Filter by

System of Measurement

Thread Size

Drive Style

Thread Spacing

Fastener Strength Grade/Class

Material

Hex Nut Profile

Thread Type

Fastener Strength Rating

Face Style

DFARS Specialty Metals

Export Control Classification Number (ECCN)

REACH

RoHS

Spanner Wrench Style

Thread Direction

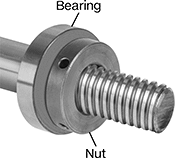

About Hex Nuts

Choose a hex nut with the right profile, material, and strength for your application.