How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

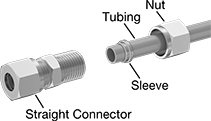

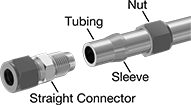

Nickel-Plated Brass Compression Fittings for Copper Tubing

- For Use With: Air, Cutting Oil, Diesel Fuel, Ethyl Alcohol, Fuel Oil, Gasoline, Hydraulic Fluid, Isopropyl Alcohol, Lubricants, Mineral Oil, Natural Gas, Steam, Water

- Temperature Range: -75° to 550° F, except 90° elbow adapters with BSPP threads are 0° to 170° F

- Tubing: Use with copper

- Specifications Met: DIN 3861, except nuts meet DIN 3870

With a nickel-plated finish, these compression fittings resist corrosion better than plain brass fittings. They have a single sleeve (ferrule) made of plain brass that gently bites into copper tubing as you tighten the nut, creating a strong seal. The nut and sleeve are included. These fittings are also known as flareless fittings. All meet DIN standards for tube fitting dimensions.

For Tube | ||||||

|---|---|---|---|---|---|---|

| OD, mm | Wall Thickness, mm | Pipe Size | Material | Maximum Pressure | Each | |

BSPT Threads | ||||||

| 4 | 1 | 1/8 | Nickel-Plated Brass | 1,800 psi @ 72° F | 0000000 | 00000 |

| 6 | 1 | 1/8 | Nickel-Plated Brass | 2,500 psi @ 72° F | 0000000 | 0000 |

| 6 | 1 | 1/4 | Nickel-Plated Brass | 2,500 psi @ 72° F | 0000000 | 0000 |

| 8 | 1 | 1/8 | Nickel-Plated Brass | 2,100 psi @ 72° F | 0000000 | 0000 |

| 8 | 1 | 1/4 | Nickel-Plated Brass | 2,100 psi @ 72° F | 0000000 | 0000 |

| 8 | 1 | 3/8 | Nickel-Plated Brass | 2,100 psi @ 72° F | 0000000 | 0000 |

| 10 | 1 | 1/4 | Nickel-Plated Brass | 1,600 psi @ 72° F | 0000000 | 0000 |

| 10 | 1 | 3/8 | Nickel-Plated Brass | 1,600 psi @ 72° F | 0000000 | 0000 |

| 12 | 1 | 3/8 | Nickel-Plated Brass | 1,000 psi @ 72° F | 0000000 | 0000 |

| 12 | 1 | 1/2 | Nickel-Plated Brass | 1,000 psi @ 72° F | 0000000 | 0000 |

| 14 | 1 | 1/2 | Nickel-Plated Brass | 1,000 psi @ 72° F | 0000000 | 0000 |

| 15 | 1 | 1/2 | Nickel-Plated Brass | 1,000 psi @ 72° F | 0000000 | 0000 |

| 16 | 1 | 1/2 | Nickel-Plated Brass | 1,000 psi @ 72° F | 00000000 | 0000 |

| 18 | 1 | 1/2 | Nickel-Plated Brass | 900 psi @ 72° F | 00000000 | 00000 |

For Tube | ||||||

|---|---|---|---|---|---|---|

| OD, mm | Wall Thickness, mm | Nut Material | Maximum Pressure | Length, mm | Each | |

