Filter by

For Use With

Container Size

Maximum Pressure

Maximum Discharge Pressure

Housing Material

Wetted Parts Material

Flow Rate

Pump Type

Air Connection Pipe Size

Maximum Temperature

Discharge Connection

Intake Tube Material

Piston Material

DFARS Specialty Metals

Export Control Classification Number (ECCN)

Air-Powered Constant-Flow-Rate Piston Pumps

Flow Rate, gpm | Air Pressure, psi | Overall | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

@ 0 psi | @ 3,000 psi | Max. ft. of Head, ft. | Max. Discharge Pressure, psi | Max. Viscosity, cP | Min. | Max. | Air Consumption, scfm | Air Connection (NPT) | Intake Pipe Connection (NPT) | Discharge Pipe Connection (NPT) | Lg. | Wd. | Ht. | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

86:1 Discharge Liquid to Inlet Air Pressure Ratio | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.19 | 0.17 | 28,764 | 12,470 | 100 | 15 | 145 | 20 | 1/4 Female | 3/8 Female | 1/4 Female | 4 5/8" | 4" | 9" | 0000000 | 000000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

28:1 Discharge Liquid to Inlet Air Pressure Ratio | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.58 | 0.13 | 9,365 | 4,060 | 100 | 15 | 145 | 20 | 1/4 Female | 3/8 Female | 1/4 Female | 4 5/8" | 4" | 9" | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

High-Pressure Air-Powered Drum Pumps for Oil

Temp., ° F | Intake | Discharge | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Flow Rate, gpm | For Container Size, gal. | Max. Viscosity, cP | Min. | Max. | Air Pressure, psi | Air Consumption, ft³/min | For Drum Opening Size | Includes | Air Connection | Tube OD | Tube Lg. | Discharge Location | Connection | Pipe Size | Each | |||

| 6 | 15 | 8,750 | 10 | 150 | 0 to 150 | 14 | 2 NPT | Drum Connector | 1/4 Female NPTF | 1 3/4" | 22" | Pump Body | Threaded | 1/2 Female NPT | 0000000 | 0000000 | ||

| 10 | 55 | 1,500 | Not Rated | 140 | 30 to 150 | 9 | 2 NPT | Drum Connector | 1/4 Female NPT | 2" | 37" | Pump Body | Threaded | 1/2 Female NPT | 0000000 | 000000 | ||

Adjustable-Flow Easy-Stroke Drum Pumps for Water and Chemicals

|  |

PPS Housing | 304 Stainless Steel Housing |

Temp. | Intake | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Flow Rate, fl oz/stroke | For Container Size, gal. | Max. Viscosity, cP | Min. | Max., ° F | For Drum Opening Size | Includes | Tube OD | Tube Lg. | For Discharge Tube ID | Spout Type | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

PPS Intake Tube and PPS Housing | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8, 10, 12 | 15 to 55 | 500 | Not Rated | 180 | 1 1/2 NPT, 2 NPT | Drum Connector | 1 5/8" | 24 1/2" to 34 1/2" | 1" | Removable | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

304 Stainless Steel Intake Tube and 304 Stainless Steel Housing | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6, 8, 10, 12 | 15 to 55 | 2,000 | Not Rated | 140 | 1 1/2 NPT, 2 NPT | Drum Connector | 1 1/8" | 18 1/2" to 32 1/2" | 11/16" | Removable | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Drum Pumps for Water and Chemicals

|  |  |  |  |  |

Style A | Style B | Style C (Shown with Connector) | Style D | Style E | Style F |

Style A

Temp. | Intake | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Flow Rate, fl oz/stroke | For Container Size, gal. | Max. Viscosity, cP | Min. | Max., ° F | For Drum Opening Size | Includes | Tube OD | Tube Lg. | Discharge Location | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

PVC Piston | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8 | 5 to 15 | 700 | Not Rated | 120 | 2 NPT | Drum Connector | 1 1/2" | 22" | Spout End | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 22 | 15 to 55 | 700 | Not Rated | 120 | 2 NPT | Drum Connector | 1 1/2" | 39" | Spout End | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Style B

