Compare over 25 types of plastic to find the right material for you.

Selecting Compatible Lead Screws and Nuts

More

Scratch-Resistant Easy-to-Form PETG

- Color: White

- Clarity: Semi Clear

- Temperature Range: -4° to 140° F

- Tensile Strength: 7,700 psi (Good)

- Impact Strength: 1.2 ft-lbs./in. (Poor)

- Hardness: Rockwell R115 (Hard)

- For Use Outdoors: No

- Specifications Met: FDA Compliant 21 CFR 177.1315, NSF/ANSI 51, UL 94 HB

A satin texture on one side of these PETG sheets makes them semiclear. The satin side is more resistant to scratching and glare than standard PETG. The other side is smooth. You can see light from the other side, but not detailed shapes. They’re often formed into complex shapes such as displays, signs, and trays, and are easy to cut with sheet metal shears. These sheets have better impact strength than Plexiglas® Acrylic and can be used in similar applications.

| Thickness | Thickness Tolerance | Temperature Range, °F | Each | |

12" × 12" | ||||

|---|---|---|---|---|

| 0.02" | -0.0015" to 0.0015" | -4° to 140° | 00000000 | 00000 |

| 0.04" | -0.002" to 0.002" | -4° to 140° | 00000000 | 0000 |

| 0.06" | -0.003" to 0.003" | -4° to 140° | 00000000 | 0000 |

24" × 24" | ||||

| 0.02" | -0.0015" to 0.0015" | -4° to 140° | 00000000 | 0000 |

| 0.04" | -0.002" to 0.002" | -4° to 140° | 00000000 | 00000 |

| 0.06" | -0.003" to 0.003" | -4° to 140° | 00000000 | 00000 |

24" × 48" | ||||

| 0.02" | -0.0015" to 0.0015" | -4° to 140° | 00000000 | 00000 |

| 0.04" | -0.002" to 0.002" | -4° to 140° | 00000000 | 00000 |

| 0.06" | -0.003" to 0.003" | -4° to 140° | 00000000 | 00000 |

Clear Easy-to-Form PETG Rods

- Color: Clear

- Temperature Range: -40° to 140° F

- Tensile Strength: 7,100-7,700 psi (Good)

- Impact Strength: 1.7 ft.-lbs./in. (Poor)

- Hardness: Rockwell R106-R115 (Hard)

- For Use Outdoors: No

- Specifications Met: FDA Compliant 21 CFR 177.1350

These PETG rods can be formed into complex shapes, such as display racks, without sacrificing durability.

Clear Easy-to-Form PETG Tubes

- Color: Clear

- Temperature Range: -40° to 140° F

- Tensile Strength: 7,100-7,700 psi (Good)

- Impact Strength: 1.7 ft.-lbs./in. (Poor)

- Hardness: Rockwell R106-R115 (Hard)

- For Use Outdoors: No

- Specifications Met: FDA Compliant 21 CFR 177.1315

Form these PETG tubes into containers, packaging, and other complex shapes without sacrificing durability.

| OD | OD Tolerance | ID | ID Tolerance | Lengths, ft. | Each | |

1/16" Wall Thick. | ||||||

|---|---|---|---|---|---|---|

| 5/16" | -0.010" to 0.010" | 3/16" | -0.010" to 0.010" | 6 | 0000000 | 00000 |

| 3/8" | -0.010" to 0.010" | 1/4" | -0.010" to 0.010" | 6 | 0000000 | 00000 |

| 1/2" | -0.010" to 0.010" | 3/8" | -0.010" to 0.010" | 6 | 0000000 | 0000 |

| 5/8" | -0.010" to 0.010" | 1/2" | -0.010" to 0.010" | 6 | 0000000 | 00000 |

| 3/4" | -0.010" to 0.010" | 5/8" | -0.010" to 0.010" | 6 | 0000000 | 00000 |

| 7/8" | -0.010" to 0.010" | 3/4" | -0.010" to 0.010" | 6 | 0000000 | 00000 |

| 1" | -0.010" to 0.010" | 7/8" | -0.010" to 0.010" | 6 | 0000000 | 00000 |

| 1 1/4" | -0.020" to 0.020" | 1 1/8" | -0.020" to 0.020" | 6 | 0000000 | 00000 |

1/8" Wall Thick. | ||||||

| 1/2" | -0.010" to 0.010" | 1/4" | -0.010" to 0.010" | 6 | 0000000 | 00000 |

| 5/8" | -0.010" to 0.010" | 3/8" | -0.010" to 0.010" | 6 | 0000000 | 00000 |

| 3/4" | -0.010" to 0.010" | 1/2" | -0.010" to 0.010" | 6 | 0000000 | 00000 |

| 7/8" | -0.010" to 0.010" | 5/8" | -0.010" to 0.010" | 6 | 0000000 | 00000 |

| 1" | -0.010" to 0.010" | 3/4" | -0.010" to 0.010" | 6 | 0000000 | 00000 |

| 1 1/4" | -0.020" to 0.020" | 1" | -0.020" to 0.020" | 6 | 0000000 | 00000 |

| 1 3/8" | -0.020" to 0.020" | 1 1/8" | -0.020" to 0.020" | 6 | 0000000 | 00000 |

| Per Ft. | ||||||

| 1 1/2" | -0.020" to 0.020" | 1 1/4" | -0.020" to 0.020" | 0000000 | 0000 | |

| 1 5/8" | -0.020" to 0.020" | 1 3/8" | -0.020" to 0.020" | 0000000 | 0000 | |

| 1 3/4" | -0.020" to 0.020" | 1 1/2" | -0.020" to 0.020" | 0000000 | 0000 | |

| 2" | -0.020" to 0.020" | 1 3/4" | -0.020" to 0.020" | 0000000 | 0000 | |

| 2 1/4" | -0.020" to 0.020" | 2" | -0.020" to 0.020" | 0000000 | 0000 | |

| 2 1/2" | -0.020" to 0.020" | 2 1/4" | -0.020" to 0.020" | 0000000 | 00000 | |

| 2 3/4" | -0.020" to 0.020" | 2 1/2" | -0.020" to 0.020" | 0000000 | 00000 | |

| 3" | -0.020" to 0.020" | 2 3/4" | -0.020" to 0.020" | 0000000 | 00000 | |

| 3 1/4" | -0.020" to 0.020" | 3" | -0.020" to 0.020" | 0000000 | 00000 | |

Clear Easy-to-Form PETG Sheets

- Color: Clear

- Temperature Range: See Table

- Tensile Strength: See Table (Good)

- Impact Strength: See Table

- Hardness: See Table (Hard)

- For Use Outdoors: No

- Specifications Met: See Table

Often fabricated into containers, trays, and packaging, these PETG sheets can be formed into complex shapes without sacrificing durability. This material can be used in similar applications as Plexiglas® Acrylic.

