Filter by

System of Measurement

For Use With

Maximum Pressure @ Temperature

Body Material

Actuation

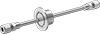

Fitting Connection

Thread Type

Minimum Temperature

Valve Function

Maximum Temperature

Shape

Actuator Housing Material

Valve Position

DFARS Specialty Metals

Fitting Type

Export Control Classification Number (ECCN)

Pressure Class

Fluid Handling