Temp. | Intake | Discharge | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Flow Rate, fl oz/stroke | For Container Size, gal. | Max. Viscosity, cP | Min. | Max., ° F | For Drum Opening Size | Includes | Tube OD | Tube Lg. | Location | Tube ID | Tube OD | Tube Lg. | Tube Material | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

PVC Piston | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8 | 5 to 15 | 700 | Not Rated | 120 | 2 NPT | Drum Connector | 1 1/2" | 22" | Tube End | 7/16" | 5/8" | 22" | PVC | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 22 | 15 to 55 | 700 | Not Rated | 120 | 2 NPT | Drum Connector | 1 1/2" | 39" | Tube End | 7/16" | 5/8" | 36" | PVC | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Style C

Temp., ° F | Intake | Discharge | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Flow Rate, fl oz/stroke | For Container Size, gal. | Max. Viscosity, cP | Min. | Max. | Tube OD | Tube Lg. | Location | Tube ID | Tube OD | Tube Lg. | Tube Material | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

CSM Piston | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 | 5 to 15 | 2,500 | 35 | 120 | 1/2" | 18" | Tube End | 7/16" | 9/16" | 9" | PVC | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Style D

Temp., ° F | Intake | Discharge | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Flow Rate, fl oz/stroke | For Container Size, gal. | Max. Viscosity, cP | Min. | Max. | For Drum Opening Size | Includes | Tube OD | Tube Lg. | Location | Tube ID | Tube OD | Tube Lg. | Tube Material | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

CSM Piston | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 | 5 | 2,500 | 35 | 120 | 61 mm | Drum Connector | 1/2" | 14 1/2" | Tube End | 7/16" | 9/16" | 36" | PVC | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 | 5 | 2,500 | 35 | 120 | 63 mm | Drum Connector | 1/2" | 14 1/2" | Tube End | 7/16" | 9/16" | 36" | PVC | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 | 5 | 2,500 | 35 | 120 | 70 mm | Drum Connector | 1/2" | 14 1/2" | Tube End | 7/16" | 9/16" | 36" | PVC | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Style E

Temp., ° F | Intake | Discharge | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Flow Rate, fl oz/stroke | For Container Size, gal. | Max. Viscosity, cP | Min. | Max. | For Drum Opening Size | Includes | Tube OD | Tube Lg. | Location | Tube ID | Tube OD | Tube Lg. | Tube Material | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

CSM Piston | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8 | 5 to 30 | 2,500 | 35 | 120 | 2 NPT | Drum Connector | 1/2" | 18" | Tube End | 7/16" | 9/16" | 48" | PVC | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Viton® Fluoroelastomer Piston | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 | 5 to 55 | 2,500 | 35 | 120 | 2 NPT | Drum Connector | 9/16" | 36" | Tube End | 7/16" | 9/16" | 9" | PVC | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Style F

Pumps | Connectors | Replacement Connectors | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Temp., ° F | Intake | Discharge | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Flow Rate, fl oz/stroke | For Container Size, gal. | Max. Viscosity, cP | Min. | Max. | For Drum Opening Size | Includes | Tube OD | Tube Lg. | Location | Tube ID | Tube OD | Tube Lg. | Tube Material | Each | Connection | Each | Pipe Size | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Buna-N Piston | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 28 | 55 | 2,500 | 35 | 120 | 2 NPT | Drum Connector | 1 1/2" | 38" | Tube End | 1 1/4" | 1 1/2" | 36" | Vinyl Plastic | 0000000 | 0000000 | — | ——— | 0 | — | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 28 | 55 | 2,500 | 35 | 120 | 2 NPT | Drum Connector | 1 1/2" | 38" | Tube End | 1 1/4" | 1 1/2" | 72" | Vinyl Plastic | 0000000 | 000000 | — | ——— | 0 | — | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Viton® Fluoroelastomer Piston | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 28 | 55 | 2,500 | 35 | 120 | 2 NPT | Drum Connector | 1 1/2" | 38" | Tube End | 1 1/4" | 1 1/2" | 36" | Polyethylene | 0000000 | 000000 | 2 5/8"-5 Buttress | 0000000 | 000000 | 2 NPT | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 28 | 55 | 2,500 | 35 | 120 | 2 NPT | Drum Connector | 1 1/2" | 38" | Tube End | 1 1/4" | 1 1/2" | 72" | Polyethylene | 0000000 | 000000 | 2 5/8"-5 Buttress | 0000000 | 00000 | 2 NPT | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Drum Pumps for Oil

