Filter by

For Flange Hole Diameter

Length

DFARS Specialty Metals

Export Control Classification Number (ECCN)

Overall Length

Aligner Connection Method

Level Orientation

Measuring Features

Graduation Location

Alignment Mechanism

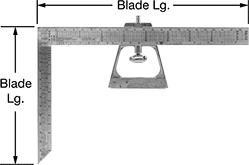

Pipefitting Squares

Blade | Graduation | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Angle Measured | Blade Lg. | For Pipe Size | Front Graduations (Numeric Graduations) | Back Graduations (Numeric Graduations) | Wd. | Thk. | Color | Color | Type | Measuring Features | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Inch | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 90° | 24" × 15 3/8" | 1, 1 1/2, 2, 2 1/2, 3, 4, 6, 8, 10, 12, 14, 16, 18, 20, 24 | 1/16" (1"), 1/16" (1") | 1/12" (1"), 1/12" (1") | 2 3/16" × 1 9/16" | 1/16" × 1/16" | Silver | Black | Etched | Bolt Chart, Chart for 150-Lb. Weld Neck Flanges, Chart for 300-Lb. Weld Neck Flanges, Chart for 45° Weld Elbows, Chart for Diameter of 150-Lb. Pipe Blinds, Chart for Diameter of 300-Lb. Pipe Blinds, Chart for OD of 150-Lb. Flanges, Chart for OD of 300-Lb. Flanges, Chart for Weld Tees | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

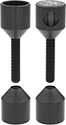

Pipe Flange Aligner Pins

Pipe Flange Aligner Pins with Horizontal Level

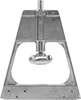

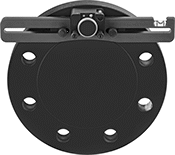

Magnetic Pipe Flange Aligners with Level

For Flange Hole Dia. | For Max. Flange Hole Ctr.-to-Ctr. Distance | Level Lg. | Aligner Connection Method | Includes | Cone Material | Magnet Material | Container Type | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Aluminum Body | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" to 2" | 9 1/2" | 10 1/2" | Magnetic | Threaded Cones | Steel | Neodymium | Carrying Case | 0000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Magnetic Pipe Flange Aligner Pins

Pipe Flange Aligners | Pipe Flange Aligner Extensions | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Flange | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Hole Dia. | Thk. | Aligner Connection Method | Magnet Material | Pair | Lg. | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16" to 7/8" | 7/8" | Magnetic | Neodymium | 0000000 | 000000 | — | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" to 1 7/16" | 1 3/8" | Magnetic | Neodymium | 0000000 | 000000 | — | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" to 1 15/16" | 2 3/4" | Magnetic | Neodymium | 0000000 | 000000 | 1 3/4" | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

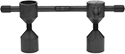

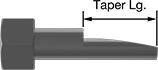

No-Strike Hex-Head Alignment Pins for Flange Bolt Holes

|

Body | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Bolt Hole Dia. | Point Dia. | Taper Lg. | Overall Lg. | Shape | Texture | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Black-Oxide Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 1/4" | 1 3/8" | 2 1/2" | Round | Smooth | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 3/8" | 1 1/2" | 2 7/8" | Round | Smooth | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 3/8" | 1 1/2" | 5 7/8" | Round | Smooth | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8" | 1/2" | 1 3/4" | 3 3/8" | Round | Smooth | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8" | 1/2" | 1 3/4" | 6 3/8" | Round | Smooth | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | 5/8" | 1 7/8" | 7" | Round | Smooth | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/8" | 11/16" | 2" | 7 1/4" | Round | Smooth | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 3/4" | 2 1/4" | 7 3/4" | Round | Smooth | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/8" | 7/8" | 2 3/4" | 6" | Round | Smooth | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/8" | 7/8" | 2 3/4" | 9" | Round | Smooth | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4" | 1" | 3" | 6 1/2" | Round | Smooth | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4" | 1" | 3" | 9 1/2" | Round | Smooth | 000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 3/8" | 1 3/16" | 3 3/8" | 7 1/2" | Round | Smooth | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 3/8" | 1 3/16" | 3 3/8" | 10 1/2" | Round | Smooth | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 1 1/4" | 3 1/2" | 10 3/4" | Round | Smooth | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 5/8" | 1 3/8" | 3 7/8" | 8 3/4" | Round | Smooth | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 5/8" | 1 3/8" | 3 7/8" | 11 3/4" | Round | Smooth | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Stepped Pipe Flange Aligner Pins

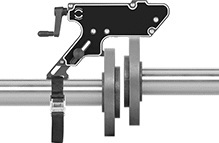

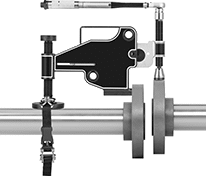

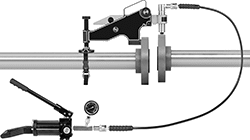

Pipe Flange Alignment Kits

Alignment Mechanism | Wt. Cap., lb. | For Min. Flange Hole Dia. | Includes | Container Type | Each | ||

|---|---|---|---|---|---|---|---|

| Hand Crank | 2,400 | 5/8" | Strap | — | 0000000 | 000000000 | |

| Ratchet | 9,900 | 1" | Socket, Strap, Wrench | Plastic Carrying Case | 0000000 | 00000000 | |

| Hydraulic | 22,200 | 1 3/8" | Hand Pump with Gauge, Hydraulic Cylinder, Hydraulic Hose, Strap | Plastic Carrying Case | 0000000 | 00000000 |

Pipe Flange Aligners with Protractor

|

For Flange Hole Dia. | Angle Measured Range | Graduations (Angle Increments) | For Distance Between Bolt Holes | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Aluminum | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/16" to 1 3/4" | 0° to 90° | 2.5° (2°) | 2" to 5 1/2" | 0000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Contour Markers

For Pipe OD | Angle Measured Range | Graduations (Angle Increments) | Mount Type | Marker Type | Includes | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Anodized Aluminum | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" to 18" | 0° to 90° | 2.5° (10°) | Magnet | Soapstone Crayon | Calibrated Protractor Dials, Holder for Soapstone Crayon, Level, Magnetic Base, Triple-Jointed Marking Arm | 000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8" to 48" | 0° to 90° | 2.5° (10°) | Magnet | Soapstone Crayon | Built-in Bubble Level, Calibrated Protractor Dials, Holder for Soapstone Crayon, Magnetic Base, Triple-Jointed Marking Arm | 000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||