needle Roller | __ | 00000000 | 000000 | 000000 | 00 |

| 47 | 24 | 20 | 40.5 | M20 | 1.5 | 21 | 30 | 0.8 | 2,600 | 10,000 | 5,700 | 250° | Needle Roller | __ | 00000000 | 000000 | 000000 | 00 |

| 52 | 24 | 20 | 40.5 | M20 | 1.5 | 21 | 36 | 0.8 | 2,600 | 10,000 | 5,700 | 250° | Needle Roller | __ | 00000000 | 000000 | 000000 | 00 |

| 72 | 29 | 24 | 49.5 | M24 | 1.5 | 25 | 63 | 0.8 | 3,100 | 10,000 | 5,900 | 250° | Needle Roller | __ | 00000000 | 000000 | 000000 | 00 |

| 80 | 35 | 30 | 63 | M30 | 1.5 | 32 | 63 | 1 | 2,200 | 22,000 | 14,000 | 250° | Needle Roller | __ | 00000000 | 000000 | 000000 | 00 |

Black-Oxide Steel Crowned Rollers without Seal | ||||||||||||||||||

| 13 | 9 | 5 | 13 | M5 | 0.8 | 7.5 | 9 | 0.6 | 20,000 | 350 | 450 | 250° | Needle Roller | __ | 00000000 | 00000 | 0000000 | 00000 |

| 22 | 12 | 10 | 23 | M10 | 1.25 | 13 | 15 | 0.6 | 13,500 | 1,300 | 1,100 | 250° | Needle Roller | __ | 00000000 | 000000 | 0000000 | 00000 |

| 26 | 12 | 10 | 23 | M10 | 1 | 12 | 15 | 0.6 | 9,000 | 2,300 | 1,700 | 250° | Needle Roller | __ | 00000000 | 000000 | 0000000 | 00000 |

| 30 | 14 | 12 | 25 | M12 | 1.5 | 14 | 19 | 0.6 | 9,600 | 1,800 | 1,500 | 250° | Needle Roller | __ | 00000000 | 000000 | 0000000 | 00000 |

| 32 | 14 | 12 | 25 | M12 | 1.5 | 14 | 21 | 0.6 | 6,400 | 3,400 | 2,400 | 250° | Needle Roller | __ | 00000000 | 000000 | 000000 | 00 |

| 35 | 18 | 16 | 32.5 | M16 | 1.5 | 18 | 24 | 0.8 | 4,200 | 6,400 | 3,800 | 250° | Needle Roller | __ | 00000000 | 000000 | 000000 | 00 |

| 72 | 29 | 24 | 49.5 | M24 | 1.5 | 25 | 63 | 0.8 | 2,100 | 14,000 | 8,700 | 250° | Needle Roller | __ | 00000000 | 000000 | 000000 | 00 |

| 80 | 35 | 30 | 63 | M30 | 1.5 | 32 | 63 | 1 | 1,500 | 22,000 | 14,000 | 250° | Needle Roller | __ | 00000000 | 000000 | 000000 | 00 |

Black-Oxide Steel Crowned Rollers with Seal | ||||||||||||||||||

| 13 | 9 | 5 | 13 | M5 | 0.8 | 7.5 | 9 | 0.6 | 20,000 | 350 | 450 | 250° | Needle Roller | __ | 00000000 | 00000 | 0000000 | 00000 |

| 16 | 11 | 6 | 16 | M6 | 1 | 9 | 11 | 0.6 | 13,000 | 500 | 1,300 | 250° | Needle Roller | __ | 00000000 | 000000 | 0000000 | 00000 |

| 19 | 11 | 8 | 20 | M8 | 1.25 | 11 | 13 | 0.6 | 10,500 | 1,100 | 1,500 | 250° | Needle Roller | __ | 00000000 | 000000 | 0000000 | 00000 |

| 22 | 12 | 10 | 23 | M10 | 1 | 12 | 15 | 0.6 | 9,000 | 2,300 | 1,700 | 250° | Needle Roller | __ | 00000000 | 000000 | 0000000 | 00000 |

| 26 | 12 | 10 | 23 | M10 | 1 | 12 | 15 | 0.6 | 9,000 | 2,300 | 1,700 | 250° | Needle Roller | __ | 00000000 | 000000 | 0000000 | 00000 |

| 30 | 14 | 12 | 25 | M12 | 1.5 | 14 | 19 | 0.6 | 6,400 | 3,400 | 2,400 | 250° | Needle Roller | __ | 00000000 | 000000 | 0000000 | 00000 |

| 32 | 14 | 12 | 25 | M12 | 1.5 | 14 | 21 | 0.6 | 6,400 | 3,400 | 2,400 | 250° | Needle Roller | __ | 00000000 | 000000 | 000000 | 00 |

| 35 | 18 | 16 | 32.5 | M16 | 1.5 | 18 | 24 | 0.8 | 4,200 | 6,400 | 3,800 | 250° | Needle Roller | __ | 00000000 | 000000 | 000000 | 00 |

| 40 | 20 | 18 | 36.5 | M18 | 1.5 | 19 | 27 | 0.8 | 3,300 | 7,200 | 4,300 | 250° | Needle Roller | __ | 00000000 | 000000 | 000000 | 00 |

| 47 | 24 | 20 | 40.5 | M20 | 1.5 | 21 | 30 | 0.8 | 2,600 | 10,000 | 5,700 | 250° | Needle Roller | __ | 00000000 | 000000 | 000000 | 00 |