Temp. Range, °F | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Thick. | Thick. Tolerance | Min. | Max. | Tensile Strength, psi | Impact Strength | Hardness | Specifications Met | Each | |

6" × 6" | |||||||||

| 0.06" | -0.006" to 0.006" | -4° | 140° | 6,900 | Not Rated | Rockwell M95 | FDA Compliant 21 CFR 177.1315, NSF/ANSI 51, UL 94 HB | 000000000 | 00000 |

| 0.08" | -0.008" to 0.008" | -4° | 140° | 6,900 | Not Rated | Rockwell M95 | FDA Compliant 21 CFR 177.1315, NSF/ANSI 51, UL 94 HB | 000000000 | 0000 |

| 0.1" | -0.01" to 0.01" | -4° | 140° | 6,900 | Not Rated | Rockwell M95 | FDA Compliant 21 CFR 177.1315, NSF/ANSI 51, UL 94 HB | 000000000 | 0000 |

| 0.118" | -0.012" to 0.012" | -4° | 140° | 6,900 | Not Rated | Rockwell M95 | FDA Compliant 21 CFR 177.1315, NSF/ANSI 51, UL 94 HB | 000000000 | 0000 |

| 0.177" | -0.018" to 0.018" | -4° | 140° | 6,900 | Not Rated | Rockwell M95 | FDA Compliant 21 CFR 177.1315, NSF/ANSI 51, UL 94 HB | 000000000 | 0000 |

| 0.236" | -0.024" to 0.024" | -4° | 140° | 6,900 | Not Rated | Rockwell M95 | FDA Compliant 21 CFR 177.1315, NSF/ANSI 51, UL 94 HB | 000000000 | 0000 |

6" × 12" | |||||||||

| 0.06" | -0.006" to 0.006" | -4° | 140° | 6,900 | Not Rated | Rockwell M95 | FDA Compliant 21 CFR 177.1315, NSF/ANSI 51, UL 94 HB | 000000000 | 0000 |

| 0.08" | -0.008" to 0.008" | -4° | 140° | 6,900 | Not Rated | Rockwell M95 | FDA Compliant 21 CFR 177.1315, NSF/ANSI 51, UL 94 HB | 000000000 | 0000 |

| 0.1" | -0.01" to 0.01" | -4° | 140° | 6,900 | Not Rated | Rockwell M95 | FDA Compliant 21 CFR 177.1315, NSF/ANSI 51, UL 94 HB | 000000000 | 0000 |

| 0.118" | -0.012" to 0.012" | -4° | 140° | 6,900 | Not Rated | Rockwell M95 | FDA Compliant 21 CFR 177.1315, NSF/ANSI 51, UL 94 HB | 000000000 | 0000 |

| 0.177" | -0.018" to 0.018" | -4° | 140° | 6,900 | Not Rated | Rockwell M95 | FDA Compliant 21 CFR 177.1315, NSF/ANSI 51, UL 94 HB | 000000000 | 0000 |

| 0.236" | -0.024" to 0.024" | -4° | 140° | 6,900 | Not Rated | Rockwell M95 | FDA Compliant 21 CFR 177.1315, NSF/ANSI 51, UL 94 HB | 000000000 | 0000 |

12" × 12" | |||||||||

| 0.02" | -0.002" to 0.002" | Not Rated | 140° | 7,700 | 1.7 ft.-lbs./in (Poor) | Rockwell R115 | FDA Compliant 21 CFR 177.1315 | 000000000 | 0000 |

| 0.03" | -0.003" to 0.003" | Not Rated | 140° | 7,700 | 1.7 ft.-lbs./in (Poor) | Rockwell R115 | FDA Compliant 21 CFR 177.1315 | 000000000 | 0000 |

| 0.04" | -0.004" to 0.004" | Not Rated | 140° | 7,700 | 1.7 ft.-lbs./in (Poor) | Rockwell R115 | FDA Compliant 21 CFR 177.1315 | 000000000 | 0000 |

| 0.06" | -0.006" to 0.006" | -40° | 140° | 7,100-7,700 | 1.7 ft.-lbs./in (Poor) | Rockwell R106-R115 | FDA Compliant 21 CFR 174.5, FDA Compliant 21 CFR 177.1315, UL 94 HB | 00000000 | 0000 |

| 0.08" | -0.008" to 0.008" | -40° | 140° | 7,100-7,700 | 1.7 ft.-lbs./in (Poor) | Rockwell R106-R115 | FDA Compliant 21 CFR 174.5, FDA Compliant 21 CFR 177.1315, UL 94 HB | 00000000 | 0000 |

| 0.1" | -0.01" to 0.01" | -40° | 140° | 7,100-7,700 | 1.7 ft.-lbs./in (Poor) | Rockwell R106-R115 | FDA Compliant 21 CFR 174.5, FDA Compliant 21 CFR 177.1315, UL 94 HB | 00000000 | 0000 |

| 0.118" | -0.012" to 0.012" | -40° | 140° | 7,100-7,700 | 1.7 ft.-lbs./in (Poor) | Rockwell R106-R115 | FDA Compliant 21 CFR 174.5, FDA Compliant 21 CFR 177.1315, UL 94 HB | 00000000 | 0000 |

| 0.177" | -0.018" to 0.018" | -40° | 140° | 7,100-7,700 | 1.7 ft.-lbs./in (Poor) | Rockwell R106-R115 | FDA Compliant 21 CFR 174.5, FDA Compliant 21 CFR 177.1315, UL 94 HB | 00000000 | 00000 |

| 0.236" | -0.024" to 0.024" | -40° | 140° | 7,100-7,700 | 1.7 ft.-lbs./in (Poor) | Rockwell R106-R115 | FDA Compliant 21 CFR 174.5, FDA Compliant 21 CFR 177.1315, UL 94 HB | 00000000 | 00000 |

