How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

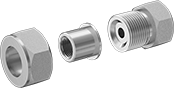

Low-Pressure Stainless Steel Threaded Pipe Fittings

Use these fittings in a low-pressure pipe line.

Fittings that meet ANSI/MSS SP-114 adhere to high-quality standards for heat treating, material thickness, and marking. 304 stainless steel fittings have very good corrosion resistance. 316 stainless steel fittings have excellent corrosion resistance.

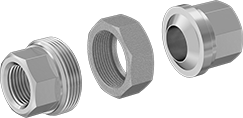

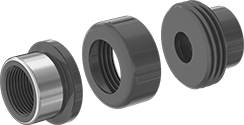

Union connectors separate into three pieces so you can access your line without unthreading pipe connections.

Female x male 90° elbow adapters are also known as street elbows.

- For Use With: Air, Natural Gas, Oil, Steam, Water

- Pressure Class: 150

- Fabrication: Heat Treated

- Specifications Met:

NPT: ANSI/MSS SP-114, ASTM A351

BSPP and BSPT: ASNI/MSS SP-114 - Pipe Nipples and Pipe: Use Schedule 40 stainless steel

- Flanges: Use Class 150 stainless steel

304 Stainless Steel | 316 Stainless Steel | ||||||

|---|---|---|---|---|---|---|---|

| Pipe Size | Max. Steam Pressure | Max. Pressure | Each | Max. Pressure | Each | ||

NPT Female | |||||||

| 1/4 | 150 psi @ 350° F | 300 psi @ 72° F | 00000000 | 000000 | 300 psi @ 72° F | 00000000 | 000000 |

BSPP Female | |||||||

| 1/4 | 150 psi @ 350° F | 150 psi @ 72° F | 00000000 | 00000 | 150 psi @ 72° F | 00000000 | 00000 |

BSPT Female | |||||||

| 1/4 | 150 psi @ 350° F | 300 psi @ 72° F | 00000000 | 00000 | 150 psi @ 72° F | 00000000 | 00000 |

- For Use With: Air, Natural Gas, Oil, Steam, Water

- Pressure Class: 150

- Fabrication: Heat Treated

- Specifications Met: ASTM A351

- Pipe Nipples and Pipe: Use Schedule 40 stainless steel

- Flanges: Use Class 150 stainless steel

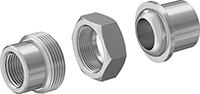

High-Pressure Stainless Steel Threaded Pipe Fittings

Use these heavy duty fittings in high-pressure flow applications.

304 stainless steel fittings have very good corrosion resistance. 316 stainless steel fittings have excellent corrosion resistance. Union connectors separate into three pieces so you can access your line without unthreading pipe connections.

- For Use With: Air, Hydraulic Fluid, Natural Gas, Oil, Steam, Water

- Pressure Class: 3000

- Specifications Met: ASTM A182

- Pipe Nipples and Pipe: Use Schedule 80 stainless steel

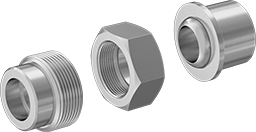

Precision Extreme-Pressure Stainless Steel Threaded Pipe Fittings

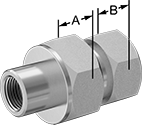

Made to tighter tolerances than other stainless steel pipe fittings, these are also known as instrumentation fittings. The male threads are rolled for extra strength in extreme-pressure applications. Fittings are commonly used to connect equipment in gas and hydraulic fluid lines. They are 316 stainless steel for excellent corrosion resistance.

Union connectors separate into three pieces so you can access your line without unthreading pipe connections.

- For Use With: Hydraulic Fluid, Liquid Nitrogen, Natural Gas, Steam, Water

- Specifications Met: ASME B1.20.1, ASME B31.1, ASME B31.3, ASTM A182, ASTM 276, ASTM A479

Hex Width | 316 Stainless Steel | ||||||

|---|---|---|---|---|---|---|---|

| Pipe Size | Dash Size | Max. Pressure | Max. Steam Pressure | (A) | (B) | Each | |

NPT Female | |||||||

| 1/4 | 04 | 6,600 psi @ 72° F | 6,600 psi @ 300° F | 1 3/8" | 1 3/16" | 000000000 | 000000 |

Medium-Pressure Stainless Steel Threaded Pipe Fittings

Choose these fittings when you want the same high-quality found in our low-pressure pipe fittings, but need more strength to handle higher pressures.