| 52 | 24 | 20 | 40.5 | M20 | 1.5 | 21 | 36 | 0.8 | 2,600 | 10,000 | 5,700 | 250° | Needle Roller | __ | 00000000 | 000000 | 000000 | 00 |

| 62 | 29 | 24 | 49.5 | M24 | 1.5 | 25 | 44 | 0.8 | 2,100 | 14,000 | 8,700 | 250° | Needle Roller | __ | 00000000 | 000000 | 000000 | 00 |

| 72 | 29 | 24 | 49.5 | M24 | 1.5 | 25 | 63 | 0.8 | 2,100 | 14,000 | 8,700 | 250° | Needle Roller | __ | 00000000 | 000000 | 000000 | 00 |

| 80 | 35 | 30 | 63 | M30 | 1.5 | 32 | 63 | 1 | 2,200 | 22,000 | 14,000 | 250° | Needle Roller | __ | 00000000 | 000000 | 000000 | 00 |

Steel Flat Rollers without Seal | ||||||||||||||||||

| 12 | 8 | 4 | 11 | M4 | 0.7 | 6 | 9 | 0.5 | 10,000 | 860 | 850 | 245° | Needle Roller | Mounting Hardware | 0000000 | 00000 | 000000 | 00 |

| 13 | 9 | 5 | 13 | M5 | 0.8 | 7.5 | 10 | 0.5 | 8,000 | 1,200 | 1,000 | 245° | Needle Roller | Mounting Hardware | 0000000 | 00000 | 0000000 | 00000 |

| 16 | 11 | 6 | 16 | M6 | 1 | 8 | 12 | 0.6 | 7,000 | 1,900 | 1,500 | 245° | Needle Roller | Mounting Hardware | 0000000 | 00000 | 0000000 | 00000 |

| 19 | 11 | 8 | 20 | M8 | 1.25 | 10 | 14 | 0.6 | 5,000 | 2,500 | 1,800 | 245° | Needle Roller | Mounting Hardware | 0000000 | 00000 | 0000000 | 00000 |

| 22 | 12 | 10 | 23 | M10 | 1.25 | 12 | 17 | 0.6 | 8,000 | 1,500 | 1,200 | 245° | Needle Roller | Mounting Hardware | 0000000 | 00000 | 0000000 | 00000 |

| 26 | 12 | 10 | 23 | M10 | 1.25 | 12 | 17 | 0.6 | 8,000 | 1,500 | 1,200 | 245° | Needle Roller | Mounting Hardware | 0000000 | 00000 | 0000000 | 00000 |

| 30 | 14 | 12 | 25 | M12 | 1.5 | 13 | 22 | 0.6 | 3,400 | 4,400 | 3,000 | 245° | Needle Roller | Mounting Hardware | 0000000 | 00000 | 0000000 | 00000 |

Steel Flat Rollers with Seal | ||||||||||||||||||

| 10 | 7 | 3 | 9 | M3 | 0.5 | 5 | 7 | 0.5 | 14,000 | 500 | 550 | 175° | Needle Roller | Mounting Hardware | 0000000 | 00000 | 000000 | 00 |

| 12 | 8 | 4 | 11 | M4 | 0.7 | 6 | 9 | 0.5 | 10,000 | 860 | 850 | 175° | Needle Roller | Mounting Hardware | 0000000 | 00000 | 000000 | 00 |

| 13 | 9 | 5 | 13 | M5 | 0.8 | 7.5 | 10 | 0.5 | 8,000 | 1,200 | 1,000 | 175° | Needle Roller | Mounting Hardware | 0000000 | 00000 | 0000000 | 00000 |

| 16 | 11 | 6 | 16 | M6 | 1 | 8 | 12 | 0.6 | 7,000 | 1,900 | 1,500 | 175° | Needle Roller | Mounting Hardware | 0000000 | 00000 | 0000000 | 00000 |

| 19 | 11 | 8 | 20 | M8 | 1.25 | 10 | 13 | 0.6 | 5,000 | 2,500 | 1,800 | 175° | Needle Roller | Mounting Hardware | 0000000 | 00000 | 0000000 | 00000 |

| 22 | 12 | 10 | 23 | M10 | 1.25 | 12 | 17 | 0.6 | 8,000 | 1,500 | 1,200 | 175° | Needle Roller | Mounting Hardware | 0000000 | 00000 | 0000000 | 00000 |

| 26 | 12 | 10 | 23 | M10 | 1.25 | 12 | 17 | 0.6 | 8,000 | 1,500 | 1,200 | 175° | Needle Roller | Mounting Hardware | 0000000 | 00000 | 0000000 | 00000 |

| 30 | 14 | 12 | 25 | M12 | 1.5 | 13 | 22 | 0.6 | 3,400 | 4,400 | 3,000 | 175° | Needle Roller | Mounting Hardware | 0000000 | 00000 | 0000000 | 00000 |

Maintenance-Free Threaded Track Rollers

Because they never need to be relubricated, these rollers are a good choice for hard-to-reach places. Also known as cam followers, track rollers support loads while guiding and positioning work. Thread the stud directly into a component or secure with a nut for through-hole mounting. Some rollers have end seals to block dirt and contamination.

Crowned rollers have a slight curve, which is invisible to the naked eye, to stay centered on surfaces that are not perfectly aligned and/or not perfectly flat.

Track lubricators reduce friction and wear without shutting down equipment. Oil-infused resin distributes lubricant onto rollers, which transfer it to your track.

