About Loc-Line and Snap-Loc Coolant Hose

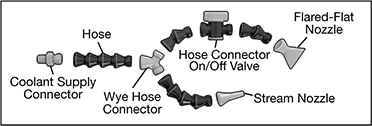

Assemble and disassemble Loc-Line and Snap-Loc coolant hose by snapping components together or pulling them apart. Assembly and separation tools (sold separately) are recommended.

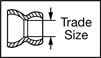

To ensure compatibility, select the color and trade size that match your current system. A system’s trade size is equal to the ID of its hose.

1/4" Loc-Line Coolant Hose

Build a custom system to deliver coolant, cutting oil, water, or air in any direction. Once in position, hose stays put—there's no spring back or movement caused by vibration or heavy flow.

Assemble and disassemble by snapping components together or pulling them apart. Assembly pliers (sold separately) are recommended. To ensure compatibility, select the color and trade size that match your current system. These components fit Loc-Line hose with a 1/4” ID.

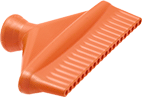

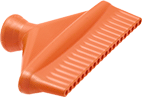

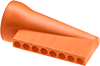

Nozzles direct flow.

For technical drawings and 3-D models, click on a part number.

Orifices | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Style | Shape | Spray Pattern | Gender | No. of | Dia. | O'all Lg. | Material | Max. Flow Rate, gph | Max. Pressure, psi | Max. Temp., °F | Pkg. Qty. | Pkg. | |

| 24 | Straight | Multiple Stream | Female | 5 | 1/16" | 7/16" | Acetal Plastic | 250 | 30 | 170° | 4 | 00000000 | 00000 |

| 24 | Straight | Multiple Stream | Female | 7 | 3/64" | 1" | Acetal Plastic | 250 | 30 | 170° | 4 | 000000000 | 0000 |

| 25 | Straight | Multiple Stream | Female | 16 | 3/64" | 1 1/2" | Acetal Plastic | 250 | 30 | 170° | 2 | 00000000 | 0000 |

| 25 | Straight | Multiple Stream | Female | 16 | 1/16" | 1 17/32" | Acetal Plastic | 250 | 30 | 170° | 2 | 00000000 | 0000 |

| 25 | Straight | Multiple Stream | Female | 20 | 5/64" | 2 1/2" | Acetal Plastic | 250 | 30 | 170° | 2 | 00000000 | 00000 |

| 26 | 90° Elbow | Multiple Stream | Female | 6 | 3/32" | 3/4" | Acetal Plastic | 250 | 30 | 170° | 2 | 0000000 | 0000 |

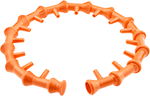

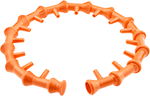

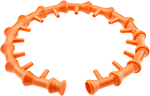

Style 28 is an assembly of 15 style 27 nozzles with a cap.

Orifices | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Style | Gender | Spray Pattern | No. of | Dia. | OD | Bend Radius | Material | Max. Flow Rate, gph | Max. Pressure, psi | Max. Temp., °F | Pkg. Qty. | Pkg. | |

| 28 | Female | Multiple Stream | 15 | 5/64" | 3 5/8" | 1 1/4" | Acetal Plastic | 250 | 30 | 170° | 1 | 00000000 | 000000 |

1/2" Loc-Line Coolant Hose

Build a custom system to deliver coolant, cutting oil, water, or air in any direction. Once in position, hose stays put—there’s no spring back or movement caused by vibration or heavy flow.

Assemble and disassemble by snapping components together or pulling them apart. Assembly pliers (sold separately) are recommended. To ensure compatibility, select the color and trade size that match your current system. These components fit Loc-Line hose with a 1/2" ID.

Nozzles direct flow.

For technical drawings and 3-D models, click on a part number.

Orifices | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Style | Shape | Spray Pattern | Gender | No. of | Dia. | O'all Lg. | Material | Max. Flow Rate, gph | Max. Pressure, psi | Max. Temp., °F | Pkg. Qty. | Pkg. | |

| 22 | Straight | Multiple Stream | Female | 5 | 1/8" | 45/64" | Acetal Plastic | 478 | 20 | 170° | 4 | 0000000 | 00000 |

| 22 | Straight | Multiple Stream | Female | 7 | 1/16" | 45/64" | Acetal Plastic | 478 | 20 | 170° | 4 | 000000000 | 0000 |

| 23 | Straight | Multiple Stream | Female | 20 | 5/64" | 2 1/2" | Acetal Plastic | 478 | 20 | 170° | 2 | 00000000 | 00000 |

| 24 | 90° Elbow | Multiple Stream | Female | 8 | 11/64" | 1 3/4" | Acetal Plastic | 478 | 20 | 170° | 2 | 0000000 | 0000 |

Style 26 is an assembly of 15 style 25 nozzles with a cap.

Orifices | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Style | Gender | Spray Pattern | No. of | Dia. | OD | Bend Radius | Material | Max. Flow Rate, gph | Max. Pressure, psi | Max. Temp., °F | Pkg. Qty. | Pkg. | |

| 26 | Female | Multiple Stream | 15 | 9/64" | 4 1/2" | 1 3/4" | Acetal Plastic | 478 | 20 | 170° | 1 | 00000000 | 000000 |

1/4" Snap-Loc Coolant Hose

Build a custom system to deliver coolant, cutting oil, water, or air in any direction. Once in position, hose stays put—there’s no spring back or movement caused by vibration or heavy flow.

Assemble and disassemble by snapping components together or pulling them apart. Assembly and separation tools (sold separately) are recommended. To ensure compatibility, select the color and trade size that match your current system. These components fit Snap-Loc hose with a 1/4" ID.

For technical drawings and 3-D models, click on a part number.

Orifices | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Style | Shape | Spray Pattern | Gender | No. of | Dia. | O'all Lg. | Material | Max. Flow Rate, gph | For Max. SSU Viscosity Grade | Max. Pressure, psi | Max. Temp., °F | Pkg. Qty. | Pkg. | |

| 14 | 90° Elbow | Multiple Stream | Female | 6 | 1/16" | 1 5/16" | Polypropylene Plastic | 500 | 200 | 30 | 200° | 2 | 0000000 | 00000 |

1/2" Snap-Loc Coolant Hose

For technical drawings and 3-D models, click on a part number.

Orifices | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Style | Shape | Spray Pattern | Gender | No. of | Dia. | O'all Lg. | Material | Max. Flow Rate, gph | For Max. SSU Viscosity Grade | Max. Pressure, psi | Max. Temp., °F | Pkg. Qty. | Pkg. | |

| 13 | 90° Elbow | Multiple Stream | Female | 7 | 1/8" | 2 3/16" | Polypropylene Plastic | 2,000 | 200 | 20 | 200° | 2 | 0000000 | 00000 |

1/4" Acid-Resistant Loc-Line Coolant Hose

Use this hose in areas exposed to acids, gasoline, alcohol, and other harsh chemicals. Build a custom system to deliver coolant, cutting oil, water, or air in any direction. Once in position, hose stays put—there’s no spring back or movement caused by vibration or heavy flow.

Assemble and disassemble by snapping components together or pulling them apart. Assembly pliers (sold separately) are recommended. To ensure compatibility, select the color and trade size that match your current system. These components fit Loc-Line hose with a 1/4" ID.

For technical drawings and 3-D models, click on a part number.