Filter by

System of Measurement

Usable Length

Length

Cotter Pin Type

Finish

Material

Retainer Shape

Chain Material

Head Diameter

Shaft Type

Export Control Classification Number (ECCN)

DFARS Specialty Metals

End Shape

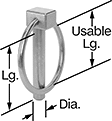

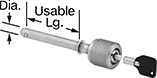

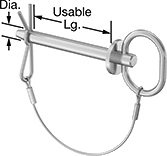

Linch Pins

Dia. | Usable Lg. | Lg. | Min. Hardness | Chain Material | Cotter Pin Material | Pkg. Qty. | Pkg. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Linch Pins | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Zinc-Yellow-Chromate-Plated Carbon Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/16" | 1" | 1 1/4" | Rockwell B81 | — | — | 5 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/16" | 1 1/4" | 1 9/16" | Rockwell B81 | — | — | 10 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 1 1/4" | 1 9/16" | Rockwell B81 | — | — | 10 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16" | 1 1/4" | 1 9/16" | Rockwell B81 | — | — | 10 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16" | 1 1/2" | 1 3/4" | Not Rated | — | — | 1 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/16" | 1 5/16" | 1 9/16" | Rockwell B81 | — | — | 10 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/16" | 1 5/16" | 1 31/32" | Rockwell B81 | — | — | 5 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/16" | 1 1/2" | 1 3/4" | Rockwell B81 | — | — | 5 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/16" | 1 1/2" | 1 31/32" | Rockwell B81 | — | — | 5 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

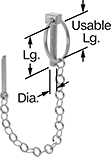

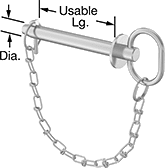

Linch Pins with Chain and Cotter Pin | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Zinc-Yellow-Chromate-Plated Carbon Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/16" | 1 1/4" | 1 9/16" | Rockwell B81 | Zinc Yellow-Chromate-Plated Steel | Zinc Yellow-Chromate-Plated Steel | 5 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 1 1/4" | 1 9/16" | Rockwell B81 | Zinc Yellow-Chromate-Plated Steel | Zinc Yellow-Chromate-Plated Steel | 5 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16" | 1 1/4" | 1 9/16" | Rockwell B81 | Zinc Yellow-Chromate-Plated Steel | Zinc Yellow-Chromate-Plated Steel | 5 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16" | 1 1/2" | 1 3/4" | Not Rated | Zinc Yellow-Chromate-Plated Steel | Steel | 1 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/16" | 1 5/16" | 1 9/16" | Rockwell B81 | Zinc Yellow-Chromate-Plated Steel | Zinc Yellow-Chromate-Plated Steel | 5 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/16" | 1 5/16" | 1 31/32" | Rockwell B81 | Zinc Yellow-Chromate-Plated Steel | Zinc Yellow-Chromate-Plated Steel | 5 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/16" | 1 1/2" | 1 7/8" | Not Rated | Zinc Yellow-Chromate-Plated Steel | Steel | 1 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

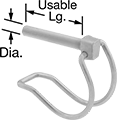

Tethered Loop-Grip Clevis Pins

Steel

|  |

With Cotter Pin and Lanyard | With Linch Pin and Chain |

Usable Lg. | Dia. Tolerance | For Max. Cotter Pin Dia. | Min. Hardness | Head Dia. | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Zinc-Yellow-Chromate-Plated Carbon Steel with Cotter Pin and Lanyard | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

3/8" Diameter | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4" | -0.010" to 0.000" | 3/32" | Rockwell C25 | 11/16" | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1/2" Diameter | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4" | -0.010" to 0.000" | 1/8" | Rockwell C25 | 15/16" | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 3/4" | -0.010" to 0.000" | 1/8" | Rockwell C25 | 15/16" | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

5/8" Diameter | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4" | -0.010" to 0.000" | 9/64" | Rockwell C25 | 1 1/16" | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6" | -0.010" to 0.000" | 9/64" | Rockwell C25 | 1 1/16" | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

3/4" Diameter | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 1/4" | -0.010" to 0.000" | 9/64" | Rockwell C25 | 1 1/4" | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 1/4" | -0.010" to 0.000" | 9/64" | Rockwell C25 | 1 1/4" | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