Track Rollers | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Roller, mm | Stud, mm | Thread | Radial Load Cap., lbs. | Roller-Mount Track Lubricators | |||||||||||||

| Dia. | Wd. | Dia. | Lg. | Size | Pitch, mm | Lg., mm | Shoulder Lg., mm | Max. Speed, rpm | Static | Dynamic | Max. Temp., °F | Bearing Type | Includes | Each | Each | ||

Steel Crowned Rollers with Seal | |||||||||||||||||

| 13 | 9 | 5 | 13 | M5 | 0.8 | 7 | 0.5 | 2,000 | 480 | 560 | 175° | Needle Roller | Mounting Hardware | 00000000 | 0000000 | 0000000 | 000000 |

| 16 | 11 | 6 | 16 | M6 | 1 | 8 | 0.6 | 1,600 | 820 | 800 | 175° | Needle Roller | Mounting Hardware | 000000 | 000000 | 0000000 | 00000 |

| 19 | 11 | 8 | 20 | M8 | 1.25 | 10 | 0.6 | 1,200 | 1,000 | 950 | 175° | Needle Roller | Mounting Hardware | 000000 | 000000 | 0000000 | 00000 |

| 22 | 12 | 10 | 23 | M10 | 1.25 | 12 | 0.6 | 1,000 | 1,500 | 1,200 | 175° | Needle Roller | Mounting Hardware | 000000 | 000000 | 0000000 | 00000 |

| 26 | 12 | 10 | 23 | M10 | 1.25 | 12 | 0.6 | 1,000 | 1,500 | 1,200 | 175° | Needle Roller | Mounting Hardware | 000000 | 000000 | 0000000 | 00000 |

| 30 | 14 | 12 | 25 | M12 | 1.5 | 13 | 0.6 | 800 | 2,200 | 1,700 | 175° | Needle Roller | Mounting Hardware | 000000 | 000000 | 0000000 | 00000 |

| 32 | 14 | 12 | 25 | M12 | 1.5 | 13 | 0.6 | 800 | 2,200 | 1,700 | 175° | Needle Roller | Mounting Hardware | 000000 | 000000 | 000000 | 00 |

| 35 | 18 | 16 | 32 | M16 | 1.5 | 17 | 0.8 | 620 | 4,100 | 2,600 | 175° | Needle Roller | Mounting Hardware | 00000000 | 000000 | 000000 | 00 |

| 40 | 20 | 18 | 36 | M18 | 1.5 | 19 | 0.8 | 550 | 5,600 | 3,300 | 175° | Needle Roller | Mounting Hardware | 00000000 | 000000 | 000000 | 00 |

| 47 | 24 | 20 | 40 | M20 | 1.5 | 21 | 0.8 | 500 | 7,700 | 4,600 | 175° | Needle Roller | Mounting Hardware | 00000000 | 000000 | 000000 | 00 |

| 52 | 24 | 20 | 40 | M20 | 1.5 | 21 | 0.8 | 500 | 7,700 | 4,600 | 175° | Needle Roller | Mounting Hardware | 00000000 | 000000 | 000000 | 00 |

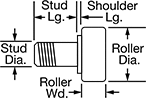

Threaded Track Rollers with Adjustable Shoulder

Also known as eccentric track rollers, the shoulder adjusts up or down to align to your track, enabling uniform alignment among rollers in a system. Secure the stud with a nut for through-hole mounting. All rollers have end seals to protect rolling elements from dirt and contamination.

Crowned rollers have a slight curve, which is invisible to the naked eye, to stay centered on surfaces that are not perfectly aligned and/or not perfectly flat.

Roller, mm | Stud, mm | Thread | Shoulder, mm | Radial Load Cap., lbs. | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Dia. | Wd. | Dia. | Lg. | Size | Pitch, mm | Lg., mm | Dia. | Lg. | Ht. Adjustment Capability, mm | Max. Speed, rpm | Static | Dynamic | Max. Temp., °F | Bearing Type | Includes | Each | |

Steel Flat Rollers with Seal | |||||||||||||||||

| 16 | 11 | 6 | 16 | M6 | 1 | 9 | 9 | 7 | 0.5 | 13,000 | 520 | 1,300 | 250° | Needle Roller | Mounting Hardware | 0000000 | 0000000 |

| 19 | 11 | 8 | 20 | M8 | 1.25 | 11 | 11 | 9 | 0.5 | 10,000 | 1,100 | 1,500 | 250° | Needle Roller | Mounting Hardware | 0000000 | 000000 |

| 22 | 12 | 10 | 23 | M10 | 1 | 12 | 13 | 10 | 0.5 | 9,000 | 2,300 | 1,700 | 250° | Needle Roller | Mounting Hardware | 0000000 | 000000 |

| 26 | 12 | 10 | 23 | M10 | 1 | 12 | 13 | 10 | 0.5 | 9,000 | 2,300 | 1,700 | 250° | Needle Roller | Mounting Hardware | 0000000 | 000000 |

Steel Crowned Rollers with Seal | |||||||||||||||||

| 16 | 11 | 6 | 16 | M6 | 1 | 9 | 9 | 7 | 0.5 | 13,000 | 520 | 1,300 | 250° | Needle Roller | Mounting Hardware | 0000000 | 000000 |

| 19 | 11 | 8 | 20 | M8 | 1.25 | 11 | 11 | 9 | 0.5 | 10,000 | 1,100 | 1,500 | 250° | Needle Roller | Mounting Hardware | 0000000 | 000000 |

| 26 | 12 | 10 | 23 | M10 | 1.25 | 13 | 13 | 10 | 0.5 | 9,000 | 2,300 | 1,700 | 250° | Needle Roller | Mounting Hardware | 0000000 | 000000 |

Miniature High-Speed Threaded Track Rollers

Built to handle high speeds for their size. These track rollers have an outer ring that supports higher speeds than standard-sized track rollers. They also create less friction than miniature high-load rollers while spinning. You can use these rollers for precise movements in robots or other miniature applications.

