About Precision Flow-Adjustment Valves

More

About Process Pumps

More

About Drum Pumps

More

How to Prime Your Pump

More

How to Determine Feet of Head

More

Compact Drum Pumps for Water and Chemicals

Designed to move low volumes of caustic liquids in confined areas, these pumps have a thin intake tube and a small handle. They are often used to pump cleaning fluids, acid-washing solutions, and bleach.

Style A pumps have a selectable flow rate, so you can adjust flow for different dispensing applications.

Temp. Range, °F | Intake | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Style | Flow Rate, oz./stroke | For Container Size, gal. | Max. Viscosity | Min. | Max. | For Drum Opening Size | Includes | Tube OD | Tube Lg. | Spout Type | Each | |

| A | 2, 4, 6, 8 | 5 | Not Rated | Not Rated | 125° | 3/4 NPT | __ | 5/8" | 18 1/4" | Fixed | 0000000 | 000000 |

| A | 2, 4, 6, 8 | 15-55 | Not Rated | Not Rated | 125° | 2 NPT, 3/4 NPT | Two Drum Connectors | 5/8" | 33" | Fixed | 0000000 | 00000 |

| A | 4, 8, 12, 16 | 15-55 | Not Rated | Not Rated | 125° | 2 NPT, 3/4 NPT | Two Drum Connectors | 5/8" | 33" | Fixed | 0000000 | 00000 |

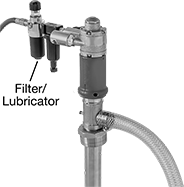

Air-Powered Drum Pumps with Hose and

Filter/Lubricator for Water, Oil, Coolants, and Chemicals

A filter/lubricator ensures efficiency and reduces wear on the pump. They have a chemically resistant seal for use with hydraulic oil and motor oil in addition to acidic and alkaline liquids such as ammonia and etching and cleaning solutions. Pumps have a nonsparking motor for use in applications where electricity is unavailable or dangerous.

Temp. Range, °F | Air Connection | Intake | Discharge | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Flow Rate, gpm | For Container Size, gal. | Max. Viscosity, cP | Min. | Max. | Air Pressure Range, psi | Air Consumption, cfm | For Drum Opening Size | Includes | Pipe Size | Gender | Thread Type | Tube OD | Tube Lg. | Tube ID | Tube Lg., ft. | Features | Each | |

| 16 | 55 | 2,000 | 35° | 150° | 80-100 | 32 | 2 NPT | Drum Connector | 1/4 | Female | NPT | 1 5/8" | 40" | 1" | 5 | 15-ft. Air Hose Assembly, Air Filter/Lubricator, Ball Valve, Muffler | 0000000 | 000000000 |

PVDF Extended-Life Air-Powered Drum Pumps for Chemicals

A chemical- and impact-resistant PVDF housing stands up to aggressive chemicals such as methyl ethyl ketone (MEK) and xylene. Also known as diaphragm pumps, they have few moving parts that can fail for a long service life. Install an air line filter/lubricator to ensure efficiency and reduce wear on the pump.

Repair kits include O-rings, valves, and diaphragms.

Temp. Range, °F | Air Connection | Intake | Discharge | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Flow Rate, gpm | For Container Size, gal. | Max. Viscosity, cP | Min. | Max. | Air Pressure, psi | Air Consumption, cfm | For Drum Opening Size | Pipe Size | Gender | Thread Type | Pipe Size | Gender | Thread Type | Tube Lg. | Pipe Size | Gender | Thread Type | Each | |

| 13 | 55 | 3,000 | 40° | 210° | 100 | 12 | 2 NPT | 1/4 | Female | NPT | 1/2 | Female | NPT | 36" | 1/2 | Female | NPT | 0000000 | 000000000 |

| Repair Kit | 00000000 | Each | 0000000 |

Fixed-Flow-Rate Metering Pumps for Chemicals

Also known as peristaltic pumps and tubing pumps, these maintain a fixed flow rate. Pumps are self-priming, which means they create a suction force to draw liquid upward and fill the pump chamber. Mount them up to 25 feet above your liquid source. All can run dry. Do not use with solids.

Pumps with Viton® fluoroelastomer tubing withstand oil such as gasoline and hydraulic oil.

