Filter by

For Use With

Container Size

Housing Material

Voltage

Flow Rate

Intake Tube Material

Maximum Temperature

Drum Pump Type

Discharge Location

Impeller Material

Maximum Flow Rate

DFARS Specialty Metals

Adjustable-Flow Easy-Stroke Drum Pumps for Water and Chemicals

Temp. | Intake | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Flow Rate, fl oz/stroke | For Container Size, gal. | Max. Viscosity, cP | Min. | Max., ° F | For Drum Opening Size | Includes | Tube OD | Tube Lg. | For Discharge Tube ID | Spout Type | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

304 Stainless Steel Intake Tube and 304 Stainless Steel Housing | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6, 8, 10, 12 | 15 to 55 | 2,000 | Not Rated | 140 | 1 1/2 NPT, 2 NPT | Drum Connector | 1 1/8" | 18 1/2" to 32 1/2" | 11/16" | Removable | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

High-Flow Electric Drum Pumps for Water, Oil, Coolants, and Chemicals

Temp., ° F | Intake | Discharge | Electrical | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Flow Rate, gpm | For Container Size, gal. | Discharge Pressure, psi | Max. Viscosity, cP | Min. | Max. | Power, hp | Current, amp | For Drum Opening Size | Includes | Tube OD | Tube Lg. | Discharge Location | Tube ID | Tube OD | Tube Lg. | Tube Material | Connection | No. of Blades | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

120V AC—Single Phase—Plug In | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 40 | 30 | 35 | 500 | 35 | 160 | 1/2 | 5.7 | 2 NPT | Drum Connector | 2" | 27" | Tube End | 1" | 1 5/16" | 60" | PVC | Straight Blade | 3 | 0000000 | 000000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 40 | 55 | 35 | 500 | -20 | 220 | 1/2 | 5.7 | 2 NPT | Drum Connector | 2" | 40" | Tube End | 1" | 1 5/16" | 60" | PVC | Straight Blade | 3 | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 40 | 55 | 35 | 500 | -20 | 220 | 1/2 | 5.7 | 2 NPT | Drum Connector | 2" | 48" | Tube End | 1" | 1 5/16" | 60" | PVC | Straight Blade | 3 | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 40 | 55 | 35 | 500 | 35 | 160 | 1/2 | 5.7 | 2 NPT | Drum Connector | 2" | 40" | Tube End | 1" | 1 5/16" | 60" | PVC | Straight Blade | 3 | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 40 | 55 | 35 | 500 | 35 | 160 | 1/2 | 5.7 | 2 NPT | Drum Connector | 2" | 48" | Tube End | 1" | 1 5/16" | 60" | PVC | Straight Blade | 3 | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Electric Drum Pump Systems for Water, Oil, Coolants, and Chemicals

Temp. | Intake | Discharge | Electrical | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Flow Rate, gpm | Discharge Pressure, psi | For Container Size, gal. | Max. Viscosity, cP | Min. | Max., ° F | Power, hp | Current, amp | For Drum Opening Size | Tube OD | Tube Lg. | Tube ID | Tube OD | Tube Lg. | Hazardous Location Rating | Enclosure Rating | Connection | No. of Blades | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

120V AC—Single Phase—NEMA 5-15 Plug In | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Polypropylene Housing | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 15 | 15 | 55 | 1,500 | Not Rated | 130 | 1 | 7.5 | 2 NPT | 1 5/8" | 39" | 1" | 1 1/4" | 72" | — | IP44 | Straight Blade | 3 | 0000000 | 000000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 15 | 15 | 55 | 1,500 | Not Rated | 130 | 1 | 7.5 | 2 NPT | 1 5/8" | 47" | 1" | 1 1/4" | 72" | — | IP44 | Straight Blade | 3 | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Aluminum Housing | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 22 | 15 | 55 | 1,500 | Not Rated | 175 | 1 | 7.5 | 2 NPT | 1 1/2" | 39" | 1" | 1 1/4" | 72" | — | IP44 | Straight Blade | 3 | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 22 | 15 | 55 | 1,500 | Not Rated | 175 | 1 | 7.5 | 2 NPT | 1 1/2" | 47" | 1" | 1 1/4" | 72" | — | IP44 | Straight Blade | 3 | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

