Filter by

For Use With

Housing Material

Container Size

Maximum Temperature

Wetted Parts Material

Fitting Connection

Drum Pump Type

Flow Rate

Body Material

Maximum Flow Rate

Spout Material

Environment

Thread Type

DFARS Specialty Metals

Adjustable-Flow Easy-Stroke Drum Pumps for Water and Chemicals

Temp. | Intake | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Flow Rate, fl oz/stroke | For Container Size, gal. | Max. Viscosity, cP | Min. | Max., ° F | For Drum Opening Size | Includes | Tube OD | Tube Lg. | For Discharge Tube ID | Spout Type | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

304 Stainless Steel Intake Tube and 304 Stainless Steel Housing | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6, 8, 10, 12 | 15 to 55 | 2,000 | Not Rated | 140 | 1 1/2 NPT, 2 NPT | Drum Connector | 1 1/8" | 18 1/2" to 32 1/2" | 11/16" | Removable | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

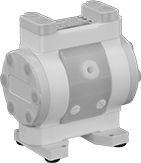

PTFE Air-Powered Double Diaphragm Pumps for Harsh Chemicals

Threaded Side Intake and Threaded Side Discharge

Double Diaphragm Pumps | Air Motor Pump Repair Kits | Fluid Side Pump Repair Kits | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Overall | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Max. Flow Rate, gpm | Max. Solids Dia. | Air Consumption, ft³/min | Air Connection Size | Intake Size | Discharge Size | Lg. | Wd. | Ht. | Each | Each | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

231 ft. Maximum Feet of Head—100 psi Maximum Discharge Pressure | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2.5 | 0.06" | 4.8 | 1/8 Female NPT | 1/4 Female NPT | 1/4 Female NPT | 3 3/8" | 5 1/2" | 6 1/2" | 000000 | 000000000 | 0000000 | 0000000 | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6.7 | 0.08" | 9.3 | 1/8 Female NPT | 3/8 Female NPT | 3/8 Female NPT | 3 1/2" | 5 7/8" | 7 5/8" | 000000 | 00000000 | 0000000 | 000000 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 16 | 0.16" | 29 | 1/4 Female NPT | 1/2 Female NPT | 1/2 Female NPT | 6" | 9 3/16" | 8" | 000000 | 00000000 | 0000000 | 000000 | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 39 | 0.24" | 46 | 1/4 Female NPT | 1 Female NPT | 1 Female NPT | 8" | 10 7/8" | 10 3/8" | 000000 | 00000000 | 0000000 | 000000 | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Precision Flow-Adjustment Valves with Push-to-Connect Fittings for Chemicals

PVDF Body

Overall | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Tube ID | For Tube OD | Flow Coefficient (Cv) | Max. Pressure @ Temp. | Ht. | Lg. | Seal Material | Panel Cutout Dia. | Packing Material | Needle Material | End-to-End Lg. | For Use With | Valve Type | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Push to Connect × Push to Connect | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8" | 1/4" | 0.3 | 125 psi @ 140° F | 2 5/8" | 2 11/16" | Fluoroelastomer | 7/8" | PTFE | PVDF | 2 11/16" | Water, Oil, Air, Argon, Butane, Carbon Dioxide, Citric Acid, Deionized Water, Diesel Fuel, Ethanol, Ethylene Glycol, Gasoline, Helium, Hydrochloric Acid, Isopropyl Alcohol, Kerosene, Krypton, Methanol (Methyl Alcohol), Mineral Spirits, Natural Gas, Neon, Nitric Acid, Nitrogen, Oxygen, Phosphoric Acid, Propane, Salt Water, Soap Solutions, Sodium Hydroxide (Caustic Soda), Sodium Hypochlorite (Bleach), Sulfuric Acid, Toluene (Methylbenzene), Xenon, Xylene | Needle | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 3/8" | 0.4 | 125 psi @ 140° F | 2 5/8" | 2 11/16" | Fluoroelastomer | 7/8" | PTFE | PVDF | 2 11/16" | Water, Oil, Air, Argon, Butane, Carbon Dioxide, Citric Acid, Deionized Water, Diesel Fuel, Ethanol, Ethylene Glycol, Gasoline, Helium, Hydrochloric Acid, Isopropyl Alcohol, Kerosene, Krypton, Methanol (Methyl Alcohol), Mineral Spirits, Natural Gas, Neon, Nitric Acid, Nitrogen, Oxygen, Phosphoric Acid, Propane, Salt Water, Soap Solutions, Sodium Hydroxide (Caustic Soda), Sodium Hypochlorite (Bleach), Sulfuric Acid, Toluene (Methylbenzene), Xenon, Xylene | Needle | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Precision Flow-Adjustment Valves with Yor-Lok Fittings for Chemicals

