Filter by

Body Material

For Use With

Fitting Connection

Maximum Pressure @ Temperature

Needle Material

Seat Material

DFARS Specialty Metals

Seat Type

Maximum Steam Pressure @ Temperature

Panel-Mount Threaded Precision Flow-Adjustment Valves

Brass Body—Straight

Overall | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Pipe Size | Flow Coefficient (Cv) | Max. Pressure @ Temp. | Ht. | Lg. | Temp. Range, ° F | Panel Cutout Dia. | Packing Material | Needle Material | End-to-End Lg. | For Use With | Valve Type | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

NPT Female × NPT Female | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4 | 0.4 | 500 psi @ 180° F | 2 5/8" | 1 3/4" | -20 to 180 | 9/16" | PTFE | 303 Stainless Steel | 1 3/4" | Water, Oil, Air, Argon, Helium, Krypton, Neon, Xenon | Needle | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4 | 0.4 | 500 psi @ 180° F | 2 5/8" | 1 3/4" | -20 to 180 | 9/16" | PTFE | Brass | 1 3/4" | Water, Oil, Air, Argon, Helium, Krypton, Neon, Xenon | Needle | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

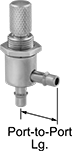

Brass Body—90° Elbow

Overall | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Pipe Size | Flow Coefficient (Cv) | Max. Pressure @ Temp. | Ht. | Lg. | Temp. Range, ° F | Panel Cutout Dia. | Packing Material | Needle Material | Port-to-Port Lg. | For Use With | Valve Type | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

NPT Female × NPT Female | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4 | 0.6 | 500 psi @ 180° F | 3 1/16" | 1 5/16" | -20 to 180 | 9/16" | PTFE | 303 Stainless Steel | 15/16" | Water, Oil, Air, Argon, Helium, Krypton, Neon, Xenon | Needle | 0000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4 | 0.6 | 500 psi @ 180° F | 3 1/16" | 1 5/16" | -20 to 180 | 9/16" | PTFE | Brass | 15/16" | Water, Oil, Air, Argon, Helium, Krypton, Neon, Xenon | Needle | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

NPT Female × NPT Male | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4 | 0.6 | 500 psi @ 180° F | 3 1/4" | 1 5/16" | -20 to 180 | 9/16" | PTFE | 303 Stainless Steel | 15/16" | Water, Oil, Air, Argon, Helium, Krypton, Neon, Xenon | Needle | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4 | 0.6 | 500 psi @ 180° F | 3 1/4" | 1 5/16" | -20 to 180 | 9/16" | PTFE | Brass | 15/16" | Water, Oil, Air, Argon, Helium, Krypton, Neon, Xenon | Needle | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Nickel-Plated Brass Body—Straight

Overall | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Pipe Size | Flow Coefficient (Cv) | Max. Pressure @ Temp. | Ht. | Lg. | Temp. Range, ° F | Panel Cutout Dia. | Packing Material | Needle Material | End-to-End Lg. | For Use With | Valve Type | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

NPT Female × NPT Female | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4 | 0.4 | 500 psi @ 180° F | 2 5/8" | 1 3/4" | -20 to 180 | 9/16" | PTFE | 303 Stainless Steel | 1 3/4" | Water, Oil, Air, Argon, Helium, Krypton, Neon, Xenon | Needle | 00000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4 | 0.4 | 500 psi @ 180° F | 2 5/8" | 1 3/4" | -20 to 180 | 9/16" | PTFE | Brass | 1 3/4" | Water, Oil, Air, Argon, Helium, Krypton, Neon, Xenon | Needle | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Nickel-Plated Brass Body—90° Elbow

Overall | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Pipe Size | Flow Coefficient (Cv) | Max. Pressure @ Temp. | Ht. | Lg. | Temp. Range, ° F | Panel Cutout Dia. | Packing Material | Needle Material | Port-to-Port Lg. | For Use With | Valve Type | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

NPT Female × NPT Female | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4 | 0.6 | 500 psi @ 180° F | 3 1/16" | 1 5/16" | -20 to 180 | 9/16" | PTFE | 303 Stainless Steel | 15/16" | Water, Oil, Air, Argon, Helium, Krypton, Neon, Xenon | Needle | 00000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4 | 0.6 | 500 psi @ 180° F | 3 1/16" | 1 5/16" | -20 to 180 | 9/16" | PTFE | Brass | 15/16" | Water, Oil, Air, Argon, Helium, Krypton, Neon, Xenon | Needle | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

