About Sleeving

More

About Heat-Shrink Tubing

More

Self-Extinguishing Spiral Sleeving

With a self-extinguishing additive, this sleeving will not produce fumes when exposed to open flame and high temperatures. Made of nylon, it also has good abrasion resistance. A reusable alternative to tape and cable ties, it allows you to route wire and cable between the spirals.

UV-resistant sleeving absorbs UV light, so it can be used in direct sunlight without getting damaged.

| ID | Expanded ID | OD | Wall Thick. | Temperature Range, °F | Specifications Met | Color | Each | |

10 ft. Lg. | ||||||||

|---|---|---|---|---|---|---|---|---|

Nylon Plastic | ||||||||

| 1/16" | 1/2" | 1/8" | 1/32" | -40° to 250° | UL Recognized Component | Clear | 00000000 | 00000 |

| 3/16" | 2" | 1/4" | 1/32" | -40° to 250° | UL Recognized Component | Clear | 00000000 | 00000 |

| 5/16" | 3" | 3/8" | 1/32" | -40° to 250° | UL Recognized Component | Clear | 00000000 | 00000 |

| 7/16" | 4" | 1/2" | 1/32" | -40° to 250° | UL Recognized Component | Clear | 00000000 | 00000 |

| 11/16" | 5" | 3/4" | 1/32" | -40° to 250° | UL Recognized Component | Clear | 00000000 | 00000 |

| 15/16" | 7" | 1" | 1/32" | -40° to 250° | UL Recognized Component | Clear | 00000000 | 00000 |

UV-Resistant Nylon Plastic | ||||||||

| 1/16" | 1/2" | 1/8" | 1/32" | -40° to 250° | UL Recognized Component | Black | 00000000 | 0000 |

| 3/16" | 2" | 1/4" | 1/32" | -40° to 250° | UL Recognized Component | Black | 00000000 | 00000 |

| 5/16" | 3" | 3/8" | 1/32" | -40° to 250° | UL Recognized Component | Black | 00000000 | 00000 |

| 7/16" | 4" | 1/2" | 1/32" | -40° to 250° | UL Recognized Component | Black | 00000000 | 00000 |

| 11/16" | 5" | 3/4" | 1/32" | -40° to 250° | UL Recognized Component | Black | 00000000 | 00000 |

| 15/16" | 7" | 1" | 1/32" | -40° to 250° | UL Recognized Component | Black | 00000000 | 00000 |

25 ft. Lg. | ||||||||

Nylon Plastic | ||||||||

| 1/16" | 1/2" | 1/8" | 1/32" | -40° to 250° | UL Recognized Component | Clear | 00000000 | 00000 |

| 3/16" | 2" | 1/4" | 1/32" | -40° to 250° | UL Recognized Component | Clear | 00000000 | 00000 |

| 5/16" | 3" | 3/8" | 1/32" | -40° to 250° | UL Recognized Component | Clear | 00000000 | 00000 |

| 7/16" | 4" | 1/2" | 1/32" | -40° to 250° | UL Recognized Component | Clear | 00000000 | 00000 |

| 11/16" | 5" | 3/4" | 1/32" | -40° to 250° | UL Recognized Component | Clear | 00000000 | 00000 |

| 15/16" | 7" | 1" | 1/32" | -40° to 250° | UL Recognized Component | Clear | 00000000 | 00000 |

UV-Resistant Nylon Plastic | ||||||||

| 1/16" | 1/2" | 1/8" | 1/32" | -40° to 250° | UL Recognized Component | Black | 0000000 | 00000 |

| 3/16" | 2" | 1/4" | 1/32" | -40° to 250° | UL Recognized Component | Black | 0000000 | 00000 |

| 5/16" | 3" | 3/8" | 1/32" | -40° to 250° | UL Recognized Component | Black | 0000000 | 00000 |

| 7/16" | 4" | 1/2" | 1/32" | -40° to 250° | UL Recognized Component | Black | 0000000 | 00000 |

| 11/16" | 5" | 3/4" | 1/32" | -40° to 250° | UL Recognized Component | Black | 0000000 | 00000 |

| 15/16" | 7" | 1" | 1/32" | -40° to 250° | UL Recognized Component | Black | 0000000 | 00000 |

