Structural Support 3D Printer Filaments

with your part to prevent the

part from losing its shape

When 3D printing a model with overhangs or hollow spaces, use these filaments to prevent the model from losing its shape. They support the structure during the printing and cooling process, then dissolve or snap away once the part is hardened. Use them in dual-extrusion fused filament fabrication (FFF) printers alongside your primary filament. Unlike parts with supports printed from a single filament, there’s no cutting, sanding, or polishing required.

Choose a filament that has similar printing requirements as your primary filament. You will want to choose a support filament that prints at a similar temperature as your primary filament and has the same requirements for a heated build chamber, so they cool at the same rate and won’t warp. Aquasys 120 filaments are compatible with the widest variety of filament materials, but they require a heated build chamber. Aquasys GP filaments are good at supporting heat-sensitive materials, such as PLA and PET, because they print well at lower temperatures and don’t need a heated build chamber.

You should also consider how you will remove the structural support filament from your finished part. Soluble filaments are well suited to print parts with complex or fragile designs as they gently dissolve off your primary part, leaving a smooth finish. Water-soluble filaments dissolve in a heated bath.

Spool | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Dia., mm | Printing Temp. | For Printer Bed Temp. | Hardness | Max. Exposure Temp. | Water Temp. to Dissolve | For Min. Nozzle Opening Dia., mm | Dia., mm | Dp., mm | Wt., g | For Use With | Each | |

Water Soluble | ||||||||||||

Aquasys 120—Clear Amber | ||||||||||||

| 1.75 | 220° to 245° C 430° to 470° F | 80° to 120° C 180° to 245° F | Rockwell C30 (Hard) | 80° C 176° F | 80° C 176° F | 0.4 | 200 | 55 | 500 | ABS Plastic ASA Plastic Nylon Plastic PETG Plastic Polypropylene Plastic TPU Plastic | 0000000 | 0000000 |

| 2.85 | 220° to 245° C 430° to 470° F | 80° to 120° C 180° to 245° F | Rockwell C30 (Hard) | 80° C 176° F | 80° C 176° F | 0.4 | 200 | 55 | 500 | ABS Plastic ASA Plastic Nylon Plastic PETG Plastic Polypropylene Plastic TPU Plastic | 0000000 | 000000 |

Aquasys GP—Semi Clear Off-White | ||||||||||||

| 1.75 | 225° to 255° C 437° to 491° F | 40° to 60° C 104° to 140° F | Not Rated | 57° C 134° F | 25° C 77° F | 0.4 | 200 | 55 | 500 | PET Plastic PETG Plastic PLA Plastic | 0000000 | 00000 |

| 2.85 | 225° to 255° C 437° to 491° F | 40° to 60° C 104° to 140° F | Not Rated | 57° C 134° F | 25° C 77° F | 0.4 | 200 | 55 | 500 | PET Plastic PETG Plastic PLA Plastic | 0000000 | 00000 |

Moisture-Resistant Polyester 3D Printer Filaments

Parts printed with these polyester filaments absorb less moisture than other types of plastic, making them ideal for use in wet or humid environments. They are more durable and flexible than PLA, and easier to print than ABS. Use these filaments with fused filament fabrication (FFF) 3D printers, and print onto a heated print bed. Printing onto a cool surface causes the molten filament to change temperature rapidly, which can warp your designs. Although finished parts are moisture-resistant, these filaments are sensitive to humidity, and should be stored in a dehumidifying cabinet or a sealed container with desiccant for the best printing quality.

PETG contains glycol, so it is less brittle and easier to print than PETT and PCTG. Carbon-fiber-filled PETG is often used to make rigid parts that are difficult to bend and break. Finished parts are easier to thread and machine than unfilled parts. Because these filaments are abrasive, use them only with abrasion-resistant nozzles.

Static-dissipative filaments make parts that protect equipment from electrostatic shocks by diverting electrostatic discharges in a controlled way. Create tool handles, tote trays, enclosures, and other parts that are used near sensitive electronics. To adjust the surface resistivity of your printed part, change the temperature of your printer’s extruder. As the extruder’s temperature increases, the printed part’s resistivity will decrease.

Antistatic filaments make parts that prevent the buildup of static electricity. This helps prevent the buildup of dust or fibers on the surface of your finished part. However, they are not as effective at preventing electrostatic discharge as static-dissipative filaments.

Tensile strength is the best measure of a filament's overall strength. Similar to the stress applied on a rope during a game of tug-of-war, it's the amount of pulling force a material can handle before breaking. A higher rating means a stronger filament. A tensile strength of 5,000 psi and above is considered good; 12,000 psi and above is excellent.

Maximum exposure temperature is the point at which a printed part will begin to deform. Above this temperature, your printed parts will start to lose structural integrity.