NPT Female × NPT Male | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4 | 0.6 | 500 psi @ 180° F | 3 1/4" | 1 5/16" | -20 to 180 | 9/16" | PTFE | 303 Stainless Steel | 15/16" | Water, Oil, Air, Argon, Helium, Krypton, Neon, Xenon | Needle | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4 | 0.6 | 500 psi @ 180° F | 3 1/4" | 1 5/16" | -20 to 180 | 9/16" | PTFE | Brass | 15/16" | Water, Oil, Air, Argon, Helium, Krypton, Neon, Xenon | Needle | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

High-Pressure Threaded Precision Flow-Adjustment Valves for Steam

316 Stainless Steel Body

Overall | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Pipe Size | Flow Coefficient (Cv) | Max. Pressure @ Temp. | Max. Steam Pressure @ Temp. | Ht. | Lg. | Temp. Range, ° F | Seal Material | Panel Cutout Dia. | Seat Material | Packing Material | Needle Material | End-to-End Lg. | For Use With | Valve Type | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

NPT Female × NPT Female | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4 | 0.58 | 10,000 psi @ 200° F | 6,200 psi @ 355° F | 3 5/8" | 2 5/16" | -40 to 400 | PTFE | 7/8" | 316 Stainless Steel | PTFE | 316 Stainless Steel | 2 5/16" | Steam | Needle | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8 | 0.58 | 10,000 psi @ 200° F | 4,800 psi @ 355° F | 3 5/8" | 2 5/16" | -40 to 400 | PTFE | 7/8" | 316 Stainless Steel | PTFE | 316 Stainless Steel | 2 5/16" | Steam | Needle | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2 | 0.6 | 10,000 psi @ 200° F | 4,800 psi @ 355° F | 3 13/16" | 2 5/16" | -40 to 400 | PTFE | 1" | 316 Stainless Steel | PTFE | 316 Stainless Steel | 2 5/8" | Steam | Needle | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Easy-Set Plastic Threaded Precision Flow-Adjustment Valves

Black Glass-Filled Polyester Plastic Body

Flow-Adjustment Valves | Mounting Nuts | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Overall | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Pipe Size | Flow Coefficient (Cv) | Max. Pressure @ Temp. | Ht. | Lg. | Temp. Range, ° F | Seal Material | Panel Cutout Dia. | Seat Material | Needle Material | End-to-End Lg. | For Use With | Valve Type | Each | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

NPTF Female × NPTF Female | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8 | 0.26 | 200 psi @ 200° F | 2 13/16" | 1 15/16" | 0 to 200 | Buna-N | 1" | Polypropylene | Zinc-Plated Steel | 1 15/16" | Air, Oxygen | Needle | 0000000 | 000000 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4 | 0.48 | 200 psi @ 200° F | 2 13/16" | 1 15/16" | 0 to 200 | Buna-N | 1" | Polypropylene | Zinc-Plated Steel | 1 15/16" | Air, Oxygen | Needle | 0000000 | 00000 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8 | 1.06 | 200 psi @ 200° F | 3 7/8" | 2 7/8" | 0 to 200 | Buna-N | 1 3/8" | Polypropylene | Zinc-Plated Steel | 2 7/8" | Air, Oxygen | Needle | 0000000 | 00000 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2 | 1.35 | 200 psi @ 200° F | 3 7/8" | 2 7/8" | 0 to 200 | Buna-N | 1 3/8" | Polypropylene | Zinc-Plated Steel | 2 7/8" | Air, Oxygen | Needle | 0000000 | 00000 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4 | 1.96 | 200 psi @ 200° F | 4 3/16" | 3" | 0 to 200 | Buna-N | 1 3/8" | Polypropylene | Zinc-Plated Steel | 3" | Air, Oxygen | Needle | 0000000 | 00000 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Black Glass-Filled Polyester Plastic Body with Internal Check Valve

Flow-Adjustment Valves | Mounting Nuts | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Overall | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Pipe Size | Flow Coefficient (Cv) | Max. Pressure @ Temp. | Ht. | Lg. | Temp. Range, ° F | Seal Material | Panel Cutout Dia. | Seat Material | Needle Material | End-to-End Lg. | For Use With | Valve Type | Each | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