PVDF Housing | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 15 | 15 | 55 | 1,500 | Not Rated | 175 | 1 | 7.5 | 2 NPT | 1 5/8" | 39" | 1" | 1 1/4" | 72" | — | IP54 | Straight Blade | 3 | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 15 | 15 | 55 | 1,500 | Not Rated | 175 | 1 | 7.5 | 2 NPT | 1 5/8" | 47" | 1" | 1 1/4" | 72" | — | IP54 | Straight Blade | 3 | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

120V AC—Single Phase—Hardwire | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

316 Stainless Steel Housing | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 18 | 15 | 55 | 1,000 | Not Rated | 175 | 1 1/3 | 9.1 | 2 NPT | 1 1/2" | 39" | 1" | 1 1/4" | 72" | NEC Class I Divisions 1, 2 Group D | IP55 | — | — | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

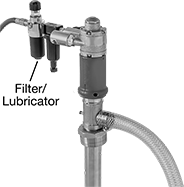

Air-Powered Drum Pumps with Hose and Filter/Lubricator for Water, Oil, Coolants, and Chemicals

Drum Pumps | Pump Repair Kits | |||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Temp., ° F | Intake | Discharge | ||||||||||||||||||||

Flow Rate, gpm | For Container Size, gal. | Max. Viscosity, cP | Min. | Max. | Air Pressure, psi | Air Consumption, ft³/min | For Drum Opening Size | Includes | Air Connection | Tube OD | Tube Lg. | Discharge Location | Tube ID | Tube Lg., ft. | Tube Material | Features | Each | Each | ||||

| 16 | 55 | 2,000 | -20 | 150 | 80 to 100 | 32 | 2 NPT | Drum Connector | 1/4 Female NPT | 1 1/2" | 40" | Tube End | 1" | 5 | PVC | 15-ft. Air Hose Assembly, Air Filter/Lubricator, Ball Valve, Muffler | 0000000 | 000000000 | 0000000 | 0000000 | ||

| 16 | 55 | 2,000 | 35 | 150 | 80 to 100 | 32 | 2 NPT | Drum Connector | 1/4 Female NPT | 1 5/8" | 40" | Tube End | 1" | 5 | PVC | 15-ft. Air Hose Assembly, Air Filter/Lubricator, Ball Valve, Muffler | 0000000 | 00000000 | 0000000 | 000000 | ||

| 22 | 55 | 330 | 35 | 160 | 80 to 100 | 32 | 2 NPT | Drum Connector | 1/4 Female NPT | 2" | 40" | Tube End | 1" | 5 | PVC | 15-ft. Air Hose Assembly, Air Filter/Lubricator, Ball Valve, Muffler | 0000000 | 00000000 | ——— | 0 | ||

| 22 | 55 | 330 | 35 | 160 | 80 to 100 | 32 | 2 NPT | Drum Connector | 1/4 Female NPT | 2" | 48" | Tube End | 1" | 5 | PVC | 15-ft. Air Hose Assembly, Air Filter/Lubricator, Ball Valve, Muffler | 0000000 | 00000000 | ——— | 0 | ||

Hazardous Location Electric Drum Pumps for Water, Oil, Coolants, and Chemicals

Drum Pumps | Pump Repair Kits | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Temp., ° F | Intake | Discharge (Pump Body) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Flow Rate, gpm | For Container Size, gal. | Discharge Pressure, psi | Max. Viscosity, cP | Min. | Max. | Power, hp | Current, amp | For Drum Opening Size | Tube OD | Tube Lg. | Discharge Location | Connection | For Tube ID | Gender | Certification | Each | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

120V AC—Single Phase—Hardwire—With Thermal Overload Protection | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 48.5 | 55 | 14 | 300 | -40 | 210 | 1/2 | 5.3 | 41 mm | 1 5/8" | 39" | Pump Body | Barbed | 1" | Male | C-UL Listed UL Listed | 00000000 | 000000000 | 00000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Air-Powered Drum Pumps for Flammable Liquid

