Filter by

Overall Height

Head Height

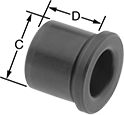

Shoulder Diameter

Height

Hardness

Export Control Classification Number (ECCN)

DFARS Specialty Metals

Mating Locating Pins and Hole Liners

Pins

|  |  |  |

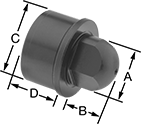

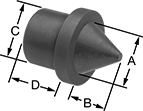

Tapered Head | Round Head | Diamond Head | Cone Head |

Head | Shank | Shoulder | Tolerance | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Dia. (A) | Ht. (B) | Dia. (C) | Ht. (D) | Dia. | Ht. | Overall Ht. | Head Dia. | Shank Dia. | Shank Ht. | Material | Hardness | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Tapered Head | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 0.375" | 1/4" | 1/2" | 0.280" | 0.032" | 0.907" | -0.0005" to 0" | -0.0003" to 0" | — | Steel | Rockwell C50 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16" | 0.407" | 5/16" | 1/2" | 0.344" | 0.032" | 0.939" | -0.0005" to 0" | -0.0003" to 0" | — | Steel | Rockwell C50 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 0.500" | 3/8" | 1/2" | 0.407" | 0.032" | 1.032" | -0.0005" to 0" | -0.0003" to 0" | — | Steel | Rockwell C50 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 0.562" | 1/2" | 1/2" | 0.532" | 0.032" | 1.094" | -0.0005" to 0" | -0.0003" to 0" | — | Steel | Rockwell C50 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 mm | 9.200 mm | 6 mm | — | 7.000 mm | 0.792 mm | 22.000 mm | -0.0127 mm to 0 mm | -0.00762 mm to 0 mm | — | Steel | Rockwell C58 to Rockwell C62 | 0000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8 mm | 10.200 mm | 8 mm | — | 9.000 mm | 0.792 mm | 23.000 mm | -0.0127 mm to 0 mm | -0.00762 mm to 0 mm | — | Steel | Rockwell C58 to Rockwell C62 | 0000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10 mm | 12.200 mm | 10 mm | — | 11.000 mm | 0.792 mm | 25.000 mm | -0.0127 mm to 0 mm | -0.00762 mm to 0 mm | — | Steel | Rockwell C58 to Rockwell C62 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12 mm | 14.200 mm | 12 mm | — | 15.000 mm | 0.792 mm | 27.000 mm | -0.0127 mm to 0 mm | -0.00762 mm to 0 mm | — | Steel | Rockwell C58 to Rockwell C62 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Round Head | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 0.219" | 13/32" | 3/8" | 0.563" | 0.063" | 0.656" | -0.0003" to 0" | -0.0003" to 0" | — | Steel | Rockwell C50 | 00000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16" | 0.281" | 1/2" | 3/8" | 0.625" | 0.063" | 0.719" | -0.0003" to 0" | -0.0003" to 0" | — | Steel | Rockwell C50 | 00000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 0.313" | 5/8" | 1/2" | 0.750" | 0.063" | 0.875" | -0.0003" to 0" | -0.0003" to 0" | — | Steel | Rockwell C50 | 00000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 0.406" | 3/4" | 1/2" | 0.875" | 0.063" | 0.969" | -0.0003" to 0" | -0.0003" to 0" | — | Steel | Rockwell C50 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8" | 0.438" | 7/8" | 1/2" | 1.000" | 0.125" | 1.063" | -0.0003" to 0" | -0.0003" to 0" | — | Steel | Rockwell C50 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | 0.563" | 1" | 3/4" | 1.125" | 0.125" | 1.438" | -0.0003" to 0" | -0.0003" to 0" | — | Steel | Rockwell C50 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 0.750" | 1 3/8" | 3/4" | 1.500" | 0.125" | 1.625" | -0.0003" to 0" | -0.0003" to 0" | — | Steel | Rockwell C50 