Temp., ° F | Intake | Discharge (Pump Body) | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Flow Rate, fl oz/stroke | For Container Size, gal. | Max. Viscosity, cP | Min. | Max. | For Drum Opening Size | Includes | Tube OD | Tube Lg. | Discharge Location | Connection | Hose Size | Gender | Thread Type | Spout Type | Drum Pump Type | Each | |||

| 16 | 15 to 55 | 316 | 50 | 110 | 2 NPT | Drum Connector | 1 1/2" | 37" | Spout End Pump Body | Threaded | 3/4 | Female | GHT | Removable | Plunger | 0000000 | 000000 | ||

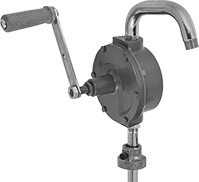

Continuous-Flow Drum Pumps for Oil

|  |  |

Style A | Style B | Style C |

Style A

Pumps | Connectors | Replacement Connectors | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Temp. | Intake | Discharge (Spout End) | ||||||||||||||||||

Flow Rate, fl oz/stroke | For Container Size, gal. | Max. Viscosity, cP | Min. | Max., ° F | For Drum Opening Size | Includes | Tube OD | Tube Lg. | Discharge Location | Pipe Size | Thread Type | Drum Pump Type | Spout Type | Each | Each | Each | ||||

| 11 | 55 | 420 | Not Rated | 300 | 2 NPT | Drum Connector | 1/2" | 40" | Spout End Pump Body | 3/4 | NPT | Crank Handle | Removable | 000000 | 0000000 | 0000000 | 000000 | ——— | 0 | |

| 32 | 15 to 55 | 500 | Not Rated | 180 | 2 NPT | 3/4" ID × 1" OD × 52" Lg. Polyethylene Tube, Drum Connector | 1 1/4" | 39 1/2" | Spout End | — | — | Crank Handle | — | 0000000 | 000000 | ——— | 0 | 0000000 | 000000 | |

Style B

Pumps | Connectors | |||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Temp. | Intake | Discharge (Hose and Nozzle) | Discharge (Spout End) | |||||||||||||||||

Flow Rate, fl oz/stroke | For Container Size, gal. | Max. Viscosity, cP | Min. | Max., ° F | For Drum Opening Size | Includes | Tube OD | Tube Lg. | Discharge Location | Hose OD | Hose Lg., ft. | Pipe Size | Thread Type | Drum Pump Type | Spout Type | Each | Each | |||

| 11 | 55 | 420 | Not Rated | 300 | 2 NPT | Drum Connector | 1/2" | 40" | Hose and Nozzle Spout End Pump Body | 5/8" | 8 | 3/4 | NPT | Crank Handle | Removable | 000000 | 0000000 | 0000000 | 000000 | |

Style C

Pumps | Pump Repair Kits | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Temp., ° F | Intake | |||||||||||||||

Flow Rate, fl oz/stroke | For Container Size, gal. | Max. Viscosity, cP | Min. | Max. | For Drum Opening Size | Includes | Tube OD | Tube Lg. | Discharge Location | For Discharge Tube ID | Drum Pump Type | Each | Each | |||

| 32 | 15 to 55 | 350 | 40 | 120 | 2 NPT | Drum Connector | 1" | 18" to 36" | Spout End | 3/4" | Crank Handle | 0000000 | 0000000 | 0000000 | 000000 | |