Fittings that meet ANSI/MSS SP-114 adhere to high-quality standards for heat treating, material thickness, and marking.

304 stainless steel fittings have very good corrosion resistance.

316 stainless steel fittings have excellent corrosion resistance.

Union connectors separate into three pieces so you can access your line without unthreading pipe connections.

- For Use With: Air, Natural Gas, Oil, Steam, Water

- Pressure Class: 1000

- Specifications Met: ANSI/MSS SP-114, ASTM A182

- Pipe Nipples and Pipe: Use Schedule 40 stainless steel

- Flanges: Use Class 150 stainless steel

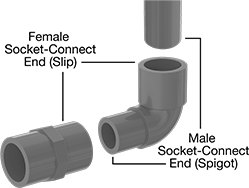

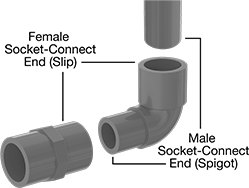

High-Pressure Socket-Connect Stainless Steel Unthreaded Pipe Fittings

Forged for excellent strength, these heavy duty socket-connect fittings stand up to high-pressure applications. They are easier to weld than butt-weld fittings because the fitting doesn’t need to align perfectly to the pipe. Slide pipe into the socket and weld for a strong, permanent connection.

304 stainless steel fittings have very good corrosion resistance. 316 stainless steel fittings have excellent corrosion resistance.

Union straight connectors separate into three pieces for access to your line.

- For Use With: Air, Hydraulic Fluid, Natural Gas, Oil, Steam, Water

- Pressure Class: 3000

- Specifications Met: ASTM A182

- Pipe Nipples and Pipe: Use Schedule 80 stainless steel

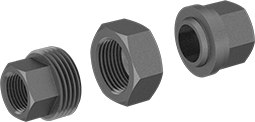

Low-Pressure Iron and Steel Threaded Pipe Fittings

Use these fittings for low-pressure applications in noncorrosive environments.

Union connectors separate into three pieces so you can access your line without unthreading pipe connections. They have a gasket that creates a tight seal.

- For Use With: Air, Steam, Oil, Water, Natural Gas

- Pressure Class: 150

- Specifications Met: See table

- Pipe Nipples and Pipe: Use Schedule 40 steel

Low-Pressure Galvanized Iron and Steel Threaded Pipe Fittings

The galvanized finish on these fittings provides fair corrosion resistance. Fittings are for use in low-pressure applications.

Union connectors separate so you can access your line without unthreading pipe connections. They have a brass gasket that creates a tight seal.

- For Use With: Air, Steam, Oil, Water, Natural Gas

- Pressure Class: 150

- Specifications Met: See table

- Pipe Nipples and Pipe: Use Schedule 40 galvanized steel

- Flanges: Use Class 150 galvanized steel

| Pipe Size | Max. Pressure | Max. Steam Pressure | Material | Gasket Material | Specifications Met | Each | |

NPT Female | |||||||

|---|---|---|---|---|---|---|---|

| 1/4 | 300 psi @ 72° F | 150 psi @ 350° F | Galvanized Iron | Brass | ASME B1.20.1, ASME B16.39, ASTM A197, UL Listed | 00000000 | 000000 |

BSPT Female | |||||||

| 1/4 | 150 psi @ 72° F | 150 psi @ 360° F | Galvanized Iron | Brass | ASTM A197, DIN EN 10226 | 00000000 | 00000 |

High-Pressure Iron and Steel Threaded Pipe Fittings

These fittings can stand up to high-pressure applications. Use them in noncorrosive environments.

Union connectors separate into three pieces so you can access your line without unthreading pipe connections.

Phosphate-coated and zinc-phosphate-coated fittings offer some corrosion resistance, but aren't intended for corrosive environments.