316 Stainless Steel Body

Overall | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Tube OD | Flow Coefficient (Cv) | Max. Pressure @ Temp. | Ht. | Lg. | Temp. Range, ° F | Seal Material | Panel Cutout Dia. | Seat Material | Packing Material | Needle Material | End-to-End Lg. | For Use With | Valve Type | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Yor-Lok × Yor-Lok | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 0.56 | 7,000 psi @ 400° F | 3 5/8" | 2 7/8" | -20 to 400 | PTFE | 0.87" | 316 Stainless Steel | PTFE | 316 Stainless Steel | 2 7/8" | Oil, Acetone, Air, Ammonia, Argon, Butane, Carbon Dioxide, Deionized Water, Diesel Fuel, Ethanol, Gasoline, Helium, Isopropyl Alcohol, Kerosene, Krypton, Methanol (Methyl Alcohol), Methyl Ethyl Ketone (MEK), Mineral Spirits, Natural Gas, Neon, Nitrogen, Oxygen, Propane, Soap Solutions, Sodium Hydroxide (Caustic Soda), Toluene (Methylbenzene), Xenon, Xylene | Needle | 0000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 0.56 | 7,000 psi @ 400° F | 3 5/8" | 2 7/8" | -20 to 400 | PTFE | 0.87" | 316 Stainless Steel | PTFE | 316 Stainless Steel | 2 7/8" | Oil, Acetone, Air, Ammonia, Argon, Butane, Carbon Dioxide, Deionized Water, Diesel Fuel, Ethanol, Gasoline, Helium, Isopropyl Alcohol, Kerosene, Krypton, Methanol (Methyl Alcohol), Methyl Ethyl Ketone (MEK), Mineral Spirits, Natural Gas, Neon, Nitrogen, Oxygen, Propane, Soap Solutions, Sodium Hydroxide (Caustic Soda), Toluene (Methylbenzene), Xenon, Xylene | Needle | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 0.56 | 7,000 psi @ 400° F | 3 5/8" | 3 1/8" | -20 to 400 | PTFE | 0.87" | 316 Stainless Steel | PTFE | 316 Stainless Steel | 3 1/8" | Oil, Acetone, Air, Ammonia, Argon, Butane, Carbon Dioxide, Deionized Water, Diesel Fuel, Ethanol, Gasoline, Helium, Isopropyl Alcohol, Kerosene, Krypton, Methanol (Methyl Alcohol), Methyl Ethyl Ketone (MEK), Mineral Spirits, Natural Gas, Neon, Nitrogen, Oxygen, Propane, Soap Solutions, Sodium Hydroxide (Caustic Soda), Toluene (Methylbenzene), Xenon, Xylene | Needle | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Threaded Precision Flow-Adjustment Valves for Chemicals

White PVDF Body

Pipe Size | Flow Coefficient (Cv) | Max. Pressure @ Temp. | Max. Temp., ° F | Panel Cutout Dia. | End-to-End Lg. | Valve Type | For Use With | Seal Material | Seat Material | Needle Material | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