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 mm | 6.000 mm | 10 mm | — | 13.000 mm | 2.000 mm | 17.000 mm | -0.00762 mm to 0 mm | -0.00762 mm to 0 mm | — | Steel | Rockwell C58 to Rockwell C62 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8 mm | 7.000 mm | 12 mm | — | 15.000 mm | 2.000 mm | 18.000 mm | -0.00762 mm to 0 mm | -0.00762 mm to 0 mm | — | Steel | Rockwell C58 to Rockwell C62 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10 mm | 9.000 mm | 15 mm | — | 18.000 mm | 2.000 mm | 22.000 mm | -0.00762 mm to 0 mm | -0.00762 mm to 0 mm | — | Steel | Rockwell C58 to Rockwell C62 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12 mm | 10.000 mm | 18 mm | — | 22.000 mm | 2.000 mm | 23.000 mm | -0.00762 mm to 0 mm | -0.00762 mm to 0 mm | — | Steel | Rockwell C58 to Rockwell C62 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Diamond Head | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 0.219" | 13/32" | 3/8" | 0.563" | 0.063" | 0.656" | -0.0003" to 0" | -0.0003" to 0" | — | Steel | Rockwell C50 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16" | 0.281" | 1/2" | 3/8" | 0.625" | 0.063" | 0.719" | -0.0003" to 0" | -0.0003" to 0" | — | Steel | Rockwell C50 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 0.313" | 5/8" | 1/2" | 0.750" | 0.063" | 0.875" | -0.0003" to 0" | -0.0003" to 0" | — | Steel | Rockwell C50 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 0.406" | 3/4" | 1/2" | 0.875" | 0.063" | 0.969" | -0.0003" to 0" | -0.0003" to 0" | — | Steel | Rockwell C50 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8" | 0.438" | 7/8" | 1/2" | 1.000" | 0.125" | 1.063" | -0.0003" to 0" | -0.0003" to 0" | — | Steel | Rockwell C50 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | 0.563" | 1" | 3/4" | 1.125" | 0.125" | 1.438" | -0.0003" to 0" | -0.0003" to 0" | — | Steel | Rockwell C50 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 0.750" | 1 3/8" | 3/4" | 1.500" | 0.125" | 1.625" | -0.0003" to 0" | -0.0003" to 0" | — | Steel | Rockwell C50 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 mm | 6.000 mm | 10 mm | — | 13.000 mm | 2.000 mm | 17.000 mm | -0.00762 mm to 0 mm | -0.00762 mm to 0 mm | — | Steel | Rockwell C58 to Rockwell C62 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8 mm | 7.000 mm | 12 mm | — | 15.000 mm | 2.000 mm | 18.000 mm | -0.00762 mm to 0 mm | -0.00762 mm to 0 mm | — | Steel | Rockwell C58 to Rockwell C62 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10 mm | 9.000 mm | 15 mm | — | 18.000 mm | 2.000 mm | 22.000 mm | -0.00762 mm to 0 mm | -0.00762 mm to 0 mm | — | Steel | Rockwell C58 to Rockwell C62 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12 mm | 10.000 mm | 18 mm | — | 22.000 mm | 2.000 mm | 23.000 mm | -0.00762 mm to 0 mm | -0.00762 mm to 0 mm | — | Steel | Rockwell C58 to Rockwell C62 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Cone Head | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/16" | 0.313" | 1/2" | 3/8" | 0.750" | 0.188" | 0.875" | -0.0045" to 0.0055" | -0.0003" to 0" | -0.0625" to 0.0625" | Steel | Rockwell C60 to Rockwell C64 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 11/16" | 0.500" | 3/4" | 9/16" | 1.000" | 0.188" | 1.250" | -0.0165" to -0.0065" | -0.0003" to 0" | -0.0625" to 0.0625" | Steel | Rockwell C60 to Rockwell C64 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