Note: The maximum pressure listed for Class 3000 fittings is for conditions where there are no sudden changes in pressure or velocity. Please refer to ASME B16.11 to determine the specific maximum operating pressure for your application.

- For Use With: Air, Hydraulic Fluid, Natural Gas, Oil, Steam, Water

- Pressure Class: 3000

- Specifications Met: MSS SP-83, ASME B1.20.1, ASTM A105

- Pipe Nipples and Pipe: Use Schedule 160 steel

- Flanges: Use Class 1500 steel

| Pipe Size | Dash Size | Max. Pressure | Max. Steam Pressure | Material | Each | |

NPT Female | ||||||

|---|---|---|---|---|---|---|

| 1/4 | 04 | 3,000 psi @ 72° F | 300 psi @ 360° F | Zinc-Phosphate-Coated Steel | 0000000 | 000000 |

High-Pressure Galvanized Steel Threaded Pipe Fittings

A galvanized finish gives these fittings better corrosion resistance than our plain steel high-pressure fittings. Also known as Pressure Class 3000 fittings, they have excellent strength to handle high-pressure applications.

Union connectors separate into three pieces so you can access your line without unthreading pipe connections.

- For Use With: Air, Hydraulic Fluid, Natural Gas, Oil, Steam, Water

- Pressure Class: 3000

- Specifications Met: ASME B1.20.1, ASTM A105, ASTM B633, MSS SP-83

- Pipe Nipples and Pipe: Use Schedule 160 steel

| Pipe Size | Dash Size | Max. Pressure | Max. Steam Pressure | Each | |

NPT Female | |||||

|---|---|---|---|---|---|

| 1/4 | 04 | 3,000 psi @ 72° F | 300 psi @ 360° F | 00000000 | 000000 |

Medium-Pressure Iron and Steel Threaded Pipe Fittings

With better strength than our low-pressure iron and steel pipe fittings, these can handle medium-pressure applications. They are for use in noncorrosive environments.

Union connectors separate into three pieces so you can access your line without unthreading pipe connections.

- For Use With: Air, Steam, Oil, Water, Natural Gas

- Pressure Class : 300

- Specifications Met: ASTM A197, UL Listed, ASME B16.39, ASME B1.20.1

- Pipe Nipples and Pipe: Use Schedule 80 steel

- Flanges: Use Class 300 or 600 steel

| Pipe Size | Max. Pressure | Max. Steam Pressure | Material | Each | |

NPT Female | |||||

|---|---|---|---|---|---|

| 1/4 | 600 psi @ 72° F | 230 psi @ 550° F | Iron | 00000000 | 000000 |

Medium-Pressure Galvanized Iron and Steel Threaded Pipe Fittings

A galvanized finish gives these fittings fair corrosion resistance. They have the strength to handle medium-pressure applications.

Union connectors separate into three pieces so you can access your line without unthreading pipe connections.

- For Use With: Air, Natural Gas, Steam, Water

- Pressure Class : 300

- Specifications Met: FM Approved, UL Listed, ASTM A197, ASTM A153, ASME B1.20.1, ASME B16.39

- Pipe Nipples and Pipe: Use Schedule 80 steel

- Flanges: Use Class 300 steel

| Pipe Size | Max. Pressure | Max. Steam Pressure | Material | Each | |

NPT Female | |||||

|---|---|---|---|---|---|

| 1/4 | 600 psi @ 72° F | 230 psi @ 550° F | Galvanized Iron | 0000000 | 000000 |

Extreme-Pressure Steel Threaded Pipe Fittings

The strongest steel fittings we offer, these can withstand extreme-pressure applications.

Union connectors separate into three pieces so you can access your line without unthreading pipe connections.

Note: The maximum pressure listed for Class 6000 fittings is for conditions where there are no sudden changes in pressure or velocity. Please refer to ASME B16.11 to determine the specific maximum operating pressure for your application.