Roller, mm | Stud, mm | Thread | Shoulder, mm | Radial Load Cap., lbs. | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Dia. | Wd. | Dia. | Lg. | Size | Pitch, mm | Lg., mm | Dia. | Lg. | Max. Speed, rpm | Static | Dynamic | Max. Temp., °F | Bearing Type | Includes | Each | |

Steel Flat Rollers without Seal | ||||||||||||||||

| 5 | 3 | 2.5 | 5 | M2.5 | 0.45 | 2.5 | 4.8 | 0.7 | 33,600 | 75 | 95 | 245° | Needle Roller | Nut | 0000000 | 0000000 |

| 6 | 4 | 3 | 6 | M3 | 0.5 | 3 | 5.8 | 0.7 | 28,000 | 130 | 140 | 245° | Needle Roller | Nut | 0000000 | 000000 |

| 8 | 5 | 4 | 8 | M4 | 0.7 | 4 | 7.7 | 1 | 21,000 | 250 | 250 | 245° | Needle Roller | Nut | 0000000 | 000000 |

440C Stainless Steel Flat Rollers without Seal | ||||||||||||||||

| 4.5 | 2.5 | 2 | 4 | M2 | 0.4 | 2 | 4.3 | 0.7 | 42,000 | 35 | 50 | 230° | Needle Roller | Nut | 0000000 | 000000 |

| 5 | 3 | 2.5 | 5 | M2.5 | 0.45 | 2.5 | 4.8 | 0.7 | 33,600 | 60 | 75 | 245° | Needle Roller | Nut | 0000000 | 000000 |

| 6 | 4 | 3 | 6 | M3 | 0.5 | 3 | 5.8 | 0.7 | 28,000 | 100 | 110 | 245° | Needle Roller | Nut | 0000000 | 000000 |

| 8 | 5 | 4 | 8 | M4 | 0.7 | 4 | 7.7 | 1 | 21,000 | 200 | 200 | 245° | Needle Roller | Nut | 0000000 | 000000 |

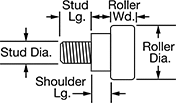

Shaft-Mount Track Rollers

Also known as yoke-style cam followers, these rollers have more mounting flexibility than threaded track rollers. They're typically mounted onto a shaft or clevis rod end. Lubricate rollers through a hole and groove in the inner ring.

Crowned rollers have a slight curve, which is invisible to the naked eye, to stay centered on surfaces that are not perfectly aligned and/or not perfectly flat.

Rollers with seal have end seals to protect rolling elements from dirt and contamination.

Roller, mm | Radial Load Cap., lbs. | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Dia. | Wd. | For Shaft Dia., mm | Overall Wd., mm | Max. Speed, rpm | Static | Dynamic | Max. Temp., °F | Bearing Type | ID | ID Tolerance | Each | |

Black-Oxide Steel Crowned Rollers with Seal | ||||||||||||

| 16 | 11 | 5 | 12 | 14,000 | 750 | 700 | 210° | Needle Roller | 5mm | -0.008mm to 0mm | 0000000 | 000000 |

| 19 | 11 | 6 | 12 | 11,000 | 900 | 750 | 210° | Needle Roller | 6mm | -0.008mm to 0mm | 0000000 | 00000 |

| 24 | 14 | 8 | 15 | 7,500 | 1,500 | 1,200 | 210° | Needle Roller | 8mm | -0.008mm to 0mm | 0000000 | 00000 |

| 30 | 14 | 10 | 15 | 5,500 | 1,900 | 1,500 | 210° | Needle Roller | 10mm | -0.008mm to 0mm | 0000000 | 00000 |

| 32 | 14 | 12 | 15 | 4,500 | 2,000 | 1,500 | 210° | Needle Roller | 12mm | -0.008mm to 0mm | 0000000 | 00000 |

| 35 | 18 | 15 | 19 | 3,600 | 3,200 | 2,100 | 210° | Needle Roller | 15mm | -0.008mm to 0mm | 0000000 | 00000 |

| 40 | 20 | 17 | 21 | 2,900 | 3,500 | 2,400 | 210° | Needle Roller | 17mm | -0.008mm to 0mm | 0000000 | 00000 |

| 47 | 24 | 20 | 25 | 2,400 | 5,800 | 3,400 | 210° | Needle Roller | 20mm | -0.008mm to 0mm | 0000000 | 00000 |

| 52 | 24 | 25 | 25 | 1,800 | 6,000 | 3,400 | 210° | Needle Roller | 25mm | -0.008mm to 0mm | 0000000 | 000000 |

| 62 | 28 | 30 | 29 | 1,300 | 8,800 | 5,200 | 210° | Needle Roller | 30mm | -0.008mm to 0mm | 0000000 | 000000 |

| 80 | 30 | 40 | 32 | 850 | 13,200 | 7,100 | 210° | Needle Roller | 40mm | -0.008mm to 0mm | 0000000 | 000000 |

High-Load Shaft-Mount Track Rollers

With a double row of cylindrical roller bearings, these rollers provide the highest combination of speed and dynamic radial load ratings of any shaft-mount track roller we offer. Also known as yoke-style cam followers, these rollers have more mounting flexibility than threaded track rollers. They're typically mounted onto a shaft or clevis rod end.

Crowned rollers have a slight curve, which is invisible to the naked eye, to stay centered on surfaces that are not perfectly aligned and/or not perfectly flat.

