How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

Plastic Pipe Fittings for Oil

Made of corrosion-resistant plastic, these fittings won’t deteriorate when used in oil applications. They also have high strength and impact resistance. Apply a non-hardening, plastic-compatible sealant to the male threads to prevent leaks. Tape or sealants with PTFE are not recommended for plastic-to-plastic threaded connections. When making a threaded connection be careful not to overtighten the threads. To prevent cracks and leaks, finger tighten the fitting, then wrench-tighten one to two turns.

Warning: Never use plastic pipe fittings and pipe with compressed air or gas.

Sealants cannot be sold to Colorado, Connecticut, District of Columbia, Delaware, Illinois, Indiana, Massachusetts, Maryland, Maine, Michigan, New Hampshire, New Jersey, Northern Virginia, New York, Ohio, Pennsylvania, Rhode Island, or Utah due to local VOC (Volatile Organic Compounds) regulations.

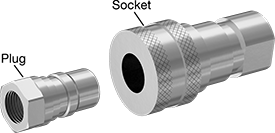

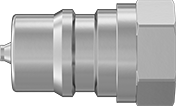

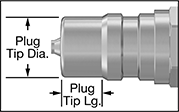

International Standard ISO B Quick-Disconnect

Hose Couplings for Hydraulic Fluid

A complete coupling consists of a plug and a socket (both sold separately) that connect and disconnect quickly. Use them if you need frequent access to a hydraulic hose line. All of the International Standard ISO B quick-disconnect plugs are compatible with any of the International Standard ISO B quick-disconnect sockets of the same coupling size, regardless of the pipe size. Couplings meet ISO 7241-1 Series B dimensional and performance standards and are compatible with Parker 60 couplings. Also known as double shut-off couplings, the plugs and sockets both have a shut-off valve that stops the flow when the coupling is separated.

Push-to-connect sockets are easier to connect than sleeve-lock sockets. Connect by pushing the plug into the socket until you hear a click. To disconnect, slide the sleeve on the socket forward until the plug ejects.

Zinc-plated steel is stronger and more durable than other metals. It has fair corrosion resistance.

Note: To ensure a correct fit, make sure that the plug and socket have the same coupling size. Pressure ratings are given for static (constant) pressure conditions.

Warning: Never attempt to connect or disconnect couplings when operating at maximum pressure. Stop the flow before you disconnect the line.

- Maximum Pressure: 3,500 psi @ 72° F

- Temperature Range: -10° to 212° F

- Compatible With: ISO 7241-1 Series B, Parker 60

- Specifications Met: ISO 7241-1 Series B

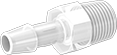

Tight-Seal Plastic Barbed Tube Fittings for Air and Water

Minimize leaks in your line—these fittings have a single barb that creates a smooth clamping surface for extra-tight connections. Fittings are nylon for excellent impact and abrasion resistance.

- Temperature Range: See table

- Tubing: Use with firm (Durometer 75A-80A) polyurethane rubber or PVC plastic

- Clarity: Black: Opaque; White: Opaque; Off-White: Semi-Clear

Tight-Seal Moisture-Resistant Plastic Barbed Tube Fittings for Air and Water

- Temperature Range: -20° to 280° F

- Tubing: Use with firm or soft (Durometer 50A-90A) polyurethane rubber or PVC plastic

- Specifications Met: FDA Compliant 21 CFR 177.2470

Fittings have a single barb that creates a smooth clamping surface for extra-tight connections that minimize leaks. Made of acetal, they won’t absorb water and lose strength, even in high-humidity environments.

| For Tube ID | Thread Size | Material | Color | Clarity | Max. Pressure | Each | |

UNF Threads | |||||||

|---|---|---|---|---|---|---|---|

| 1/16" | 10-32 | Acetal Plastic | White | Semi-Clear | Not Rated | 0000000 | 00000 |

| 1/16" | 1/4"-28 | Acetal Plastic | White | Semi-Clear | Not Rated | 00000000 | 0000 |

| 3/32" | 10-32 | Acetal Plastic | White | Semi-Clear | Not Rated | 00000000 | 000 |

| 3/32" | 1/4"-28 | Acetal Plastic | White | Semi-Clear | Not Rated | 00000000 | 000 |

| 1/8" | 10-32 | Acetal Plastic | White | Semi-Clear | Not Rated | 0000000 | 000 |

| 1/8" | 1/4"-28 | Acetal Plastic | White | Semi-Clear | Not Rated | 00000000 | 0000 |

| 5/32" | 10-32 | Acetal Plastic | White | Semi-Clear | Not Rated | 00000000 | 000 |

| 5/32" | 1/4"-28 | Acetal Plastic | White | Semi-Clear | Not Rated | 00000000 | 0000 |

| 3/16" | 1/4"-28 | Acetal Plastic | White | Semi-Clear | Not Rated | 00000000 | 0000 |

Grease Fittings

Thread these fittings into motors, bearings, engine blocks, and other machinery to create a lubrication point. They’re also known as hydraulic grease fittings.