50 ft. Lg. | ||||||||

Nylon Plastic | ||||||||

| 1/16" | 1/2" | 1/8" | 1/32" | -40° to 250° | UL Recognized Component | Clear | 00000000 | 00000 |

| 3/16" | 2" | 1/4" | 1/32" | -40° to 250° | UL Recognized Component | Clear | 00000000 | 00000 |

| 5/16" | 3" | 3/8" | 1/32" | -40° to 250° | UL Recognized Component | Clear | 00000000 | 00000 |

| 7/16" | 4" | 1/2" | 1/32" | -40° to 250° | UL Recognized Component | Clear | 00000000 | 00000 |

| 11/16" | 5" | 3/4" | 1/32" | -40° to 250° | UL Recognized Component | Clear | 00000000 | 000000 |

| 15/16" | 7" | 1" | 1/32" | -40° to 250° | UL Recognized Component | Clear | 00000000 | 000000 |

UV-Resistant Nylon Plastic | ||||||||

| 1/16" | 1/2" | 1/8" | 1/32" | -40° to 250° | UL Recognized Component | Black | 0000000 | 00000 |

| 3/16" | 2" | 1/4" | 1/32" | -40° to 250° | UL Recognized Component | Black | 0000000 | 00000 |

| 5/16" | 3" | 3/8" | 1/32" | -40° to 250° | UL Recognized Component | Black | 0000000 | 00000 |

| 7/16" | 4" | 1/2" | 1/32" | -40° to 250° | UL Recognized Component | Black | 0000000 | 00000 |

| 11/16" | 5" | 3/4" | 1/32" | -40° to 250° | UL Recognized Component | Black | 0000000 | 000000 |

| 15/16" | 7" | 1" | 1/32" | -40° to 250° | UL Recognized Component | Black | 0000000 | 000000 |

100 ft. Lg. | ||||||||

Nylon Plastic | ||||||||

| 1/16" | 1/2" | 1/8" | 1/32" | -40° to 250° | UL Recognized Component | Clear | 00000000 | 00000 |

| 3/16" | 2" | 1/4" | 1/32" | -40° to 250° | UL Recognized Component | Clear | 00000000 | 00000 |

| 5/16" | 3" | 3/8" | 1/32" | -40° to 250° | UL Recognized Component | Clear | 00000000 | 000000 |

| 7/16" | 4" | 1/2" | 1/32" | -40° to 250° | UL Recognized Component | Clear | 00000000 | 000000 |

| 11/16" | 5" | 3/4" | 1/32" | -40° to 250° | UL Recognized Component | Clear | 00000000 | 000000 |

| 15/16" | 7" | 1" | 1/32" | -40° to 250° | UL Recognized Component | Clear | 00000000 | 000000 |

UV-Resistant Nylon Plastic | ||||||||

| 1/16" | 1/2" | 1/8" | 1/32" | -40° to 250° | UL Recognized Component | Black | 0000000 | 00000 |

| 3/16" | 2" | 1/4" | 1/32" | -40° to 250° | UL Recognized Component | Black | 0000000 | 00000 |

| 5/16" | 3" | 3/8" | 1/32" | -40° to 250° | UL Recognized Component | Black | 0000000 | 000000 |

| 7/16" | 4" | 1/2" | 1/32" | -40° to 250° | UL Recognized Component | Black | 0000000 | 000000 |

| 11/16" | 5" | 3/4" | 1/32" | -40° to 250° | UL Recognized Component | Black | 0000000 | 000000 |

| 15/16" | 7" | 1" | 1/32" | -40° to 250° | UL Recognized Component | Black | 0000000 | 000000 |

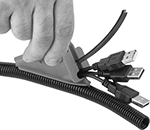

Hook-and-Loop Wrap-Around Sleeving

A strip of hook-and-loop creates a strong seal along the entire length of this sleeving, yet it can be opened at any point to access contents. Wrap it around wire, cable, and hose without disconnecting them.