Lubricate rollers without seal through a hole and groove in the inner ring.

Roller, mm | Radial Load Cap., lbs. | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Dia. | Wd. | For Shaft Dia., mm | Overall Wd., mm | Max. Speed, rpm | Static | Dynamic | Max. Temp., °F | Bearing Type | Each | |

Steel Flat Rollers without Seal | ||||||||||

| 35 | 18 | 15 | 19 | 280 | 6,100 | 5,200 | 245° | Cylindrical Roller | 0000000 | 0000000 |

| 40 | 20 | 17 | 21 | 240 | 6,900 | 5,600 | 245° | Cylindrical Roller | 0000000 | 000000 |

| 42 | 18 | 15 | 19 | 280 | 6,100 | 5,200 | 245° | Cylindrical Roller | 0000000 | 000000 |

| 47 | 20 | 17 | 21 | 240 | 6,900 | 5,600 | 245° | Cylindrical Roller | 0000000 | 000000 |

| 47 | 24 | 20 | 25 | 210 | 11,000 | 8,700 | 245° | Cylindrical Roller | 0000000 | 000000 |

| 52 | 24 | 20 | 25 | 210 | 11,000 | 8,700 | 245° | Cylindrical Roller | 0000000 | 000000 |

| 52 | 24 | 25 | 25 | 160 | 13,000 | 9,600 | 245° | Cylindrical Roller | 0000000 | 000000 |

| 62 | 24 | 25 | 25 | 160 | 13,000 | 9,600 | 245° | Cylindrical Roller | 0000000 | 000000 |

| 72 | 28 | 30 | 29 | 140 | 16,900 | 13,000 | 245° | Cylindrical Roller | 0000000 | 000000 |

| 90 | 30 | 50 | 32 | 80 | 33,200 | 21,600 | 245° | Cylindrical Roller | 0000000 | 000000 |

Steel Crowned Rollers without Seal | ||||||||||

| 35 | 18 | 15 | 19 | 280 | 6,100 | 5,200 | 245° | Cylindrical Roller | 0000000 | 000000 |

| 40 | 20 | 17 | 21 | 240 | 6,900 | 5,600 | 245° | Cylindrical Roller | 0000000 | 000000 |

| 42 | 18 | 15 | 19 | 280 | 6,100 | 5,200 | 245° | Cylindrical Roller | 0000000 | 000000 |

| 47 | 24 | 20 | 25 | 210 | 11,000 | 8,700 | 245° | Cylindrical Roller | 0000000 | 000000 |

| 52 | 24 | 20 | 25 | 210 | 11,000 | 8,700 | 245° | Cylindrical Roller | 0000000 | 000000 |

| 52 | 24 | 25 | 25 | 160 | 13,000 | 9,600 | 245° | Cylindrical Roller | 0000000 | 000000 |

| 62 | 24 | 25 | 25 | 160 | 13,000 | 9,600 | 245° | Cylindrical Roller | 0000000 | 000000 |

| 90 | 30 | 40 | 32 | 100 | 27,400 | 19,400 | 245° | Cylindrical Roller | 0000000 | 000000 |

| 100 | 30 | 45 | 32 | 90 | 30,300 | 20,500 | 245° | Cylindrical Roller | 0000000 | 000000 |

Threaded V-Groove Track Rollers

Thread the stud directly into a component or secure with a nut for through-hole mounting. Rollers are for use with Angle Rails for V-Groove Track Rollers. They handle radial and thrust (top and side) loads and work well in dirty environments because debris falls off the angled rail. Also known as cam followers, track rollers support loads while guiding and positioning work. All rollers are permanently lubricated.

440C stainless steel rollers offer better corrosion resistance than steel rollers.

Rollers with a plastic overmold make less than noise than other rollers, and they’re suitable for corrosive environments. However, they have lower weight capacities than other similarly sized rollers and they’re less corrosion resistant than other stainless steel rollers.

Rollers with a seal block out dust and other contaminants better than shielded rollers, but they hold more heat. Their seal also helps retain lubricant.

Roller, mm | Stud, mm | Thread | Shoulder, mm | Groove, mm | Radial Load Cap., lbs. | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Dia. | Wd. | Dia. | Lg. | Size | Pitch, mm | Lg., mm | Dia. | Lg. | Wd. | Dp. | Max. Speed | Static | Dynamic | Static Thrust Load Cap., lbs. | Max. Temp., °F | Bearing Type | Includes | Each | |

Steel V-Groove Rollers with Seal | |||||||||||||||||||

| 40 | 19.2 | 10 | 23 | M10 | 1 | 13 | 13.1 | 0.8 | 14 | 7 | Not Rated | 220 | 240 | 130 | 225° | Ball | Mounting Hardware | 0000000 | 000000 |

| 50 | 21.2 | 12 | 25 | M12 | 1.5 | 14 | 15.9 | 0.8 | 18 | 9 | Not Rated | 600 | 510 | 370 | 225° | Ball | Mounting Hardware | 0000000 | 00000 |

| 60 | 31.4 | 14 | 40 | M14 | 2 | 26 | 18 | 1.6 | 20 | 10 | Not Rated | 1,100 | 1,050 | 680 | 225° | Ball | Mounting Hardware | 0000000 | 00000 |

| 90 | 42.9 | 24 | 57.9 | M24 | 3 | 35 | 32 | 1.6 | 28 | 14 | Not Rated | 2,260 | 1,980 | 1,400 | 225° | Ball | Mounting Hardware | 0000000 | 000000 |