- For Use With: Air, Hydraulic Fluid, Natural Gas, Oil, Steam, Water

- Pressure Class: 6000

- Specifications Met: ASME B1.20.1, ASTM A105

- Pipe Nipples and Pipe: Use Schedule XXH steel

- Flanges: Use Class 1500 steel

| Pipe Size | Dash Size | Max. Pressure | Max. Steam Pressure | Material | Each | |

NPT Female | ||||||

|---|---|---|---|---|---|---|

| 1/4 | 04 | 6,000 psi @ 72° F | 300 psi @ 360° F | Steel | 00000000 | 000000 |

High-Pressure Socket-Connect Steel Unthreaded Pipe Fittings

Socket-connect fittings are easier to weld than butt-weld fittings because the fitting doesn’t need to align perfectly to the pipe. Slide pipe into the socket and weld for a strong, permanent connection. Fittings have heavy duty construction that stands up to high-pressure applications. They are for use in noncorrosive environments.

Union straight connectors separate into three pieces for access to your line.

- For Use With: Air, Steam, Oil, Water, Natural Gas

- Pressure Class : 3000

- Specifications Met: ASTM A105, MSS SP-83

- Pipe Nipples and Pipe: Use Schedule 80 steel

- Flanges: Use Class 300 and 600 steel

| Pipe Size | Max. Pressure | Material | Each | |

| 1/4 | 3,000 psi @ 72° F | Steel | 000000000 | 000000 |

High-Pressure Brass Threaded Pipe Fittings

These fittings have the strength to handle high-pressure applications. They are brass for good corrosion resistance.

Union connectors separate into three pieces so you can access your line without unthreading pipe connections.

- For Use With: Air, Natural Gas, Oil, Water

| Pipe Size | Max. Pressure | Each | |

NPT Female | |||

|---|---|---|---|

| 1/4 | 1,200 psi @ 72° F | 000000000 | 000000 |

High-Pressure Brass Threaded Pipe Fittings for Drinking Water

Use these heavy duty fittings for high-pressure drinking water applications. They are brass which has good corrosion resistance. They meet NSF/ANSI 61 safety standards for use with drinking water systems.

Union connectors separate into three pieces so you can access your line without unthreading pipe connections.

NPTF (Dryseal) threads are compatible with NPT threads.

- For Use With: Drinking Water

- Specifications Met: NSF/ANSI 61

| Pipe Size | Max. Pressure | Each | |

NPTF Female | |||

|---|---|---|---|

| 1/4 | 1,000 psi @ 72° F | 00000000 | 000000 |

Low-Pressure Brass and Bronze Threaded Pipe Fittings

Use these fittings in low-pressure flow applications. They have good corrosion resistance. Fittings rated for use with drinking water meet NSF/ANSI 61 safety standards.

Union connectors separate into three pieces so you can access your line without unthreading pipe connections.

- For Use With:

NPT: Air, Drinking Water, Natural Gas, Oil

BSPT: Air, Natural Gas, Oil, Steam, Water - Pressure Class: 125

- Specifications Met:

NPT: ASME B1.20.1, ASME B16.15, NSF/ANSI 61

BSPT: ASME BS21, ASTM B584 - Pipe Nipples and Pipe: Use Schedule 40 brass

- Flanges:

NPT: Use Class 150 brass

BSPT: Use Class 150 bronze

Low-Pressure Plated Brass Threaded Pipe Fittings

Used in low-pressure pipe lines, these brass fittings have a plating that makes them shiny and improves corrosion resistance.

Chrome-plated brass fittings are shinier and withstand corrosion better than nickel-plated brass fittings.

Union connectors separate into three pieces so you can access your line without unthreading pipe connections.

- For Use With: Air, Natural Gas, Oil, Steam, Water

- Pressure Class: 125

- Specifications Met: ASTM B456

- Pipe Nipples and Pipe: Use Schedule 40 brass

| Pipe Size | Max. Pressure | Max. Steam Pressure | Each | |

NPT Female | ||||

|---|---|---|---|---|

Chrome-Plated Brass | ||||

| 1/4 | 200 psi @ 72° F | 125 psi @ 400° F | 00000000 | 000000 |

Medium-Pressure Brass and Bronze Threaded Pipe Fittings

Choose these fittings when you need better strength than our low-pressure brass and bronze pipe fittings. They offer good corrosion resistance.

Union connectors separate into three pieces so you can access your line without unthreading pipe connections.