12" × 24" | |||||||||

| 0.02" | -0.002" to 0.002" | Not Rated | 140° | 7,700 | 1.7 ft.-lbs./in (Poor) | Rockwell R115 | FDA Compliant 21 CFR 177.1315 | 000000000 | 0000 |

| 0.03" | -0.003" to 0.003" | Not Rated | 140° | 7,700 | 1.7 ft.-lbs./in (Poor) | Rockwell R115 | FDA Compliant 21 CFR 177.1315 | 000000000 | 0000 |

| 0.04" | -0.004" to 0.004" | Not Rated | 140° | 7,700 | 1.7 ft.-lbs./in (Poor) | Rockwell R115 | FDA Compliant 21 CFR 177.1315 | 000000000 | 0000 |

| 0.06" | -0.006" to 0.006" | -40° | 140° | 7,100-7,700 | 1.7 ft.-lbs./in (Poor) | Rockwell R106-R115 | FDA Compliant 21 CFR 174.5, FDA Compliant 21 CFR 177.1315, UL 94 HB | 00000000 | 0000 |

| 0.08" | -0.008" to 0.008" | -40° | 140° | 7,100-7,700 | 1.7 ft.-lbs./in (Poor) | Rockwell R106-R115 | FDA Compliant 21 CFR 174.5, FDA Compliant 21 CFR 177.1315, UL 94 HB | 00000000 | 0000 |

| 0.1" | -0.01" to 0.01" | -40° | 140° | 7,100-7,700 | 1.7 ft.-lbs./in (Poor) | Rockwell R106-R115 | FDA Compliant 21 CFR 174.5, FDA Compliant 21 CFR 177.1315, UL 94 HB | 00000000 | 00000 |

| 0.118" | -0.012" to 0.012" | -40° | 140° | 7,100-7,700 | 1.7 ft.-lbs./in (Poor) | Rockwell R106-R115 | FDA Compliant 21 CFR 174.5, FDA Compliant 21 CFR 177.1315, UL 94 HB | 00000000 | 00000 |

| 0.177" | -0.018" to 0.018" | -40° | 140° | 7,100-7,700 | 1.7 ft.-lbs./in (Poor) | Rockwell R106-R115 | FDA Compliant 21 CFR 174.5, FDA Compliant 21 CFR 177.1315, UL 94 HB | 00000000 | 00000 |

| 0.236" | -0.024" to 0.024" | -40° | 140° | 7,100-7,700 | 1.7 ft.-lbs./in (Poor) | Rockwell R106-R115 | FDA Compliant 21 CFR 174.5, FDA Compliant 21 CFR 177.1315, UL 94 HB | 00000000 | 00000 |

12" × 36" | |||||||||

| 0.02" | -0.002" to 0.002" | Not Rated | 140° | 7,700 | 1.7 ft.-lbs./in (Poor) | Rockwell R115 | FDA Compliant 21 CFR 177.1315 | 000000000 | 0000 |

| 0.03" | -0.003" to 0.003" | Not Rated | 140° | 7,700 | 1.7 ft.-lbs./in (Poor) | Rockwell R115 | FDA Compliant 21 CFR 177.1315 | 000000000 | 0000 |

| 0.04" | -0.004" to 0.004" | Not Rated | 140° | 7,700 | 1.7 ft.-lbs./in (Poor) | Rockwell R115 | FDA Compliant 21 CFR 177.1315 | 000000000 | 0000 |

| 0.06" | -0.006" to 0.006" | -4° | 140° | 6,900 | Not Rated | Rockwell M95 | FDA Compliant 21 CFR 177.1315, NSF/ANSI 51, UL 94 HB | 000000000 | 0000 |

| 0.08" | -0.008" to 0.008" | -4° | 140° | 6,900 | Not Rated | Rockwell M95 | FDA Compliant 21 CFR 177.1315, NSF/ANSI 51, UL 94 HB | 000000000 | 00000 |

| 0.1" | -0.01" to 0.01" | -4° | 140° | 6,900 | Not Rated | Rockwell M95 | FDA Compliant 21 CFR 177.1315, NSF/ANSI 51, UL 94 HB | 000000000 | 00000 |

| 0.118" | -0.012" to 0.012" | -4° | 140° | 6,900 | Not Rated | Rockwell M95 | FDA Compliant 21 CFR 177.1315, NSF/ANSI 51, UL 94 HB | 000000000 | 00000 |

| 0.177" | -0.018" to 0.018" | -4° | 140° | 6,900 | Not Rated | Rockwell M95 | FDA Compliant 21 CFR 177.1315, NSF/ANSI 51, UL 94 HB | 000000000 | 00000 |

| 0.236" | -0.024" to 0.024" | -4° | 140° | 6,900 | Not Rated | Rockwell M95 | FDA Compliant 21 CFR 177.1315, NSF/ANSI 51, UL 94 HB | 000000000 | 00000 |

12" × 48" | |||||||||

| 0.02" | -0.002" to 0.002" | Not Rated | 140° | 7,700 | 1.7 ft.-lbs./in (Poor) | Rockwell R115 | FDA Compliant 21 CFR 177.1315 | 000000000 | 0000 |

| 0.03" | -0.003" to 0.003" | Not Rated | 140° | 7,700 | 1.7 ft.-lbs./in (Poor) | Rockwell R115 | FDA Compliant 21 CFR 177.1315 | 000000000 | 0000 |

| 0.04" | -0.004" to 0.004" | Not Rated | 140° | 7,700 | 1.7 ft.-lbs./in (Poor) | Rockwell R115 | FDA Compliant 21 CFR 177.1315 | 000000000 | 0000 |

| 0.06" | -0.006" to 0.006" | -4° | 140° | 6,900 | Not Rated | Rockwell M95 | FDA Compliant 21 CFR 177.1315, NSF/ANSI 51, UL 94 HB | 000000000 | 00000 |

| 0.08" | -0.008" to 0.008" | -4° | 140° | 6,900 | Not Rated | Rockwell M95 | FDA Compliant 21 CFR 177.1315, NSF/ANSI 51, UL 94 HB | 000000000 | 00000 |

| 0.1" | -0.01" to 0.01" | -4° | 140° | 6,900 | Not Rated | Rockwell M95 | FDA Compliant 21 CFR 177.1315, NSF/ANSI 51, UL 94 HB | 000000000 | 00000 |

| 0.118" | -0.012" to 0.012" | -4° | 140° | 6,900 | Not Rated | Rockwell M95 | FDA Compliant 21 CFR 177.1315, NSF/ANSI 51, UL 94 HB | 000000000 | 00000 |

| 0.177" | -0.018" to 0.018" | -4° | 140° | 6,900 | Not Rated | Rockwell M95 | FDA Compliant 21 CFR 177.1315, NSF/ANSI 51, UL 94 HB | 000000000 | 00000 |

| 0.236" | -0.024" to 0.024" | -4° | 140° | 6,900 | Not Rated | Rockwell M95 | FDA Compliant 21 CFR 177.1315, NSF/ANSI 51, UL 94 HB | 000000000 | 00000 |

