Filter by

Shape

System of Measurement

Flexibility

Tolerance Rating

Hardness Rating

Fabrication

Tensile Strength

Color

Clarity

For Use With

Specifications Met

Density

Dielectric Strength

Flammability Rating

For Use Outdoors

Export Control Classification Number (ECCN)

REACH

RoHS

DFARS Specialty Metals

Flexural Modulus

Impact Strength

About Plastic

Compare over 25 types of plastic to find the right material for you.

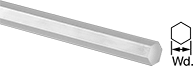

Wear-Resistant Nylon Hexagonal Bars

- Color: Off-White

- Max. Temperature: 185° F

- Tensile Strength: 11,200-12,300 psi (Good)

- Impact Strength: 0.6-1.4 ft.-lbs./in. (Poor)

- Hardness: Rockwell R108-R121 (Hard)

- For Use Outdoors: No

- Specifications Met: ASTM D5989, ASTM D6779, UL 94 V-2

These nylon 6/6 hex bars are often machined into gears and other high-wear parts. They have a slippery surface that reduces wear caused by friction.