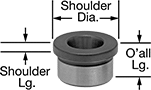

Hole Liners

Shank | Shoulder | Tolerance | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Pin Head Dia. | ID | Dia. (C) | Ht. (D) | Dia. | Ht. | Overall Ht. | Shank Dia. | Shank Ht. | ID | Material | Hardness | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Tapered-Head Pins | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 1/4" | 1/2" | 3/8" | 0.625" | 0.094" | 0.469" | -0.0003" to 0" | 0.0014" to 0.0017" | 0" to 0.0004" | Steel | Rockwell C60 to Rockwell C64 | 000000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16" | 5/16" | 1/2" | 3/8" | 0.625" | 0.094" | 0.469" | -0.0003" to 0" | 0.0014" to 0.0017" | 0" to 0.0004" | Steel | Rockwell C60 to Rockwell C64 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 3/8" | 5/8" | 1/2" | 0.750" | 0.094" | 0.594" | -0.0003" to 0" | 0.0014" to 0.0017" | 0" to 0.0004" | Steel | Rockwell C60 to Rockwell C64 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 1/2" | 3/4" | 5/8" | 0.875" | 0.094" | 0.719" | -0.0003" to 0" | 0.0015" to 0.0018" | 0" to 0.0004" | Steel | Rockwell C60 to Rockwell C64 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 mm | 6 mm | 10 mm | 7 mm | 13.000 mm | 3.000 mm | 10.000 mm | 0.023 mm to 0.032 mm | -0.254 mm to 0.254 mm | 0 mm to 0.0102 mm | Steel | Rockwell C58 to Rockwell C62 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8 mm | 8 mm | 12 mm | 7 mm | 15.000 mm | 3.000 mm | 10.000 mm | 0.028 mm to 0.039 mm | -0.254 mm to 0.254 mm | 0 mm to 0.0102 mm | Steel | Rockwell C58 to Rockwell C62 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10 mm | 10 mm | 15 mm | 9 mm | 18.000 mm | 3.000 mm | 12.000 mm | 0.028 mm to 0.039 mm | -0.254 mm to 0.254 mm | 0 mm to 0.0102 mm | Steel | Rockwell C58 to Rockwell C62 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12 mm | 12 mm | 18 mm | 12 mm | 22.000 mm | 3.000 mm | 15.000 mm | 0.028 mm to 0.039 mm | -0.254 mm to 0.254 mm | 0 mm to 0.0102 mm | Steel | Rockwell C58 to Rockwell C62 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Diamond- and Round-Head Pins | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 1/4" | 13/32" | 7/16" | 0.563" | 0.063" | 0.500" | -0.0003" to 0" | — | 0.0001" to 0.0005" | Steel | Rockwell C50 to Rockwell C62 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16" | 5/16" | 1/2" | 7/16" | 0.625" | 0.063" | 0.500" | -0.0003" to 0" | — | 0.0001" to 0.0005" | Steel | Rockwell C50 to Rockwell C62 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 3/8" | 5/8" | 7/16" | 0.750" | 0.063" | 0.500" | -0.0003" to 0" | — | 0.0001" to 0.0005" | Steel | Rockwell C50 to Rockwell C62 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 1/2" | 3/4" | 1/2" | 0.875" | 0.063" | 0.562" | -0.0003" to 0" | — | 0.0001" to 0.0005" | Steel | Rockwell C50 to Rockwell C62 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8" | 5/8" | 7/8" | 1/2" | 1.000" | 0.125" | 0.625" | -0.0003" to 0" | — | 0.0002" to 0.0006" | Steel | Rockwell C50 to Rockwell C62 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | 3/4" | 1" | 1/2" | 1.125" | 0.125" | 0.625" | -0.0003" to 0" | — | 0.0002" to 0.0006" | Steel | Rockwell C50 to Rockwell C62 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 1" | 1 3/8" | 11/16" | 1.500" | 0.125" | 0.812" | -0.0003" to 0" | — | 0.0002" to 0.0006" | Steel | Rockwell C50 to Rockwell C62 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 mm | 6 mm | 10 mm | 8 mm | 13.000 mm | 2.000 mm | 10.000 mm | 0.023 mm to 0.032 mm | -0.254 mm to 0.254 mm | 0 mm to 0.0102 mm | Steel | Rockwell C58 to Rockwell C62 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8 mm | 8 mm | 12 mm | 8 mm | 15.000 mm | 2.000 mm | 10.000 mm | 0.028 mm to 0.039 mm | -0.254 mm to 0.254 mm | 0 mm to 0.0102 mm | Steel | Rockwell C58 to Rockwell C62 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10 mm | 10 mm | 15 mm | 10 mm | 18.000 mm | 2.000 mm | 12.000 mm | 0.028 mm to 0.039 mm | -0.254 mm to 0.254 mm | 0 mm to 0.0102 mm | Steel | Rockwell C58 to Rockwell C62 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12 mm | 12 mm | 18 mm | 10 mm | 22.000 mm | 2.000 mm | 12.000 mm | 0.028 mm to 0.039 mm | -0.254 mm to 0.254 mm | 0 mm to 0.0102 mm | Steel | Rockwell C58 to Rockwell C62 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Conical-Head Pins | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/16" | 3/8" | 1/2" | 1/4" | 0.750" | 0.250" | 0.500" | -0.0003" to 0" | -0.0625" to 0.0625" | -0.01" to 0" | Steel | Rockwell C60 to Rockwell C64 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 11/16" | 5/8" | 3/4" | 3/8" | 1.000" | 0.375" | 0.750" | -0.0003" to 0" | -0.0625" to 0.0625" | -0.014" to -0.004" | Steel | Rockwell C60 to Rockwell C64 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Alignment Locks