24" × 24" | |||||||||

| 0.02" | -0.002" to 0.002" | Not Rated | 140° | 7,700 | 1.7 ft.-lbs./in (Poor) | Rockwell R115 | FDA Compliant 21 CFR 177.1315 | 000000000 | 0000 |

| 0.03" | -0.003" to 0.003" | Not Rated | 140° | 7,700 | 1.7 ft.-lbs./in (Poor) | Rockwell R115 | FDA Compliant 21 CFR 177.1315 | 000000000 | 0000 |

| 0.04" | -0.004" to 0.004" | Not Rated | 140° | 7,700 | 1.7 ft.-lbs./in (Poor) | Rockwell R115 | FDA Compliant 21 CFR 177.1315 | 000000000 | 0000 |

| 0.06" | -0.006" to 0.006" | -40° | 140° | 7,100-7,700 | 1.7 ft.-lbs./in (Poor) | Rockwell R106-R115 | FDA Compliant 21 CFR 174.5, FDA Compliant 21 CFR 177.1315, UL 94 HB | 00000000 | 00000 |

| 0.08" | -0.008" to 0.008" | -40° | 140° | 7,100-7,700 | 1.7 ft.-lbs./in (Poor) | Rockwell R106-R115 | FDA Compliant 21 CFR 174.5, FDA Compliant 21 CFR 177.1315, UL 94 HB | 00000000 | 00000 |

| 0.1" | -0.01" to 0.01" | -40° | 140° | 7,100-7,700 | 1.7 ft.-lbs./in (Poor) | Rockwell R106-R115 | FDA Compliant 21 CFR 174.5, FDA Compliant 21 CFR 177.1315, UL 94 HB | 00000000 | 00000 |

| 0.118" | -0.012" to 0.012" | -40° | 140° | 7,100-7,700 | 1.7 ft.-lbs./in (Poor) | Rockwell R106-R115 | FDA Compliant 21 CFR 174.5, FDA Compliant 21 CFR 177.1315, UL 94 HB | 00000000 | 00000 |

| 0.177" | -0.018" to 0.018" | -40° | 140° | 7,100-7,700 | 1.7 ft.-lbs./in (Poor) | Rockwell R106-R115 | FDA Compliant 21 CFR 174.5, FDA Compliant 21 CFR 177.1315, UL 94 HB | 00000000 | 00000 |

| 0.236" | -0.024" to 0.024" | -40° | 140° | 7,100-7,700 | 1.7 ft.-lbs./in (Poor) | Rockwell R106-R115 | FDA Compliant 21 CFR 174.5, FDA Compliant 21 CFR 177.1315, UL 94 HB | 00000000 | 00000 |

24" × 36" | |||||||||

| 0.02" | -0.002" to 0.002" | Not Rated | 140° | 7,700 | 1.7 ft.-lbs./in (Poor) | Rockwell R115 | FDA Compliant 21 CFR 177.1315 | 000000000 | 0000 |

| 0.03" | -0.003" to 0.003" | Not Rated | 140° | 7,700 | 1.7 ft.-lbs./in (Poor) | Rockwell R115 | FDA Compliant 21 CFR 177.1315 | 000000000 | 00000 |

| 0.04" | -0.004" to 0.004" | Not Rated | 140° | 7,700 | 1.7 ft.-lbs./in (Poor) | Rockwell R115 | FDA Compliant 21 CFR 177.1315 | 000000000 | 00000 |

| 0.06" | -0.006" to 0.006" | -4° | 140° | 6,900 | Not Rated | Rockwell M95 | FDA Compliant 21 CFR 177.1315, NSF/ANSI 51, UL 94 HB | 000000000 | 00000 |

| 0.08" | -0.008" to 0.008" | -4° | 140° | 6,900 | Not Rated | Rockwell M95 | FDA Compliant 21 CFR 177.1315, NSF/ANSI 51, UL 94 HB | 000000000 | 00000 |

| 0.1" | -0.01" to 0.01" | -4° | 140° | 6,900 | Not Rated | Rockwell M95 | FDA Compliant 21 CFR 177.1315, NSF/ANSI 51, UL 94 HB | 000000000 | 00000 |

| 0.118" | -0.012" to 0.012" | -4° | 140° | 6,900 | Not Rated | Rockwell M95 | FDA Compliant 21 CFR 177.1315, NSF/ANSI 51, UL 94 HB | 000000000 | 00000 |

| 0.177" | -0.018" to 0.018" | -4° | 140° | 6,900 | Not Rated | Rockwell M95 | FDA Compliant 21 CFR 177.1315, NSF/ANSI 51, UL 94 HB | 000000000 | 00000 |

| 0.236" | -0.024" to 0.024" | -4° | 140° | 6,900 | Not Rated | Rockwell M95 | FDA Compliant 21 CFR 177.1315, NSF/ANSI 51, UL 94 HB | 000000000 | 00000 |

24" × 48" | |||||||||

| 0.02" | -0.002" to 0.002" | Not Rated | 140° | 7,700 | 1.7 ft.-lbs./in (Poor) | Rockwell R115 | FDA Compliant 21 CFR 177.1315 | 000000000 | 0000 |

| 0.03" | -0.003" to 0.003" | Not Rated | 140° | 7,700 | 1.7 ft.-lbs./in (Poor) | Rockwell R115 | FDA Compliant 21 CFR 177.1315 | 000000000 | 00000 |

| 0.04" | -0.004" to 0.004" | Not Rated | 140° | 7,700 | 1.7 ft.-lbs./in (Poor) | Rockwell R115 | FDA Compliant 21 CFR 177.1315 | 000000000 | 00000 |

| 0.06" | -0.006" to 0.006" | -40° | 140° | 7,100-7,700 | 1.7 ft.-lbs./in (Poor) | Rockwell R106-R115 | FDA Compliant 21 CFR 174.5, FDA Compliant 21 CFR 177.1315, UL 94 HB | 00000000 | 00000 |

| 0.08" | -0.008" to 0.008" | -40° | 140° | 7,100-7,700 | 1.7 ft.-lbs./in (Poor) | Rockwell R106-R115 | FDA Compliant 21 CFR 174.5, FDA Compliant 21 CFR 177.1315, UL 94 HB | 00000000 | 00000 |

| 0.1" | -0.01" to 0.01" | -40° | 140° | 7,100-7,700 | 1.7 ft.-lbs./in (Poor) | Rockwell R106-R115 | FDA Compliant 21 CFR 174.5, FDA Compliant 21 CFR 177.1315, UL 94 HB | 00000000 | 00000 |

