About Precision Flow-Adjustment Valves

More

About Process Pumps

More

About Drum Pumps

More

How to Prime Your Pump

More

How to Determine Feet of Head

More

Selectable-Flow-Rate Easy-Stroke Drum Pumps for Water and Chemicals

These pumps have a selectable flow rate, so you can adjust flow for different dispensing applications. A lever handle maximizes output with each stroke for low-effort dispensing.

Whenever working with flammable liquids, always bond and ground your application for static control. For more information about bonding and grounding, see Sections 1910.106 and 1910.107 of the Federal OSHA Code or see bonding and grounding equipment.

Temp. Range, °F | Intake | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Flow Rate, oz./stroke | For Container Size, gal. | Max. Viscosity, cP | Min. | Max. | For Drum Opening Size | Includes | Tube OD | Tube Lg. | For Discharge Tube ID | Spout Type | Each | |

Stainless Steel Intake Tube and Housing | ||||||||||||

| 6, 8, 10, 12 | 15-55 | 2,000 | Not Rated | 140° | 1 1/2 NPT, 2 NPT | Drum Connector | 1 1/8" | 18 1/2"-32 1/2" | 11/16" | Removable | 0000000 | 0000000 |

Drum Pumps for Fuel and Flammable Liquid

All of these pumps have bonding and grounding wires, while some also have an internal flame arrester, to pump fuel, cleaning solvents, and lacquer thinners.

Always bond and ground your application for static control. For more information about bonding and grounding, see Sections 1910.106 and 1910.107 of the Federal OSHA Code or see bonding and grounding equipment.

Steel pumps work with fuels and flammable liquids, but not especially aggressive and corrosive chemicals.

Stainless steel pumps handle aggressive and corrosive liquids that steel pumps cannot.

Pumps for 5-gallon containers have a drum connector that fits Rieke flex spouts and two screw cap adapters: 1 3/4" and 2 1/8".

Repair kits include components such as extension tubes, gaskets, and pistons.

Intake | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Flow Rate, oz./stroke | For Container Size, gal. | Max. Viscosity, cP | Max. Temp. | For Drum Opening Size | Includes | Tube OD | Tube Lg. | Features | Each | |

Steel | ||||||||||

| 4 | 5 | 110 | Not Rated | 1 3/4", 2 1/4", 2 1/8", 2 7/8" | Drum Connector, Flex Spout Adapter, Two Screw Cap Adapters (1 3/4" & 2 1/8") | 1/2" | 16" | Bonding and Grounding Wires, Internal Flame Arrester | 0000000 | 0000000 |

| 8 | 55 | 110 | Not Rated | 2 NPT | Drum Connector | 1/2" | 22" | Bonding and Grounding Wires, Internal Flame Arrester | 0000000 | 000000 |

316 Stainless Steel | ||||||||||

| 10 | 5-7 | 650 | 140° F | 2 5/8", 2" | Drum Connector | 1 1/2" | 18" | Bonding and Grounding Wires | 0000000 | 000000 |

| 20 | 30-55 | 650 | 140° F | 2" | Drum Connector | 1 1/2" | 37 1/2" | Bonding and Grounding Wires | 0000000 | 000000 |

| Repair Kit for Steel Pumps with 110 cP Max. Viscosity | 0000000 | Each | 0000000 |

Air-Powered Drum Pumps for Flammable Liquid

These pumps have a motor that is rated for IEC Zone 1, Groups IIB and IIA; and IEC Zone 21, Groups IIIC, IIIB, and IIIA hazardous locations with flammable gases and vapors, so they can be used with liquids such as acetone, ethanol, methyl ethyl ketone (MEK), xylene, and mineral spirits. Motor is nonsparking for use in applications where electricity is unavailable or dangerous. Install an air line filter/lubricator to ensure efficiency and reduce wear on the pump.

Always bond and ground your application for static control. For more information about bonding and grounding, see Sections 1910.106 and 1910.107 of the Federal OSHA Code or see bonding and grounding equipment.

Temp. Range, °F | Air Connection | Intake | Discharge | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Flow Rate, gpm | For Container Size, gal. | Max. Viscosity, cP | Min. | Max. | Air Pressure Range, psi | Air Consumption, cfm | For Drum Opening Size | Includes | Pipe Size | Gender | Thread Type | Tube OD | Tube Lg. | Tube Connection Type | For Tube ID | Each | |

| 26 | 55 | 1,100 | -40° | 210° | 44-87 | 53 | 2 NPT | Drum Connector | 3/8 | Female | NPT | 1 5/8" | 39" | Barbed | 1" | 0000000 | 000000000 |

| 26 | 55 | 1,100 | -40° | 210° | 44-87 | 53 | 2 NPT | Drum Connector | 3/8 | Female | NPT | 1 5/8" | 47" | Barbed | 1" | 0000000 | 00000000 |

| 53 | 55 | 1,000 | -40° | 210° | 44-87 | 53 | 2 NPT | Drum Connector | 3/8 | Female | NPT | 1 5/8" | 39" | Barbed | 1" | 0000000 | 00000000 |

| 53 | 55 | 1,000 | -40° | 210° | 44-87 | 53 | 2 NPT | Drum Connector | 3/8 | Female | NPT | 1 5/8" | 47" | Barbed | 1" | 0000000 | 00000000 |