Drum Pumps for Fuel and Flammable Liquid

Pumps | Pump Repair Kits | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Intake | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Flow Rate, fl oz/stroke | For Container Size, gal. | Max. Viscosity, cP | Max. Temp., ° F | For Drum Opening Size | Includes | Tube OD | Tube Lg. | Features | Each | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel Housing | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 | 5 | 110 | Not Rated | 1 3/4", 2 1/8", 2 1/4", 2 7/8" | Drum Connector, Flex Spout Adapter, Two Screw Cap Adapters (1 3/4" & 2 1/8") | 1/2" | 16" | Bonding and Grounding Wires, Internal Flame Arrester | 0000000 | 0000000 | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 | 5 | 650 | Not Rated | 1 3/4", 2 1/8", 2 1/4", 2 7/8" | Drum Connector, Flex Spout Adapter, Two Screw Cap Adapters (1 3/4" & 2 1/8") | 1 1/8" | 15" | Bonding and Grounding Wires, Internal Flame Arrester | 0000000 | 000000 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8 | 15 to 55 | 650 | Not Rated | 2 NPT | Drum Connector | 9/16" | 16" to 38" | Bonding and Grounding Wires, Internal Flame Arrester | 0000000 | 000000 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8 | 55 | 110 | Not Rated | 2 NPT | Drum Connector | 1/2" | 22" | Bonding and Grounding Wires, Internal Flame Arrester | 0000000 | 000000 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

316 Stainless Steel Housing | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10 | 5 to 7 | 650 | 140 | 2", 2 5/8" | Drum Connector | 1 1/2" | 18" | Bonding and Grounding Wires | 0000000 | 000000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 20 | 30 to 55 | 650 | 140 | 2" | Drum Connector | 1 1/2" | 37 1/2" | Bonding and Grounding Wires | 0000000 | 000000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Drum Pumps for Water and Coolant

Pumps | Pump Repair Kits | Replacement Connectors | Pail Adapters | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Temp. | Intake | |||||||||||||||||||

Flow Rate, fl oz/stroke | For Container Size, gal. | Max. Viscosity, cP | Min. | Max., ° F | For Drum Opening Size | Includes | Tube OD | Tube Lg. | Discharge Location | Each | Each | Pipe Size | Each | Each | ||||||

| 8 | 5 to 15 | 300 | Not Rated | 140 | 2 NPT | Drum Connector | 1/2" | 22 1/2" | Spout End | 0000000 | 0000000 | 0000000 | 000000 | 2 NPT | 0000000 | 000000 | 0000000 | 000000 | ||

| 16 | 15 to 55 | 300 | Not Rated | 140 | 2 NPT | Drum Connector | 1 1/8" | 39 1/2" | Spout End | 0000000 | 000000 | 0000000 | 00000 | 2 NPT | 0000000 | 00000 | ——— | 0 | ||

Easy-Stroke Drum Pumps for Water, Coolant, and Chemicals

Temp., ° F | Intake | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Style | Flow Rate, fl oz/stroke | For Container Size, gal. | Max. Viscosity, cP | Min. | Max. | For Drum Opening Size | Includes | Tube OD | Tube Lg. | Discharge Location | Drum Pump Type | Each | |||

| B | 11 | 15 to 55 | 250 | -15 | 150 | 2 NPT | Drum Connector | 1" | 19 3/4" to 35 1/2" | Spout End | Lever Handle | 0000000 | 0000000 | ||

Nondrip Drum Pumps for Water and Chemicals

Long-Reach Suction Drum Pumps for Fuel

|

Temp., ° F | Intake | Discharge | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Flow Rate, fl oz/stroke | Max. Viscosity, cP | Min. | Max. | Tube OD | Tube Lg. | Tube ID | Tube OD | Tube Lg. | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

PVC Housing | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 | 2,500 | 35 | 120 | 9/16" | 72" | 7/16" | 9/16" | 36" | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Quick-Dispensing Drum Pumps for Fuel

Pumps | Pump Repair Kits | ||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Temp. | Intake | Discharge (Pump Body) | |||||||||||||||||||||

Flow Rate, fl oz/stroke | For Container Size, gal. | Max. Viscosity, cP | Min. | Max., ° F | For Drum Opening Size | Includes | Tube OD | Tube Lg. | Discharge Location | For Discharge Hose ID | Connection | Pipe Size | Gender | Thread Type | Spout Type | Drum Pump Type | Max. Shackle Dia. | Each | Each | ||||

| 32 | 55 | 410 | Not Rated | 70 | 2 NPT | Drum Connector | 1 5/16" | 34" | Spout End Pump Body | 3/4" | Threaded | 3/4 | Female | NPT | Removable | Lever Handle | 1/4" | 0000000 | 0000000 | 0000000 | 000000 | ||