Temp., ° F | Intake | Discharge (Pump Body) | |||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Flow Rate, gpm | For Container Size, gal. | Max. Viscosity, cP | Min. | Max. | Air Pressure, psi | Air Consumption, ft³/min | For Drum Opening Size | Includes | Air Connection | Tube OD | Tube Lg. | Discharge Location | Connection | For Tube ID | Gender | Certification | Features | Each | |||

| 26 | 55 | 1,100 | -40 | 210 | 44 to 87 | 53 | 2 NPT | Drum Connector | 3/8 Female NPT | 1 5/8" | 39" | Pump Body | Barbed | 1" | Male | CE Marked | Bonding and Grounding Wires, Hanger | 0000000 | 000000000 | ||

| 26 | 55 | 1,100 | -40 | 210 | 44 to 87 | 53 | 2 NPT | Drum Connector | 3/8 Female NPT | 1 5/8" | 47" | Pump Body | Barbed | 1" | Male | CE Marked | Bonding and Grounding Wires, Hanger | 0000000 | 00000000 | ||

| 53 | 55 | 1,000 | -40 | 210 | 44 to 87 | 53 | 2 NPT | Drum Connector | 3/8 Female NPT | 1 5/8" | 39" | Pump Body | Barbed | 1" | Male | CE Marked | Bonding and Grounding Wires, Hanger | 0000000 | 00000000 | ||

| 53 | 55 | 1,000 | -40 | 210 | 44 to 87 | 53 | 2 NPT | Drum Connector | 3/8 Female NPT | 1 5/8" | 47" | Pump Body | Barbed | 1" | Male | CE Marked | Bonding and Grounding Wires, Hanger | 0000000 | 00000000 | ||

Drum Pumps for Water and Chemicals

Style B

Drum Pumps | Replacement Connectors | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Temp., ° F | Intake | Discharge | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Flow Rate, fl oz/stroke | For Container Size, gal. | Max. Viscosity, cP | Min. | Max. | For Drum Opening Size | Includes | Tube OD | Tube Lg. | Location | Tube ID | Tube OD | Tube Lg. | Tube Material | Each | Pipe Size | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

PVC Piston | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8 | 5 | 750 | 40 | 120 | 70 mm | Drum Connector | 1/2" | 13" | Tube End | 7/16" | 5/8" | 22" | PVC | 00000000 | 000000 | 2 NPT | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Polypropylene Long-Life Air-Powered Drum Pumps for Chemicals

Drum Pumps | Pump Repair Kits | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Temp., ° F | Intake | Discharge | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Flow Rate, gpm | For Container Size, gal. | Max. Viscosity, cP | Min. | Max. | Air Pressure, psi | Air Consumption, ft³/min | For Drum Opening Size | Includes | Air Connection | Connection | Pipe Size | Tube Lg. | Discharge Location | Connection | Pipe Size | Each | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Santoprene Diaphragm | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 13 | 55 | 3,000 | 30 | 180 | 100 | 12 | 2 NPT | Drum Connector | 1/4 Female NPT | Threaded | 1/2 Female NPT | 36" | Pump Body | Threaded | 1/2 Female NPT | 0000000 | 0000000 | 0000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 31 | 55 | 8,000 | 30 | 180 | 100 | 40 | 2 NPT | Drum Connector | 1/4 Female NPT | Threaded | 3/4 Female NPT | 36" | Pump Body | Threaded | 3/4 Female NPT | 0000000 | 00000000 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

PTFE Diaphragm | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 13 | 55 | 3,000 | 40 | 180 | 100 | 12 | 2 NPT | Drum Connector | 1/4 Female NPT | Threaded | 1/2 Female NPT | 36" | Pump Body | Threaded | 1/2 Female NPT | 0000000 | 000000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 28 | 55 | 8,000 | 40 | 180 | 100 | 40 | 2 NPT | Drum Connector | 1/4 Female NPT | Threaded | 3/4 Female NPT | 36" | Pump Body | Threaded | 3/4 Female NPT | 0000000 | 00000000 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Adjustable-Flow Electric Drum Pumps for Water, Oil, Coolants, and Chemicals

Pump Body

Drum Pumps | Pump Repair Kits | Connectors | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Temp. | Intake | Discharge (Pump Body) | Electrical | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Style | Flow Rate, gpm | Discharge Pressure, psi | For Container Size, gal. | Max. Viscosity, cP | Min. | Max., ° F | Power, hp | Current, amp | For Drum Opening Size | Tube OD | Tube Lg. | Connection | For Tube ID | Connection | No. of Blades | Each | Each | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