NPTF Female × NPTF Female | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8 | 0.26 | 200 psi @ 200° F | 2 13/16" | 1 15/16" | 0 to 200 | Buna-N | 1" | Polypropylene | Zinc-Plated Steel | 1 15/16" | Air, Oxygen | Needle | 00000000 | 000000 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4 | 0.48 | 200 psi @ 200° F | 2 13/16" | 1 15/16" | 0 to 200 | Buna-N | 1" | Polypropylene | Zinc-Plated Steel | 1 15/16" | Air, Oxygen | Needle | 00000000 | 00000 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8 | 1.06 | 200 psi @ 200° F | 3 7/8" | 2 7/8" | 0 to 200 | Buna-N | 1 3/8" | Polypropylene | Zinc-Plated Steel | 2 7/8" | Air, Oxygen | Needle | 00000000 | 00000 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2 | 1.35 | 200 psi @ 200° F | 3 7/8" | 2 7/8" | 0 to 200 | Buna-N | 1 3/8" | Polypropylene | Zinc-Plated Steel | 2 7/8" | Air, Oxygen | Needle | 00000000 | 00000 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4 | 1.96 | 200 psi @ 200° F | 4 3/16" | 3" | 0 to 200 | Buna-N | 1 3/8" | Polypropylene | Zinc-Plated Steel | 3" | Air, Oxygen | Needle | 00000000 | 000000 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Panel-Mount High-Pressure Threaded Precision Flow-Adjustment Valves

Steel Body

Overall | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Pipe Size | Flow Coefficient (Cv) | Max. Pressure @ Temp. | Ht. | Lg. | Temp. Range, ° F | Panel Cutout Dia. | Packing Material | Needle Material | End-to-End Lg. | For Use With | Valve Type | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

NPT Female × NPT Female | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4 | 0.6 | 10,000 psi @ 100° F | 4 1/8" | 2 1/4" | -50 to 1,000 | 11/16" | Graphite | 316 Stainless Steel | 2 1/4" | Water, Oil, Air, Argon, Helium, Krypton, Neon, Xenon | Needle | 0000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

316 Stainless Steel Body

Overall | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Pipe Size | Flow Coefficient (Cv) | Max. Pressure @ Temp. | Ht. | Lg. | Temp. Range, ° F | Panel Cutout Dia. | Packing Material | Needle Material | End-to-End Lg. | For Use With | Valve Type | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

NPT Female × NPT Female | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4 | 0.6 | 10,000 psi @ 100° F | 4 1/8" | 2 1/4" | -50 to 1,000 | 11/16" | Graphite | 316 Stainless Steel | 2 1/4" | Water, Oil, Air, Argon, Helium, Krypton, Neon, Xenon | Needle | 0000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Compact Precision Flow-Adjustment Valves with Barbed Fittings

Handle-Operated Valve | Screwdriver-Operated Valve | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Tube ID | Max. Pressure @ Temp. | Temp. Range, ° F | Panel Cutout Dia. | Port-to-Port Lg. | Valve Type | For Use With | Seal Material | Each | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

303 Stainless Steel Body | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Barbed × Barbed | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/16" | 180 psi @ 150° F | -40 to 200 | 5/16" | 7/16" | Needle | Water, Oil, Air, Argon, Helium, Krypton, Neon, Xenon | Buna-N | 00000000 | 000000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8" | 180 psi @ 150° F | -40 to 200 | 5/16" | 9/16" | Needle | Water, Oil, Air, Argon, Helium, Krypton, Neon, Xenon | Buna-N | 00000000 | 00000 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Plastic Threaded Precision Flow-Adjustment Valves

Dark Gray PVC Body

Flow-Adjustment Valves | Mounting Nuts | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Overall | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Pipe Size | Flow Coefficient (Cv) | Max. Pressure @ Temp. | Ht. | Lg. | Temp. Range, ° F | Seal Material | Panel Cutout Dia. | Seat Material | Needle Material | End-to-End Lg. | For Use With | Valve Type | Each | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

NPT Female × NPT Female | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8 | 0.4 | 125 psi @ 140° F | 2 5/8" | 2" | 35 to 140 | EPDM | 7/8" | PVC | PVC | 2" | Water, Air, Argon, Helium, Krypton, Neon, Xenon | Needle | 0000000 | 000000 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4 | 0.4 | 125 psi @ 140° F | 2 5/8" | 2" | 35 to 140 | EPDM | 7/8" | PVC | PVC | 2" | Water, Air, Argon, Helium, Krypton, Neon, Xenon | Needle | 0000000 | 00000 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

NPT Female × NPT Male | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8 | 0.3 | 125 psi @ 140° F | 2 5/8" | 2 1/4" | 35 to 140 | EPDM | 7/8" | PVC | PVC | 2 1/4" | Water, Air, Argon, Helium, Krypton, Neon, Xenon | Needle | 0000000 | 00000 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4 | 0.4 | 125 psi @ 140° F | 2 5/8" | 2 3/8" | 35 to 140 | EPDM | 7/8" | PVC | PVC | 2 3/8" | Water, Air, Argon, Helium, Krypton, Neon, Xenon | Needle | 0000000 | 00000 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