7/8" Diameter | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7" | -0.012" to 0.000" | 11/64" | Rockwell C28 | 1 7/16" | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1" Diameter | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7" | -0.010" to 0.000" | 11/64" | Rockwell C25 | 1 5/8" | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1 1/8" Diameter | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7" | -0.016" to 0.016" | 3/16" | Rockwell C19 | 2" | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1 1/4" Diameter | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7" | -0.016" to 0.016" | 3/16" | Rockwell C19 | 2" | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Zinc-Yellow-Chromate-Plated Carbon Steel with Linch Pin and Chain | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

3/8" Diameter | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4" | -0.012" to 0.000" | 13/64" | Rockwell C28 | 13/16" | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1/2" Diameter | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4" | -0.012" to 0.000" | 13/64" | Rockwell C28 | 1" | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 3/4" | -0.012" to 0.000" | 13/64" | Rockwell C28 | 1" | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

5/8" Diameter | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4" | -0.012" to 0.000" | 17/64" | Rockwell C28 | 1 1/4" | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 3/4" | -0.012" to 0.000" | 13/64" | Rockwell C28 | 1 1/4" | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

3/4" Diameter | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4" | -0.012" to 0.000" | 17/64" | Rockwell C28 | 1 3/8" | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 1/4" | -0.012" to 0.000" | 13/64" | Rockwell C28 | 1 3/8" | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

7/8" Diameter | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7" | -0.012" to 0.000" | 25/64" | Rockwell C28 | 1 1/2" | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1" Diameter | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7" | -0.012" to 0.000" | 9/32" | Rockwell C28 | 1 5/8" | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1 1/8" Diameter | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7" | -0.012" to 0.000" | 9/32" | Rockwell C28 | 1 3/4" | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1 1/4" Diameter | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7" | -0.012" to 0.000" | 9/32" | Rockwell C28 | 1 7/8" | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

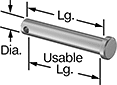

Clevis Pins

Steel

Head | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Usable Lg. | Dia. Tolerance | For Max. Cotter Pin Dia. | Min. Hardness | Lg. | Dia. | Ht. | Pkg. Qty. | Pkg. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Zinc-Yellow-Chromate-Plated Carbon Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1/8" Diameter | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8" | -0.005" to 0.000" | 3/32" | Rockwell B63 | 3/4" | 1/4" | 1/16" | 1 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 13/16" | -0.005" to 0.000" | 3/32" | Rockwell B63 | 1" | 1/4" | 1/16" | 1 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/16" | -0.005" to 0.000" | 3/32" | Rockwell B63 | 1 1/4" | 1/4" | 1/16" | 1 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

3/16" Diameter | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9/16" | -0.007" to -0.002" | 1/16" | Rockwell B63 | 3/4" | 5/16" | 1/16" | 25 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 13/16" | -0.007" to -0.002" | 1/16" | Rockwell B63 | 1" | 5/16" | 1/16" | 25 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/16" | -0.007" to -0.002" | 1/16" | Rockwell B63 | 1 1/4" | 5/16" | 1/16" | 25 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 5/16" | -0.007" to -0.002" | 1/16" | Rockwell B63 | 1 1/2" | 5/16" | 1/16" | 25 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1/4" Diameter | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9/16" | -0.007" to -0.002" | 1/16" | Rockwell B63 | 3/4" | 3/8" | 3/32" | 25 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 13/16" | -0.007" to -0.002" | 1/16" | Rockwell B63 | 1" | 3/8" | 3/32" | 25 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/16" | -0.007" to -0.002" | 1/16" | Rockwell B63 | 1 1/4" | 3/8" | 3/32" | 25 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 5/16" | -0.007" to -0.002" | 1/16" | Rockwell B63 | 1 1/2" | 3/8" | 3/32" | 25 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 9/16" | -0.007" to -0.002" | 3/32" | Rockwell B63 | 1 3/4" | 3/8" | 3/32" | 25 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 5/16" | -0.007" to -0.002" | 3/32" | Rockwell B63 | 3 1/2" | 3/8" | 3/32" | 10 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