PVDF Extended-Life Air-Powered Drum Pumps for Chemicals

A chemical- and impact-resistant PVDF housing stands up to aggressive chemicals such as methyl ethyl ketone (MEK) and xylene. Also known as diaphragm pumps, they have few moving parts that can fail for a long service life. Install an air line filter/lubricator to ensure efficiency and reduce wear on the pump.

Repair kits include O-rings, valves, and diaphragms.

Temp. Range, °F | Air Connection | Intake | Discharge | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Flow Rate, gpm | For Container Size, gal. | Max. Viscosity, cP | Min. | Max. | Air Pressure, psi | Air Consumption, cfm | For Drum Opening Size | Pipe Size | Gender | Thread Type | Pipe Size | Gender | Thread Type | Tube Lg. | Pipe Size | Gender | Thread Type | Each | |

| 13 | 55 | 3,000 | 40° | 210° | 100 | 12 | 2 NPT | 1/4 | Female | NPT | 1/2 | Female | NPT | 36" | 1/2 | Female | NPT | 0000000 | 000000000 |

| Repair Kit | 00000000 | Each | 0000000 |

Hazardous Location Electric Drum Pumps

for Water, Oil, Coolants, and Chemicals

These pumps quickly empty drum contents by moving 48 gallons of liquid per minute. They are often used with lubricating oil as well as with chemicals such as detergents and etching and cleaning solutions. Their electric motors are explosion proof and UL listed for Class I, Divisions 1 and 2, Groups C and D; and Class II, Division 2, Groups F and G environments where flammable gases and combustible dust may be present.

Temp. Range, °F | Intake | Discharge | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Flow Rate, gpm | Discharge Pressure, psi | For Container Size, gal. | Max. Viscosity, cP | Min. | Max. | Horsepower | Current, A | For Drum Opening Size | Tube OD | Tube Lg. | Tube Connection Type | For Tube ID | Thermal Protection | Each | |

120V AC, Single Phase | |||||||||||||||

Hardwire | |||||||||||||||

| 48.5 | 14 | 55 | 300 | -40° | 210° | 1/2 hp | 5.3 | 41 mm | 1 5/8" | 39" | Barbed | 1" | With Thermal Overload Protection | 00000000 | 000000000 |

Electric Drum Pump Systems for Water, Oil, Coolants, and Chemicals

Including nozzles and connectors, these pumps come with everything you need to start pumping. All include a pump assembly, 1" ID hose, dispensing nozzle, drum connector, and storage bracket.

Pumps with a 316 stainless steel housing are often used with fuel, acetone, methyl ethyl ketone (MEK), xylene, and mineral spirits. Their motors are rated IP55 and are CSA certified for use in Class I, Divisions 1 and 2, Group D hazardous environments with flammable gases and vapors.

Temp. Range, °F | Intake | Discharge | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Flow Rate, gpm | Discharge Pressure, psi | For Container Size, gal. | Max. Viscosity, cP | Min. | Max. | Horsepower | Current, A | For Drum Opening Size | Tube OD | Tube Lg. | Tube ID | Tube OD | Tube Lg. | Environmental Rating | Each | |

120V AC, Single Phase—Hardwire | ||||||||||||||||

316 Stainless Steel Housing | ||||||||||||||||

| 18 | 15 | 55 | 1,000 | Not Rated | 175° | 1 1/3 hp | 9.1 | 2 NPT | 1 1/2" | 39" | 1" | 1 1/4" | 72" | NEC Class I Divisions 1, 2 Group D IP55 | 0000000 | 000000000 |

PTFE Air-Powered Transfer Pumps for Harsh Chemicals

With all PTFE wetted parts, these pumps offer the best chemical resistance of all our air-powered transfer pumps and can handle solvents and petroleum-based fluids that PVDF pumps can’t. Pumps are self-priming, which means they create a suction force to draw liquid upward to fill the pump chamber. All can run dry.

Fluid-side maintenance kits include diaphragms, check valve balls, and seals.

Air-motor maintenance kits include seals, O-rings, gaskets, retaining rings, and an air valve spool.