NPT Male × NPT Male | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4 | 0.4 | 125 psi @ 140° F | 2 5/8" | 2 11/16" | 35 to 140 | EPDM | 7/8" | PVC | PVC | 2 11/16" | Water, Air, Argon, Helium, Krypton, Neon, Xenon | Needle | 0000000 | 00000 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

White Polypropylene Body

Flow-Adjustment Valves | Mounting Nuts | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Overall | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Pipe Size | Flow Coefficient (Cv) | Max. Pressure @ Temp. | Ht. | Lg. | Temp. Range, ° F | Seal Material | Panel Cutout Dia. | Seat Material | Needle Material | End-to-End Lg. | For Use With | Valve Type | Each | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

NPT Female × NPT Female | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8 | 0.4 | 125 psi @ 140° F | 2 5/8" | 2" | 35 to 140 | EPDM | 7/8" | Polypropylene | Polypropylene | 2" | Water, Air, Argon, Helium, Krypton, Neon, Xenon | Needle | 0000000 | 000000 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4 | 0.4 | 125 psi @ 140° F | 2 5/8" | 2" | 35 to 140 | EPDM | 7/8" | Polypropylene | Polypropylene | 2" | Water, Air, Argon, Helium, Krypton, Neon, Xenon | Needle | 0000000 | 00000 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

NPT Female × NPT Male | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8 | 0.3 | 125 psi @ 140° F | 2 5/8" | 2 1/4" | 35 to 140 | EPDM | 7/8" | Polypropylene | Polypropylene | 2 1/4" | Water, Air, Argon, Helium, Krypton, Neon, Xenon | Needle | 0000000 | 00000 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4 | 0.4 | 125 psi @ 140° F | 2 5/8" | 2 3/8" | 35 to 140 | EPDM | 7/8" | Polypropylene | Polypropylene | 2 3/8" | Water, Air, Argon, Helium, Krypton, Neon, Xenon | Needle | 0000000 | 00000 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

NPT Male × NPT Male | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4 | 0.4 | 125 psi @ 140° F | 2 5/8" | 2 11/16" | 35 to 140 | EPDM | 7/8" | Polypropylene | Polypropylene | 2 11/16" | Water, Air, Argon, Helium, Krypton, Neon, Xenon | Needle | 0000000 | 00000 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Precision Flow-Adjustment Valves with Yor-Lok Fittings for Chemicals

316 Stainless Steel Body

Overall | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Tube OD | Flow Coefficient (Cv) | Max. Pressure @ Temp. | Ht. | Lg. | Temp. Range, ° F | Seal Material | Panel Cutout Dia. | Seat Material | Packing Material | Needle Material | End-to-End Lg. | For Use With | Valve Type | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Yor-Lok × Yor-Lok | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 0.56 | 7,000 psi @ 400° F | 3 5/8" | 2 7/8" | -20 to 400 | PTFE | 0.87" | 316 Stainless Steel | PTFE | 316 Stainless Steel | 2 7/8" | Oil, Acetone, Air, Ammonia, Argon, Butane, Carbon Dioxide, Deionized Water, Diesel Fuel, Ethanol, Gasoline, Helium, Isopropyl Alcohol, Kerosene, Krypton, Methanol (Methyl Alcohol), Methyl Ethyl Ketone (MEK), Mineral Spirits, Natural Gas, Neon, Nitrogen, Oxygen, Propane, Soap Solutions, Sodium Hydroxide (Caustic Soda), Toluene (Methylbenzene), Xenon, Xylene | Needle | 0000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 0.56 | 7,000 psi @ 400° F | 3 5/8" | 2 7/8" | -20 to 400 | PTFE | 0.87" | 316 Stainless Steel | PTFE | 316 Stainless Steel | 2 7/8" | Oil, Acetone, Air, Ammonia, Argon, Butane, Carbon Dioxide, Deionized Water, Diesel Fuel, Ethanol, Gasoline, Helium, Isopropyl Alcohol, Kerosene, Krypton, Methanol (Methyl Alcohol), Methyl Ethyl Ketone (MEK), Mineral Spirits, Natural Gas, Neon, Nitrogen, Oxygen, Propane, Soap Solutions, Sodium Hydroxide (Caustic Soda), Toluene (Methylbenzene), Xenon, Xylene | Needle | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 0.56 | 7,000 psi @ 400° F | 3 5/8" | 3 1/8" | -20 to 400 | PTFE | 0.87" | 316 Stainless Steel | PTFE | 316 Stainless Steel | 3 1/8" | Oil, Acetone, Air, Ammonia, Argon, Butane, Carbon Dioxide, Deionized Water, Diesel Fuel, Ethanol, Gasoline, Helium, Isopropyl Alcohol, Kerosene, Krypton, Methanol (Methyl Alcohol), Methyl Ethyl Ketone (MEK), Mineral Spirits, Natural Gas, Neon, Nitrogen, Oxygen, Propane, Soap Solutions, Sodium Hydroxide (Caustic Soda), Toluene (Methylbenzene), Xenon, Xylene | Needle | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Precision Flow-Adjustment Valves with Push-to-Connect Fittings

