Plastic-Body Blowguns

The lightweight plastic construction makes these blowguns more comfortable to hold than metal. They have an angled nozzle that can direct air over and around obstacles. Pull the trigger to adjust the airflow rate from a puff to a blast. Volume (dB) is measured 3 ft. from the blowgun at 100 psi.

Tapered nonmarring nozzle tips won’t damage your workpiece.

All safety nozzle tips have holes around the circumference so air can escape if the nozzle is blocked.

Safety nozzle tip cannot be removed once installed on a blowgun.

Safety nozzle tip with chip guard creates an air curtain around the airstream to deflect flying chips and dust.

High-flow nozzle tip amplifies the airflow to double that of other nozzles. It cannot be removed once installed on a blowgun.

Chip shield fits over the blowgun nozzle to protect the user from flying debris.

Guns used with tips that meet OSHA 29 CFR 1910.242 will conform to requirements for maximum air outlet pressure.

| Dia. | Volume, dB | Specifications Met | Material | Each | |

Tapered Nonmarring | |||||

|---|---|---|---|---|---|

| 1/2" | 98 | __ | Rubber | 0000000 | 00000 |

| 1" | 98 | __ | Rubber | 0000000 | 00000 |

| 1 5/16" | 98 | __ | Rubber | 0000000 | 00000 |

Safety | |||||

| 1/2" | 94 | OSHA Compliant 29 CFR 1910.242 | Aluminum | 0000000 | 00000 |

Safety with Chip Guard | |||||

| 1/2" | 86 | OSHA Compliant 29 CFR 1910.242 | Aluminum | 0000000 | 00000 |

Low-Noise Safety | |||||

| 13/16" | 82 | OSHA Compliant 29 CFR 1910.242 | Acetal Plastic | 0000000 | 00000 |

High Flow | |||||

| 9/16" | 95 | OSHA Compliant 29 CFR 1910.242 | Aluminum | 0000000 | 00000 |

| OD | Material | Each | |

| 4" | Plastic | 00000000 | 00000 |

Blowguns with Nonmarring Tip

The rubber tip won't damage your workpiece.

Blowguns with angled nozzle can direct air over and around obstacles.

Air Inlet | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Nozzle Lg. | Air Consumption | Volume | Max. Inlet Pressure, psi | Pipe Size | Thread Type | Gender | Body Material | Nozzle Tip Material | Grip Style | Each | |

Pistol Shape with Angled Nozzle | |||||||||||

Lever Control | |||||||||||

| 4 1/2" | 16 cfm @ 100 psi | Not Rated | 90 | 1/4 | NPT | Female | Plastic | Rubber | Plain | 00000000 | 000000 |

Pocket Blowguns

Compact enough to carry with you, these guns have a built-in quick-disconnect hose coupling for easy connection to an air line. Volume (dBA) is measured 3 ft. from the blowgun at 100 psi.

ARO shape couplings are also known as A style.

European shape couplings are also known as V style.

Industrial shape couplings are also known as M style.

Tru-Flate shape couplings are also known as T style.

Blowguns that meet OSHA Compliant 29 CFR 1910.242 conform to requirements for maximum air outlet pressure.

Air Inlet | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Air Inlet Quick-Disconnect Shape | Nozzle Lg. | Air Consumption | Volume, dBA | Overall Lg. | Max. Inlet Pressure, psi | Coupling Size | Gender | Body Material | Nozzle Tip Material | Specifications Met | Each | |

Pistol | ||||||||||||

| ARO | 2" | 13.5 cfm @ 100 psi | 87 | 4 1/2" | 174 | 1/4 | Male | Plastic | Nylon Plastic | OSHA Compliant 29 CFR 1910.242 | 0000000 | 000000 |

| European | 2" | 13.5 cfm @ 100 psi | 87 | 4 1/2" | 174 | 3/8 | Male | Plastic | Nylon Plastic | OSHA Compliant 29 CFR 1910.242 | 0000000 | 00000 |

| Industrial | 2" | 13.5 cfm @ 100 psi | 87 | 4 9/16" | 174 | 1/4 | Male | Plastic | Nylon Plastic | OSHA Compliant 29 CFR 1910.242 | 0000000 | 00000 |

| Tru-Flate | 2" | 13.5 cfm @ 100 psi | 87 | 4 1/2" | 174 | 1/4 | Male | Plastic | Nylon Plastic | OSHA Compliant 29 CFR 1910.242 | 0000000 | 00000 |

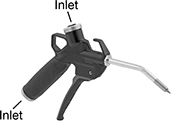

Dual Air-Inlet Blowguns

Two inlets allow connection to air lines above or below. Use the top inlet when the blowgun is suspended from an overhead hose and the bottom inlet for bench and floor hoses. Pull the trigger to adjust the airflow rate from a puff to a blast. The angled nozzle can direct air over and around obstacles. Blowgun conforms to OSHA 29 CFR 1910.242 requirements for maximum air outlet pressure.