Overall | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Max. Flow Rate, gpm | Air Consumption, cfm | Air Connection (NPT) | Intake Pipe Connection (NPT) | Discharge Pipe Connection (NPT) | Lg. | Wd. | Ht. | Each | |

231 Max. ft. of Head—100 psi Max. Discharge Pressure | |||||||||

| 2.5 | 4.8 | 1/8 Female | 1/4 Female | 1/4 Female | 3 3/8" | 5 1/2" | 6 1/2" | 000000 | 000000000 |

| 6.7 | 9.3 | 1/8 Female | 3/8 Female | 3/8 Female | 3 1/2" | 5 7/8" | 7 5/8" | 000000 | 00000000 |

| 16 | 29 | 1/4 Female | 1/2 Female | 1/2 Female | 6" | 9 3/16" | 8" | 000000 | 00000000 |

| 39 | 46 | 1/4 Female | 1 Female | 1 Female | 8" | 10 7/8" | 10 3/8" | 000000 | 00000000 |

| Fluid-Side Maintenance Kit for 2925N1 | 0000000 | Each | 0000000 |

| Air-Motor Maintenance Kit for 2925N1 | 0000000 | Each | 000000 |

| Fluid-Side Maintenance Kit for 2925N4 | 0000000 | Each | 00000000 |

| Air-Motor Maintenance Kit for 2925N4 | 0000000 | Each | 000000 |

| Fluid-Side Maintenance Kit for 2925N2 | 0000000 | Each | 000000 |

| Air-Motor Maintenance Kit for 2925N2 | 0000000 | Each | 000000 |

| Fluid-Side Maintenance Kit for 2925N3 | 0000000 | Each | 00000000 |

| Air-Motor Maintenance Kit for 2925N3 | 0000000 | Each | 000000 |

316 Stainless Steel Air-Powered Transfer Pumps

for Chemicals, Fuel, and Flammable Liquids

With a 316 stainless steel housing and a PTFE diaphragm, these pumps resist a variety of acids, alkalies, and flammable liquids such as phosphoric acid, acetone, and methyl ethyl ketone (MEK). They're designed for moving large volumes of thick sludges and slurries in demanding environments. Pumps are self-priming, which means they create a suction force to draw liquid upward to fill the pump chamber. All are submersible and can run dry.

Fluid-side maintenance kits include diaphragms, check valve balls, and seals.

Air-motor maintenance kits include seals, O-rings, gaskets, retaining rings, and an air valve spool.

Max. Flow Rate, gpm | Overall | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Max. Flow Rate, gpm | @ 80 ft. of Head | @ 120 ft. of Head | @ 160 ft. of Head | Max. Viscosity, cP | Air Consumption, cfm | Air Connection (NPT) | Intake Pipe Connection (NPT) | Discharge Pipe Connection (NPT) | Lg. | Wd. | Ht. | Each | |

289 Max. ft. of Head—125 psi Max. Discharge Pressure | |||||||||||||

| 15 | 12 | 10 | 7 | 10,000 | 20 | 1/4 Female | 1/2 Female | 1/2 Female | 9" | 10" | 10" | 00000000 | 000000000 |

| 45 | 38 | 30 | 19 | 20,000 | 40 | 1/2 Female | 1 Female | 1 Female | 13" | 10" | 13" | 00000000 | 00000000 |

| 106 | 77 | 62 | 45 | 30,000 | 50 | 3/4 Female | 1 1/2 Female | 1 1/2 Female | 15" | 17" | 22" | 00000000 | 00000000 |

| 150 | 104 | 76 | 53 | 40,000 | 100 | 3/4 Female | 2 Female | 2 Female | 15" | 17" | 26" | 00000000 | 00000000 |

| 235 | 174 | 127 | 90 | 50,000 | 140 | 3/4 Female | 3 Female | 3 Female | 17" | 20" | 32" | 00000000 | 000000000 |

| Fluid-Side Maintenance Kit for 41655K32 | 0000000 | Each | 000000000 |

| Air-Motor Maintenance Kit for 41655K29, 41655K31, 41655K32 | 0000000 | Each | 000000 |

| Air-Motor Maintenance Kit for 41655K27 | 0000000 | Each | 000000 |

| Fluid-Side Maintenance Kit for 41655K27 | 0000000 | Each | 000000 |

| Fluid-Side Maintenance Kit for 41655K31 | 0000000 | Each | 00000000 |

| Air-Motor Maintenance Kit for 41655K28 | 0000000 | Each | 000000 |

| Fluid-Side Maintenance Kit for 41655K28 | 0000000 | Each | 000000 |

| Fluid-Side Maintenance Kit for 41655K29 | 0000000 | Each | 00000000 |

Aluminum Air-Powered Transfer Pumps for Oil, Chemicals, and Fuel

These pumps have a PTFE diaphragm compatible with oil, fuel, and chemicals such as mineral spirits, methyl ethyl ketone (MEK), and xylene. They have a rugged aluminum housing for moving large volumes of thick sludges and slurries in demanding environments. Pumps are self-priming, which means they create a suction force to draw liquid upward to fill the pump chamber. All are submersible and can run dry.

