Filter by

Material

Maximum Holding Torque

Input Shaft Rotation

Mounting Position

Maximum Output Torque @ Input Speed

Export Control Classification Number (ECCN)

DFARS Specialty Metals

Speed Reducers for Position- and Speed-Control Motors

With 1 Output Shaft

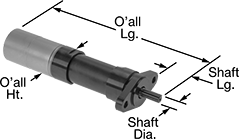

Max. Output | Max. Input | Output Shaft | Overall | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Torque | Speed, rpm | Speed, rpm | Power, hp | For Input Shaft Dia. | Dia. | Lg. | Lg. | Wd. | Ht. | Radial Load Cap., lb. | Enclosure Rating | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For NEMA 23 Motor Frames | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

3:1 Speed Ratio | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 240 in·lbf @ 1,750 rpm | 2,000 | 6,000 | 2.89 | 1/4" | 0.38" | 1" | 4 1/2" | 2 1/2" | 2 1/2" | 348 | IP65 | 00000000 | 000000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

5:1 Speed Ratio | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 345 in·lbf @ 1,750 rpm | 1,200 | 6,000 | 3.24 | 1/4" | 0.38" | 1" | 4 1/2" | 2 1/2" | 2 1/2" | 348 | IP65 | 00000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

10:1 Speed Ratio | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 265 in·lbf @ 1,750 rpm | 600 | 6,000 | 1.45 | 1/4" | 0.38" | 1" | 4 1/2" | 2 1/2" | 2 1/2" | 348 | IP65 | 00000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

20:1 Speed Ratio | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 345 in·lbf @ 1,750 rpm | 300 | 6,000 | 1.08 | 1/4" | 0.38" | 1" | 5 3/4" | 2 1/2" | 2 1/2" | 348 | IP65 | 00000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

50:1 Speed Ratio | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 345 in·lbf @ 1,750 rpm | 120 | 6,000 | 0.46 | 1/4" | 0.38" | 1" | 5 3/4" | 2 1/2" | 2 1/2" | 348 | IP65 | 00000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For NEMA 34 Motor Frames | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

3:1 Speed Ratio | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 743 in·lbf @ 1,750 rpm | 1,833 | 5,500 | 6.75 | 1/2" | 1/2" | 1.25" | 5 1/4" | 3 1/2" | 3 1/2" | 630 | IP65 | 00000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

5:1 Speed Ratio | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 867 in·lbf @ 1,750 rpm | 1,100 | 5,500 | 5.73 | 1/2" | 1/2" | 1.25" | 5 1/4" | 3 1/2" | 3 1/2" | 630 | IP65 | 00000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

10:1 Speed Ratio | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 797 in·lbf @ 1,750 rpm | 550 | 5,500 | 3.04 | 1/2" | 1/2" | 1.25" | 5 1/4" | 3 1/2" | 3 1/2" | 630 | IP65 | 00000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

20:1 Speed Ratio | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 867 in·lbf @ 1,750 rpm | 275 | 5,500 | 1.97 | 1/2" | 1/2" | 1.25" | 7" | 3 1/2" | 3 1/2" | 630 | IP65 | 00000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

50:1 Speed Ratio | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 867 in·lbf @ 1,750 rpm | 110 | 5,500 | 0.87 | 1/2" | 1/2" | 1.25" | 7" | 3 1/2" | 3 1/2" | 630 | IP65 | 00000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Stepper Gearmotors

Overall | Shaft | Keyway, mm | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Max. Holding Torque, in·ozf | Max. Rotation Speed, rpm | Max. Current per Phase, amp | Full Step Increment | No. of Wire Leads | Lg. | Wd. | Ht. | Dia., mm | Lg., mm | Ctr.-to-Base Lg. | Type | Key Included | Lg. | Wd. | Dp. | Temp. Range, ° F | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Square Body | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

NEMA 17 Frame Size | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 280 | 400 | 0.7 | 0.36° | 4 | 3.3" | 1.7" | 1.7" | 5 | 29 | 0.84" | D-Profile | — | — | — | — | 0 to 120 | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 560 | 400 | 2 | 0.36° | 4 | 4" | 1.7" | 1.7" | 5 | 29 | 0.84" | D-Profile | — | — | — | — | 0 to 120 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