Tapered Round Alignment Locks

Mounting | Male | Female | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

OD | OD Tolerance | ID | Material | No. of Holes | For Fastener Thread Size | Fasteners Included | Choose a Height | Each | Each | |||

| 1/2" | -0.0005" to 0" | 5/16" | Steel | 1 | 10-24 | No | 11/16", 7/8", 1 3/16", 1 3/8" | 0000000 | 000000 | 0000000 | 000000 | |

| 3/4" | -0.0005" to 0" | 1/2" | Steel | 1 | 1/4"-20 | No | 11/16", 7/8", 1 3/16", 1 3/8" | 0000000 | 00000 | 0000000 | 00000 | |

| 1" | -0.0005" to 0" | 5/8" | Steel | 1 | 1/4"-20 | No | 11/16", 7/8", 1 3/16", 1 3/8" | 0000000 | 00000 | 0000000 | 00000 | |

| 1 1/2" | -0.0005" to 0" | 1" | Steel | 1 | 5/16"-18 | No | 1 1/8", 1 3/8", 1 5/8" | 0000000 | 00000 | 0000000 | 00000 | |

| 2" | -0.0005" to 0" | 1 1/2" | Steel | 1 | 5/16"-18 | No | 1 1/8", 1 3/8", 1 5/8" | 0000000 | 00000 | 0000000 | 00000 | |

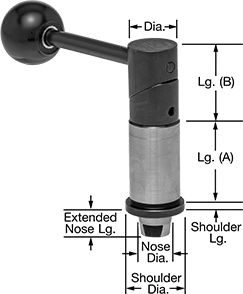

High-Precision Index Plungers

|  |

Plungers | Bushings |

Lg. | Shoulder | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Dia. | Dia. Tolerance | (A) | (B) | Dia. | Lg. | Nose Dia. | Extended Nose Lg. | Overall Lg. | Material | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Plungers | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.752" | 0" to 0.0003" | 1 1/4" | 1 1/8" | 7/8" | 1/8" | 1/2" | 5/16" | — | Steel | 0000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.127" | 0" to 0.0003" | 1 7/8" | 1 1/2" | 1 1/4" | 1/8" | 3/4" | 3/8" | — | Steel | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.502" | 0" to 0.0004" | 2 1/8" | 1 7/8" | 1 5/8" | 1/8" | 1" | 3/8" | — | Steel | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Bushings | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.752" | 0" to 0.0003" | — | — | 7/8" | 1/8" | — | — | 1/2" | Steel | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.127" | 0" to 0.0003" | — | — | 1 1/4" | 1/8" | — | — | 5/8" | Steel | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.502" | 0" to 0.0004" | — | — | 1 5/8" | 1/8" | — | — | 3/4" | Steel | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