Fluid-side maintenance kits include diaphragms, check valve balls, and seals.

Air-motor maintenance kits include seals, O-rings, gaskets, retaining rings, and an air valve spool.

Max. Flow Rate, gpm | Overall | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Max. Flow Rate, gpm | @ 80 ft. of Head | @ 120 ft. of Head | @ 160 ft. of Head | Max. Viscosity, cP | Air Consumption, cfm | Air Connection (NPT) | Intake Pipe Connection (NPT) | Discharge Pipe Connection (NPT) | Lg. | Wd. | Ht. | Each | |

289 Max. ft. of Head—125 psi Max. Discharge Pressure | |||||||||||||

| 15 | 12 | 10 | 7 | 10,000 | 20 | 1/4 Female | 1/2 Female, 1/2 Female | 1/2 Female, 1/2 Female | 9" | 10" | 12" | 0000000 | 000000000 |

| 45 | 38 | 30 | 19 | 20,000 | 40 | 1/2 Female | 1 Female | 1 Female | 13" | 10" | 13" | 0000000 | 00000000 |

| 106 | 77 | 62 | 45 | 30,000 | 50 | 3/4 Female | 1 1/2 Female | 1 1/2 Female | 15" | 17" | 22" | 0000000 | 00000000 |

| 150 | 104 | 76 | 53 | 40,000 | 100 | 3/4 Female | 2 Female | 2 Female | 15" | 17" | 26" | 0000000 | 00000000 |

| 235 | 174 | 127 | 90 | 50,000 | 140 | 3/4 Female | 3 Female | 3 Female | 17" | 20" | 32" | 0000000 | 00000000 |

| Fluid-Side Maintenance Kit for 9948K21 | 0000000 | Each | 000000000 |

| Air-Motor Maintenance Kit for 9948K21, 9948K23 and 9948K24 | 0000000 | Each | 000000 |

| Air-Motor Maintenance Kit for 9948K16 | 0000000 | Each | 000000 |

| Fluid-Side Maintenance Kit for 9948K16 | 0000000 | Each | 000000 |

| Air-Motor Maintenance Kit for 9948K19 | 0000000 | Each | 000000 |

| Fluid-Side Maintenance Kit for 9948K19 | 0000000 | Each | 000000 |

| Fluid-Side Maintenance Kit for 9948K23 | 0000000 | Each | 00000000 |

| Fluid-Side Maintenance Kit for 9948K24 | 0000000 | Each | 00000000 |

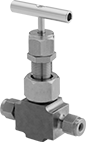

Precision Flow-Adjustment Valves with Yor-Lok Fittings for Chemicals

- Valve Type: Needle

- For Use With: Oil, Acetone, Air, Ammonia, Argon, Butane, Carbon Dioxide, Deionized Water, Diesel Fuel, Ethanol, Gasoline, Helium, Isopropyl Alcohol, Kerosene, Krypton, Methanol, Methyl Ethyl Ketone, Mineral Spirits, Natural Gas, Neon, Nitrogen, Oxygen, Propane, Soap Solutions, Sodium Hydroxide, Toluene, Xenon, Xylene

- Seal Material: PTFE Plastic

- Seat Material: 316 Stainless Steel

- Packing Material: PTFE Plastic

- Needle Material: 316 Stainless Steel

For extra gripping power and a strong seal, these valves have Yor-Lok fittings with two sleeves that bite into tubing as you tighten the nut. All are compatible with Swagelok®, Let-Lok, and Parker A-Lok fittings. The 316 stainless steel body, seal and needle, and the PTFE seat and packing can withstand aggressive and corrosive solutions in chemical-processing applications. Turn the handle to adjust flow in small increments for metering, sampling, and other applications requiring fine flow control. Threads and a hex nut below the handle allow you to mount these valves in instrument panels. All have a nut that can be tightened to compress the packing if it leaks. Valves have bubble-tight soft seats that provide a tight seal when the valve is completely closed.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

| For Tube OD | Flow Coefficient (Cv) | Max. Pressure | Temperature Range, °F | Panel Cutout Dia. | End-to-End Lg. | Each | |

316 Stainless Steel Body | |||||||

|---|---|---|---|---|---|---|---|

Yor Lok × Yor Lok | |||||||

| 1/4" | 0.56 | 7000 psi @ 400° F | -20° to 400° | 0.87" | 2 7/8" | 0000000 | 0000000 |

| 3/8" | 0.56 | 7000 psi @ 400° F | -20° to 400° | 0.87" | 2 7/8" | 0000000 | 000000 |

| 1/2" | 0.56 | 7000 psi @ 400° F | -20° to 400° | 0.87" | 3 1/8" | 0000000 | 000000 |