NEMA 23 Frame Size | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1,465 | 400 | 2.2 | 0.36° | 4 | 6.4" | 2.6" | 2.6" | 16 | 29.5 | 1.18" | D-Profile | — | 25 | 5 | 3 | 0 to 120 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2,102 | 400 | 5 | 0.36° | 4 | 7.2" | 2.6" | 2.6" | 16 | 29.5 | 1.18" | D-Profile | — | 25 | 5 | 3 | 0 to 120 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2,931 | 200 | 2.2 | 0.18° | 4 | 6.4" | 2.6" | 2.6" | 16 | 29.5 | 1.18" | D-Profile | — | 25 | 5 | 3 | 0 to 120 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4,205 | 200 | 5 | 0.18° | 4 | 7.2" | 2.6" | 2.6" | 16 | 29.5 | 1.18" | D-Profile | — | 25 | 5 | 3 | 0 to 120 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5,537 | 100 | 2.2 | 0.09° | 4 | 7.2" | 2.6" | 2.6" | 16 | 29.5 | 1.18" | D-Profile | — | 25 | 5 | 3 | 0 to 120 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7,944 | 100 | 5 | 0.09° | 4 | 8.1" | 2.6" | 2.6" | 16 | 29.5 | 1.18" | D-Profile | — | 25 | 5 | 3 | 0 to 120 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 13,842 | 40 | 2.2 | 0.036° | 4 | 7.2" | 2.6" | 2.6" | 16 | 29.5 | 1.18" | D-Profile | — | 25 | 5 | 3 | 0 to 120 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 19,681 | 40 | 5 | 0.036° | 4 | 8.1" | 2.6" | 2.6" | 16 | 29.5 | 1.18" | D-Profile | — | 25 | 5 | 3 | 0 to 120 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

NEMA 34 Frame Size | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3,058 | 400 | 3.5 | 0.36° | 4 | 8.5" | 3.5" | 3.5" | 22 | 37.5 | 1.77" | Keyed | No | 30 | 6 | 3.5 | 0 to 120 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6,117 | 200 | 3.5 | 0.18° | 4 | 8.5" | 3.5" | 3.5" | 22 | 37.5 | 1.77" | Keyed | No | 30 | 6 | 3.5 | 0 to 120 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 11,555 | 100 | 3.5 | 0.09° | 4 | 8.5" | 3.5" | 3.5" | 22 | 37.5 | 1.77" | Keyed | No | 30 | 6 | 3.5 | 0 to 120 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 28,888 | 40 | 3.5 | 0.036° | 4 | 8.5" | 3.5" | 3.5" | 22 | 37.5 | 1.77" | Keyed | No | 30 | 6 | 3.5 | 0 to 120 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Round Body | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

NEMA 5 Frame Size | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 27.8 | 680 | 0.56 | 1.875° | 4 | 2.6" | 0.5" | 0.5" | 3 | 8.5 | 0.26" | D-Profile | — | — | — | — | 0 to 120 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 27.8 | 680 | 0.9 | 1.875° | 4 | 2.6" | 0.5" | 0.5" | 3 | 8.5 | 0.26" | D-Profile | — | — | — | — | 0 to 120 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 41.7 | 40 | 0.56 | 0.11° | 4 | 2.9" | 0.5" | 0.5" | 3 | 8.5 | 0.26" | D-Profile | — | — | — | — | 0 to 120 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 41.7 | 40 | 0.9 | 0.11° | 4 | 2.9" | 0.5" | 0.5" | 3 | 8.5 | 0.26" | D-Profile | — | — | — | — | 0 to 120 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 41.7 | 165 | 0.56 | 0.45° | 4 | 2.8" | 0.5" | 0.5" | 3 | 8.5 | 0.26" | D-Profile | — | — | — | — | 0 to 120 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 41.7 | 165 | 0.9 | 0.45° | 4 | 2.8" | 0.5" | 0.5" | 3 | 8.5 | 0.26" | D-Profile | — | — | — | — | 0 to 120 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

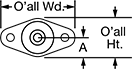

Compact Air-Powered Gearmotors

Face Mount

@ 90 psi | Overall | Shaft | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Power, hp | Maximum Speed, rpm | Starting Torque, in·lbf | Max. Pressure, psi | Air Consumption @ 90 psi, ft³/min | Noise Level | Lg. | Wd. | Ht. | Dia. | Lg. | Center to Base (A) | Type | Direction of Operation | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1/4 NPT Female Threaded Inlet | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.31 | 85 | 396 | 90 | 17.5 | Not Rated | 8 3/4" | 3 1/4" | 1 3/4" | 3/8" | 1" | 0.88" | Keyed | Clockwise, Counterclockwise | 0000000 | 000000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.31 | 169 | 247.2 | 90 | 17.5 | Not Rated | 8 3/4" | 3 1/4" | 1 3/4" | 3/8" | 1" | 0.88" | Keyed | Clockwise, Counterclockwise | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.31 | 280 | 147.6 | 90 | 17.5 | Not Rated | 8 3/4" | 3 1/4" | 1 3/4" | 3/8" | 1" | 0.88" | Keyed | Clockwise, Counterclockwise | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.34 | 450 | 106.2 | 90 | 18 | Not Rated | 8" | 3 1/4" | 1 3/4" | 3/8" | 1" | 0.88" | Keyed | Clockwise, Counterclockwise | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||