Dark Gray PVC Body

Flow-Adjustment Valves | Mounting Nuts | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Overall | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Tube OD | Flow Coefficient (Cv) | Max. Pressure @ Temp. | Ht. | Lg. | Temp. Range, ° F | Seal Material | Panel Cutout Dia. | Seat Material | Needle Material | End-to-End Lg. | For Use With | Valve Type | Each | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Push to Connect × Push to Connect | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 0.3 | 125 psi @ 140° F | 2 5/8" | 2 11/16" | 35 to 140 | EPDM | 7/8" | PVC | PVC | 2 13/16" | Water, Air, Argon, Helium, Krypton, Neon, Xenon | Needle | 0000000 | 000000 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 0.4 | 125 psi @ 140° F | 2 5/8" | 2 11/16" | 35 to 140 | EPDM | 7/8" | PVC | PVC | 2 13/16" | Water, Air, Argon, Helium, Krypton, Neon, Xenon | Needle | 0000000 | 00000 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

White Polypropylene Body

Flow-Adjustment Valves | Mounting Nuts | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Overall | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Tube OD | Flow Coefficient (Cv) | Max. Pressure @ Temp. | Ht. | Lg. | Temp. Range, ° F | Seal Material | Panel Cutout Dia. | Seat Material | Needle Material | End-to-End Lg. | For Use With | Valve Type | Each | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Push to Connect × Push to Connect | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 0.3 | 125 psi @ 140° F | 2 5/8" | 2 11/16" | 35 to 140 | EPDM | 7/8" | Polypropylene | Polypropylene | 2 13/16" | Water, Air, Argon, Helium, Krypton, Neon, Xenon | Needle | 0000000 | 000000 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 0.4 | 125 psi @ 140° F | 2 5/8" | 2 11/16" | 35 to 140 | EPDM | 7/8" | Polypropylene | Polypropylene | 2 13/16" | Water, Air, Argon, Helium, Krypton, Neon, Xenon | Needle | 0000000 | 00000 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Threaded Precision Flow-Adjustment Valves for Chemicals

Dark Gray PVC Body

Overall | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Pipe Size | Flow Coefficient (Cv) | Max. Pressure @ Temp. | Ht. | Lg. | Temp. Range, ° F | Seal Material | Panel Cutout Dia. | Seat Material | Needle Material | End-to-End Lg. | For Use With | Valve Type | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

NPT Female × NPT Female | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4 | 0.64 | 150 psi @ 70° F | 3 7/16" | 2 1/2" | 40 to 150 | Fluoroelastomer | 1 5/16" | PTFE | PVC | 2 1/2" | Water, Citric Acid, Diesel Fuel, Ethylene Glycol, Hydrochloric Acid, Isopropyl Alcohol, Kerosene, Nitric Acid, Phosphoric Acid, Salt Water, Soap Solutions | Needle | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8 | 0.72 | 150 psi @ 70° F | 3 7/16" | 2 1/2" | 40 to 150 | Fluoroelastomer | 1 5/16" | PTFE | PVC | 2 1/2" | Water, Citric Acid, Diesel Fuel, Ethylene Glycol, Hydrochloric Acid, Isopropyl Alcohol, Kerosene, Nitric Acid, Phosphoric Acid, Salt Water, Soap Solutions | Needle | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2 | 0.79 | 150 psi @ 70° F | 3 7/16" | 2 1/2" | 40 to 150 | Fluoroelastomer | 1 5/16" | PTFE | PVC | 2 1/2" | Water, Citric Acid, Diesel Fuel, Ethylene Glycol, Hydrochloric Acid, Isopropyl Alcohol, Kerosene, Nitric Acid, Phosphoric Acid, Salt Water, Soap Solutions | Needle | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

White PVDF Body

Pipe Size | Flow Coefficient (Cv) | Max. Pressure @ Temp. | Max. Temp., ° F | Panel Cutout Dia. | End-to-End Lg. | Valve Type | For Use With | Seal Material | Seat Material | Needle Material | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