Overall | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Flow Rate, gal./day (For Tube ID) | Max. Pressure, psi | Max. Viscosity, cP | Temp. Range, °F | Horsepower | Current, A | Lg. | Wd. | Ht. | Includes | Each | |

115V AC,Single Phase—Plug | |||||||||||

PVDF Plastic and Viton® Fluoroelastomer Rubber Wetted Parts Material | |||||||||||

| 0.02 (1/32") 0.07 (1/16") 0.25 (1/8") | 30 | 800 | 32° to 122° | Subfractional | 0.03 | 5 1/2" | 3 1/4" | 3 3/4" | 4 1/2" Lg. of 1/32" ID Viton® Fluoroelastomer Tubing (Shore A60), 4 1/2" Lg. of 1/16" ID Viton® Fluoroelastomer Tubing (Shore A60), 4 1/2" Lg. of 1/8" ID Viton® Fluoroelastomer Tubing (Shore A60) | 000000000 | 0000000 |

| 0.11 (1/32") 0.34 (1/16") 1.25 (1/8") | 30 | 800 | 32° to 122° | Subfractional | 0.03 | 5 1/2" | 3 1/4" | 3 3/4" | 4 1/2" Lg. of 1/32" ID Viton® Fluoroelastomer Tubing (Shore A60), 4 1/2" Lg. of 1/16" ID Viton® Fluoroelastomer Tubing (Shore A60), 4 1/2" Lg. of 1/8" ID Viton® Fluoroelastomer Tubing (Shore A60) | 000000000 | 000000 |

| 0.87 (1/16") 3.53 (1/8") 6.84 (3/16") | 30 | 800 | 32° to 122° | Subfractional | 0.03 | 5 1/2" | 3 1/4" | 3 3/4" | 6" Lg. of 1/16" ID Viton® Fluoroelastomer Tubing (Shore A60), 6" Lg. of 1/8" ID Viton® Fluoroelastomer Tubing (Shore A60), 6" Lg. of 3/16" ID Viton® Fluoroelastomer Tubing (Shore A60) | 000000000 | 000000 |

| 1.75 (1/16") 7.07 1/8") 13.68 (3/16") | 30 | 800 | 32° to 122° | Subfractional | 0.03 | 5 1/2" | 3 1/4" | 3 3/4" | 6" Lg. of 1/16" ID Viton® Fluoroelastomer Tubing (Shore A60), 6" Lg. of 1/8" ID Viton® Fluoroelastomer Tubing (Shore A60), 6" Lg. of 3/16" ID Viton® Fluoroelastomer Tubing (Shore A60) | 000000000 | 000000 |

| 22.80 (3/16") 38.00 (1/4") | 15 | 500 | 32° to 122° | Subfractional | 0.52 | 5" | 5" | 7" | 6" Lg. of 3/16" ID Viton® Fluoroelastomer Tubing (Shore A60), 6" Lg. of 1/4" ID Viton® Fluoroelastomer Tubing (Shore A60) | 000000000 | 000000 |

| 45.6 (3/16") 76.00 (1/4") | 15 | 200 | 32° to 122° | Subfractional | 0.65 | 5" | 5" | 7" | 6" Lg. of 3/16" ID Viton® Fluoroelastomer Tubing (Shore A60), 6" Lg. of 1/4" ID Viton® Fluoroelastomer Tubing (Shore A60) | 000000000 | 000000 |

| 228.00 (3/16") 380.00 (1/4") | 15 | 50 | 32° to 122° | Subfractional | 1.74 | 5" | 5" | 7" | 6" Lg. of 3/16" ID Viton® Fluoroelastomer Tubing (Shore A60), 6" Lg. of 1/4" ID Viton® Fluoroelastomer Tubing (Shore A60) | 000000000 | 000000 |

PTFE Air-Powered Transfer Pumps for Harsh Chemicals

With all PTFE wetted parts, these pumps offer the best chemical resistance of all our air-powered transfer pumps and can handle solvents and petroleum-based fluids that PVDF pumps can’t. Pumps are self-priming, which means they create a suction force to draw liquid upward to fill the pump chamber. All can run dry.

Fluid-side maintenance kits include diaphragms, check valve balls, and seals.

Air-motor maintenance kits include seals, O-rings, gaskets, retaining rings, and an air valve spool.

Overall | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Max. Flow Rate, gpm | Air Consumption, cfm | Air Connection (NPT) | Intake Pipe Connection (NPT) | Discharge Pipe Connection (NPT) | Lg. | Wd. | Ht. | Each | |

231 Max. ft. of Head—100 psi Max. Discharge Pressure | |||||||||

| 2.5 | 4.8 | 1/8 Female | 1/4 Female | 1/4 Female | 3 3/8" | 5 1/2" | 6 1/2" | 000000 | 000000000 |

| 6.7 | 9.3 | 1/8 Female | 3/8 Female | 3/8 Female | 3 1/2" | 5 7/8" | 7 5/8" | 000000 | 00000000 |

| 16 | 29 | 1/4 Female | 1/2 Female | 1/2 Female | 6" | 9 3/16" | 8" | 000000 | 00000000 |

| 39 | 46 | 1/4 Female | 1 Female | 1 Female | 8" | 10 7/8" | 10 3/8" | 000000 | 00000000 |