Short Nuts | ||||||

| 4 | 1 | Nickel-Plated Brass | 1,800 psi @ 72° F | 11 | 00000000 | 00000 |

| 6 | 1 | Nickel-Plated Brass | 2,500 psi @ 72° F | 12 | 00000000 | 000 |

| 8 | 1 | Nickel-Plated Brass | 2,100 psi @ 72° F | 12 | 00000000 | 000 |

| 10 | 1 | Nickel-Plated Brass | 1,600 psi @ 72° F | 16 | 00000000 | 0000 |

| 12 | 1 | Nickel-Plated Brass | 1,000 psi @ 72° F | 16 | 00000000 | 0000 |

| 14 | 1 | Nickel-Plated Brass | 1,000 psi @ 72° F | 19 | 00000000 | 0000 |

| 15 | 1 | Nickel-Plated Brass | 1,000 psi @ 72° F | 17 | 00000000 | 0000 |

For Tube | |||||

|---|---|---|---|---|---|

| OD, mm | Wall Thickness, mm | Sleeve Material | Maximum Pressure | Each | |

| 4 | 1 | Brass | 1,800 psi @ 72° F | 00000000 | 00000 |

| 6 | 1 | Brass | 2,500 psi @ 72° F | 00000000 | 000 |

| 8 | 1 | Brass | 2,100 psi @ 72° F | 00000000 | 000 |

| 10 | 1 | Brass | 1,600 psi @ 72° F | 00000000 | 000 |

| 12 | 1 | Brass | 1,000 psi @ 72° F | 00000000 | 000 |

| 14 | 1 | Brass | 1,000 psi @ 72° F | 00000000 | 000 |

| 15 | 1 | Brass | 1,000 psi @ 72° F | 00000000 | 000 |

Precision Compression Fittings for Stainless Steel Tubing

- For Use With: Air, Cutting Oil, Ethyl Alcohol, Fuel Oil, Gasoline, Hydraulic Fluid, Isopropyl Alcohol, Mineral Oil, Natural Gas, Steam, Water

- Temperature Range: -420° to 1200° F

- Tubing: Use with welded or seamless 304 or 316 stainless steel that meets ASTM A213, ASTM A249, or ASTM A269

- Compatible With: Parker CPI

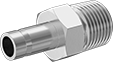

Made to tighter tolerances than other compression fittings, these are designed for high-precision applications. Also known as instrumentation fittings and flareless fittings. They come with a nut and a single sleeve (ferrule). The sleeve bites into tubing as you tighten the nut to create a strong seal. Fittings are 316 stainless steel for excellent corrosion resistance. A molybdenum disulfide coating on the nut acts as a lubricant for easy installation.

Fittings with tube stem insert into the tube end of another fitting in place of a length of tubing.

| Tube Stem OD | Pipe Size | Material | Max. Pressure | Each | |

| 1/8" | 1/8 | 316 Stainless Steel | 5,500 psi @ 72° F | 00000000 | 000000 |

| 1/8" | 1/4 | 316 Stainless Steel | 5,500 psi @ 72° F | 00000000 | 00000 |

| 1/4" | 1/8 | 316 Stainless Steel | 4,000 psi @ 72° F | 00000000 | 00000 |

| 1/4" | 1/4 | 316 Stainless Steel | 4,000 psi @ 72° F | 00000000 | 00000 |

| 1/4" | 3/8 | 316 Stainless Steel | 4,000 psi @ 72° F | 00000000 | 00000 |

| 3/8" | 1/4 | 316 Stainless Steel | 2,600 psi @ 72° F | 00000000 | 00000 |

| 3/8" | 3/8 | 316 Stainless Steel | 2,600 psi @ 72° F | 00000000 | 00000 |

| 3/8" | 1/2 | 316 Stainless Steel | 2,600 psi @ 72° F | 00000000 | 00000 |

| 1/2" | 3/8 | 316 Stainless Steel | 2,100 psi @ 72° F | 00000000 | 00000 |

| 1/2" | 1/2 | 316 Stainless Steel | 2,100 psi @ 72° F | 00000000 | 00000 |

| 3/4" | 3/4 | 316 Stainless Steel | 2,100 psi @ 72° F | 00000000 | 00000 |

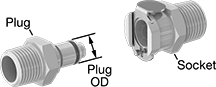

Plastic Quick-Disconnect Tube Couplings for Air and Water

Lighter in weight than their metal counterparts, these quick-disconnect couplings are made of acetal plastic. They are moisture resistant, so they won’t absorb water and lose strength, even in high-humidity environments. A complete coupling consists of a plug and socket; choose a set for both, or select a plug and socket separately. Because they're quick disconnect, they're helpful for lines you frequently need to access.

Latch-lock sockets connect and disconnect with just one hand. Join sockets with a push and disconnect sockets by pressing the latch.

