Filter by

For Use With

Body Material

Fitting Connection

Connects To

Voltage

Shape

Actuation Mechanism

Maximum Pressure @ Temperature

Actuator Housing Material

Handle Style

Needle Material

Valve Type

DFARS Specialty Metals

Seat Material

Gender

Maximum Temperature

Actuator Mount Location

Threaded Precision Flow-Adjustment Valves for Chemicals

White PVDF Body

Pipe Size | Flow Coefficient (Cv) | Max. Pressure @ Temp. | Max. Temp., ° F | Panel Cutout Dia. | End-to-End Lg. | Valve Type | For Use With | Seal Material | Seat Material | Needle Material | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

NPT Female × NPT Female | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4 | 0.64 | 150 psi @ 70° F | 300 | 1 5/16" | 2 1/2" | Needle | Water, Oil, Food, Beverage, Citric Acid, Deionized Water, Diesel Fuel, Ethanol, Ethylene Glycol, Fuel Oil, Gasoline, Hydrochloric Acid, Isopropyl Alcohol, Kerosene, Methanol (Methyl Alcohol), Mineral Spirits, Phosphoric Acid, Salt Water, Soap Solutions, Sodium Hydroxide (Caustic Soda), Sodium Hypochlorite (Bleach), Sulfuric Acid | Fluoroelastomer | PTFE | Polypropylene | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8 | 0.72 | 150 psi @ 70° F | 300 | 1 5/16" | 2 1/2" | Needle | Water, Oil, Food, Beverage, Citric Acid, Deionized Water, Diesel Fuel, Ethanol, Ethylene Glycol, Fuel Oil, Gasoline, Hydrochloric Acid, Isopropyl Alcohol, Kerosene, Methanol (Methyl Alcohol), Mineral Spirits, Phosphoric Acid, Salt Water, Soap Solutions, Sodium Hydroxide (Caustic Soda), Sodium Hypochlorite (Bleach), Sulfuric Acid | Fluoroelastomer | PTFE | Polypropylene | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2 | 0.79 | 150 psi @ 70° F | 300 | 1 5/16" | 2 1/2" | Needle | Water, Oil, Food, Beverage, Citric Acid, Deionized Water, Diesel Fuel, Ethanol, Ethylene Glycol, Fuel Oil, Gasoline, Hydrochloric Acid, Isopropyl Alcohol, Kerosene, Methanol (Methyl Alcohol), Mineral Spirits, Phosphoric Acid, Salt Water, Soap Solutions, Sodium Hydroxide (Caustic Soda), Sodium Hypochlorite (Bleach), Sulfuric Acid | Fluoroelastomer | PTFE | Polypropylene | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

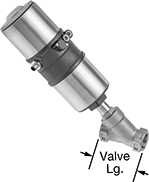

Air-Driven Flow-Adjustment Valves

Pipe Size | Gender | Thread Type | Flow Coefficient (Cv) | Max. Pressure @ Temp. | Valve Type | Temp. Range, ° F | Input Signal | Valve Lg. | Overall Ht. | Air Connection | For Use With | Seal Material | Certification | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Stainless Steel Body with M12 Plug In Connection | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Single Acting: Air-to-Open, Spring-Return (Fail Closed)—24V DC | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2 | Female | NPT | 5 | 230 psi @ 265° F | Zero Pressure Drop, Globe | 14 to 130 | 4 to 20 mA, 0 to 10V DC | 2 9/16" | 3 9/16" | 1/8 BSPP Female | Water, Oil, Food | PTFE | C-UL Listed, UL Listed | 000000 | 000000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4 | Female | NPT | 8.26 | 230 psi @ 265° F | Zero Pressure Drop, Globe | 14 to 130 | 4 to 20 mA, 0 to 10V DC | 2 15/16" | 3 9/16" | 1/8 BSPP Female | Water, Oil, Food | PTFE | C-UL Listed, UL Listed | 000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | Female | NPT | 13.95 | 230 psi @ 265° F | Zero Pressure Drop, Globe | 14 to 130 | 4 to 20 mA, 0 to 10V DC | 3 1/2" | 4 3/4" | 1/8 BSPP Female | Water, Oil, Food | PTFE | C-UL Listed, UL Listed | 000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | Female | NPT | 43.02 | 230 psi @ 265° F | Zero Pressure Drop, Globe | 14 to 130 | 4 to 20 mA, 0 to 10V DC | 7 9/32" | 6 1/4" | 1/8 BSPP Female | Water, Oil, Food | PTFE | C-UL Listed, UL Listed | 000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||