- For Use With: Air, Natural Gas, Oil, Water

- Pressure Class: 250

- Specifications Met: ASME B1.20.1, ASME B16.15, ASTM B584

- Pipe Nipples and Pipe: Use Schedule 80 brass

| Pipe Size | Max. Pressure | Material | Each | |

NPT Female | ||||

|---|---|---|---|---|

| 1/4 | 400 psi @ 72° F | Brass | 0000000 | 000000 |

Low-Pressure Aluminum Threaded Pipe Fittings

In addition to being lightweight, these aluminum fittings offer good corrosion resistance. Use them in low-pressure flow applications. To prevent cracking, do not tighten more than a 1/4-turn past hand tight.

Union connectors separate into three pieces so you can access your line without unthreading pipe connections.

- For Use With: Air, Oil, Water

- Pipe Nipples and Pipe: Use Schedule 40 aluminum

- Flanges: Use Class 125 aluminum

| Pressure Class | Pipe Size | Max. Pressure | Each | |

NPT Female | ||||

|---|---|---|---|---|

| 150 | 1/4 | 150 psi @ 72° F | 000000000 | 000000 |

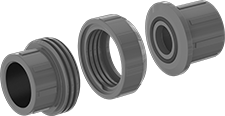

Thick-Wall Plastic Pipe Fittings for Water

Connect these fittings to Schedule 80 pipe. With thicker, stronger walls than standard-wall fittings, they can handle heavy duty supply applications, such as water processing, wastewater treatment, and irrigation. Fittings are plastic for good corrosion resistance. They meet ASTM specifications and testing requirements for material quality.

Fittings for drinking water meet NSF/ANSI Standard 61.

Attach socket-connect ends to unthreaded pipe or another socket-connect fitting with a PVC primer and cement (also known as solvent weld).

To prevent leaks in threaded connections, apply a sealant to the male threads. For plastic threads, apply a non-hardening, plastic-compatible sealant sealant. Tape or sealants with PTFE are not recommended for plastic-to-plastic connections. Note: For fittings that are not rated for pressure, you can use the pressure rating of the plastic pipe as a reference. Threaded fittings are limited to 50% of the rated pressure of the pipe.

Warning: Never use plastic pipe fittings and pipe with compressed air or gas.

- For Use With: Drinking Water, Water

- Maximum Temperature: 140° F

- Specifications Met: ASTM D1784, NSF/ANSI 61

- Pipe Nipples and Pipe: Use Schedule 80 PVC Plastic

- Flanges: Use Class 150 PVC Plastic

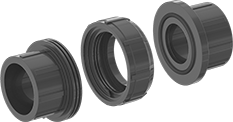

Unions separate into three pieces so you can access your line.

| Pipe Size | Socket Depth | Material | O-Ring Material | Color | Each | |

| 1/4 | 5/8" | PVC Plastic | Viton® Fluoroelastomer Rubber | Dark Gray | 0000000 | 000000 |

- For Use With: Drinking Water, Water

- Maximum Temperature: 140° F

- Specifications Met: ASTM D1784, NSF/ANSI 61

- Pipe Nipples and Pipe: Use Schedule 80 PVC Plastic

- Flanges: Use Class 150 PVC Plastic

Unions separate into three pieces so you can access your line.

| Pipe Size | Material | O-Ring Material | Color | Each | |

NPT Threads | |||||

|---|---|---|---|---|---|

| 1/4 | PVC Plastic | EPDM Rubber | Dark Gray | 0000000 | 000000 |

- For Use With: Drinking Water, Water

- Maximum Temperature: 140° F

- Specifications Met: ASTM D1784, NSF/ANSI 61

- Pipe Nipples and Pipe: Use Schedule 80 PVC Plastic

- Flanges: Use Class 150 PVC Plastic

Unions separate into three pieces so you can access your line.

| Pipe Size | Socket Depth | Material | O-Ring Material | Color | Each | |

NPT Threads | ||||||

|---|---|---|---|---|---|---|

| 1/4 | 5/8" | PVC Plastic | EPDM Rubber | Dark Gray | 00000000 | 000000 |

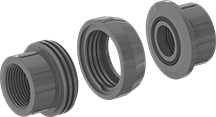

- For Use With: Drinking Water, Water

- Maximum Temperature: 140° F

- Specifications Met: ASTM D1784, NSF/ANSI 61

- Pipe Nipples and Pipe: Use Schedule 80 PVC Plastic

- Flanges: Use Class 150 PVC Plastic

Fittings with stainless steel collar have a reinforcement on the female threads to prevent the threads from cracking.