Plugs and sockets with shut-off have a valve to stop the flow when the coupling is separated, so air or water won’t spill from your line.

Note: For a complete coupling, order a plug and a socket with the same coupling size.

- Temperature Range: -40° to 180° F

- Tubing: Use with nylon plastic or polyethylene plastic, see table for hardness

Open Flow | ||||||||

|---|---|---|---|---|---|---|---|---|

| For Tube OD | For Tube ID | Coupling Size | Plug OD | Material | Color | Max. Pressure | Each | |

| 4mm | 2mm | 1/8 | 5/16" | Acetal Plastic | White | 100 psi @ 72° F | 00000000 | 00000 |

- Temperature Range: -40° to 180° F

- Tubing: Use with firm or hard (Durometer 85A-60D) nylon plastic or polyethylene plastic

Stainless Steel Barbed Tube Fittings for Food and Beverage

- Temperature Range: -20° to 750° F

- Tubing: Use with soft or firm (Durometer 65A-90A) polyurethane rubber or PVC plastic

- Specifications Met: See table

Made of stainless steel, these fittings are more durable than plastic barbed tube fittings for food and beverage. They have single or multiple barbs that grip onto tubing.

Compression connections bite into hard metal and plastic tubing. They’re also known as flareless fittings.

| For Tube ID (Barbed) | For Tube OD (Compression) | Material | Max. Pressure | Specifications Met | Each | |

| 1/4" | 1/4" | 303 Stainless Steel | 270 psi @ 72° F | ASTM A581, ASTM A582 | 00000000 | 00000 |

| 1/4" | 3/8" | 303 Stainless Steel | 270 psi @ 72° F | ASTM A581, ASTM A582 | 00000000 | 0000 |

| 3/8" | 1/4" | 303 Stainless Steel | 270 psi @ 72° F | ASTM A581, ASTM A582 | 00000000 | 0000 |

| 3/8" | 3/8" | 303 Stainless Steel | 270 psi @ 72° F | ASTM A581, ASTM A582 | 00000000 | 0000 |

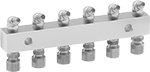

Grease Fitting Junction Blocks

Choose these blocks if you need to lubricate multiple points but need to control how each is greased. Unlike grease fitting manifolds, these blocks have multiple fittings, so you control what each point receives and when. Use the compression fittings on the outlets to connect tubing (not included) between the grease fittings and lubrication points.

Magnetic-mount blocks stick to machines and other steel surfaces.

Zinc-plated steel blocks have mild corrosion resistance. 303 stainless steel blocks are more corrosion resistant than zinc-plated steel blocks and have good chemical resistance.

| Number of Inlets | Number of Outlets | For Tube OD | For NLGI Viscosity Grade | Overall Wd. | Overall Dp. | Overall Ht. | Max. Pressure, psi | Each | |

Zinc-Plated Steel | |||||||||

|---|---|---|---|---|---|---|---|---|---|

Junction Blocks | |||||||||

| 3 | 3 | 1/4" | 00, 0, 1, 2 | 2 3/4" | 3/4" | 2 3/4" | 1,800 | 000000 | 000000 |

| 6 | 6 | 1/4" | 00, 0, 1, 2 | 5 3/4" | 3/4" | 2 3/4" | 1,800 | 000000 | 000000 |

| 10 | 10 | 1/4" | 00, 0, 1, 2 | 9 3/4" | 3/4" | 2 1/2" | 5,000 | 000000 | 000000 |

Magnetic-Mount Junction Blocks | |||||||||

| 3 | 3 | 1/4" | 00, 0, 1, 2 | 5 5/8" | 1 11/16" | 2 11/16" | 5,000 | 000000 | 000000 |

| 6 | 6 | 1/4" | 00, 0, 1, 2 | 6 5/8" | 1 11/16" | 2 11/16" | 5,000 | 000000 | 000000 |

| 10 | 10 | 1/4" | 00, 0, 1, 2 | 10 5/8" | 1 11/16" | 2 3/4" | 5,000 | 000000 | 000000 |

