Filter by

System of Measurement

Thread Size

Fastener Strength Grade/Class

Locking Type

Thread Type

Hex Nut Profile

Material

Specifications Met

Performance

DFARS Specialty Metals

Sold As

Export Control Classification Number (ECCN)

Drive Style

Thread Direction

Insert Maximum Temperature

Distorted Thread Type

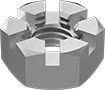

Nylon-Insert Locknuts

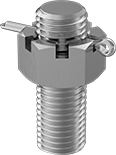

Top-Lock Distorted-Thread Locknuts

|

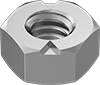

Medium-Strength Steel

Thread Size | Wd., mm | Ht., mm | Fastener Strength Grade/Class | Specs. Met | Pkg. Qty. | Pkg. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Zinc-Yellow-Chromate-Plated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M36 × 4 mm | 55 | 36 | ISO Class 8 | DIN 980V | 1 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||