NPT Female × NPT Female | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4 | 0.64 | 150 psi @ 70° F | 300 | 1 5/16" | 2 1/2" | Needle | Water, Oil, Food, Beverage, Citric Acid, Deionized Water, Diesel Fuel, Ethanol, Ethylene Glycol, Fuel Oil, Gasoline, Hydrochloric Acid, Isopropyl Alcohol, Kerosene, Methanol (Methyl Alcohol), Mineral Spirits, Phosphoric Acid, Salt Water, Soap Solutions, Sodium Hydroxide (Caustic Soda), Sodium Hypochlorite (Bleach), Sulfuric Acid | Fluoroelastomer | PTFE | Polypropylene | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8 | 0.72 | 150 psi @ 70° F | 300 | 1 5/16" | 2 1/2" | Needle | Water, Oil, Food, Beverage, Citric Acid, Deionized Water, Diesel Fuel, Ethanol, Ethylene Glycol, Fuel Oil, Gasoline, Hydrochloric Acid, Isopropyl Alcohol, Kerosene, Methanol (Methyl Alcohol), Mineral Spirits, Phosphoric Acid, Salt Water, Soap Solutions, Sodium Hydroxide (Caustic Soda), Sodium Hypochlorite (Bleach), Sulfuric Acid | Fluoroelastomer | PTFE | Polypropylene | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2 | 0.79 | 150 psi @ 70° F | 300 | 1 5/16" | 2 1/2" | Needle | Water, Oil, Food, Beverage, Citric Acid, Deionized Water, Diesel Fuel, Ethanol, Ethylene Glycol, Fuel Oil, Gasoline, Hydrochloric Acid, Isopropyl Alcohol, Kerosene, Methanol (Methyl Alcohol), Mineral Spirits, Phosphoric Acid, Salt Water, Soap Solutions, Sodium Hydroxide (Caustic Soda), Sodium Hypochlorite (Bleach), Sulfuric Acid | Fluoroelastomer | PTFE | Polypropylene | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Black Polypropylene Body

Overall | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Pipe Size | Flow Coefficient (Cv) | Max. Pressure @ Temp. | Ht. | Lg. | Temp. Range, ° F | Seal Material | Panel Cutout Dia. | Seat Material | Needle Material | End-to-End Lg. | For Use With | Valve Type | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

NPT Female × NPT Female | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4 | 0.64 | 150 psi @ 70° F | 3 7/16" | 2 1/2" | 40 to 260 | Fluoroelastomer | 1 5/16" | PTFE | Polypropylene | 2 1/2" | Water, Citric Acid, Ethylene Glycol, Hydrochloric Acid, Isopropyl Alcohol, Kerosene, Nitric Acid, Salt Water, Soap Solutions | Needle | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8 | 0.72 | 150 psi @ 70° F | 3 7/16" | 2 1/2" | 40 to 260 | Fluoroelastomer | 1 5/16" | PTFE | Polypropylene | 2 1/2" | Water, Citric Acid, Ethylene Glycol, Hydrochloric Acid, Isopropyl Alcohol, Kerosene, Nitric Acid, Salt Water, Soap Solutions | Needle | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2 | 0.79 | 150 psi @ 70° F | 3 7/16" | 2 1/2" | 40 to 260 | Fluoroelastomer | 1 5/16" | PTFE | Polypropylene | 2 1/2" | Water, Citric Acid, Ethylene Glycol, Hydrochloric Acid, Isopropyl Alcohol, Kerosene, Nitric Acid, Salt Water, Soap Solutions | Needle | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Precision Flow-Adjustment Valves with Yor-Lok Fittings for Steam

316 Stainless Steel Body

Overall | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Tube ID | For Tube OD | Flow Coefficient (Cv) | Max. Pressure @ Temp. | Max. Steam Pressure @ Temp. | Ht. | Lg. | Seal Material | Panel Cutout Dia. | Seat Material | Packing Material | Needle Material | End-to-End Lg. | For Use With | Valve Type | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Yor-Lok × Yor-Lok | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/16" | 1/4" | 0.6 | 10,000 psi @ 200° F | 6,200 psi @ 355° F | 3 5/8" | 2 7/8" | PTFE | 7/8" | 316 Stainless Steel | PTFE | 316 Stainless Steel | 2 7/8" | Steam | Needle | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/16" | 3/8" | 0.6 | 10,000 psi @ 200° F | 4,800 psi @ 355° F | 3 5/8" | 2 7/8" | PTFE | 7/8" | 316 Stainless Steel | PTFE | 316 Stainless Steel | 2 7/8" | Steam | Needle | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/16" | 1/2" | 0.6 | 10,000 psi @ 200° F | 4,800 psi @ 355° F | 3 5/8" | 3 1/8" | PTFE | 7/8" | 316 Stainless Steel | PTFE | 316 Stainless Steel | 3 1/8" | Steam | Needle | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Precision Flow-Adjustment Valves with Barbed Fittings for Chemicals