303 Stainless Steel | |||||||||

Junction Blocks | |||||||||

| 3 | 3 | 1/4" | 00, 0, 1, 2 | 2 3/4" | 3/4" | 2 1/2" | 5,000 | 000000 | 000000 |

| 6 | 6 | 1/4" | 00, 0, 1, 2 | 5 3/4" | 3/4" | 2 1/2" | 5,000 | 000000 | 000000 |

| 10 | 10 | 1/4" | 00, 0, 1, 2 | 9 3/4" | 3/4" | 2 1/2" | 5,000 | 000000 | 000000 |

Grease Fitting Manifolds

Save time by sending grease from one fitting to multiple points. These manifolds come with everything you need to set up a remote lubrication system. They deliver the same amount of grease to each lubrication point, so you’ll sometimes see them used to grease an entire machine. All lubrication points connected to the manifold must use the same type of grease.

The tubing attaches to the compression fittings on the manifold’s outlets. To connect the other end of the tubing to your lubrication point, use a compression fitting, an adapter, or both. Adapters come in a variety of shapes and sizes to reach tight or hard-to-reach areas.

Female Compression Tube Outlet | Female NPT Grease Fitting Inlet | Overall | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Number of Outlets | For Tube OD | Number of Inlets | Shape | Pipe Size | Wd. | Dp. | Ht. | Max. Pressure, psi | Includes | For NLGI Viscosity Grade | Each | |

Aluminum | ||||||||||||

| 4 | 1/4" | 1 | 65° Elbow | 1/4 | 2 7/8" | 2" | 4" | 2,000 | 25 ft. Lg. 1/4" OD Tubing with NLGI 1 Grease 4 Each 1/8 NPT Male × 1/4" Female Straight Compression Tube Fittings 2 Each 1/8 NPT Female × 1/4"-28 UNF Male Straight Adapters 2 Each 1/8 NPT Female × 1/4"-28 SAE-LT Male 90° Elbow Adapters 2 Each 1/8 NPT Female × 1/8 NPT Male 45° Elbow Adapters 2 Each 1/8 NPT Female × 1/8 NPT Male 90° Elbow Adapters 1 Each Plastic Grease Fitting Dust Cap 8 Each Tubing Inserts 8 Each Cable Ties | 0, 00, 1, 2 | 0000000 | 0000000 |

| 6 | 1/4" | 1 | 65° Elbow | 1/4 | 2 7/8" | 2" | 4" | 2,000 | 50 ft. Lg. 1/4" OD Tubing with NLGI 1 Grease 6 Each 1/8 NPT Male × 1/4" Female Straight Compression Tube Fittings 2 Each 1/8 NPT Female × 1/4"-28 UNF Male Straight Adapters 3 Each 1/8 NPT Female × 1/4"-28 SAE-LT Male 90° Elbow Adapters 2 Each 1/8 NPT Female × 1/8 NPT Male 45° Elbow Adapters 3 Each 1/8 NPT Female × 1/8 NPT Male 90° Elbow Adapters 1 Each Plastic Grease Fitting Dust Cap 12 Each Tubing Inserts 12 Each Cable Ties | 0, 00, 1, 2 | 0000000 | 000000 |

| 12 | 1/4" | 1 | 65° Elbow | 1/4 | 2 7/8" | 2 5/8" | 4" | 2,000 | 100 ft. Lg. 1/4" OD Tubing with NLGI 1 Grease 12 Each 1/8 NPT Male × 1/4" Female Straight Compression Tube Fittings 4 Each 1/8 NPT Female × 1/4"-28 UNF Male Straight Adapters 6 Each 1/8 NPT Female × 1/4"-28 SAE-LT Male 90° Elbow Adapters 4 Each 1/8 NPT Female × 1/8 NPT Male 45° Elbow Adapters 6 Each 1/8 NPT Female × 1/8 NPT Male 90° Elbow Adapters 1 Each Plastic Grease Fitting Dust Cap 24 Each Tubing Inserts 24 Each Cable Ties | 0, 00, 1, 2 | 0000000 | 000000 |