Roller, mm | Stud, mm | Thread | Groove, mm | Radial Load Cap., lbs. | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Dia. | Wd. | Dia. | Lg. | Size | Pitch, mm | Lg., mm | Shoulder Lg., mm | Hex Shoulder Wd., mm | Wd. | Dp. | Max. Speed, rpm | Static | Dynamic | Static Thrust Load Cap., lbs. | Max. Temp., °F | Bearing Type | Features | Includes | Each | |

440C Stainless Steel V-Groove Rollers with Seal | ||||||||||||||||||||

| 15 | 6 | 4 | 10 | M4 | 0.7 | 6 | 2 | 9.5 | 3 | 1 | 7,000 | 270 | 270 | 50 | 500° | Ball | __ | Mounting Hardware | 0000000 | 0000000 |

| 20 | 8 | 6 | 15 | M6 | 1 | 9 | 2.1 | 12 | 4 | 2 | 5,000 | 220 | 220 | 45 | 500° | Ball | __ | Mounting Hardware | 0000000 | 000000 |

| 31 | 11 | 10 | 25 | M10 | 1.5 | 15 | 2.6 | 14 | 6 | 3 | 3,400 | 490 | 450 | 110 | 500° | Ball | __ | Mounting Hardware | 0000000 | 000000 |

| 31 | 11 | 10 | 25 | M10 | 1.5 | 15 | 2.6 | 14 | 6 | 3 | 3,400 | 590 | 590 | 140 | 210° | Ball | __ | Mounting Hardware | 0000000 | 000000 |

| 46 | 16 | 12 | 15 | M12 | 1.75 | 15 | 5.6 | 19.05 | 8 | 4 | 2,200 | 1,100 | 1,100 | 300 | 500° | Ball | __ | __ | 0000000 | 000000 |

440C Stainless Steel V-Groove Rollers without Seal | ||||||||||||||||||||

| 15 | 6 | 6 | 8 | M6 | 1 | 7 | 2.9 | 11 | 3 | 1 | 1,290 | 6 | 6 | 3 | 245° | Ball | Plastic Overmold, Shielded | __ | 0000000 | 00000 |

Steel V-Groove Rollers with Seal | ||||||||||||||||||||

| 15 | 6 | 4 | 10 | M4 | 0.7 | 6 | 2 | 11 | 3 | 1 | 7,000 | 140 | 140 | 20 | 210° | Ball | __ | Mounting Hardware | 0000000 | 00000 |

| 15 | 6 | 6 | 8 | M6 | 1 | 7 | 2.9 | 9.5 | 3 | 1 | 7,000 | 140 | 140 | 20 | 210° | Ball | __ | __ | 0000000 | 00000 |

| 20 | 8 | 6 | 15 | M6 | 1 | 9 | 2.1 | 12 | 4 | 2 | 5,300 | 270 | 270 | 50 | 210° | Ball | __ | Mounting Hardware | 0000000 | 00000 |

| 20 | 8 | 8 | 8 | M8 | 1.25 | 8 | 3.3 | 11.11 | 4 | 2 | 5,000 | 270 | 270 | 50 | 245° | Ball | __ | __ | 0000000 | 00000 |

| 31 | 11 | 10 | 11 | M10 | 1.5 | 11 | 4.1 | 14.29 | 6 | 3 | 3,400 | 590 | 590 | 140 | 245° | Ball | __ | __ | 0000000 | 00000 |

| 31 | 11 | 10 | 25 | M10 | 1.5 | 15 | 2.6 | 14 | 6 | 3 | 3,400 | 590 | 590 | 140 | 210° | Ball | __ | Mounting Hardware | 0000000 | 00000 |

| 46 | 16 | 12 | 15 | M12 | 1.75 | 15 | 5.6 | 19.05 | 8 | 4 | 2,200 | 1,300 | 1,300 | 380 | 245° | Ball | __ | __ | 0000000 | 00000 |

Steel V-Groove Rollers without Seal | ||||||||||||||||||||

| 20 | 8 | 6 | 15 | M6 | 1 | 9 | 2.1 | 12 | 4 | 2 | 5,300 | 270 | 270 | 50 | 245° | Ball | Shielded | Mounting Hardware | 0000000 | 00000 |

| 20 | 8 | 8 | 8 | M8 | 1.25 | 8 | 3.3 | 11.11 | 4 | 2 | 5,300 | 120 | 120 | 20 | 245° | Ball | Shielded | __ | 0000000 | 00000 |

| 31 | 11 | 10 | 11 | M10 | 1.5 | 11 | 4 | 14 | 5 | 3 | 620 | 16 | 16 | 9 | 245° | Ball | Plastic Overmold, Shielded | __ | 0000000 | 00000 |

Threaded V-Groove Track Rollers with Adjustable Shoulder

Also known as eccentric track rollers, the shoulder adjusts up or down to align to your track, enabling uniform alignment among rollers in a system. Rollers are for use with Angle Rails for V-Groove Track Rollers. They handle radial and thrust (top and side) loads and work well in dirty environments because debris falls off the angled rail. Secure the stud with a nut for through-hole mounting. All rollers are permanently lubricated.

440C stainless steel rollers offer better corrosion resistance than steel rollers.

Rollers with a plastic overmold make less noise than other rollers, and they’re suitable for corrosive environments. However, they have lower weight capacities than other similarly sized rollers and they’re less corrosion resistant than other stainless steel rollers.

Rollers with a seal block out dust and other contaminants better than shielded rollers, but they hold more heat. Their seal also helps retain lubricant.