NPT Female × NPT Female | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4 | 0.64 | 150 psi @ 70° F | 300 | 1 5/16" | 2 1/2" | Needle | Water, Oil, Food, Beverage, Citric Acid, Deionized Water, Diesel Fuel, Ethanol, Ethylene Glycol, Fuel Oil, Gasoline, Hydrochloric Acid, Isopropyl Alcohol, Kerosene, Methanol (Methyl Alcohol), Mineral Spirits, Phosphoric Acid, Salt Water, Soap Solutions, Sodium Hydroxide (Caustic Soda), Sodium Hypochlorite (Bleach), Sulfuric Acid | Fluoroelastomer | PTFE | Polypropylene | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8 | 0.72 | 150 psi @ 70° F | 300 | 1 5/16" | 2 1/2" | Needle | Water, Oil, Food, Beverage, Citric Acid, Deionized Water, Diesel Fuel, Ethanol, Ethylene Glycol, Fuel Oil, Gasoline, Hydrochloric Acid, Isopropyl Alcohol, Kerosene, Methanol (Methyl Alcohol), Mineral Spirits, Phosphoric Acid, Salt Water, Soap Solutions, Sodium Hydroxide (Caustic Soda), Sodium Hypochlorite (Bleach), Sulfuric Acid | Fluoroelastomer | PTFE | Polypropylene | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2 | 0.79 | 150 psi @ 70° F | 300 | 1 5/16" | 2 1/2" | Needle | Water, Oil, Food, Beverage, Citric Acid, Deionized Water, Diesel Fuel, Ethanol, Ethylene Glycol, Fuel Oil, Gasoline, Hydrochloric Acid, Isopropyl Alcohol, Kerosene, Methanol (Methyl Alcohol), Mineral Spirits, Phosphoric Acid, Salt Water, Soap Solutions, Sodium Hydroxide (Caustic Soda), Sodium Hypochlorite (Bleach), Sulfuric Acid | Fluoroelastomer | PTFE | Polypropylene | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Precision Flow-Adjustment Valves with Barbed Fittings for Chemicals

For Tube ID | For Tube OD | Flow Coefficient (Cv) | Max. Pressure @ Temp. | Max. Temp., ° F | Panel Cutout Dia. | End-to-End Lg. | Valve Type | For Use With | Seal Material | Packing Material | Needle Material | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Black PVDF Body | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Barbed × Barbed | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 3/8" | 0.3 | 125 psi @ 140° F | 140 | 7/8" | 3 5/16" | Needle | Water, Oil, Air, Argon, Butane, Carbon Dioxide, Citric Acid, Deionized Water, Diesel Fuel, Ethanol, Ethylene Glycol, Gasoline, Helium, Hydrochloric Acid, Isopropyl Alcohol, Kerosene, Krypton, Methanol (Methyl Alcohol), Mineral Spirits, Natural Gas, Neon, Nitric Acid, Nitrogen, Oxygen, Phosphoric Acid, Propane, Salt Water, Soap Solutions, Sodium Hydroxide (Caustic Soda), Sodium Hypochlorite (Bleach), Sulfuric Acid, Toluene (Methylbenzene), Xenon, Xylene | PTFE | PTFE | PVDF | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 1/2" | 0.3 | 125 psi @ 140° F | 140 | 7/8" | 3 5/16" | Needle | Water, Oil, Air, Argon, Butane, Carbon Dioxide, Citric Acid, Deionized Water, Diesel Fuel, Ethanol, Ethylene Glycol, Gasoline, Helium, Hydrochloric Acid, Isopropyl Alcohol, Kerosene, Krypton, Methanol (Methyl Alcohol), Mineral Spirits, Natural Gas, Neon, Nitric Acid, Nitrogen, Oxygen, Phosphoric Acid, Propane, Salt Water, Soap Solutions, Sodium Hydroxide (Caustic Soda), Sodium Hypochlorite (Bleach), Sulfuric Acid, Toluene (Methylbenzene), Xenon, Xylene | PTFE | PTFE | PVDF | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 5/8" | 0.4 | 125 psi @ 140° F | 140 | 7/8" | 3 5/16" | Needle | Water, Oil, Air, Argon, Butane, Carbon Dioxide, Citric Acid, Deionized Water, Diesel Fuel, Ethanol, Ethylene Glycol, Gasoline, Helium, Hydrochloric Acid, Isopropyl Alcohol, Kerosene, Krypton, Methanol (Methyl Alcohol), Mineral Spirits, Natural Gas, Neon, Nitric Acid, Nitrogen, Oxygen, Phosphoric Acid, Propane, Salt Water, Soap Solutions, Sodium Hydroxide (Caustic Soda), Sodium Hypochlorite (Bleach), Sulfuric Acid, Toluene (Methylbenzene), Xenon, Xylene | PTFE | PTFE | PVDF | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||