Filter by

For Use On

Material

Consistency

Performance

Manufacturer

Formulation

Export Control Classification Number (ECCN)

DFARS Specialty Metals

Surface Filler Patches

Temp. Range, ° F | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Mfr. Model No. | Container Type | Lg. | Wd. | Begins to Harden, min. | Reaches Full Strength | Mixing Req. | Mix Ratio | For Use Outdoors | Min. | Max. | Color | Process After Hardening | For Use On | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Devcon Zip Patch™ | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 11500 | Patch | 4" | 9" | 5 | 4 hr. | No | — | Yes | -40 | 200 | Brown | Machine, Drill, Sand, Saw, Tap | Aluminum, Brass, Bronze, Copper, Steel, Stainless Steel, Cast Iron, Titanium, ABS, CPVC, PETG, Polycarbonate, Polyimide, Polystyrene, Polyurethane Rubber, PVC, PVDF, Ceramic, Fiberglass, Wood | 0000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Epoxy Surface Fillers | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| — | Patch | 4" | 6" | 1 | 30 min. | Yes | 1:1 | Yes | — | 425 | Clear | Sand | Aluminum, Brass, Bronze, Copper, Vinyl Plastic, EPDM, SBR, Steel, Stainless Steel, Cast Iron, Titanium, ABS, CPVC, PETG, Polycarbonate, Polyimide, Polystyrene, Polyurethane Rubber, PVC, PVDF, Fiberglass, Wood | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Surface Fillers

Container | Temp. Range, ° F | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Size, fl. oz. | Type | Begins to Harden, min. | Reaches Full Strength, hr. | Consistency | Mixing Req. | Mix Ratio | Approx. Coverage @ Thk. | Max. Thk. | For Use Outdoors | Min. | Max. | Color | Process After Hardening | For Use On | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Polyester Plastic Surface Fillers | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8 | Tube | 15 | 3 | Paste | Yes | 50:1 | Not Rated | 1/2" | Yes | -40 | 180 | Varies | Sand | Fiberglass | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

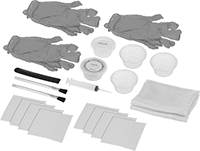

Water-Resistant Surface Filler Kits

West System 105K

Includes | Formulation | Consistency | For Use Outdoors | Temp. Range, ° F | Process After Hardening | For Use On | Each | ||

|---|---|---|---|---|---|---|---|---|---|

| 8 One-Time-Use Packets of 101-TS Two-Part Epoxy Filler 0.1-oz. 406 Collodial Silica Filler 0.1-oz. 410 Low-Density Filler Two Brushes Reusable Mixing Stick Three Mixing Cups 15" × 15" Fiberglass Cloth Syringe Dispenser Three Pairs of Disposable Gloves | Epoxy | Thin Liquid | Yes | 35 to 130 | Machine, Drill, Sand, Saw, Tap | Aluminum, Steel, Stainless Steel, ABS, PVC, Fiberglass, Wood | 0000000 | 000000 |