Roller, mm | Stud, mm | Thread | Groove, mm | Radial Load Cap., lbs. | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Dia. | Wd. | Dia. | Lg. | Size | Pitch, mm | Lg., mm | Shoulder Lg., mm | Hex Shoulder Wd., mm | Wd. | Dp. | Max. Speed, rpm | Static | Dynamic | Static Thrust Load Cap., lbs. | Max. Temp., °F | Features | Includes | Each | |

Steel V-Groove Rollers with Seal | |||||||||||||||||||

| 20 | 8 | 6 | 8 | M6 | 1 | 6 | 3.4 | 11.11 | 4 | 2 | 5,000 | 270 | 270 | 50 | 245° | __ | Mounting Hardware | 0000000 | 000000 |

| 31 | 11 | 10 | 11 | M8 | 1.25 | 9 | 4.1 | 14.29 | 6 | 3 | 3,400 | 590 | 590 | 140 | 245° | __ | Mounting Hardware | 0000000 | 00000 |

| 31 | 11 | 10 | 25 | M10 | 1.5 | 15 | 2.6 | 14 | 10 | 3 | 3,400 | 590 | 590 | 140 | 210° | __ | Mounting Hardware | 0000000 | 00000 |

| 46 | 16 | 11 | 15 | M10 | 1.5 | 11 | 5.7 | 19.05 | 8 | 4 | 2,200 | 1,300 | 1,300 | 380 | 245° | __ | Mounting Hardware | 0000000 | 00000 |

| 46 | 16 | 12 | 30 | M12 | 1.75 | 18 | 3.4 | 19 | 8 | 4 | 2,200 | 1,300 | 1,300 | 350 | 210° | __ | Mounting Hardware | 0000000 | 00000 |

| 60 | 19 | 12 | 19 | M12 | 1.75 | 14 | 6.8 | 22.23 | 9 | 5 | 1,700 | 2,100 | 2,100 | 900 | 210° | __ | __ | 0000000 | 00000 |

440C Stainless Steel V-Groove Rollers with Seal | |||||||||||||||||||

| 20 | 8 | 6 | 15 | M6 | 1 | 9 | 2.1 | 12 | 4 | 2 | 5,300 | 220 | 220 | 40 | 500° | __ | Mounting Hardware | 0000000 | 000000 |

| 46 | 16 | 12 | 30 | M12 | 1.75 | 18 | 3.4 | 19 | 8 | 4 | 2,200 | 1,100 | 1,100 | 300 | 500° | __ | Mounting Hardware | 0000000 | 000000 |

440C Stainless Steel V-Groove Rollers without Seal | |||||||||||||||||||

| 20 | 8 | 6 | 8 | M6 | 1 | 6 | 3.3 | 11.11 | 4 | 2 | 5,300 | 270 | 270 | 50 | 245° | Shielded | __ | 0000000 | 00000 |

| 20 | 8 | 6 | 8 | M6 | 1 | 6 | 3.3 | 12 | 4 | 2 | 975 | 12 | 12 | 6 | 245° | Plastic Overmold, Shielded | __ | 0000000 | 00000 |

| 20 | 8 | 6 | 15 | M6 | 1 | 9 | 2.1 | 12 | 4 | 2 | 3,400 | 270 | 270 | 50 | 245° | Shielded | Mounting Hardware | 0000000 | 00000 |

| 31 | 11 | 10 | 11 | M8 | 1.25 | 8 | 4 | 14 | 6 | 3 | 620 | 16 | 16 | 9 | 245° | Plastic Overmold, Shielded | __ | 0000000 | 00000 |

Flanged Threaded Track Rollers

Thread the stud directly into a component or secure with a nut for through-hole mounting. The flange provides guidance and helps the roller stay on track. All rollers are permanently lubricated and have end seals to retain lubricant and protect rolling elements from dirt and contamination.

Roller | Stud | Thread | Shoulder | Flange | Static Load Cap., lbs. | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Dia. | Wd. | Dia. | Lg. | Size | Lg. | Dia. | Lg. | OD | Thick. | Max. Speed, rpm | Radial | Thrust | Max. Temp., °F | Includes | Each | |

Steel Flat Rollers with Seal | ||||||||||||||||

Ball Bearing | ||||||||||||||||

| 26mm | 20mm | 10mm | 23mm | M10 | 13mm | 13.1mm | 0.8mm | 35mm | 5mm | Not Rated | 220 | 130 | 225° | Mounting Hardware | 00000000 | 000000 |

| 35mm | 22mm | 16mm | 32.5mm | M16 | 18mm | 19.1mm | 0.8mm | 46mm | 5mm | Not Rated | 600 | 370 | 225° | Mounting Hardware | 00000000 | 00000 |

| 40mm | 30mm | 14mm | 40mm | M14 | 26mm | 18mm | 1.6mm | 54mm | 8.8mm | Not Rated | 1,100 | 680 | 225° | Mounting Hardware | 00000000 | 00000 |

| 50mm | 40mm | 16mm | 50mm | M16 | 35mm | 23mm | 1.6mm | 68mm | 14mm | Not Rated | 1,600 | 1,000 | 225° | Mounting Hardware | 00000000 | 000000 |

Roller Bearing | ||||||||||||||||

| 72mm | 44mm | 24mm | 49.5mm | M24 | 25mm | 32mm | 1.6mm | 90mm | 14mm | Not Rated | 7,600 | 4,500 | 225° | Mounting Hardware | 00000000 | 000000 |

| 76mm | 52mm | 30mm | 69.5mm | M30 | 40mm | 44.5mm | 1.6mm | 98mm | 14mm | Not Rated | 19,900 | 12,000 | 225° | Mounting Hardware | 00000000 | 000000 |

| 80mm | 52mm | 30mm | 69.5mm | M30 | 40mm | 44.5mm | 1.6mm | 102mm | 14mm | Not Rated | 19,900 | 12,000 | 225° | Mounting Hardware | 00000000 | 000000 |

| 100mm | 52mm | 30mm | 80mm | M30 | 50mm | 44.5mm | 1.6mm | 125mm | 14mm | Not Rated | 19,900 | 12,000 | 225° | Mounting Hardware | 00000000 | 000000 |