120V AC—Single Phase—Plug In—With Thermal Overload Protection | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | 0 to 35 | 16 | 55 | 1,500 | Not Rated | 175 | 1 | 8.5 | 2" | 1 1/2" | 39" | Barbed | 1" | Straight Blade | 3 | 0000000 | 000000000 | 0000000 | 0000000 | 0000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | 0 to 35 | 16 | 55 | 1,500 | Not Rated | 175 | 1 | 8.5 | 2" | 1 1/2" | 47" | Barbed | 1" | Straight Blade | 3 | 0000000 | 00000000 | 0000000 | 000000 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Stainless Steel Long-Life Air-Powered Drum Pumps for Chemicals

Drum Pumps | Pump Repair Kits | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Temp., ° F | Intake | Discharge | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Flow Rate, gpm | For Container Size, gal. | Max. Viscosity, cP | Min. | Max. | Air Pressure, psi | Air Consumption, ft³/min | For Drum Opening Size | Includes | Air Connection | Connection | Pipe Size | Tube Lg. | Discharge Location | Connection | Pipe Size | Each | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

PTFE Diaphragm | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 28 | 55 | 8,000 | 40 | 210 | 100 | 40 | 2 NPT | Drum Connector | 1/4 Female NPT | Threaded | 3/4 Female NPT | 39" | Pump Body | Threaded | 3/4 Female NPT | 0000000 | 000000000 | 00000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

PVDF Long-Life Air-Powered Drum Pumps for Chemicals

Drum Pumps | Pump Repair Kits | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Temp., ° F | Intake | Discharge | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Flow Rate, gpm | For Container Size, gal. | Max. Viscosity, cP | Min. | Max. | Air Pressure, psi | Air Consumption, ft³/min | For Drum Opening Size | Includes | Air Connection | Connection | Pipe Size | Tube Lg. | Discharge Location | Connection | Pipe Size | Each | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

PTFE Diaphragm | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 13 | 55 | 3,000 | 40 | 210 | 100 | 12 | 2 NPT | Drum Connector | 1/4 Female NPT | Threaded | 1/2 Female NPT | 36" | Pump Body | Threaded | 1/2 Female NPT | 0000000 | 000000000 | 00000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

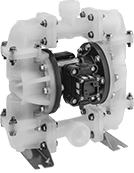

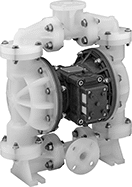

Polypropylene Air-Powered Double Diaphragm Pumps for Chemicals

Threaded Bottom Intake and Threaded Top Discharge

Double Diaphragm Pumps | Air Motor Pump Repair Kits | Fluid Side Pump Repair Kits | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Max. Flow Rate, gpm | Overall | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Max. Flow Rate, gpm | @ 40 ft. of Head | @ 120 ft. of Head | @ 160 ft. of Head | Max. Viscosity, cP | Air Consumption, ft³/min | Air Connection Size | Intake Size | Discharge Size | Lg. | Wd. | Ht. | Each | Each | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

231 ft. Maximum Feet of Head—100 psi Maximum Discharge Pressure | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 | 3.5 | 2 | 1 | 5,000 | 6 | 1/4 Female NPT | 1/4 Female NPT, 1/2 Male NPT | 1/4 Female NPT, 1/2 Male NPT | 6" | 7" | 8" | 0000000 | 0000000 | 0000000 | 0000000 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 14 | 12 | 8 | 5 | 10,000 | 16 | 1/4 Female NPT | 1/2 Female NPT, 1 Male NPT | 1/2 Female NPT, 1 Male NPT | 7" | 10" | 12" | 0000000 | 000000 | 0000000 | 000000 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 23 | 19 | 13 | 8 | 10,000 | 20 | 1/4 Female NPT | 3/4 Female NPT, 1 1/2 Male NPT | 3/4 Female NPT, 1 1/2 Male NPT | 7" | 12" | 13" | 00000000 | 00000000 | 0000000 | 000000 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Flanged Bottom Intake and Flanged Top Discharge

Double Diaphragm Pumps | Air Motor Pump Repair Kits | Fluid Side Pump Repair Kits | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Max. Flow Rate, gpm | Flange | Bolt | Overall | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Max. Flow Rate, gpm | @ 40 ft. of Head | @ 120 ft. of Head | @ 160 ft. of Head | Max. Viscosity, cP | Air Consumption, ft³/min | Air Connection Size | Intake Size | Discharge Size | OD | Thk. | Pressure Class | Circle Dia. | Hole Dia. | Lg. | Wd. | Ht. | Each | Each | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

