Filter by

Seal OD

Material

For Use With

Groove Diameter

For Cylinder Type

Seal Thickness

Color

Shaft Seal Motion

System of Measurement

Speed

Maximum Speed

Hardness

Maximum Temperature

Export Control Classification Number (ECCN)

DFARS Specialty Metals

REACH

RoHS

Filler Material

Minimum Temperature

Wear Rings

| |

Profile |

|  |

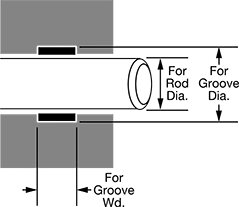

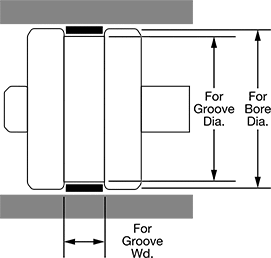

Rod Installation | Piston Installation |

Made from glass-filled nylon for excellent wear resistance and strength.

Gap Size—Gap size is the maximum distance between the split ends of the ring while it is in use. Rings are closed when not in use.

For Rod Sealing | For Piston Sealing | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Rod Dia. | For Groove Dia. | For Bore Dia. | For Groove Dia. | Gap Size | Max. Speed, ft/sec | Temp. Range, ° F | Hardness | Color | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Glass-Filled Nylon | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For 0.260" Wide Grooves | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 0.750" | 3/4" | 0.500" | 0.093" | 3 | -40 to 275 | Rockwell R120 (Extra Hard) | Gray | 1453N11 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | 1.000" | 1" | 0.750" | 0.093" | 3 | -40 to 275 | Rockwell R120 (Extra Hard) | Gray | 1453N13 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 1.250" | 1 1/4" | 1.000" | 0.093" | 3 | -40 to 275 | Rockwell R120 (Extra Hard) | Gray | 1453N17 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4" | 1.500" | 1 1/2" | 1.250" | 0.093" | 3 | -40 to 275 | Rockwell R120 (Extra Hard) | Gray | 1453N19 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 3/8" | 1.625" | 1 5/8" | 1.375" | 0.093" | 3 | -40 to 275 | Rockwell R120 (Extra Hard) | Gray | 1453N22 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 1.750" | 1 3/4" | 1.500" | 0.093" | 3 | -40 to 275 | Rockwell R120 (Extra Hard) | Gray | 1453N24 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 5/8" | 1.875" | 1 7/8" | 1.625" | 0.093" | 3 | -40 to 275 | Rockwell R120 (Extra Hard) | Gray | 1453N26 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 3/4" | 2.000" | 2" | 1.750" | 0.093" | 3 | -40 to 275 | Rockwell R120 (Extra Hard) | Gray | 1453N28 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 7/8" | 2.125" | 2 1/8" | 1.875" | 0.093" | 3 | -40 to 275 | Rockwell R120 (Extra Hard) | Gray | 1453N31 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 2.250" | 2 1/4" | 2.000" | 0.093" | 3 | -40 to 275 | Rockwell R120 (Extra Hard) | Gray | 1453N33 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 1/4" | 2.500" | 2 1/2" | 2.250" | 0.093" | 3 | -40 to 275 | Rockwell R120 (Extra Hard) | Gray | 1453N37 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 1/2" | 2.750" | 2 3/4" | 2.500" | 0.093" | 3 | -40 to 275 | Rockwell R120 (Extra Hard) | Gray | 1453N39 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 3/4" | 3.000" | 3" | 2.750" | 0.093" | 3 | -40 to 275 | Rockwell R120 (Extra Hard) | Gray | 1453N42 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3" | 3.250" | 3 1/4" | 3.000" | 0.093" | 3 | -40 to 275 | Rockwell R120 (Extra Hard) | Gray | 1453N44 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 1/4" | 3.500" | 3 1/2" | 3.250" | 0.093" | 3 | -40 to 275 | Rockwell R120 (Extra Hard) | Gray | 1453N46 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 3/4" | 4.000" | 4" | 3.750" | 0.093" | 3 | -40 to 275 | Rockwell R120 (Extra Hard) | Gray | 1453N48 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For 0.385" Wide Grooves | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 1.250" | 1 1/4" | 1.000" | 0.093" | 3 | -40 to 275 | Rockwell R120 (Extra Hard) | Gray | 1453N18 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4" | 1.500" | 1 1/2" | 1.250" | 0.093" | 3 | -40 to 275 | Rockwell R120 (Extra Hard) | Gray | 1453N21 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 1.750" | 1 3/4" | 1.500" | 0.093" | 3 | -40 to 275 | Rockwell R120 (Extra Hard) | Gray | 1453N25 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 3/4" | 2.000" | 2" | 1.750" | 0.093" | 3 | -40 to 275 | Rockwell R120 (Extra Hard) | Gray | 1453N29 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 2.250" | 2 1/4" | 2.000" | 0.093" | 3 | -40 to 275 | Rockwell R120 (Extra Hard) | Gray | 1453N34 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 1/4" | 2.500" | 2 1/2" | 2.250" | 0.093" | 3 | -40 to 275 | Rockwell R120 (Extra Hard) | Gray | 1453N38 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 3/4" | 3.000" | 3" | 2.750" | 0.093" | 3 | -40 to 275 | Rockwell R120 (Extra Hard) | Gray | 1453N43 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 1/4" | 3.500" | 3 1/2" | 3.250" | 0.093" | 3 | -40 to 275 | Rockwell R120 (Extra Hard) | Gray | 1453N47 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 3/4" | 4.000" | 4" | 3.750" | 0.093" | 3 | -40 to 275 | Rockwell R120 (Extra Hard) | Gray | 1453N49 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||