Quick-Dispensing Drum Pumps with Nozzle for Fuel

Pumps | Pump Repair Kits | ||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Temp. | Intake | Discharge (Hose and Nozzle) | Discharge (Pump Body) | ||||||||||||||||||||

Flow Rate, fl oz/stroke | For Container Size, gal. | Max. Viscosity, cP | Min. | Max., ° F | For Drum Opening Size | Includes | Tube OD | Tube Lg. | Discharge Location | Hose ID | Hose Lg., ft. | Connection | Pipe Size | Gender | Thread Type | Drum Pump Type | Max. Shackle Dia. | Each | Each | ||||

| 32 | 55 | 410 | Not Rated | 70 | 2 NPT | Drum Connector, Vacuum Breaker | 1 5/16" | 34" | Hose and Nozzle Pump Body | 3/4" | 8 | Threaded | 3/4 | Female | NPT | Lever Handle | 1/4" | 0000000 | 0000000 | 0000000 | 000000 | ||

Easy-Stroke Drum Pumps for Oil

Temp., ° F | Intake | Discharge (Pump Body) | ||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Style | Flow Rate, fl oz/stroke | For Container Size, gal. | Max. Viscosity, cP | Min. | Max. | For Drum Opening Size | Includes | Tube OD | Tube Lg. | Discharge Location | For Discharge Tube ID | Connection | Pipe Size | Hose Size | Gender | Thread Type | Spout Type | Drum Pump Type | Each | |||

| A | 10 | 30 to 55 | 319 | 60 | 100 | 2 NPT | Drum Connector | 1 3/4" | 18" to 34" | Spout End Pump Body | — | Threaded | — | 3/4 | Male | GHT | Removable | Lever Handle | 0000000 | 000000 | ||

| A | 12 | 30 to 55 | 319 | 60 | 100 | 2 NPT | Drum Connector | 1 3/4" | 18" to 34" | Spout End Pump Body | — | Threaded | 1/2 | — | Male | NPTF | Removable, Nondrip | Lever Handle | 0000000 | 00000 | ||

| B | 18 | 15 to 55 | 4,000 | Not Rated | 140 | 2 NPT | Drum Connector | 1 1/2" | 18" to 35" | Spout End | 1" | — | — | — | — | — | Removable, Nondrip | Lever Handle | 0000000 | 00000 | ||

Siphon Drum Pumps

|  |

Style A | Style B |

Temp. | Intake | Discharge | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Style | Flow Rate, gpm | For Container Size, gal. | Max. Viscosity, cP | Min. | Max., ° F | For Drum Opening Size | Includes | Tube OD | Tube Lg. | Discharge Location | Tube ID | Tube OD | Tube Lg. | Tube Material | Drum Pump Type | Each | |||

| A | 5 | 15 to 55 | 88 | Not Rated | 140 | 2 NPT | Drum Connector | 7/8" | 34" | Tube End | 13/16" | 1" | 48" | Polyethylene | Siphon | 0000000 | 000000 | ||

| A | 7 | 15 to 55 | 88 | Not Rated | 140 | 2 NPT | Drum Connector | 1" | 34" | Tube End | 13/16" | 1" | 48" | Polyethylene | Siphon | 0000000 | 00000 | ||

| B | 5 to 7 | 5 | 650 | Not Rated | 140 | 2 NPS, 70 mm | Drum Connector | 1 1/2" | 16" | Tube End | 1" | 1 1/4" | 60" | PVC | Siphon | 0000000 | 00000 | ||

| B | 5 to 7 | 5 to 6 | 650 | Not Rated | 140 | 2 NPS | Drum Connector | 1 1/2" | 16" | Tube End | 1" | 1 1/4" | 60" | PVC | Siphon | 0000000 | 00000 | ||

| B | 5 to 7 | 15 | 650 | Not Rated | 140 | 2 NPS | Drum Connector | 1 1/2" | 24" | Tube End | 1" | 1 1/4" | 60" | PVC | Siphon | 0000000 | 00000 | ||