Zinc-plated steel fittings have mild corrosion resistance. Brass fittings resist corrosion better than zinc-plated steel fittings. 303 stainless steel fittings are more corrosion resistant than brass fittings and have good chemical resistance.

Fittings with a check valve prevent grease from leaking when pressure causes backward flow. The valve stays closed when not in use to keep out dirt and other contaminants.

UNF threads are similar to threads on a machine screw or bolt. They require a sealant, such as an O-ring, to minimize leakage.

Male

Threads

Pkg. | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Material | Overall Ht. | Thread Lg. | Shank Lg. | Hex Size | Max. Pressure, psi | Check Valve Type | Pkg. Qty. | 1-9 | 10-Up | |

6-40 UNF Threads | ||||||||||

| Zinc-Plated Steel | 1/2" | 9/64" | 9/64" | 1/4" | 10,000 | Without Valve | 10 | 0000000 | 00000 | 00000 |

10-32 UNF Threads | ||||||||||

| Zinc-Plated Steel | 15/32" | 7/64" | 5/64" | 1/4" | 10,000 | Without Valve | 10 | 0000000 | 0000 | 0000 |

| Zinc-Plated Steel | 1/2" | 1/8" | 1/8" | 1/4" | 10,000 | Without Valve | 10 | 0000000 | 0000 | 0000 |

1/4"-28 UNF Threads | ||||||||||

| Zinc-Plated Steel | 33/64" | 5/32" | 5/32" | 9/32" | 10,000 | Ball | 10 | 0000000 | 0000 | 0000 |

| Brass | 17/32" | 5/32" | 5/32" | 9/32" | 10,000 | Ball | 5 | 000000 | 0000 | 0000 |

| Brass | 19/32" | 7/32" | 7/32" | 9/32" | 10,000 | Ball | 5 | 000000 | 0000 | 0000 |

5/16"-24 UNF Threads | ||||||||||

| Zinc-Plated Steel | 21/32" | 5/32" | 5/32" | 3/8" | 10,000 | Ball | 10 | 0000000 | 0000 | 0000 |

| Zinc-Plated Steel | 2 61/64" | 7/32" | 2 35/64" | 11/32" | 10,000 | Ball | 3 | 0000000 | 0000 | 0000 |

| Brass | 19/32" | 7/32" | 7/32" | 11/32" | 10,000 | Ball | 5 | 0000000 | 0000 | 0000 |

| 303 Stainless Steel | 19/32" | 7/32" | 7/32" | 11/32" | 10,000 | Ball | 3 | 0000000 | 00000 | 00000 |

3/8"-24 UNF Threads | ||||||||||

| Zinc-Plated Steel | 5/8" | 1/4" | 1/4" | 7/16" | 8,000 | Ball | 10 | 0000000 | 00000 | 0000 |

| Brass | 19/32" | 7/32" | 7/32" | 7/16" | 10,000 | Ball | 5 | 0000000 | 00000 | 0000 |

| 303 Stainless Steel | 19/32" | 7/32" | 7/32" | 7/16" | 10,000 | Ball | 3 | 0000000 | 00000 | 00000 |

1/2"-20 UNF Threads | ||||||||||

| Zinc-Plated Steel | 11/16" | 1/4" | 1/4" | 9/16" | 1,450 | Ball | 10 | 00000000 | 00000 | 00000 |

Pkg. | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Material | Overall Ht. | Thread Lg. | Shank Lg. | Hex Size | Max. Pressure, psi | Check Valve Type | Pkg. Qty. | 1-9 | 10-Up | |

1/4"-28 UNF Threads | ||||||||||

| Brass | 45/64" | 7/32" | 7/32" | 11/32" | 10,000 | Ball | 3 | 000000 | 000000 | 00000 |

5/16"-24 UNF Threads | ||||||||||

| Zinc-Plated Steel | 23/32" | 5/32" | 13/64" | 23/64" | 8,000 | Ball | 10 | 00000000 | 00000 | 0000 |

3/8"-24 UNF Threads | ||||||||||

| Zinc-Plated Steel | 51/64" | 7/32" | 7/32" | 7/16" | 1,450 | Ball | 10 | 00000000 | 0000 | 0000 |