231 ft. Maximum Feet of Head—100 psi Maximum Discharge Pressure | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 23 | 19 | 13 | 8 | 10,000 | 20 | 1/4 Female NPT | 1 | 1 | 4 1/4" | 11/16" | 125 | 3 1/8" | 5/8" | 7 5/8" | 11 13/16" | 15 1/8" | 00000000 | 000000000 | 0000000 | 0000000 | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 100 | 83 | 51 | 32 | 30,000 | 50 | 3/4 Female NPT | 1 1/2 | 1 1/2 | 5" | 13/16" | 125 | 3 7/8" | 5/8" | 13" | 23" | 29" | 00000000 | 00000000 | 0000000 | 000000 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

288 ft. Maximum Feet of Head—125 psi Maximum Discharge Pressure | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 63 | 53 | 40 | 35 | 20,000 | 35 | 1/2 Female NPT | 1 | 1 | 4 1/4" | 3/4" | 125 | 3 1/8" | 9/16" | 12" | 17" | 21" | 0000000 | 00000000 | 0000000 | 000000 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

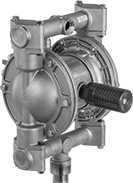

316 Stainless Steel Air-Powered Double Diaphragm Pumps for Chemicals, Fuel, and Flammable Liquids

Threaded Bottom Intake and Threaded Top Discharge

Double Diaphragm Pumps | Air Motor Pump Repair Kits | Fluid Side Pump Repair Kits | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Max. Flow Rate, gpm | Overall | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Max. Flow Rate, gpm | @ 80 ft. of Head | @ 120 ft. of Head | @ 160 ft. of Head | Max. Solids Dia. | Max. Viscosity, cP | Air Consumption, ft³/min | Air Connection Size | Intake Size | Discharge Size | Lg. | Wd. | Ht. | Each | Each | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

289 ft. Maximum Feet of Head—125 psi Maximum Discharge Pressure | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 15 | 12 | 10 | 7 | 1/8" | 10,000 | 20 | 1/4 Female NPT | 1/2 Female NPT | 1/2 Female NPT | 9" | 10" | 10" | 00000000 | 000000000 | 0000000 | 0000000 | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 45 | 38 | 30 | 19 | 1/4" | 20,000 | 40 | 1/2 Female NPT | 1 Female NPT | 1 Female NPT | 13" | 10" | 13" | 00000000 | 00000000 | 0000000 | 000000 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 106 | 77 | 62 | 45 | 1/4" | 30,000 | 50 | 3/4 Female NPT | 1 1/2 Female NPT | 1 1/2 Female NPT | 15" | 17" | 22" | 00000000 | 00000000 | 0000000 | 000000 | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 150 | 104 | 76 | 53 | 1/4" | 40,000 | 100 | 3/4 Female NPT | 2 Female NPT | 2 Female NPT | 15" | 17" | 26" | 00000000 | 00000000 | 0000000 | 000000 | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 235 | 174 | 127 | 90 | 3/8" | 50,000 | 140 | 3/4 Female NPT | 3 Female NPT | 3 Female NPT | 17" | 20" | 32" | 00000000 | 000000000 | 0000000 | 000000 | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Smooth-Flow Air-Powered Double Diaphragm Pumps

Barbed Bottom Intake and Barbed Top Discharge

Double Diaphragm Pumps | Air Motor Pump Repair Kits | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Max. Flow Rate, gpm | Overall | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Max. Flow Rate, gpm | @ 80 ft. of Head | @ 120 ft. of Head | Max. Viscosity, cP | Air Consumption, ft³/min | Air Tube Connection | Intake Tube Connection | Discharge Tube Connection | Diaphragm Material | Lg. | Wd. | Ht. | Each | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

135 ft. Maximum Feet of Head—58 psi Maximum Discharge Pressure | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.6 | 0.5 | 0.4 | 2,500 | 0.48 | 1/4" Barbed Male | 3/8" Barbed Male | 3/8" Barbed Male | Buna-N | 4" | 6" | 6" | 0000000 | 0000000 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.6 | 0.5 | 0.4 | 2,500 | 0.48 | 1/4" Barbed Male | 3/8" Barbed Male | 3/8" Barbed Male | Fluoroelastomer | 4" | 6" | 6" | 0000000 | 000000 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||