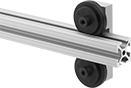

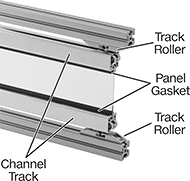

T-Slotted Framing Linear Bearings and Track Rollers

Track rollers are for applications that don't require high precision, such as sliding door frames, glides, and track systems. Multiple track rollers can be used on a rail. Because they’re side mount, they allow you to attach and roll components along the side of the rail.

Sleeve bearings don’t need to be lubricated, but they aren’t as long-lasting and don’t roll as smoothly as ball bearings. Ball bearings last longer and roll more smoothly than sleeve bearings but need to be lubricated.

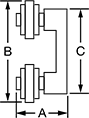

Roller | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Rail Ht. | Capacity, lbs. | (A) | (B) | (C) | Dia. | Color | Material | Carriage Material | Includes | Mounting Fasteners Included | Each | |

Silver Carriage | ||||||||||||

Side-Mount for Single Rails | ||||||||||||

Sleeve Bearing—Bronze | ||||||||||||

| 25mm | 25 | 33mm | 90mm | 78mm | 38mm | Blue | Nylon Plastic | Anodized Aluminum | One Carriage with Two Rollers | Yes | 0000000 | 000000 |

Ball Bearing—Steel | ||||||||||||

| 1 1/2" | 25 | 1 7/8" | 5 1/8" | 4 5/8" | 2" | Black | Nylon Plastic | Anodized Aluminum | One Carriage with Two Rollers | Yes | 0000000 | 000000 |

| 40mm | 25 | 49mm | 137mm | 123mm | 54mm | Blue | Nylon Plastic | Anodized Aluminum | One Carriage with Two Rollers | Yes | 0000000 | 000000 |

Side-Mount for Double Rails | ||||||||||||

Sleeve Bearing—Bronze | ||||||||||||

| 50mm | 25 | 33mm | 115mm | 103mm | 38mm | Blue | Nylon Plastic | Anodized Aluminum | One Carriage with Two Rollers | Yes | 0000000 | 00000 |

Ball Bearing—Steel | ||||||||||||

| 3" | 25 | 1 7/8" | 6 5/8" | 6 1/8" | 2" | Black | Nylon Plastic | Anodized Aluminum | One Carriage with Two Rollers | Yes | 0000000 | 000000 |

| 80mm | 25 | 49mm | 177mm | 163mm | 54mm | Blue | Nylon Plastic | Anodized Aluminum | One Carriage with Two Rollers | Yes | 0000000 | 000000 |

Black Carriage | ||||||||||||

Side-Mount for Single Rails | ||||||||||||

Sleeve Bearing—Bronze | ||||||||||||

| 1" | 25 | 1 5/16" | 3 5/8" | 3 1/8" | 1 1/2" | Black | Nylon Plastic | Anodized Aluminum | One Carriage with Two Rollers | Yes | 0000000 | 00000 |

| 1 1/2" | 25 | 1 7/8" | 5 1/8" | 4 5/8" | 2" | Black | Nylon Plastic | Anodized Aluminum | One Carriage with Two Rollers | Yes | 0000000 | 000000 |

| 40mm | 25 | 49mm | 137mm | 123mm | 54mm | Blue | Nylon Plastic | Anodized Aluminum | One Carriage with Two Rollers | Yes | 0000000 | 000000 |

Side-Mount for Double Rails | ||||||||||||

Sleeve Bearing—Bronze | ||||||||||||

| 2" | 25 | 1 5/16" | 4 5/8" | 4 1/8" | 1 1/2" | Black | Nylon Plastic | Anodized Aluminum | One Carriage with Two Rollers | Yes | 0000000 | 00000 |

| 3" | 25 | 1 7/8" | 6 5/8" | 6 1/8" | 2" | Black | Nylon Plastic | Anodized Aluminum | One Carriage with Two Rollers | Yes | 0000000 | 000000 |

| 80mm | 25 | 49mm | 177mm | 163mm | 54mm | Blue | Nylon Plastic | Anodized Aluminum | One Carriage with Two Rollers | Yes | 0000000 | 000000 |

High-capacity track rollers are best for moving heavy items that don’t require high precision, such as sliding doors. They travel inside channel tracks (sold separately). Attach your sliding component to the other side of the track roller. Included locking end stops bring a sliding component to a stop and hold it in place.

Note: Sliding doors must be guided above and below to keep the door moving straight and prevent it from swinging.

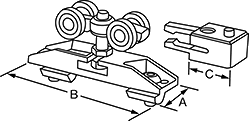

Roller | Silver Carriage | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Rail Ht., mm | Capacity, lbs. | (A), mm | (B), mm | (C), mm | Dia., mm | Color | Material | Carriage Material | Includes | Mounting Fasteners Included | Each | |

Bottom/Top-Mount for Single Rails | ||||||||||||

Ball Bearing—Steel | ||||||||||||

| 40 | 65 | 25 | 110 | 31 | 21 | White | Polyurethane Rubber | Aluminum | Two Carriages, Two Locking End Stops, Two Slides with Four Rollers | Yes | 0000000 | 000000 |