3/8" Diameter | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | -0.007" to -0.002" | 1/8" | Rockwell B63 | 1" | 1/2" | 1/8" | 10 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/8" | -0.007" to -0.002" | 5/32" | Rockwell B63 | 1 1/8" | 1/2" | 1/8" | 10 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | -0.007" to -0.002" | 1/8" | Rockwell B63 | 1 1/4" | 1/2" | 1/8" | 10 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/8" | -0.007" to -0.002" | 5/32" | Rockwell B63 | 1 3/8" | 1/2" | 1/8" | 10 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4" | -0.007" to -0.002" | 1/8" | Rockwell B63 | 1 1/2" | 1/2" | 1/8" | 10 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | -0.007" to -0.002" | 5/32" | Rockwell B63 | 1 3/4" | 1/2" | 1/8" | 10 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 3/4" | -0.007" to -0.002" | 1/8" | Rockwell B63 | 2" | 1/2" | 1/8" | 10 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | -0.007" to -0.002" | 5/32" | Rockwell B63 | 2 1/4" | 1/2" | 1/8" | 10 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 1/4" | -0.007" to -0.002" | 5/32" | Rockwell B63 | 2 1/2" | 1/2" | 1/8" | 10 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 1/2" | -0.007" to -0.002" | 5/32" | Rockwell B63 | 2 3/4" | 1/2" | 1/8" | 10 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3" | -0.007" to -0.002" | 5/32" | Rockwell B63 | 3 1/4" | 1/2" | 1/8" | 10 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 3/4" | -0.007" to -0.002" | 5/32" | Rockwell B63 | 4" | 1/2" | 1/8" | 10 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1/2" Diameter | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | -0.009" to -0.004" | 5/32" | Rockwell B63 | 1 1/4" | 5/8" | 5/32" | 10 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4" | -0.009" to -0.004" | 1/8" | Rockwell B63 | 1 1/2" | 5/8" | 5/32" | 10 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | -0.009" to -0.004" | 5/32" | Rockwell B63 | 1 3/4" | 5/8" | 5/32" | 10 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 3/4" | -0.009" to -0.004" | 1/8" | Rockwell B63 | 2" | 5/8" | 5/32" | 10 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | -0.009" to -0.004" | 5/32" | Rockwell B63 | 2 1/4" | 5/8" | 5/32" | 5 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 1/4" | -0.009" to -0.004" | 5/32" | Rockwell B63 | 2 1/2" | 5/8" | 5/32" | 5 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 1/2" | -0.009" to -0.004" | 5/32" | Rockwell B63 | 2 3/4" | 5/8" | 5/32" | 5 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 3/4" | -0.009" to -0.004" | 1/8" | Rockwell B63 | 3" | 5/8" | 5/32" | 10 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 1/4" | -0.009" to -0.004" | 5/32" | Rockwell B63 | 3 1/2" | 5/8" | 5/32" | 5 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 3/4" | -0.009" to -0.004" | 5/32" | Rockwell B63 | 4" | 5/8" | 5/32" | 5 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 1/4" | -0.009" to -0.004" | 5/32" | Rockwell B63 | 4 1/2" | 5/8" | 5/32" | 1 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 3/4" | -0.009" to -0.004" | 5/32" | Rockwell B63 | 5" | 5/8" | 5/32" | 5 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

5/8" Diameter | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | -0.009" to -0.004" | 5/32" | Rockwell B63 | 1 3/4" | 13/16" | 7/32" | 5 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 3/4" | -0.009" to -0.004" | 5/32" | Rockwell B63 | 2" | 13/16" | 7/32" | 5 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | -0.009" to -0.004" | 5/32" | Rockwell B63 | 2 1/4" | 13/16" | 7/32" | 5 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 1/4" | -0.009" to -0.004" | 5/32" | Rockwell B63 | 2 1/2" | 13/16" | 7/32" | 5 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 3/4" | -0.009" to -0.004" | 5/32" | Rockwell B63 | 3" | 13/16" | 7/32" | 5 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 1/4" | -0.009" to -0.004" | 5/32" | Rockwell B63 | 3 1/2" | 13/16" | 7/32" | 1 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 3/4" | -0.009" to -0.004" | 5/32" | Rockwell B63 | 4" | 13/16" | 7/32" | 1 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 1/4" | -0.009" to -0.004" | 5/32" | Rockwell B63 | 5 1/2" | 13/16" | 7/32" | 1 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