1/2"-20 UNF Threads | ||||||||||

| Zinc-Plated Steel | 7/8" | 1/4" | 1/4" | 9/16" | 1,450 | Ball | 3 | 00000000 | 00000 | 00000 |

Pkg. | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Material | Overall Ht. | Thread Lg. | Shank Lg. | Hex Size | Max. Pressure, psi | Check Valve Type | Pkg. Qty. | 1-9 | 10-Up | |

3/8"-24 UNF Threads | ||||||||||

| Zinc-Plated Steel | 63/64" | 7/32" | 7/32" | 7/16" | 1,450 | Ball | 10 | 00000000 | 000000 | 000000 |

Pkg. | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Material | Overall Ht. | Thread Lg. | Shank Lg. | Hex Size | Max. Pressure, psi | Check Valve Type | Pkg. Qty. | 1-9 | 10-Up | |

1/4"-28 UNF Threads | ||||||||||

| Zinc-Plated Steel | 39/64" | 7/64" | 1/8" | 3/8" | 10,000 | Ball | 10 | 0000000 | 000000 | 00000 |

| Brass | 59/64" | 7/32" | 7/32" | 11/32" | 10,000 | Ball | 1 | 000000 | 0000 | 0000 |

5/16"-24 UNF Threads | ||||||||||

| Zinc-Plated Steel | 59/64" | 7/32" | 7/32" | 11/32" | 1,450 | Ball | 10 | 00000000 | 0000 | 0000 |

| Brass | 59/64" | 7/32" | 7/32" | 11/32" | 10,000 | Ball | 3 | 0000000 | 00000 | 0000 |

| 303 Stainless Steel | 59/64" | 7/32" | 7/32" | 11/32" | 10,000 | Ball | 1 | 0000000 | 00000 | 0000 |

3/8"-24 UNF Threads | ||||||||||

| Zinc-Plated Steel | 63/64" | 7/32" | 7/32" | 7/16" | 1,450 | Ball | 10 | 00000000 | 00000 | 0000 |

1/2"-20 UNF Threads | ||||||||||

| Zinc-Plated Steel | 57/64" | 1/4" | 1/4" | 9/16" | 1,450 | Ball | 5 | 00000000 | 00000 | 00000 |

Button-Head Grease Fittings

Often used on earth movers, mining equipment, and other heavy machinery, these fittings have a T-shaped top that holds the dispensing tip in place so it won’t pop off when adding grease. They're best for machinery requiring high volumes of grease because they let more grease pass through than standard grease fittings, thanks to a larger opening. An integral check valve prevents grease from leaking when pressure causes backward flow. The valve stays closed when not in use to keep out dirt and other contaminants.

Zinc-plated steel fittings have mild corrosion resistance. UNF threads are similar to threads on a machine screw or bolt. They require a sealant, such as an O-ring, to minimize leakage.

Flush-Style Grease Fittings

The nipple doesn't stick out, so these fittings fit in tight spaces and won't be damaged if something knocks into them. An integral check valve prevents grease from leaking when pressure causes backward flow. The valve stays closed when not in use to keep out dirt and other contaminants.

Zinc-plated steel fittings have mild corrosion resistance.

Install Styles A, B, and D with a slotted screwdriver. Install Style C with a hex wrench. UNF threads are similar to threads on a machine screw or bolt. They require a sealant, such as an O-ring, to minimize leakage.

Pkg. | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Style | Material | Overall Ht. | Thread Lg. | Shank Lg. | Slot Lg. | Hex Size | Max. Pressure, psi | Check Valve Type | Pkg. Qty. | 1-9 | 10-Up | |

Straight with Male Threads | ||||||||||||

10-32 UNF Threads | ||||||||||||

| A | Zinc-Plated Steel | 23/64" | 3/16" | 7/32" | 1/4" | __ | 8,000 | Ball | 5 | 000000000 | 00000 | 00000 |

1/4"-28 UNF Threads | ||||||||||||

| C | Zinc-Plated Steel | 13/32" | 19/64" | 19/64" | __ | 5/16" | 10,000 | Ball | 5 | 00000000 | 0000 | 0000 |

Grease Fitting Adapters

When the size or thread type of a fitting doesn't match an existing opening, use these adapters to make the connection.

Zinc-plated steel adapters have mild corrosion resistance. UNF threads are similar to threads on a machine screw or bolt. They require a sealant, such as an O-ring, to minimize leakage. SAE-LT threads are tapered but designed to be installed into a 1/4"-28 straight-thread UNF hole.