Air Inlet | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Nozzle Lg. | Air Consumption | Volume | Max. Inlet Pressure, psi | Pipe Size | Thread Type | Gender | Body Material | Nozzle Tip Material | Specifications Met | Each | |

Pistol | |||||||||||

| 4" | 13 cfm @ 100 psi | 83 dBA | 145 | 1/4 | NPT | Female | Plastic | 316 Stainless Steel | OSHA Compliant 29 CFR 1910.242 | 0000000 | 0000000 |

Plastic-Body Extended-Reach Blowguns

Lightweight and more comfortable to hold than metal-body blowguns, these also have a long nozzle to access hard-to-reach areas. Pull the trigger to adjust the airflow rate from a puff to a blast. Volume is measured 3 ft. from the blowgun at 100 psi.

Tapered nonmarring nozzle tips won’t damage your workpiece.

All safety nozzle tips have holes around the circumference so air can escape if the nozzle is blocked.

Safety nozzle tip cannot be removed once installed on a blowgun.

Safety nozzle tip with chip guard creates an air curtain around the airstream to deflect flying chips and dust.

High-flow nozzle tip amplifies the airflow to double that of other nozzles. It cannot be removed once installed on a blowgun.

Chip shield fits over the blowgun nozzle to protect the user from flying debris.

Guns used with tips that meet OSHA 29 CFR 1910.242 will conform to requirements for maximum air outlet pressure.

Blowguns | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

Air Inlet | Repl. Nozzles | |||||||||||

| Nozzle Lg. | Air Consumption | Volume | Max. Inlet Pressure, psi | Pipe Size | Thread Type | Gender | Body Material | Nozzle Tip Material | Each | Each | ||

Pistol | ||||||||||||

| 6" | 10 cfm @ 100 psi | 90 dBA | 150 | 1/4 | NPT | Female | Plastic | Brass | 0000000 | 000000 | 0000000 | 000000 |

| 13" | 22 cfm @ 100 psi | 94 dB | 230 | 1/4 | NPT | Female | Plastic | Brass | 0000000 | 00000 | 0000000 | 00000 |

| 18" | 10 cfm @ 100 psi | 90 dBA | 150 | 1/4 | NPT | Female | Plastic | Brass | 0000000 | 00000 | 0000000 | 00000 |

| 20" | 22 cfm @ 100 psi | 94 dB | 230 | 1/4 | NPT | Female | Plastic | Brass | 0000000 | 00000 | 0000000 | 00000 |

| 24" | 10 cfm @ 100 psi | 90 dBA | 150 | 1/4 | NPT | Female | Plastic | Brass | 0000000 | 00000 | 0000000 | 00000 |

| 36" | 10 cfm @ 100 psi | 90 dBA | 150 | 1/4 | NPT | Female | Plastic | Brass | 0000000 | 00000 | 0000000 | 00000 |

| Dia. | Volume, dB | Specifications Met | Material | Each | |

Tapered Nonmarring | |||||

|---|---|---|---|---|---|

| 1/2" | 98 | __ | Rubber | 0000000 | 00000 |

| 1" | 98 | __ | Rubber | 0000000 | 00000 |

| 1 5/16" | 98 | __ | Rubber | 0000000 | 00000 |

Safety | |||||

| 1/2" | 94 | OSHA Compliant 29 CFR 1910.242 | Aluminum | 0000000 | 00000 |

Safety with Chip Guard | |||||

| 1/2" | 86 | OSHA Compliant 29 CFR 1910.242 | Aluminum | 0000000 | 00000 |

Low-Noise Safety | |||||

| 13/16" | 82 | OSHA Compliant 29 CFR 1910.242 | Acetal Plastic | 0000000 | 00000 |

High Flow | |||||

| 9/16" | 95 | OSHA Compliant 29 CFR 1910.242 | Aluminum | 0000000 | 00000 |

| OD | Material | Each | |

| 4" | Plastic | 00000000 | 00000 |

Adjustable-Length Blowguns

Increase your reach with the telescoping nozzle. These blowguns conform to OSHA 29 CFR 1910.242 requirements for maximum air outlet pressure.

