How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

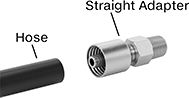

Crimp-On Hose Fittings for Hydraulic Fluid

Crimp these fittings onto hydraulic hose for a permanent, leak-tight connection. Since they crimp on, they handle higher pressure than screw-on fittings. To install, use Parker crimping tools and dies (not included).

Fittings with a female end swivel 360° until tightened without you needing to move or twist the entire hose, making them easy to install.

Fittings with a 37° flared end are also known as JIC (Joint Industrial Council) fittings.

Note: Fittings are only for use with hydraulic hose.

- Maximum Pressure: See table

- Temperature Range: -40° to 210° F

- For Hose Manufacturer Series:

Parker 43 Series Fittings: 302 SAE J517 100R2AT, 422 SAE J517 100R1AT, 487 ISO17582-AC, 777 ISO17582-CC

Parker 56 Series Fittings: 510D J517 SAE 100R7, 518D J517 SAE 100R7

For Hose | |||||||

|---|---|---|---|---|---|---|---|

| ID | OD | For Tube OD | Thread Size | Dash Size | Max. Pressure | Each | |

Zinc-Plated Steel—Parker 56 Series | |||||||

| 1/8" | 5/16" | 1/8" | 5/16"-24 | 02 | 3,000 psi @ 72° F | 0000000 | 000000 |

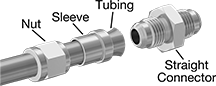

37° Flared Fittings for Stainless Steel Tubing

- Tubing: Use with welded or seamless 304 or 316 stainless steel that meets ASTM A213, ASTM A249, or ASTM A269

- Specifications Met: ISO 8434, SAE J514, except fittings with BSPP and BSPT threads meet SAE J514 only

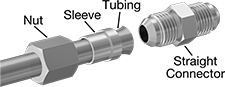

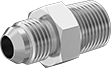

Also known as JIC (Joint Industrial Council) fittings, these provide a tight metal-to-metal seal on tubing that is flared to 37°. They withstand high pressure, so they’re often used in hydraulic applications. Made from 316 stainless steel, they resist corrosion from water and chemicals. A complete fitting requires a nut and a sleeve (ferrule) for each tube end. Nuts and sleeves are sold separately.

BSPP threads and UN/UNF (SAE Straight) male threads have a gasket to protect against leaks. UN/UNF (SAE Straight) threads are also known as O-ring boss threads.

- For Use With: See table

- Temperature Range: See table

| For Tube OD | Pipe Size | Thread Size | For Use With | Material | Gasket Material | Max. Pressure | Temp. Range, °F | Each | |

NPT Threads | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| 1/8" | 1/8 | __ | Air, Hydraulic Fluid, Isopropyl Alcohol, Natural Gas, Phosphoric Acid, Water | 316 Stainless Steel | __ | 6,000 psi @ 72° F | -420° to 1200° | 000000000 | 000000 |

UN/UNF (SAE Straight) Threads | |||||||||

| 1/8" | __ | 5/16"-24 | Air, Hydraulic Fluid, Isopropyl Alcohol, Water | 316 Stainless Steel | Fluoroelastomer Rubber | 6,000 psi @ 72° F | -15° to 400° | 000000000 | 00000 |

- For Use With: Air, Hydraulic Fluid, Isopropyl Alcohol, Natural Gas, Phosphoric Acid, Water

- Temperature Range: -420° to 1,200° F

| For Tube OD | Nut Material | Each | |

| 1/8" | 316 Stainless Steel | 000000000 | 00000 |

- For Use With: Air, Hydraulic Fluid, Isopropyl Alcohol, Natural Gas, Phosphoric Acid, Water

- Temperature Range: -420° to 1,200° F

Use these sleeves with a nut and fitting to provide a tight metal-to-metal seal on stainless steel tubing that is flared to 37°. Sleeves are 316 stainless steel for excellent corrosion resistance. They are also known as ferrules.

For Tube OD | |||

|---|---|---|---|

| Inch | Sleeve Material | Each | |

Inch | |||

| 1/8" | 316 Stainless Steel | 000000000 | 00000 |

Precision AN 37° Flared Fittings for Stainless Steel Tubing

- For Use With: Air, Cutting Oil, Fuel Oil, Hydraulic Fluid, Mineral Oil, Water

- Temperature Range: -320° to 1200° F

- Tubing: Use with seamless 304 or 316 stainless steel

- Specifications Met: See table

The threads on the tube end of these fittings are Class 3A or 3B and adhere to tighter tolerances than other 37° flared fittings. They are made to exact AS (formerly AN) specifications and provide a tight metal-to-metal seal on tubing that is flared to 37°. Fittings require a nut and a sleeve (ferrule) for each tube end. Nuts and sleeves are sold separately.

304 stainless steel fittings have very good corrosion resistance. 316 stainless steel fittings have excellent corrosion resistance.

Grease Fittings

Thread these fittings into motors, bearings, engine blocks, and other machinery to create a lubrication point. They’re also known as hydraulic grease fittings.

Zinc-plated steel fittings have mild corrosion resistance. Brass fittings resist corrosion better than zinc-plated steel fittings. 303 stainless steel fittings are more corrosion resistant than brass fittings and have good chemical resistance.

Fittings with a check valve prevent grease from leaking when pressure causes backward flow. The valve stays closed when not in use to keep out dirt and other contaminants.

UNF threads are similar to threads on a machine screw or bolt. They require a sealant, such as an O-ring, to minimize leakage.

Male

Threads

Pkg. | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Material | Overall Ht. | Thread Lg. | Shank Lg. | Hex Size | Max. Pressure, psi | Check Valve Type | Pkg. Qty. | 1-9 | 10-Up | |

5/16"-24 UNF Threads | ||||||||||

| Zinc-Plated Steel | 21/32" | 5/32" | 5/32" | 3/8" | 10,000 | Ball | 10 | 0000000 | 00000 | 00000 |

| Zinc-Plated Steel | 2 61/64" | 7/32" | 2 35/64" | 11/32" | 10,000 | Ball | 3 | 0000000 | 0000 | 0000 |

| Brass | 19/32" | 7/32" | 7/32" | 11/32" | 10,000 | Ball | 5 | 0000000 | 0000 | 0000 |

| 303 Stainless Steel | 19/32" | 7/32" | 7/32" | 11/32" | 10,000 | Ball | 3 | 0000000 | 00000 | 00000 |

Pkg. | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Material | Overall Ht. | Thread Lg. | Shank Lg. | Hex Size | Max. Pressure, psi | Check Valve Type | Pkg. Qty. | 1-9 | 10-Up | |

5/16"-24 UNF Threads | ||||||||||

| Zinc-Plated Steel | 23/32" | 5/32" | 13/64" | 23/64" | 8,000 | Ball | 10 | 00000000 | 000000 | 00000 |

Pkg. | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Material | Overall Ht. | Thread Lg. | Shank Lg. | Hex Size | Max. Pressure, psi | Check Valve Type | Pkg. Qty. | 1-9 | 10-Up | |

5/16"-24 UNF Threads | ||||||||||

| Zinc-Plated Steel | 59/64" | 7/32" | 7/32" | 11/32" | 1,450 | Ball | 10 | 00000000 | 00000 | 00000 |

| Brass | 59/64" | 7/32" | 7/32" | 11/32" | 10,000 | Ball | 3 | 0000000 | 00000 | 0000 |

| 303 Stainless Steel | 59/64" | 7/32" | 7/32" | 11/32" | 10,000 | Ball | 1 | 0000000 | 00000 | 0000 |