For Tube ID | For Tube OD | Flow Coefficient (Cv) | Max. Pressure @ Temp. | Max. Temp., ° F | Panel Cutout Dia. | End-to-End Lg. | Valve Type | For Use With | Seal Material | Packing Material | Needle Material | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Black PVDF Body | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Barbed × Barbed | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 3/8" | 0.3 | 125 psi @ 140° F | 140 | 7/8" | 3 5/16" | Needle | Water, Oil, Air, Argon, Butane, Carbon Dioxide, Citric Acid, Deionized Water, Diesel Fuel, Ethanol, Ethylene Glycol, Gasoline, Helium, Hydrochloric Acid, Isopropyl Alcohol, Kerosene, Krypton, Methanol (Methyl Alcohol), Mineral Spirits, Natural Gas, Neon, Nitric Acid, Nitrogen, Oxygen, Phosphoric Acid, Propane, Salt Water, Soap Solutions, Sodium Hydroxide (Caustic Soda), Sodium Hypochlorite (Bleach), Sulfuric Acid, Toluene (Methylbenzene), Xenon, Xylene | PTFE | PTFE | PVDF | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 1/2" | 0.3 | 125 psi @ 140° F | 140 | 7/8" | 3 5/16" | Needle | Water, Oil, Air, Argon, Butane, Carbon Dioxide, Citric Acid, Deionized Water, Diesel Fuel, Ethanol, Ethylene Glycol, Gasoline, Helium, Hydrochloric Acid, Isopropyl Alcohol, Kerosene, Krypton, Methanol (Methyl Alcohol), Mineral Spirits, Natural Gas, Neon, Nitric Acid, Nitrogen, Oxygen, Phosphoric Acid, Propane, Salt Water, Soap Solutions, Sodium Hydroxide (Caustic Soda), Sodium Hypochlorite (Bleach), Sulfuric Acid, Toluene (Methylbenzene), Xenon, Xylene | PTFE | PTFE | PVDF | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 5/8" | 0.4 | 125 psi @ 140° F | 140 | 7/8" | 3 5/16" | Needle | Water, Oil, Air, Argon, Butane, Carbon Dioxide, Citric Acid, Deionized Water, Diesel Fuel, Ethanol, Ethylene Glycol, Gasoline, Helium, Hydrochloric Acid, Isopropyl Alcohol, Kerosene, Krypton, Methanol (Methyl Alcohol), Mineral Spirits, Natural Gas, Neon, Nitric Acid, Nitrogen, Oxygen, Phosphoric Acid, Propane, Salt Water, Soap Solutions, Sodium Hydroxide (Caustic Soda), Sodium Hypochlorite (Bleach), Sulfuric Acid, Toluene (Methylbenzene), Xenon, Xylene | PTFE | PTFE | PVDF | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Precision Flow-Adjustment Valves with Push-to-Connect Fittings for Chemicals

PVDF Body

Overall | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Tube ID | For Tube OD | Flow Coefficient (Cv) | Max. Pressure @ Temp. | Ht. | Lg. | Seal Material | Panel Cutout Dia. | Packing Material | Needle Material | End-to-End Lg. | For Use With | Valve Type | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Push to Connect × Push to Connect | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8" | 1/4" | 0.3 | 125 psi @ 140° F | 2 5/8" | 2 11/16" | Fluoroelastomer | 7/8" | PTFE | PVDF | 2 11/16" | Water, Oil, Air, Argon, Butane, Carbon Dioxide, Citric Acid, Deionized Water, Diesel Fuel, Ethanol, Ethylene Glycol, Gasoline, Helium, Hydrochloric Acid, Isopropyl Alcohol, Kerosene, Krypton, Methanol (Methyl Alcohol), Mineral Spirits, Natural Gas, Neon, Nitric Acid, Nitrogen, Oxygen, Phosphoric Acid, Propane, Salt Water, Soap Solutions, Sodium Hydroxide (Caustic Soda), Sodium Hypochlorite (Bleach), Sulfuric Acid, Toluene (Methylbenzene), Xenon, Xylene | Needle | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 3/8" | 0.4 | 125 psi @ 140° F | 2 5/8" | 2 11/16" | Fluoroelastomer | 7/8" | PTFE | PVDF | 2 11/16" | Water, Oil, Air, Argon, Butane, Carbon Dioxide, Citric Acid, Deionized Water, Diesel Fuel, Ethanol, Ethylene Glycol, Gasoline, Helium, Hydrochloric Acid, Isopropyl Alcohol, Kerosene, Krypton, Methanol (Methyl Alcohol), Mineral Spirits, Natural Gas, Neon, Nitric Acid, Nitrogen, Oxygen, Phosphoric Acid, Propane, Salt Water, Soap Solutions, Sodium Hydroxide (Caustic Soda), Sodium Hypochlorite (Bleach), Sulfuric Acid, Toluene (Methylbenzene), Xenon, Xylene | Needle | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Precision Flow-Adjustment Valves with Push-to-Connect Fittings for Food and Beverage