| 0.118" | -0.012" to 0.012" | -40° | 140° | 7,100-7,700 | 1.7 ft.-lbs./in (Poor) | Rockwell R106-R115 | FDA Compliant 21 CFR 174.5, FDA Compliant 21 CFR 177.1315, UL 94 HB | 00000000 | 00000 |

| 0.177" | -0.018" to 0.018" | -40° | 140° | 7,100-7,700 | 1.7 ft.-lbs./in (Poor) | Rockwell R106-R115 | FDA Compliant 21 CFR 174.5, FDA Compliant 21 CFR 177.1315, UL 94 HB | 00000000 | 00000 |

| 0.236" | -0.024" to 0.024" | -40° | 140° | 7,100-7,700 | 1.7 ft.-lbs./in (Poor) | Rockwell R106-R115 | FDA Compliant 21 CFR 174.5, FDA Compliant 21 CFR 177.1315, UL 94 HB | 00000000 | 00000 |

48" × 48" | |||||||||

| 0.02" | -0.002" to 0.002" | Not Rated | 140° | 7,700 | 1.7 ft.-lbs./in (Poor) | Rockwell R115 | FDA Compliant 21 CFR 177.1315 | 000000000 | 00000 |

| 0.03" | -0.003" to 0.003" | Not Rated | 140° | 7,700 | 1.7 ft.-lbs./in (Poor) | Rockwell R115 | FDA Compliant 21 CFR 177.1315 | 000000000 | 00000 |

| 0.04" | -0.004" to 0.004" | Not Rated | 140° | 7,700 | 1.7 ft.-lbs./in (Poor) | Rockwell R115 | FDA Compliant 21 CFR 177.1315 | 000000000 | 00000 |

| 0.06" | -0.006" to 0.006" | -40° | 140° | 7,100-7,700 | 1.7 ft.-lbs./in (Poor) | Rockwell R106-R115 | FDA Compliant 21 CFR 174.5, FDA Compliant 21 CFR 177.1315, UL 94 HB | 00000000 | 00000 |

| 0.08" | -0.008" to 0.008" | -40° | 140° | 7,100-7,700 | 1.7 ft.-lbs./in (Poor) | Rockwell R106-R115 | FDA Compliant 21 CFR 174.5, FDA Compliant 21 CFR 177.1315, UL 94 HB | 00000000 | 00000 |

| 0.1" | -0.01" to 0.01" | -40° | 140° | 7,100-7,700 | 1.7 ft.-lbs./in (Poor) | Rockwell R106-R115 | FDA Compliant 21 CFR 174.5, FDA Compliant 21 CFR 177.1315, UL 94 HB | 00000000 | 00000 |

| 0.118" | -0.012" to 0.012" | -40° | 140° | 7,100-7,700 | 1.7 ft.-lbs./in (Poor) | Rockwell R106-R115 | FDA Compliant 21 CFR 174.5, FDA Compliant 21 CFR 177.1315, UL 94 HB | 00000000 | 00000 |

| 0.177" | -0.018" to 0.018" | -40° | 140° | 7,100-7,700 | 1.7 ft.-lbs./in (Poor) | Rockwell R106-R115 | FDA Compliant 21 CFR 174.5, FDA Compliant 21 CFR 177.1315, UL 94 HB | 00000000 | 000000 |

| 0.236" | -0.024" to 0.024" | -40° | 140° | 7,100-7,700 | 1.7 ft.-lbs./in (Poor) | Rockwell R106-R115 | FDA Compliant 21 CFR 174.5, FDA Compliant 21 CFR 177.1315, UL 94 HB | 00000000 | 000000 |

48" × 96" | |||||||||

| 0.02" | -0.002" to 0.002" | Not Rated | 140° | 7,700 | 1.7 ft.-lbs./in (Poor) | Rockwell R115 | FDA Compliant 21 CFR 177.1315 | 000000000 | 00000 |

| 0.03" | -0.003" to 0.003" | Not Rated | 140° | 7,700 | 1.7 ft.-lbs./in (Poor) | Rockwell R115 | FDA Compliant 21 CFR 177.1315 | 000000000 | 00000 |

| 0.04" | -0.004" to 0.004" | Not Rated | 140° | 7,700 | 1.7 ft.-lbs./in (Poor) | Rockwell R115 | FDA Compliant 21 CFR 177.1315 | 000000000 | 00000 |

| 0.06" | -0.006" to 0.006" | -40° | 140° | 7,100-7,700 | 1.7 ft.-lbs./in (Poor) | Rockwell R106-R115 | FDA Compliant 21 CFR 174.5, FDA Compliant 21 CFR 177.1315, UL 94 HB | 00000000 | 00000 |

| 0.08" | -0.008" to 0.008" | -40° | 140° | 7,100-7,700 | 1.7 ft.-lbs./in (Poor) | Rockwell R106-R115 | FDA Compliant 21 CFR 174.5, FDA Compliant 21 CFR 177.1315, UL 94 HB | 00000000 | 000000 |

| 0.1" | -0.01" to 0.01" | -40° | 140° | 7,100-7,700 | 1.7 ft.-lbs./in (Poor) | Rockwell R106-R115 | FDA Compliant 21 CFR 174.5, FDA Compliant 21 CFR 177.1315, UL 94 HB | 00000000 | 000000 |

| 0.118" | -0.012" to 0.012" | -40° | 140° | 7,100-7,700 | 1.7 ft.-lbs./in (Poor) | Rockwell R106-R115 | FDA Compliant 21 CFR 174.5, FDA Compliant 21 CFR 177.1315, UL 94 HB | 00000000 | 000000 |

| 0.177" | -0.018" to 0.018" | -40° | 140° | 7,100-7,700 | 1.7 ft.-lbs./in (Poor) | Rockwell R106-R115 | FDA Compliant 21 CFR 174.5, FDA Compliant 21 CFR 177.1315, UL 94 HB | 00000000 | 000000 |

| 0.236" | -0.024" to 0.024" | -40° | 140° | 7,100-7,700 | 1.7 ft.-lbs./in (Poor) | Rockwell R106-R115 | FDA Compliant 21 CFR 174.5, FDA Compliant 21 CFR 177.1315, UL 94 HB | 00000000 | 000000 |

Clear Plastic Selector Packs

Pack includes one piece each of acrylic, cast acrylic, cellulose, PETG, and polycarbonate.

| Material | Wd. | Lg. | Number of Pieces | Each | |

| Acrylic Plastic, Cellulose Plastic, PETG Plastic, Polycarbonate Plastic | 2" | 2" | 5 | 000000 | 000000 |

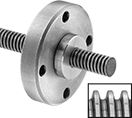

Precision Acme Lead Screws and Nuts

Pair with a motor in automated motion and positioning applications. A tight thread fit allows these lead screws and nuts to make accurate, repeatable starts and stops. Also known as single-start and self-locking lead screws and nuts, they have a single thread that runs the length of the screw. The nut travels only when the screw turns, so your system won’t unexpectedly move when the lead screw is at rest. To ensure compatibility, please select components that have the same thread direction, thread size, and number of thread starts.

