About Glove Sizing

More

About Heat-Shrink Tubing

More

About Sleeving

More

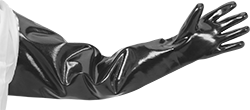

Oil- and Acid-Resistant Gloves

Protect your hands from oil, acids, and scrapes while you’re working.

Gloves with sleeve have a grommet on each sleeve that allows you to tie them across your shoulders.

Neoprene gloves are more durable than neoprene-coated latex, neoprene/latex blend, and nitrile gloves. They withstand deterioration from petroleum products and solvents such as alcohol.

Gloves with a cotton fabric lining and fleece fabric lining absorb perspiration.

Available Sizes | |

|---|---|

| Size | Glove Size |

| XL | 10 |

Pair | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Texture | Lining Material | Thick., mil | Lg. | Color | For Use With | Features | Size | 1-11 | 12-Up | |

Gloves with Sleeve | ||||||||||

Neoprene Rubber | ||||||||||

| Smooth | Fleece Fabric | 30 | 31" | Black | Nitric Acid, Sulfuric Acid | 1/2" Diameter Brass Grommets | XL | 0000000 | 000000 | 000000 |

Chemical-Resistant Sleeves

Use these sleeves alone or with gloves to protect your arm from oils and most acids.

Neoprene-coated nylon sleeves resist the most chemicals of the sleeves we carry.

PVC-coated polyester sleeves provide some chemical and acid resistance. They also protect your arm from abrasive material.

Acid- and Heat-Protection Gloves

The lining withstands intermittent heat, while the outer layer of material acts as a barrier to chemicals and solvents. All of these gloves are textured on the fingers and palm for added grip.

Neoprene gloves with a cotton or fleece lining handle higher temperatures than nitrile/neoprene gloves, but they’re also thicker.

FDA compliant gloves are safe for use with food.

One-Piece Glove Box Gloves

Seamless one-piece construction provides maximum strength and integrity. Use these gloves in glove boxes to safely handle hazardous substances or avoid contaminating sensitive materials. Attach them to a glove box using glove box mounting clamps (sold separately).

Neoprene gloves are for applications that require more chemical resistance and durability than latex gloves.

Available Sizes | |

|---|---|

| Size | Glove Size |

| M | 8 |

| L | 8 1/2 |

| XL | 9 3/4 |

| XL | 10 |

| 2XL | 10 1/2 |

| 3XL | 11 1/2 |

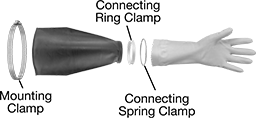

Two-Piece Glove Box Gloves

For applications that require frequent glove changes, the sleeves stay connected to the glove box so you can quickly change the size or type of glove being used. Use these gloves in glove boxes to safely handle hazardous substances or avoid contaminating sensitive materials. They fit 8" diameter glove box access holes. Attach gloves to sleeves using the included sleeve-to-glove connecting spring clamp and sleeve-to-glove connecting ring clamp. Attach sleeves to a glove box using glove box mounting clamps (sold separately).

Neoprene gloves are chemical resistant and durable.

Available Sizes | |

|---|---|

| Size | Glove Size |

| S | 7 |

| M | 8 |

| L | 9 |

| XL | 10 |

| 2XL | 11 |

| Clamp ID | Clamp Type | Material | Pkg. Qty. | Pkg. | |

| 8" | Worm Drive | Steel | 2 | 0000000 | 000000 |

Chemical-Resistant Heat-Shrink Tubing

Use this tubing where wire and cable may be exposed to chemicals, oil, and acids.

Neoprene rubber tubing is abrasion resistant. Viton® fluoroelastomer rubber tubing is more chemical resistant than neoprene rubber. It’s also abrasion resistant and withstands temperatures up to 390° F.

SAE AMS-DTL-23053/1 Class 2, 23053/2 Class 2, and 23053/13 tubing meets requirements for material quality and color.

Dielectric strength is the maximum voltage a material can handle before it starts to breakdown. The higher the dielectric strength of a material, the better it is for preventing electricity, heat, or signal from dissipating from wire and cable.

- Shrink Ratio: 2:1

- Dielectric Strength: 800 V/mil

- Shrink Temperature: 275° F

- Temperature Range: -90° to 250° F

- Specifications Met: SAE AMS-DTL-23053/1 Class 2

- Shrink Ratio: 2:1

- Dielectric Strength: 200 V/mil

- Shrink Temperature: 350° F

- Temperature Range: -65° to 390° F

- Specifications Met: SAE AMS-DTL-23053/13

ID | 1/2 ft. Lg. | ||||

|---|---|---|---|---|---|

| Before Shrinking | Min. After Shrinking | Min. Wall Thick. After Shrinking | Color | Each | |

| 0.19" | 0.11" | 0.04" | Black | 0000000 | 00000 |

| 0.25" | 0.13" | 0.04" | Black | 0000000 | 0000 |

| 0.38" | 0.19" | 0.04" | Black | 0000000 | 0000 |

| 0.5" | 0.25" | 0.04" | Black | 0000000 | 0000 |

| 0.63" | 0.31" | 0.04" | Black | 0000000 | 0000 |

| 0.75" | 0.38" | 0.04" | Black | 0000000 | 0000 |

| 1" | 0.5" | 0.05" | Black | 0000000 | 0000 |

Abrasion-Resistant Tape Sleeving

Made of neoprene rubber, this sleeving has excellent abrasion resistance. It also resists acids, alkalies, oil, and gasoline. A good option for emergency patches, it can be quickly applied to hose or cable like tape. Secure the ends of the sleeving with the included tape.

| Wd. | Thick. | Includes | Temperature Range, °F | Color | Each | |

3 ft. Lg. | ||||||

|---|---|---|---|---|---|---|

Neoprene Rubber | ||||||

| 1" | 1/8" | Tape | -20° to 200° | Black | 0000000 | 000000 |

6 ft. Lg. | ||||||

Neoprene Rubber | ||||||

| 1" | 1/8" | Tape | -20° to 200° | Black | 0000000 | 00000 |

10 ft. Lg. | ||||||

Neoprene Rubber | ||||||

| 1" | 1/8" | Tape | -20° to 200° | Black | 0000000 | 00000 |

15 ft. Lg. | ||||||

Neoprene Rubber | ||||||

| 1" | 1/8" | Tape | -20° to 200° | Black | 0000000 | 00000 |