3/4" Diameter | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 3/4" | -0.009" to -0.004" | 5/32" | Rockwell B63 | 2" | 15/16" | 17/64" | 1 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 1/4" | -0.009" to -0.004" | 5/32" | Rockwell B63 | 2 1/2" | 15/16" | 17/64" | 1 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 1/2" | -0.009" to -0.004" | 5/32" | Rockwell B63 | 2 3/4" | 15/16" | 17/64" | 1 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 3/4" | -0.009" to -0.004" | 5/32" | Rockwell B63 | 3" | 15/16" | 17/64" | 1 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 1/4" | -0.009" to -0.004" | 5/32" | Rockwell B63 | 3 1/2" | 15/16" | 17/64" | 1 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 1/2" | -0.009" to -0.004" | 5/32" | Rockwell B63 | 3 3/4" | 15/16" | 17/64" | 1 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 3/4" | -0.009" to -0.004" | 5/32" | Rockwell B63 | 4" | 15/16" | 17/64" | 1 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 1/4" | -0.009" to -0.004" | 5/32" | Rockwell B63 | 4 1/2" | 15/16" | 17/64" | 1 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 3/4" | -0.009" to -0.004" | 5/32" | Rockwell B63 | 5" | 15/16" | 17/64" | 1 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 1/4" | -0.009" to -0.004" | 5/32" | Rockwell B63 | 6 1/2" | 15/16" | 17/64" | 1 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1" Diameter | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 15/16" | -0.009" to -0.004" | 13/64" | Rockwell B63 | 2 1/4" | 1 3/16" | 11/32" | 1 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 3/16" | -0.009" to -0.004" | 13/64" | Rockwell B63 | 2 1/2" | 1 3/16" | 11/32" | 1 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 7/16" | -0.009" to -0.004" | 13/64" | Rockwell B63 | 2 3/4" | 1 3/16" | 11/32" | 1 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 11/16" | -0.009" to -0.004" | 13/64" | Rockwell B63 | 3" | 1 3/16" | 11/32" | 1 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 15/16" | -0.009" to -0.004" | 13/64" | Rockwell B63 | 3 1/4" | 1 3/16" | 11/32" | 1 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 3/16" | -0.009" to -0.004" | 13/64" | Rockwell B63 | 3 1/2" | 1 3/16" | 11/32" | 1 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 11/16" | -0.009" to -0.004" | 13/64" | Rockwell B63 | 4" | 1 3/16" | 11/32" | 1 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 3/16" | -0.009" to -0.004" | 13/64" | Rockwell B63 | 4 1/2" | 1 3/16" | 11/32" | 1 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 11/16" | -0.009" to -0.004" | 13/64" | Rockwell B63 | 6" | 1 3/16" | 11/32" | 1 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Wire-Retainer-End Clips for Telescoping Tubing

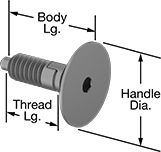

Double-Locking Quick-Release Pins with Key

Steel

Usable Lg. | Dia. at Extended Ball Ht. | Double Shear Breaking Strength, lbf | Min. Hardness | Handle Material | Ball Material | No. of Keys Included | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

High-Strength Zinc-Yellow-Chromate-Plated Alloy Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1/4" Diameter | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 0.284" | 8,200 | Rockwell C33 | Zinc | Stainless Steel | 2 | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 0.284" | 8,200 | Rockwell C33 | Zinc | Stainless Steel | 2 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

5/16" Diameter | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 0.37" | 12,800 | Rockwell C33 | Zinc | Stainless Steel | 2 | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 0.37" | 12,800 | Rockwell C33 | Zinc | Stainless Steel | 2 | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