For Tube ID | For Tube OD | Max. Pressure @ Temp. | Max. Temp., ° F | Panel Cutout Dia. | End-to-End Lg. | Valve Type | For Use With | Seal Material | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

PVC Body | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Push to Connect × Push to Connect | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8" | 1/4" | 125 psi @ 140° F | 140 | 7/8" | 2 11/16" | Needle | Food, Beverage | Buna-N | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 3/8" | 125 psi @ 140° F | 140 | 7/8" | 2 11/16" | Needle | Food, Beverage | Buna-N | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Precision Flow-Adjustment Valves with Barbed Fittings

Dark Gray PVC Body

Flow-Adjustment Valves | Mounting Nuts | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Overall | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Tube ID | Flow Coefficient (Cv) | Max. Pressure @ Temp. | Ht. | Lg. | Temp. Range, ° F | Seal Material | Panel Cutout Dia. | Seat Material | Needle Material | End-to-End Lg. | For Use With | Valve Type | Each | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Barbed × Barbed | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 0.3 | 125 psi @ 140° F | 2 5/8" | 3 5/16" | 35 to 140 | EPDM | 7/8" | PVC | PVC | 3 3/8" | Water, Air, Argon, Helium, Krypton, Neon, Xenon | Needle | 0000000 | 000000 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 0.3 | 125 psi @ 140° F | 2 5/8" | 3 5/16" | 35 to 140 | EPDM | 7/8" | PVC | PVC | 3 3/8" | Water, Air, Argon, Helium, Krypton, Neon, Xenon | Needle | 0000000 | 00000 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 0.4 | 125 psi @ 140° F | 2 5/8" | 3 5/16" | 35 to 140 | EPDM | 7/8" | PVC | PVC | 3 3/8" | Water, Air, Argon, Helium, Krypton, Neon, Xenon | Needle | 0000000 | 00000 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

White Polypropylene Body

Flow-Adjustment Valves | Mounting Nuts | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Overall | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Tube ID | Flow Coefficient (Cv) | Max. Pressure @ Temp. | Ht. | Lg. | Temp. Range, ° F | Seal Material | Panel Cutout Dia. | Seat Material | Needle Material | End-to-End Lg. | For Use With | Valve Type | Each | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Barbed × Barbed | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 0.3 | 125 psi @ 140° F | 2 5/8" | 3 5/16" | 35 to 140 | EPDM | 7/8" | Polypropylene | Polypropylene | 3 3/8" | Water, Air, Argon, Helium, Krypton, Neon, Xenon | Needle | 0000000 | 000000 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 0.3 | 125 psi @ 140° F | 2 5/8" | 3 5/16" | 35 to 140 | EPDM | 7/8" | Polypropylene | Polypropylene | 3 3/8" | Water, Air, Argon, Helium, Krypton, Neon, Xenon | Needle | 0000000 | 00000 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 0.4 | 125 psi @ 140° F | 2 5/8" | 3 5/16" | 35 to 140 | EPDM | 7/8" | Polypropylene | Polypropylene | 3 3/8" | Water, Air, Argon, Helium, Krypton, Neon, Xenon | Needle | 0000000 | 00000 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Precision Flow-Adjustment Valves with Barbed Fittings for Food and Beverage

For Tube ID | For Tube OD | Flow Coefficient (Cv) | Max. Pressure @ Temp. | Max. Temp., ° F | Panel Cutout Dia. | End-to-End Lg. | Valve Type | For Use With | Seal Material | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

PVC Body | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Barbed × Barbed | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 3/8" | 0.3 | 125 psi @ 140° F | 140 | 7/8" | 3 5/16" | Needle | Food, Beverage | PTFE | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 1/2" | 0.3 | 125 psi @ 140° F | 140 | 7/8" | 3 5/16" | Needle | Food, Beverage | PTFE | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||