Air Inlet | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Nozzle Lg. | Air Consumption | Volume | Max. Inlet Pressure, psi | Pipe Size | Thread Type | Gender | Body Material | Nozzle Tip Material | Specifications Met | Each | |

Pistol | |||||||||||

| 12"-32" | 11 cfm @ 100 psi | Not Rated | 120 | 1/4 | NPT | Female | Plastic | ABS Plastic | OSHA Compliant 29 CFR 1910.242 | 0000000 | 000000 |

Plastic-Body High-Airflow Blowguns

Maximize comfort and minimize strain with these lightweight blowguns. They provide more than two times the airflow of standard guns. Pull the trigger to adjust the airflow rate from a puff to a blast. To spray liquids, connect a water line to the inlet. Guns conform to OSHA 29 CFR 1910.242 requirements for maximum air outlet pressure. Volume (dB) is measured 3 ft. from the blowgun at 100 psi.

Air Inlet | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Nozzle Lg. | Air Consumption | Volume, dB | Max. Inlet Pressure, psi | Pipe Size | Thread Type | Gender | Body Material | Nozzle Tip Material | Specifications Met | Each | |

Pistol | |||||||||||

| 2 7/8" | 43 cfm @ 100 psi | 103 | 232 | 1/4 | NPT | Female | Plastic | Aluminum | OSHA Compliant 29 CFR 1910.242 | 000000 | 000000 |

Wide-Airflow Blowguns

The flat nozzle distributes air over a wider area than focused-airflow blowguns. All of these blowguns conform to OSHA 29 CFR 1910.242 requirements for maximum air outlet pressure.

Blowguns with a nylon nozzle tip won't damage your workpiece.

Air Inlet | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Nozzle Lg. | Air Consumption | Volume | Max. Inlet Pressure, psi | Pipe Size | Thread Type | Gender | Body Material | Nozzle Tip Material | Specifications Met | Each | |

Pistol | |||||||||||

| 2" | 22 cfm @ 100 psi | 81 dBA | 145 | 1/4 | NPT | Female | Plastic | Nylon Plastic | OSHA Compliant 29 CFR 1910.242 | 0000000 | 0000000 |

| 3 1/2" | 25 cfm @ 100 psi | 85 dBA | 145 | 1/4 | NPT | Female | Plastic | Zinc | OSHA Compliant 29 CFR 1910.242 | 0000000 | 000000 |

Personnel Cleaning Blow-Off Systems

Safely blow dust and debris off your clothes. These blowers are a safer alternative to compressed air and help you meet OSHA regulations. A heavy duty plastic body protects these blowers from damage and wear.

Bring portable blowers to job sites. They can also be used to clear off machinery and benchtops around your shop. Clean hard-to-reach areas with an extra-long hose.

Wall-mount blowers automatically shut off after 60 seconds to save energy. A holster stores the nozzle out of the way when blowers are not in use. Blowers include a chip guard and a swivel hose connector.

Chip guards prevent loose particles from flying back towards the user.

Swivel hose connectors enable the nozzle to rotate freely for easy movement.

Hose | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Nozzle Lg. | Volume, dB | Horsepower, hp | Air Pressure, psi | Dia. | Lg., ft. | Body Material | Ht. | Wd. | Dp. | Current, A | Voltage | Cord Lg., ft. | Mounting Fasteners Included | Specifications Met | Features | Each | |

Portable | |||||||||||||||||

| 2" | 74 | 0.6 | 3 | 1 1/2" | 8 | Plastic | 13 3/4" | 11" | 14" | 10.8 | 120V AC | 6 | __ | OSHA Compliant 29 CFR 1910.242 | __ | 0000000 | 000000000 |

Wall Mount | |||||||||||||||||

| 2" | 78 | 1.75 | 3 | 1 1/2" | 4 1/2 | Plastic | 16" | 14" | 12" | 10.8 | 120V AC | 6 | No | OSHA Compliant 29 CFR 1910.242 | Automatic Shut-Off | 0000000 | 00000000 |

Air-Powered Hand-Held Vacuum/Blowers for Dry Pickup

Use as either a vacuum or a blower—change the airflow direction to switch functions. These vacuum/blowers clean up dirt, dust, metal chips, and glass around machinery and workstations.

Vacuuming requires the reusable collection bag with clamp or the discharge hose, both sold separately.

Vacuum/blower with blowout tube simultaneously dislodges and vacuums debris such as metal chips.