Carbon steel lead screws and flanges have good machinability. Black-oxide alloy steel lead screws are hard and strong. They have mild corrosion resistance and a dark surface color. 303 and 304 stainless steel lead screws and flanges have good corrosion resistance.

PET plastic nuts are lightweight and corrosion resistant.

Travel distance per turn, also known as screw lead, is the distance a nut moves with one revolution of the lead screw.

| Thread Size | Thread Type | Lg. | Dia. | No. of Thread Starts | Speed Ratio | Travel Distance per Turn | Thread Fit | Hardness | Dynamic Thrust Load Cap., lbs. | Temperature Range, °F | Each | |

PET Plastic | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 3/8"-8 | Acme | 3/4" | 1.344" | 1 | 1:1 | 0.125" | Class 2C | Not Rated | 350 | 15° to 175° | 00000000 | 000000 |

| 3/8"-10 | Acme | 3/4" | 1.344" | 1 | 1:1 | 0.1" | Class 2C | Not Rated | 350 | 15° to 175° | 00000000 | 00000 |

| 3/8"-12 | Acme | 3/4" | 1.344" | 1 | 1:1 | 0.083" | Class 2C | Not Rated | 350 | 15° to 175° | 00000000 | 00000 |

| 3/8"-16 | Acme | 3/4" | 1.344" | 1 | 1:1 | 0.063" | Class 2C | Not Rated | 350 | 15° to 175° | 0000000 | 00000 |

| 1/2"-10 | Acme | 1" | 1.465" | 1 | 1:1 | 0.1" | Class 2C | Not Rated | 650 | 15° to 175° | 00000000 | 00000 |

| 5/8"-5 | Acme | 1 1/4" | 1.859" | 1 | 1:1 | 0.2" | Class 2C | Not Rated | 1,000 | 15° to 175° | 0000000 | 00000 |

| 5/8"-8 | Acme | 1 1/4" | 1.859" | 1 | 1:1 | 0.125" | Class 2C | Not Rated | 1,000 | 15° to 175° | 00000000 | 00000 |

| 5/8"-10 | Acme | 1 1/4" | 1.859" | 1 | 1:1 | 0.1" | Class 2C | Not Rated | 1,000 | 15° to 175° | 00000000 | 00000 |

| 3/4"-5 | Acme | 1 1/2" | 2.234" | 1 | 1:1 | 0.2" | Class 2C | Not Rated | 1,450 | 15° to 175° | 00000000 | 000000 |

| 3/4"-6 | Acme | 1 1/2" | 2.234" | 1 | 1:1 | 0.167" | Class 2C | Not Rated | 1,450 | 15° to 175° | 00000000 | 000000 |

| 3/4"-10 | Acme | 1 1/2" | 2.234" | 1 | 1:1 | 0.1" | Class 2C | Not Rated | 1,450 | 15° to 175° | 00000000 | 000000 |

| Thread Size | Thread Type | Lg. | Dia. | No. of Thread Starts | Speed Ratio | Travel Distance per Turn | Thread Fit | Hardness | Dynamic Thrust Load Cap., lbs. | Temperature Range, °F | Each | |

PET Plastic | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 3/8"-8 | Acme | 3/4" | 1.344" | 1 | 1:1 | 0.125" | Class 2C | Not Rated | 350 | 15° to 175° | 00000000 | 000000 |

| 3/8"-10 | Acme | 3/4" | 1.344" | 1 | 1:1 | 0.1" | Class 2C | Not Rated | 350 | 15° to 175° | 00000000 | 00000 |

| 3/8"-12 | Acme | 3/4" | 1.344" | 1 | 1:1 | 0.083" | Class 2C | Not Rated | 350 | 15° to 175° | 00000000 | 00000 |

| 1/2"-10 | Acme | 1" | 1.465" | 1 | 1:1 | 0.1" | Class 2C | Not Rated | 650 | 15° to 175° | 00000000 | 00000 |

| 5/8"-8 | Acme | 1 1/4" | 1.859" | 1 | 1:1 | 0.125" | Class 2C | Not Rated | 1,000 | 15° to 175° | 00000000 | 00000 |

| 5/8"-10 | Acme | 1 1/4" | 1.859" | 1 | 1:1 | 0.1" | Class 2C | Not Rated | 1,000 | 15° to 175° | 00000000 | 00000 |

| 3/4"-5 | Acme | 1 1/2" | 2.234" | 1 | 1:1 | 0.2" | Class 2C | Not Rated | 1,450 | 15° to 175° | 00000000 | 000000 |

| 3/4"-6 | Acme | 1 1/2" | 2.234" | 1 | 1:1 | 0.167" | Class 2C | Not Rated | 1,450 | 15° to 175° | 00000000 | 000000 |

| 3/4"-10 | Acme | 1 1/2" | 2.234" | 1 | 1:1 | 0.1" | Class 2C | Not Rated | 1,450 | 15° to 175° | 00000000 | 000000 |

Combine externally threaded nuts with a flange to create a custom flange nut.

