How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

Low-Pressure Iron and Steel Threaded Pipe Fittings

Use these fittings for low-pressure applications in noncorrosive environments.

- For Use With: Air, Steam, Oil, Water, Natural Gas

- Pressure Class: 150

- Specifications Met: ASME B1.20.1, ASME B16.3, UL Listed

- Pipe Nipples and Pipe: Use Schedule 40 steel

| Pipe Size | Max. Pressure | Max. Steam Pressure | Material | Each | |

NPT Female | |||||

|---|---|---|---|---|---|

| 1/2 | 300 psi @ 72° F | 150 psi @ 350° F | Iron | 000000000 | 00000 |

| 3/4 | 300 psi @ 72° F | 150 psi @ 350° F | Iron | 000000000 | 0000 |

| 1 | 300 psi @ 72° F | 150 psi @ 350° F | Iron | 000000000 | 00000 |

| 1 1/4 | 300 psi @ 72° F | 150 psi @ 350° F | Iron | 000000000 | 00000 |

| 1 1/2 | 300 psi @ 72° F | 150 psi @ 350° F | Iron | 000000000 | 00000 |

| 2 | 300 psi @ 72° F | 150 psi @ 350° F | Iron | 000000000 | 00000 |

Standard-Wall Plastic Pipe Fittings for Water

Connect these fittings to Schedule 40 plastic pipe–they are the industry standard for residential and commercial low-pressure plumbing and water supply applications. They are plastic for good corrosion resistance.

Fittings for drinking water meet NSF/ANSI Standard 61.

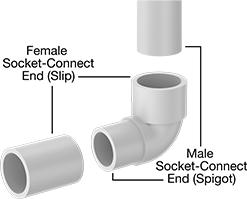

Attach socket-connect ends to unthreaded pipe or another socket-connect fitting with a PVC primer and cement (also known as solvent weld).

To prevent leaks in threaded connections, apply a sealant to the male threads. Threaded connections can be taken apart as needed for maintenance and repair. For plastic threads, apply a non-hardening, plastic-compatible sealant. Tape or sealants with PTFE are not recommended for plastic-to-plastic connections. Fittings that meet ASTM D1784, ASTM D1785, and ASTM D4066 adhere to specifications and testing requirements for material quality.

Note: For fittings that are not rated for pressure, you can use the pressure rating of the plastic pipe as a reference. Threaded fittings are limited to 50% of the rated pressure of the pipe.

Warning: Never use plastic pipe fittings and pipe with compressed air or gas.

- For Use With: Drinking Water, Water

- Maximum Temperature: 140° F

- Specifications Met: ASTM D1784, NSF/ANSI 61

- Pipe Nipples and Pipe: Use Schedule 40 PVC Plastic

- Flanges: Use Class 150 PVC Plastic

- For Use With: Drinking Water, Water

- Maximum Temperature: 140° F

- Specifications Met: ASTM D1784, NSF/ANSI 61

- Pipe Nipples and Pipe: Use Schedule 40 PVC Plastic

- Flanges: Use Class 150 PVC Plastic

Press-Connect Fittings for Copper Tubing

- For Use With: Drinking Water

- Maximum Pressure: Fittings compatible with Viega ProPress or Viega ProPress XL-C: 200 psi @ 72° F

Fittings compatible with Viega Pex or Viega PureFlow Press: 100 psi @ 72° F - Temperature Range: 0° to 250° F

- Tubing: Fittings compatible with Viega ProPress or Viega ProPress XL-C: Use with K, M, L copper

Fittings compatible with Viega Pex or Viega PureFlow Press: Use with hard polyethylene plastic - Specifications Met: See table

Crimp these fittings to copper tubing with a crimping tool (sold separately). An O-ring on the inside of the fitting creates a leak-tight connection that doesn’t require heat or soldering. They are comparable to Viega ProPress fittings. Fittings have good corrosion resistance. They meet NSF/ANSI safety standards for use with drinking water systems.

Copper tube size is the accepted designation of the copper tubing industry, not the actual tube OD.

Mounting Hole | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Copper Tube Size | For Tube OD | Pipe Size | Material | Dia. | No. of | Compatible With | Specifications Met | Each | |

NPT Threads | |||||||||

| 1/2 | 5/8" | 1/2 | Bronze | 1/4" | 2 | Viega ProPress | ASME B16.51, ASME B31.1, ASME B31.3, ASME B31.9, NSF/ANSI 61, UL 213 | 00000000 | 000000 |

| 3/4 | 7/8" | 3/4 | Bronze | 1/4" | 2 | Viega ProPress | ASME B16.51, ASME B31.1, ASME B31.3, ASME B31.9, NSF/ANSI 61, UL 213 | 00000000 | 00000 |

| 1 | 1 1/8" | 1/2 | Bronze | 1/4" | 2 | Viega ProPress | ASME B16.51, ASME B31.1, ASME B31.3, ASME B31.9, NSF/ANSI 61, UL 213 | 00000000 | 00000 |

Jaws for copper tube sizes ½ to 2 fit directly into the included crimping tool.

Battery | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| For Copper Tube Size | For Tube OD | Voltage | No. Included | Cap., amp-hrs. | Battery Charger Included | Battery Charging Time, min. | Compatible With | Specifications Met | Each | |

| 1/2, 3/4, 1, 1 1/4, 1 1/2, 2 | 5/8", 7/8", 1 1/8", 1 3/8", 1 5/8", 2 1/8" | 18V DC | 2 | 3 | Yes | 39 | Viega ProPress | EMC 2011/65/EU, EMC 2014/30/EU, IEC 62841-1, UL 62841-1 | 00000000 | 000000000 |