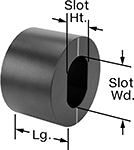

Slotted Bushings

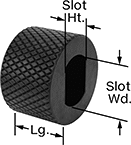

Slot | Tolerance | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Pin Dia. | Ht. | Wd. | Lg. | OD | Slot Ht. | OD | Hardness | Material | Includes | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Slotted Bushings with Etched Line | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8" | 1/8" | 1/4" | 1/2" | 3/8" | 0.0001" to 0.0007" | 0.0001" to 0.0004" | Rockwell C58 | Black-Oxide Steel | — | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/16" | 3/16" | 3/8" | 1/2" | 1/2" | 0.0001" to 0.0007" | 0.0001" to 0.0004" | Rockwell C58 | Black-Oxide Steel | — | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.1925" | 0.1935" | 3/8" | 1/2" | 1/2" | 0.0001" to 0.0006" | 0.0001" to 0.0004" | Rockwell C58 | Black-Oxide Steel | — | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 1/4" | 3/8" | 1/2" | 3/4" | 0.0001" to 0.0007" | 0.0001" to 0.0004" | Rockwell C58 | Black-Oxide Steel | — | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.257" | 0.257" | 3/8" | 1/2" | 3/4" | 0.0001" to 0.0007" | 0.0001" to 0.0004" | Rockwell C58 | Black-Oxide Steel | — | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16" | 5/16" | 7/16" | 1/2" | 3/4" | 0.0001" to 0.0007" | 0.0001" to 0.0004" | Rockwell C58 | Black-Oxide Steel | — | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 3/8" | 1/2" | 1/2" | 1" | 0.0001" to 0.0007" | 0.0001" to 0.0004" | Rockwell C58 | Black-Oxide Steel | — | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 1/2" | 5/8" | 1/2" | 1" | 0.0001" to 0.0007" | 0.0001" to 0.0004" | Rockwell C58 | Black-Oxide Steel | — | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8" | 5/8" | 3/4" | 1" | 1 1/4" | 0.0001" to 0.0007" | 0.0001" to 0.0004" | Rockwell C58 | Black-Oxide Steel | — | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | 3/4" | 7/8" | 1" | 1 1/2" | 0.0001" to 0.001" | 0.0001" to 0.0004" | Rockwell C58 | Black-Oxide Steel | — | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