Spool | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Dia., mm | Printing Temp. | For Printer Bed Temp. | Tensile Strength | Hardness | Surface Resistivity, ohms/sq. | Max. Exposure Temp. | For Min. Nozzle Opening Dia., mm | Dia., mm | Dp., mm | Wt., g | Each | |

PETG Plastic—Static Dissipative | ||||||||||||

Opaque Black | ||||||||||||

| 1.75 | 230° to 260° C 446° to 500° F | 60° to 90° C 140° to 194° F | 7,250 psi (Good) | Rockwell R110 (Hard) | 107-109 | 75° C 167° F | 0.4 | 200 | 75 | 750 | 0000000 | 0000000 |

| 2.85 | 230° to 260° C 446° to 500° F | 60° to 90° C 140° to 194° F | 7,250 psi (Good) | Rockwell R110 (Hard) | 107-109 | 75° C 167° F | 0.4 | 200 | 75 | 750 | 0000000 | 000000 |

Carbon-Fiber-Filled PETG Plastic—Antistatic | ||||||||||||

Opaque Black | ||||||||||||

| 1.75 | 230° to 260° C 446° to 500° F | 60° C 140° F | 8,120 psi (Good) | Not Rated | 109-1012 | 77° C 170° F | 0.4 | 200 | 60 | 750 | 000000 | 00000 |

| 2.85 | 230° to 260° C 446° to 500° F | 60° C 140° F | 8,120 psi (Good) | Not Rated | 109-1012 | 77° C 170° F | 0.4 | 200 | 60 | 750 | 0000000 | 00000 |

Dremel 3D Printer Filaments

Build parts and prototypes from these filaments using Dremel fused filament fabrication (FFF) 3D printers. An RFID tag on the spool communicates with your printer, automatically adjusting it to the correct temperature and print speed for the filament material and notifying you when the filament is running out.

PETG is more moisture resistant than ECO-ABS, making it a great choice for printing parts for use in humid or wet environments. Generally, PETG’s other properties fall somewhere between those of PLA and ECO-ABS. It’s more flexible and durable than PLA, but less so than ECO-ABS. It’s harder to print than PLA because it requires a heated printer bed, but easier to print than ECO-ABS. PETG filaments should be kept in a sealed container with a desiccant.

Tensile strength is the best measure of a filament's overall strength. Similar to the stress applied on a rope during a game of tug-of-war, it's the amount of pulling force a material can handle before breaking. A higher rating means a stronger filament. A tensile strength of 5,000 psi and above is considered good; 12,000 psi and above is excellent.

Maximum exposure temperature is the point at which a printed part will begin to deform. Above this temperature, your printed parts will start to lose structural integrity.

Spool | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Manufacturer Model No. | Dia., mm | Printing Temp. | For Printer Bed Temp. | Tensile Strength | Max. Exposure Temp. | For Min. Nozzle Opening Dia., mm | Dia., mm | Dp., mm | Wt., g | Color | Each | |

PETG Plastic | ||||||||||||

| PETG-TRA-01 | 1.75 | 240° to 260° C 464° to 500° F | 80° C 175° F | 7,250 psi (Good) | 84° C 183° F | 0.2 | 181 | 55 | 750 | Clear | 0000000 | 000000 |

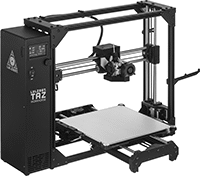

Filament 3D Printers

Melt and extrude plastic filaments to build quick and inexpensive prototypes, custom and complex parts, and manufacturing aids such as jigs and fixtures. These 3D printers are also known as fused filament fabrication (FFF) and fused deposition modeling (FDM) printers. They meet U.S. and international standards for safety.

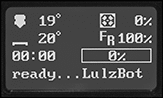

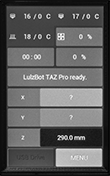

LulzBot printers are compatible with many different materials, so they’re useful across a wide range of applications. They have a minimum layer height that is twice as thin as MakerBot printers, meaning they print a finer level of detail. LulzBot printers come with open source software, so you can manually adjust temperature and print settings. All have heated printer beds to prevent parts from warping during cooling.

Mini 3 printers are the smallest in our offering but also the fastest; use them to quickly print small pieces. They have a magnetic bed which makes it easy to remove delicate prints without breaking them.

The TAZ Workhorse+ and TAZ Pro printer beds are reversible—prints adhere well to the PEI glass side, while the borosilicate glass side is especially flat for perfectly level prints. The TAZ Workhorse+ printers have the best combination of size and speed in our offering. The TAZ Pro printers are not as fast as the Mini 3 or the Workhorse+, but have dual extruders so you can print structural supports. Dual extruders can also print two different colors into a single part.

Max. Printing | Printer Bed | Overall | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Lg. | Wd. | Ht. | Min. Layer Ht., mm | Printer Speed, mm/s | Material | Type | Lg. | Wd. | Ht. | Accuracy, mm | Data Connection Type | Current, A | Voltage | Specifications Met | Each | |

Mini 3 | ||||||||||||||||

| 7" | 7" | 7" | 0.05 | 500 | PEI Glass | Heated, Magnetic | 18" | 13" | 24" | ±0.2 | USB-A | 3.2 | 120V AC, 240V AC | UL Listed, ETL Listed, C-ETL Listed, OSHW Certified, CSA Certified, CE Marked | 0000000 | 000000000 |

TAZ Workhorse+ | ||||||||||||||||

| 11" | 11" | 11 1/8" | 0.05 | 300 | Borosilicate Glass PEI Glass | Heated, Magnetic | 32 3/4" | 20" | 20 1/2" | ±0.2 | Standard SD Card, USB-A | 3.2 | 120V AC, 240V AC | UL Listed, ETL Listed, C-ETL Listed, OSHW Certified, CSA Certified, CE Marked | 0000000 | 00000000 |

TAZ Pro | ||||||||||||||||

| 11" | 11" | 11 1/8" | 0.05 | 200 | Borosilicate Glass PEI Glass | Heated | 32 5/8" | 28" | 20 1/2" | ±0.2 | USB-A | 3.2 | 120V AC, 240V AC | UL Listed, ETL Listed, C-ETL Listed, OSHW Certified, CSA Certified, CE Marked | 0000000 | 00000000 |