Nylon sleeving is made of tightly braided fibers for excellent abrasion resistance. It has the toughness of metal, yet remains flexible. Polyurethane-coated nylon sleeving works well outdoors, resisting both moisture and UV rays. It also stands up to chemicals and oil.

Zippered Wrap-Around Sleeving

Zip this sleeving around wire, cable, and hose without disconnecting them; it has a slit along the entire length. Made of nylon, it provides good abrasion resistance.

Abrasion-Resistant Expandable Sleeving

Braided from thick plastic strands, this sleeving has excellent abrasion resistance. It’s expandable, so it stretches to fit over items for easy installation, then tightens around its contents for a secure fit. The braided construction permits heat and moisture to dissipate.

Nylon sleeving is thicker than polyester sleeving, so it withstands contact with rougher surfaces but is not as chemical resistant as polyester.

| ID | Expanded ID | Wall Thick. | Temperature Range, °F | Color | Lg., ft. | Each | |

Nylon Fabric | |||||||

|---|---|---|---|---|---|---|---|

| 1/2" | 5/8" | 1/16" | -75° to 300° | Black | 3 | 000000 | 00000 |

| 1/2" | 5/8" | 1/16" | -75° to 300° | Black | 10 | 000000 | 00000 |

| 1/2" | 5/8" | 1/16" | -75° to 300° | Black | 100 | 0000000 | 00000 |

| 3/4" | 1" | 1/16" | -75° to 300° | Black | 3 | 000000 | 0000 |

| 3/4" | 1" | 1/16" | -75° to 300° | Black | 10 | 000000 | 00000 |

| 3/4" | 1" | 1/16" | -75° to 300° | Black | 50 | 0000000 | 00000 |

| 1 1/4" | 1 1/2" | 1/16" | -75° to 300° | Black | 3 | 000000 | 0000 |

| 1 1/4" | 1 1/2" | 1/16" | -75° to 300° | Black | 10 | 000000 | 00000 |

| 1 1/4" | 1 1/2" | 1/16" | -75° to 300° | Black | 50 | 0000000 | 00000 |

| 1 3/4" | 2" | 1/16" | -75° to 300° | Black | 3 | 000000 | 0000 |

| 1 3/4" | 2" | 1/16" | -75° to 300° | Black | 10 | 0000000 | 00000 |

| 1 3/4" | 2" | 1/16" | -75° to 300° | Black | 25 | 0000000 | 00000 |

Abrasion-Resistant Sleeving

Tightly braided fibers give this sleeving excellent abrasion resistance. As it wears, the fibers frizz and make the outer wall thicker for improved protection. The interior is smooth to reduce snags during installation. It meets Mine Safety and Health Administration (MSHA) standards for fire protection in mines. Because this sleeving is non-expandable, it does not stretch, so it’s best for applications where you know the exact diameter of the items you need to protect.

Nylon sleeving is thicker than polyester sleeving, so it withstands contact with rougher surfaces. However, it can’t handle temperatures as high.