3/8" Diameter | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 0.435" | 18,400 | Rockwell C33 | Zinc | Stainless Steel | 2 | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 3/4" | 0.435" | 18,400 | Rockwell C33 | Zinc | Stainless Steel | 2 | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 0.435" | 18,400 | Rockwell C33 | Zinc | Stainless Steel | 2 | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 1/2" | 0.435" | 18,400 | Rockwell C33 | Zinc | Stainless Steel | 2 | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1/2" Diameter | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 0.589" | 32,500 | Rockwell C33 | Zinc | Stainless Steel | 2 | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 1/2" | 0.589" | 32,500 | Rockwell C33 | Zinc | Stainless Steel | 2 | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3" | 0.589" | 32,500 | Rockwell C33 | Zinc | Stainless Steel | 2 | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 1/2" | 0.589" | 32,500 | Rockwell C33 | Zinc | Stainless Steel | 2 | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

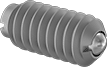

Low-Profile Knob-Grip Retractable Spring Plungers

Nose | Nose Force, lbf | Body | Handle | Twist-to-Lock | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Thread Size | Thread Lg. | Extended Lg. | Dia. | Extended | Compressed | Material | Lg. | Material | Dia. | Drive Style | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel Nose | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-20 | 0.6" | 0.125" | 0.123" | 1 | 4 | Steel | 0.81" | Zinc-Yellow-Chromate-Plated Steel | 3/4" | Hex | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16"-18 | 0.8" | 0.187" | 0.154" | 1 | 6 | Steel | 1.07" | Zinc-Yellow-Chromate-Plated Steel | 7/8" | Hex | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 1" | 0.22" | 0.185" | 1 | 8 | Steel | 1.26" | Zinc-Yellow-Chromate-Plated Steel | 1" | Hex | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-13 | 1.09" | 0.25" | 0.248" | 1 | 10 | Steel | 1.38" | Zinc-Yellow-Chromate-Plated Steel | 1 1/4" | Hex | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Ball-Nose Spring Plungers

Spring Plungers | Spring Plunger Drivers | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Nose | Nose Force, lbf | Body | Drive Style | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Thread Size | Extended Lg. | Dia. | Extended | Compressed | Material | Lg. | Front | Back | Each | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

440C Stainless Steel Nose | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10-32 | 0.025" | 0.094" | 2 | 5 | Zinc Yellow-Chromate Plated Steel | 0.51" | Spring Plunger Driver | Slotted | 0000000 | 00000 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-20 | 0.035" | 0.125" | 4 | 12 | Zinc Yellow-Chromate Plated Steel | 0.53" | Spring Plunger Driver | Slotted | 0000000 | 0000 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16"-18 | 0.04" | 0.156" | 6 | 17 | Zinc Yellow-Chromate Plated Steel | 0.58" | Spring Plunger Driver | Slotted | 0000000 | 0000 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 0.048" | 0.188" | 6 | 21 | Zinc Yellow-Chromate Plated Steel | 0.63" | Spring Plunger Driver | Slotted | 0000000 | 0000 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-13 | 0.072" | 0.281" | 6 | 30 | Zinc Yellow-Chromate Plated Steel | 0.75" | Spring Plunger Driver | Slotted | 0000000 | 0000 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8"-11 | 0.096" | 0.375" | 7 | 50 | Zinc Yellow-Chromate Plated Steel | 0.98" | Spring Plunger Driver | Slotted | 0000000 | 0000 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

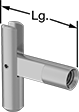

Toggle Anchors for Hollow Block and Brick

Thread | Ultimate Strength | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

Size | Dp. | Lg. | Usable Lg. | Wing Span | Drill Bit Size | Material | Pull-Out, lbf | Shear | Conditions Tested In | Each | ||

| 3/8"-16 | 1/2" | 2" | 1 1/2" | 2" | 1/2" | Zinc-Yellow-Chromate-Plated Steel | 3,200 | Not Rated | 1,500 psi Concrete | 000000000 | 000000 | |

| 1/2"-13 | 11/16" | 2 1/4" | 1 5/8" | 2" | 5/8" | Zinc-Yellow-Chromate-Plated Steel | 5,600 | Not Rated | 1,500 psi Concrete | 000000000 | 00000 | |