External Thread | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Thread Size | Thread Type | Lg. | Dia. | No. of Thread Starts | Speed Ratio | Travel Distance per Turn | Size | Lg. | Thread Fit | Hardness | Dynamic Thrust Load Cap., lbs. | Temperature Range, °F | Each | |

PET Plastic | ||||||||||||||

| 1/4"-16 | Acme | 5/8" | 0.688" | 1 | 1:1 | 0.063" | 9/16"-18 | 3/8" | Class 2C | Not Rated | 160 | 15° to 175° | 000000000 | 000000 |

| 1/4"-20 | Acme | 5/8" | 0.688" | 1 | 1:1 | 0.05" | 9/16"-18 | 3/8" | Class 2C | Not Rated | 160 | 15° to 175° | 000000000 | 00000 |

| 3/8"-8 | Acme | 5/8" | 0.688" | 1 | 1:1 | 0.125" | 9/16"-18 | 3/8" | Class 2C | Not Rated | 350 | 15° to 175° | 000000000 | 00000 |

| 3/8"-10 | Acme | 5/8" | 0.688" | 1 | 1:1 | 0.1" | 9/16"-18 | 3/8" | Class 2C | Not Rated | 350 | 15° to 175° | 000000000 | 00000 |

| 3/8"-12 | Acme | 5/8" | 0.688" | 1 | 1:1 | 0.083" | 9/16"-18 | 3/8" | Class 2C | Not Rated | 350 | 15° to 175° | 000000000 | 00000 |

| 3/8"-16 | Acme | 5/8" | 0.688" | 1 | 1:1 | 0.063" | 9/16"-18 | 3/8" | Class 2C | Not Rated | 350 | 15° to 175° | 000000000 | 00000 |

| 1/2"-10 | Acme | 3/4" | 1.125" | 1 | 1:1 | 0.1" | 15/16"-16 | 1/2" | Class 2C | Not Rated | 650 | 15° to 175° | 000000000 | 00000 |

| 5/8"-8 | Acme | 1" | 1.125" | 1 | 1:1 | 0.125" | 15/16"-16 | 1/2" | Class 2C | Not Rated | 1,000 | 15° to 175° | 000000000 | 00000 |

| 5/8"-10 | Acme | 1" | 1.125" | 1 | 1:1 | 0.1" | 15/16"-16 | 1/2" | Class 2C | Not Rated | 1,000 | 15° to 175° | 000000000 | 00000 |

| 3/4"-5 | Acme | 1 1/4" | 1.125" | 1 | 1:1 | 0.2" | 1"-18 | 1/2" | Class 2C | Not Rated | 1,450 | 15° to 175° | 000000000 | 00000 |

| 3/4"-6 | Acme | 1 1/4" | 1.125" | 1 | 1:1 | 0.167" | 1"-18 | 1/2" | Class 2C | Not Rated | 1,450 | 15° to 175° | 000000000 | 00000 |

| 3/4"-10 | Acme | 1 1/4" | 1.125" | 1 | 1:1 | 0.1" | 1"-18 | 1/2" | Class 2C | Not Rated | 1,450 | 15° to 175° | 000000000 | 00000 |

| 1"-4 | Acme | 1 1/2" | 1.5" | 1 | 1:1 | 0.25" | 1 3/8"-16 | 1/2" | Class 2C | Not Rated | 2,500 | 15° to 175° | 000000000 | 00000 |

| 1"-5 | Acme | 1 1/2" | 1.5" | 1 | 1:1 | 0.2" | 1 3/8"-16 | 1/2" | Class 2C | Not Rated | 2,500 | 15° to 175° | 000000000 | 00000 |

| 1"-6 | Acme | 1 1/2" | 1.5" | 1 | 1:1 | 0.167" | 1 3/8"-16 | 1/2" | Class 2C | Not Rated | 2,500 | 15° to 175° | 000000000 | 00000 |

| 1"-10 | Acme | 1 1/2" | 1.5" | 1 | 1:1 | 0.1" | 1 3/8"-16 | 1/2" | Class 2C | Not Rated | 2,500 | 15° to 175° | 000000000 | 00000 |

| 1 1/4"-5 | Acme | 1 3/4" | 2.125" | 1 | 1:1 | 0.2" | 1 31/32"-18 | 13/16" | Class 2C | Not Rated | 3,900 | 15° to 175° | 000000000 | 000000 |

| 1 1/2"-4 | Acme | 2 19/64" | 2.125" | 1 | 1:1 | 0.25" | 1 31/32"-18 | 13/16" | Class 2C | Not Rated | 6,000 | 15° to 175° | 000000000 | 000000 |

| 2"-4 | Acme | 3 15/32" | 2.75" | 1 | 1:1 | 0.25" | 2 35/64"-18 | 7/8" | Class 2C | Not Rated | 10,000 | 15° to 175° | 000000000 | 000000 |

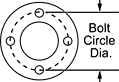

Thread onto an externally threaded acme nut to create a custom flange nut.

Carbon steel flanges have good machinability. However, they will rust when exposed to moisture. Black-oxide carbon steel flanges have mild corrosion resistance in dry environments and a dark surface color. 303 stainless steel flanges have good corrosion resistance.

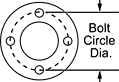

| Flange Thread Size | Flange Dia. | Flange Thick. | Bolt Circle Dia. | Flange Hardness | Each | |

1117 Carbon Steel | ||||||

|---|---|---|---|---|---|---|

| 1 3/8"-16 | 2 49/64" | 33/64" | 2 17/64" | Brinell 156 | 000000000 | 000000 |

| 1 31/32"-18 | 4 13/64" | 53/64" | 3 7/16" | Brinell 156 | 000000000 | 00000 |

| 2 35/64"-18 | 4 15/16" | 29/32" | 4 1/16" | Brinell 156 | 000000000 | 00000 |

Black-Oxide 1117 Carbon Steel | ||||||

| 9/16"-18 | 1 39/64" | 13/32" | 1 1/8" | Brinell 135 | 00000000 | 00000 |

| 15/16"-16 | 2 39/64" | 17/32" | 2 3/32" | Brinell 135 | 00000000 | 00000 |

| 1 3/8"-16 | 2 49/64" | 33/64" | 2 17/64" | Brinell 135 | 00000000 | 00000 |

| 1 31/32"-18 | 4 13/64" | 53/64" | 3 7/16" | Brinell 135 | 00000000 | 00000 |

1215 Carbon Steel | ||||||

| 9/16"-18 | 1 39/64" | 13/32" | 1 1/8" | Not Rated | 000000000 | 00000 |

| 15/16"-16 | 2 5/8" | 17/32" | 2 3/32" | Not Rated | 000000000 | 00000 |

303 Stainless Steel | ||||||

| 9/16"-18 | 1 39/64" | 13/32" | 1 1/8" | Brinell 140 | 0000000 | 00000 |

| 15/16"-16 | 2 5/8" | 17/32" | 2 3/32" | Brinell 140 | 0000000 | 00000 |

| 1 3/8"-16 | 2 49/64" | 33/64" | 2 17/64" | Brinell 140 | 0000000 | 00000 |

| 1 31/32"-18 | 4 13/64" | 53/64" | 3 7/16" | Brinell 140 | 0000000 | 000000 |

| 2 35/64"-18 | 4 15/16" | 29/32" | 4 1/16" | Brinell 140 | 0000000 | 000000 |

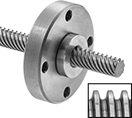

Fast-Travel Precision Acme Lead Screws and Nuts

Multiple thread channels (also known as thread starts) create faster linear travel than lead screws with a single thread start. The threads have a tight thread fit for accurate, repeatable starts and stops. Pair with a motor in automated motion and positioning applications. To ensure compatibility, please select components that have the same thread direction, thread size, and number of thread starts.