Per Ft. | ||||||||

|---|---|---|---|---|---|---|---|---|

| ID | Wall Thick. | Temperature Range, °F | Certification | Color | Lengths, ft. | 1-99 | 100-Up | |

Nylon Fabric | ||||||||

| 3/4" | 3/64" | -40° to 190° | MSHA Accepted | Black | 00000000 | 00000 | 00000 | |

| 7/8" | 3/64" | -40° to 190° | MSHA Accepted | Black | 00000000 | 0000 | 0000 | |

| 1" | 3/64" | -40° to 190° | MSHA Accepted | Black | 00000000 | 0000 | 0000 | |

| 1 1/8" | 3/64" | -40° to 190° | MSHA Accepted | Black | 00000000 | 0000 | 0000 | |

| 1 1/4" | 3/64" | -40° to 190° | MSHA Accepted | Black | 00000000 | 0000 | 0000 | |

| 1 1/2" | 3/64" | -40° to 190° | MSHA Accepted | Black | 00000000 | 0000 | 0000 | |

| 1 5/8" | 3/64" | -40° to 190° | MSHA Accepted | Black | 00000000 | 0000 | 0000 | |

| 1 3/4" | 3/64" | -40° to 190° | MSHA Accepted | Black | 00000000 | 0000 | 0000 | |

| 1 7/8" | 3/64" | -40° to 190° | MSHA Accepted | Black | 00000000 | 0000 | 0000 | |

| 2 1/16" | 3/64" | -40° to 190° | MSHA Accepted | Black | 00000000 | 0000 | 0000 | |

| 2 1/4" | 3/64" | -40° to 190° | MSHA Accepted | Black | 00000000 | 0000 | 0000 | |

| 2 5/8" | 3/64" | -40° to 190° | MSHA Accepted | Black | 00000000 | 0000 | 0000 | |

| 2 15/16" | 3/64" | -40° to 190° | MSHA Accepted | Black | 00000000 | 0000 | 0000 | |

| 3 11/16" | 3/64" | -40° to 190° | MSHA Accepted | Black | 00000000 | 0000 | 0000 | |

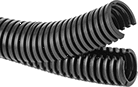

High-Strength Slit Corrugated Sleeving

Made of nylon, this sleeving is the most impact- and abrasion-resistant slit corrugated sleeving we offer. It resists acids and solvents. Wrap it around wire, cable, and hose without disconnecting them. It has a slit along the entire length that will not gap when flexing.

| ID | OD | Temperature Range, °F | Color | 5 ft. | 25 ft. | 50 ft. | 100 ft. | |

Nylon Plastic | ||||||||

|---|---|---|---|---|---|---|---|---|

| 1/4" | 3/8" | -40° to 300° | Black | 0000000 | ||||

| 3/8" | 1/2" | -40° to 300° | Black | 0000000 | ||||

| 7/16" | 9/16" | -40° to 300° | Black | 00000000 | ||||

| 1/2" | 11/16" | -40° to 300° | Black | 0000000 | ||||

| 5/8" | 3/4" | -40° to 300° | Black | 0000000 | ||||

| 3/4" | 15/16" | -40° to 300° | Black | 0000000 | ||||

| 7/8" | 1 1/8" | -40° to 300° | Black | 00000000 | ||||

| 1" | 1 1/16" | -40° to 300° | Black | 0000000 | ||||

| 1 1/8" | 1 3/8" | -40° to 300° | Black | 00000000 | ||||

| 1 1/4" | 1 1/2" | -40° to 300° | Black | 0000000 | ||||

| 1 1/2" | 1 15/16" | -40° to 300° | Black | 0000000 | ||||

Heat-Reflective Slit Corrugated Sleeving

Made of aluminum with a nylon liner, this sleeving reflects heat away from contents and withstands temperatures up to 300° F to protect against internal and external sources of heat. Often used in automotive applications, it resists antifreeze, brake fluid, gasoline, and oil. Wrap it around wire, cable, and hose without disconnecting them. It has a slit along the entire length that will not gap when flexing. The corrugated construction gives it the impact and abrasion resistance of conduit but with better flexibility.

Slit Corrugated Sleeving with Closure Strip

Seal out dirt and dust better than standard slit sleeving—this sleeving secures shut with a closure strip. A slit along its entire length lets you install it around wire, cable, and hose that are already connected. Made of corrugated nylon, it resists wear and impact better than polyethylene sleeving and about as well as conduit. It’s ideal for high-traffic areas. It also resists acids and solvents, and it won’t crack from exposure to direct sunlight.