| Fluid-Side Maintenance Kit for 2925N1 | 0000000 | Each | 0000000 |

| Air-Motor Maintenance Kit for 2925N1 | 0000000 | Each | 000000 |

| Fluid-Side Maintenance Kit for 2925N4 | 0000000 | Each | 00000000 |

| Air-Motor Maintenance Kit for 2925N4 | 0000000 | Each | 000000 |

| Fluid-Side Maintenance Kit for 2925N2 | 0000000 | Each | 000000 |

| Air-Motor Maintenance Kit for 2925N2 | 0000000 | Each | 000000 |

| Fluid-Side Maintenance Kit for 2925N3 | 0000000 | Each | 00000000 |

| Air-Motor Maintenance Kit for 2925N3 | 0000000 | Each | 000000 |

Threaded Precision Flow-Adjustment Valves for Chemicals

To withstand aggressive and corrosive solutions in chemical-processing applications, these valves have a fluoroelastomer seal and a plastic body. Turn the handle to adjust flow in small increments for metering, sampling, and other applications requiring fine flow control.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

- Valve Type: Needle

- For Use With: Water, Oil, Beverage, Citric Acid, Deionized Water, Diesel Fuel, Ethanol, Ethylene Glycol, Food, Fuel Oil, Gasoline, Hydrochloric Acid, Isopropyl Alcohol, Kerosene, Methanol, Mineral Spirits, Phosphoric Acid, Salt Water, Soap Solutions, Sodium Hydroxide, Sodium Hypochlorite, Sulfuric Acid

- Seal Material: Fluoroelastomer Rubber

- Seat Material: PTFE Plastic

- Needle Material: Polypropylene Plastic

Precision Flow-Adjustment Valves with Barbed Fittings for Chemicals

- Valve Type: Needle

- For Use With: Water, Oil, Air, Argon, Butane, Carbon Dioxide, Citric Acid, Deionized Water, Diesel Fuel, Ethanol, Ethylene Glycol, Gasoline, Helium, Hydrochloric Acid, Isopropyl Alcohol, Kerosene, Krypton, Methanol, Mineral Spirits, Natural Gas, Neon, Nitric Acid, Nitrogen, Oxygen, Phosphoric Acid, Propane, Salt Water, Soap Solutions, Sodium Hydroxide, Sodium Hypochlorite, Sulfuric Acid, Toluene, Xenon, Xylene

- Seal Material: PTFE Plastic

- Packing Material: PTFE Plastic

- Needle Material: PVDF Plastic

Barbs grip onto tubing, providing a secure hold. To withstand aggressive and corrosive solutions in chemical-processing applications, these valves have a PTFE seal and a PVDF body. Turn the handle to adjust flow in small increments for metering, sampling, and other applications requiring fine flow control. Threads and a hex nut below the handle allow you to install these valves in instrument panels. They have a nut that can be tightened to compress the packing if it leaks.

For technical drawings and 3-D models, click on a part number.

| For Tube ID | For Tube OD | Flow Coefficient (Cv) | Max. Pressure | Max. Temperature, °F | Panel Cutout Dia. | End-to-End Lg. | Each | |

Black PVDF Plastic Body | ||||||||

|---|---|---|---|---|---|---|---|---|

Barbed × Barbed | ||||||||

| 1/4" | 3/8" | 0.3 | 125 psi @ 140° F | 140° | 7/8" | 3 5/16" | 0000000 | 000000 |

| 3/8" | 1/2" | 0.3 | 125 psi @ 140° F | 140° | 7/8" | 3 5/16" | 0000000 | 00000 |

| 1/2" | 5/8" | 0.4 | 125 psi @ 140° F | 140° | 7/8" | 3 5/16" | 0000000 | 00000 |

Precision Flow-Adjustment Valves with Push-to-Connect Fittings for Chemicals

- Valve Type: Needle

- For Use With: Water, Oil, Air, Argon, Butane, Carbon Dioxide, Citric Acid, Deionized Water, Diesel Fuel, Ethanol, Ethylene Glycol, Gasoline, Helium, Hydrochloric Acid, Isopropyl Alcohol, Kerosene, Krypton, Methanol, Mineral Spirits, Natural Gas, Neon, Nitric Acid, Nitrogen, Oxygen, Phosphoric Acid, Propane, Salt Water, Soap Solutions, Sodium Hydroxide, Sodium Hypochlorite, Sulfuric Acid, Toluene, Xenon, Xylene

- Seal Material: Fluoroelastomer Rubber

- Packing Material: PTFE Plastic

- Needle Material: PVDF Plastic

Insert tubing into the fittings on these valves—no heat, solder, or flux required. With a fluoroelastomer seal and a PVDF body, they can withstand aggressive and corrosive solutions in chemical-processing applications. Turn the handle to adjust flow in small increments for metering, sampling, and other applications requiring fine flow control. Threads and a hex nut below the handle allow you to install these valves in instrument panels. They have a nut that can be tightened to compress the packing if it leaks.