Carbon steel lead screws and flanges have good machinability. 303 and 304 stainless steel lead screws and flanges have good corrosion resistance.

PET plastic nuts are lightweight and corrosion resistant.

Travel distance per turn, also known as screw lead, is the distance a nut moves with one revolution of the lead screw.

| Thread Size | Thread Type | Lg. | Dia. | No. of Thread Starts | Speed Ratio | Travel Distance per Turn | Thread Fit | Hardness | Dynamic Thrust Load Cap., lbs. | Temperature Range, °F | Each | |

PET Plastic | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1/4"-12 | Acme | 3/4" | 1.344" | 4 | 4:1 | 0.333" | Class 2C | Not Rated | 160 | 15° to 175° | 00000000 | 000000 |

| 3/8"-8 | Acme | 3/4" | 1.344" | 2 | 2:1 | 0.25" | Class 2C | Not Rated | 350 | 15° to 175° | 00000000 | 00000 |

| 3/8"-8 | Acme | 3/4" | 1.344" | 4 | 4:1 | 0.5" | Class 2C | Not Rated | 350 | 15° to 175° | 00000000 | 00000 |

| 3/8"-10 | Acme | 3/4" | 1.344" | 2 | 2:1 | 0.2" | Class 2C | Not Rated | 350 | 15° to 175° | 00000000 | 00000 |

| 1/2"-8 | Acme | 1" | 1.469" | 2 | 2:1 | 0.25" | Class 2C | Not Rated | 650 | 15° to 175° | 0000000 | 00000 |

| 1/2"-10 | Acme | 1" | 1.469" | 2 | 2:1 | 0.2" | Class 2C | Not Rated | 650 | 15° to 175° | 0000000 | 00000 |

| 1/2"-10 | Acme | 1" | 1.469" | 5 | 5:1 | 0.5" | Class 2C | Not Rated | 650 | 15° to 175° | 00000000 | 00000 |

Combine externally threaded nuts with a flange to create a custom flange nut.

External Thread | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Thread Size | Thread Type | Lg. | Dia. | No. of Thread Starts | Speed Ratio | Travel Distance per Turn | Size | Lg. | Thread Fit | Hardness | Dynamic Thrust Load Cap., lbs. | Temperature Range, °F | Each | |

PET Plastic | ||||||||||||||

| 1/4"-12 | Acme | 5/8" | 0.688" | 4 | 4:1 | 0.333" | 9/16"-18 | 3/8" | Class 2C | Not Rated | 160 | 15° to 175° | 000000000 | 000000 |

| 3/8"-5 | Acme | 5/8" | 0.688" | 5 | 5:1 | 1" | 9/16"-18 | 3/8" | Class 2C | Not Rated | 250 | 15° to 175° | 000000000 | 00000 |

| 3/8"-8 | Acme | 5/8" | 0.688" | 2 | 2:1 | 0.25" | 9/16"-18 | 3/8" | Class 2C | Not Rated | 350 | 15° to 175° | 000000000 | 00000 |

| 3/8"-8 | Acme | 5/8" | 0.688" | 4 | 4:1 | 0.5" | 9/16"-18 | 3/8" | Class 2C | Not Rated | 350 | 15° to 175° | 000000000 | 00000 |

| 3/8"-10 | Acme | 5/8" | 0.688" | 2 | 2:1 | 0.2" | 9/16"-18 | 3/8" | Class 2C | Not Rated | 350 | 15° to 175° | 000000000 | 00000 |

| 1/2"-8 | Acme | 3/4" | 1.125" | 2 | 2:1 | 0.25" | 15/16"-16 | 1/2" | Class 2C | Not Rated | 650 | 15° to 175° | 000000000 | 00000 |

| 1/2"-10 | Acme | 3/4" | 1.125" | 2 | 2:1 | 0.2" | 15/16"-16 | 1/2" | Class 2C | Not Rated | 650 | 15° to 175° | 000000000 | 00000 |

| 1/2"-10 | Acme | 3/4" | 1.125" | 5 | 5:1 | 0.5" | 15/16"-16 | 1/2" | Class 2C | Not Rated | 650 | 15° to 175° | 000000000 | 00000 |

| 3/4"-8 | Acme | 1 1/4" | 1.125" | 4 | 4:1 | 0.5" | 1"-18 | 1/2" | Class 2C | Not Rated | 1,450 | 15° to 175° | 000000000 | 00000 |

| 1"-4 | Acme | 1 1/2" | 1.5" | 2 | 2:1 | 0.5" | 1 3/8"-16 | 1/2" | Class 2C | Not Rated | 2,500 | 15° to 175° | 000000000 | 00000 |

Thread onto an externally threaded acme nut to create a custom flange nut.

Carbon steel flanges have good machinability. However, they will rust when exposed to moisture. Black-oxide carbon steel flanges have mild corrosion resistance in dry environments and a dark surface color. 303 stainless steel flanges have good corrosion resistance.

| Flange Thread Size | Flange Dia. | Flange Thick. | Bolt Circle Dia. | Flange Hardness | Each | |

1117 Carbon Steel | ||||||

|---|---|---|---|---|---|---|

| 1 3/8"-16 | 2 49/64" | 33/64" | 2 17/64" | Brinell 156 | 000000000 | 000000 |

1215 Carbon Steel | ||||||

| 1"-18 | 2 5/8" | 17/32" | 2 3/32" | Not Rated | 000000000 | 00000 |

| 15/16"-16 | 2 5/8" | 17/32" | 2 3/32" | Not Rated | 000000000 | 00000 |

| 9/16"-18 | 1 39/64" | 13/32" | 1 1/8" | Not Rated | 000000000 | 00000 |

303 Stainless Steel | ||||||

| 1 3/8"-16 | 2 49/64" | 33/64" | 2 17/64" | Brinell 140 | 0000000 | 00000 |

| 1"-18 | 2 5/8" | 17/32" | 2 3/32" | Brinell 140 | 0000000 | 00000 |

| 15/16"-16 | 2 5/8" | 17/32" | 2 3/32" | Brinell 140 | 0000000 | 00000 |

| 9/16"-18 | 1 39/64" | 13/32" | 1 1/8" | Brinell 140 | 0000000 | 00000 |