Unions separate into three pieces so you can access your line.

| Pipe Size | Socket Depth | Material | Collar Material | O-Ring Material | Color | Each | |

NPT Threads | |||||||

|---|---|---|---|---|---|---|---|

| 1/4 | 5/8" | PVC Plastic | Stainless Steel | EPDM Rubber | Dark Gray | 0000000 | 000000 |

CPVC Pipe Fittings for Hot Water

Made of CPVC, these fittings can handle high temperatures. They have thick, strong walls to handle heavy duty industrial plumbing and water supply applications, such as water processing and waste water treatment. They also have good corrosion resistance. These fittings are comparable to Corzan. Some meet ASTM D1784 specifications and testing requirements for material quality.

Fittings for drinking water meet NSF/ANSI Standard 61.

Schedule 80 fittings have thick, strong walls for heavy duty, industrial applications.

Note: For fittings that are not rated for pressure, you can use the pressure rating of the plastic pipe as a reference. Threaded fittings are limited to 50% of the rated pressure of the pipe.

Warning: Never use plastic pipe fittings and pipe with compressed air or gas.

Sealants cannot be sold to Colorado, Connecticut, District of Columbia, Delaware, Illinois, Indiana, Massachusetts, Maryland, Maine, Michigan, New Hampshire, New Jersey, Northern Virginia, New York, Ohio, Pennsylvania, Rhode Island, or Utah due to local regulatory limits on VOCs (Volatile Organic Compounds).

- For Use With: Acetic Acid (10%), Calcium Chloride, Deionized Water, Drinking Water, Hydrochloric Acid (25%), Nitric Acid (10%), Phosphoric Acid (85%), Salt Water, Sulfuric Acid (75%), Water

- Maximum Temperature: 200° F

- Specifications Met: ASTM D1784, NSF/ANSI 61

- Pipe Nipples and Pipe: Use Schedule 80 CPVC Plastic

- Flanges: Use Class 150 CPVC Plastic

Attach socket-connect ends to unthreaded pipe or another socket-connect fitting with a CPVC primer and cement (also known as solvent weld).

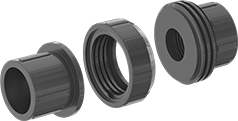

Unions separate into three pieces so you can access your line.

| Pipe Size | Socket Depth | Material | O-Ring Material | Schedule | Color | Max. Pressure | Each | |

| 1/4 | 5/8" | CPVC Plastic | Viton® Fluoroelastomer Rubber | 80 | Light Gray | Not Rated | 0000000 | 000000 |

- For Use With:

Fittings with EPDM Rubber O-Rings: Drinking Water, Water

All other fittings: Acetic Acid (10%), Calcium Chloride, Deionized Water, Drinking Water, Hydrochloric Acid (25%), Nitric Acid (10%), Phosphoric Acid (85%), Salt Water, Sulfuric Acid (75%), Water - Maximum Temperature: 200° F

- Specifications Met: ASTM D1784, NSF/ANSI 61

- Pipe Nipples and Pipe: Use Schedule 80 CPVC Plastic

- Flanges: Use Class 150 CPVC Plastic

To prevent leaks in threaded connections, apply a non-hardening, plastic-compatible sealant to the male threads. Tape or sealants with PTFE are not recommended for plastic-to-plastic threaded connections. When making a threaded connection be careful not to overtighten the threads. To prevent cracks and leaks, finger tighten the fitting, then wrench-tighten one to two turns.

Unions separate into three pieces so you can access your line.

| Pipe Size | Material | O-Ring Material | Schedule | Color | Max. Pressure | Each | |

NPT Threads | |||||||

|---|---|---|---|---|---|---|---|

| 1/4 | CPVC Plastic | EPDM Rubber | 80 | Light Gray | Not Rated | 0000000 | 000000 |