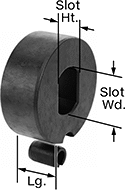

Slotted Bushings with Spring Pin | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/16" | 3/16" | 5/16" | 13/32" | 3/4" | 0.0001" to 0.0007" | 0.0001" to 0.0004" | Rockwell C58 | Black-Oxide Steel | 3/16" Slotted Spring Pin | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 1/4" | 3/8" | 13/32" | 3/4" | 0.0001" to 0.0007" | 0.0001" to 0.0004" | Rockwell C58 | Black-Oxide Steel | 3/16" Slotted Spring Pin | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 1/4" | 3/8" | 13/32" | 1" | 0.0001" to 0.0007" | 0.0001" to 0.0004" | Rockwell C58 | Black-Oxide Steel | 3/16" Slotted Spring Pin | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16" | 5/16" | 7/16" | 13/32" | 1" | 0.0001" to 0.0007" | 0.0001" to 0.0004" | Rockwell C58 | Black-Oxide Steel | 3/16" Slotted Spring Pin | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 3/8" | 1/2" | 13/32" | 1" | 0.0001" to 0.0007" | 0.0001" to 0.0004" | Rockwell C58 | Black-Oxide Steel | 3/16" Slotted Spring Pin | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 1/2" | 5/8" | 13/32" | 1" | 0.0001" to 0.0007" | 0.0001" to 0.0004" | Rockwell C58 | Black-Oxide Steel | 3/16" Slotted Spring Pin | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 1/2" | 5/8" | 29/32" | 1" | 0.0001" to 0.0007" | 0.0001" to 0.0004" | Rockwell C58 | Black-Oxide Steel | 3/16" Slotted Spring Pin | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8" | 5/8" | 3/4" | 29/32" | 1 1/4" | 0.0001" to 0.0007" | 0.0001" to 0.0004" | Rockwell C58 | Black-Oxide Steel | 3/16" Slotted Spring Pin | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | 3/4" | 13/16" | 1" | 1 1/2" | 0.0001" to 0.0007" | 0.0001" to 0.0004" | Rockwell C58 | Black-Oxide Steel | 3/16" Slotted Spring Pin | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/8" | 7/8" | 1" | 1" | 1 1/2" | 0.0001" to 0.0007" | 0.0001" to 0.0004" | Rockwell C58 | Black-Oxide Steel | 3/16" Slotted Spring Pin | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 1" | 1 1/16" | 1" | 1 1/2" | 0.0001" to 0.0007" | 0.0001" to 0.0004" | Rockwell C58 | Black-Oxide Steel | 3/16" Slotted Spring Pin | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 mm | 6 mm | 9 mm | 9 mm | 20 mm | 0.00 mm to 0.03 mm | 0.0025 mm to 0.0102 mm | Rockwell C58 | Black-Oxide Steel | 5 mm Slotted Spring Pin | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8 mm | 8 mm | 11 mm | 9 mm | 24 mm | 0.00 mm to 0.03 mm | 0.0025 mm to 0.0102 mm | Rockwell C58 | Black-Oxide Steel | 5 mm Slotted Spring Pin | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10 mm | 10 mm | 13 mm | 9 mm | 24 mm | 0.00 mm to 0.03 mm | 0.0025 mm to 0.0102 mm | Rockwell C58 | Black-Oxide Steel | 5 mm Slotted Spring Pin | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12 mm | 12 mm | 15 mm | 14 mm | 24 mm | 0.00 mm to 0.03 mm | 0.0025 mm to 0.0102 mm | Rockwell C58 | Black-Oxide Steel | 5 mm Slotted Spring Pin | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 16 mm | 16 mm | 18 mm | 12 mm | 30 mm | 0.00 mm to 0.03 mm | 0.0025 mm to 0.0102 mm | Rockwell C58 | Black-Oxide Steel | 5 mm Slotted Spring Pin | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 20 mm | 20 mm | 22 mm | 19 mm | 36 mm | 0.00 mm to 0.03 mm | 0.0025 mm to 0.0102 mm | Rockwell C58 | Black-Oxide Steel | 5 mm Slotted Spring Pin | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 mm | 25 mm | 27 mm | 19 mm | 40 mm | 0.00 mm to 0.03 mm | 0.0025 mm to 0.0102 mm | Rockwell C58 | Black-Oxide Steel | 5 mm Slotted Spring Pin | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Strong-Hold Slotted Bushings for Plastic

Slot | Tolerance | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Pin Dia. | Ht. | Wd. | Lg. | OD | Slot Ht. | OD | Hardness | Material | Surface Texture | Each | |||

| 3/16" | 3/16" | 5/16" | 1/2" | 0.565" | 0" to 0.001" | -0.005" to 0.005" | Rockwell C58 | Black-Oxide Steel | Knurled | 0000000 | 000000 | ||

| 1/4" | 1/4" | 3/8" | 1/2" | 0.64" | 0" to 0.001" | -0.005" to 0.005" | Rockwell C58 | Black-Oxide Steel | Knurled | 0000000 | 00000 | ||

| 5/16" | 5/16" | 7/16" | 1/2" | 0.765" | 0" to 0.001" | -0.005" to 0.005" | Rockwell C58 | Black-Oxide Steel | Knurled | 0000000 | 00000 | ||

| 3/8" | 3/8" | 1/2" | 1/2" | 0.89" | 0" to 0.001" | -0.005" to 0.005" | Rockwell C58 | Black-Oxide Steel | Knurled | 0000000 | 00000 | ||

| 1/2" | 1/2" | 5/8" | 1/2" | 1.015" | 0" to 0.001" | -0.005" to 0.005" | Rockwell C58 | Black-Oxide Steel | Knurled | 0000000 | 00000 | ||

| 1/2" | 1/2" | 5/8" | 1" | 1.015" | 0" to 0.001" | -0.005" to 0.005" | Rockwell C58 | Black-Oxide Steel | Knurled | 0000000 | 00000 | ||