Speed up installation with the included tool, which routes cables and the rubber closure strip through the sleeving while closing the slit like a zipper. To use the tool, you have to disconnect your cables on one end. The tool holds plug ends while it pulls your cables through, so you don’t have to route bulky plugs through the sleeving.

32 ft. Lg. | |||||||

|---|---|---|---|---|---|---|---|

| ID | OD | Temperature Range, °F | Environmental Rating | Includes | Color | Each | |

Nylon Plastic with TPE Rubber Strip | |||||||

| 3/8" | 1/2" | -40° to 200° | IP50 | Installation Tool | Black | 0000000 | 000000 |

| 7/16" | 9/16" | -40° to 200° | IP50 | Installation Tool | Black | 0000000 | 00000 |

| 5/8" | 13/16" | -40° to 200° | IP50 | Installation Tool | Black | 0000000 | 00000 |

| 7/8" | 1 1/16" | -40° to 200° | IP50 | Installation Tool | Black | 0000000 | 000000 |

| 1 3/16" | 1 5/16" | -40° to 200° | IP50 | Installation Tool | Black | 0000000 | 000000 |

High-Strength Two-Piece Interlocking Corrugated Sleeving

Made of nylon, this sleeving stands up to scrapes and impact better than polyethylene sleeving, so it’s ideal for high-traffic areas. Since it’s corrugated, its impact and scrape resistance is similar to conduit, but it’s more flexible. It has two interlocking halves that nest into each other to fully enclose its contents, sealing it against dust and dirt—even when flexing. Often used instead of conduit, it has a long lifespan and is easier to install. Fit it around your wire, cable, or hose without having to disconnect them.

Because this sleeving is nylon, it also resists acids and solvents, and it won’t crack in direct sunlight. IP rated, it protects your components even in high-pressure, high-temperature washdowns.

| ID | OD | Temperature Range, °F | Environmental Rating | Color | 5 ft. Lg. | 25 ft. Lg. | 50 ft. Lg. | |

Nylon Plastic | ||||||||

|---|---|---|---|---|---|---|---|---|

| 1/4" | 3/8" | -40° to 245° | IP68, IP69K | Black | 00000000 | |||

| 7/16" | 5/8" | -40° to 245° | IP68, IP69K | Black | 00000000 | |||

| 9/16" | 13/16" | -40° to 245° | IP68, IP69K | Black | 00000000 | |||

| 7/8" | 1 1/8" | -40° to 245° | IP68, IP69K | Black | 00000000 | |||

| 1 1/16" | 1 3/8" | -40° to 245° | IP68, IP69K | Black | 00000000 | |||

| 1 1/4" | 1 11/16" | -40° to 245° | IP68, IP69K | Black | 00000000 | |||

| 1 3/4" | 2 1/8" | -40° to 245° | IP68, IP69K | Black | 00000000 | |||

Moisture-Seal Wrap for Heat-Shrink Tubing

Use this wrap with heat-shrink tubing to create a moisture-resistant seal. Apply it like tape around wire and cable, and slide the tubing over the wrap. The wrap melts when tubing is heated and bonds to the underlying surface.

Nylon plastic wrap is ultra thin, so you can wrap it around each individual wire as well as your whole bundle for enhanced protection. Along with water, it resists oils, chemicals, and grease.

Dielectric strength is the maximum voltage a material can handle before it starts to breakdown. The higher the dielectric strength of a material, the better it is for preventing electricity, heat, or signal from dissipating from wire and cable.

25 ft. Lg. | |||||||

|---|---|---|---|---|---|---|---|

| Thick. | Wd. | Color | Clarity | Temperature Range, °F | Dielectric Strength | Each | |

Nylon Plastic | |||||||

| 0.008" | 2" | Yellow | Semi-Clear | -65° to 275° | 300 V/mil | 00000000 | 0000000 |