How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

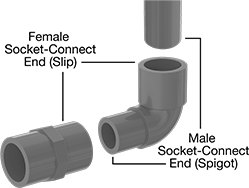

Thick-Wall Plastic Pipe Fittings for Water

Connect these fittings to Schedule 80 pipe. With thicker, stronger walls than standard-wall fittings, they can handle heavy duty supply applications, such as water processing, wastewater treatment, and irrigation. Fittings are plastic for good corrosion resistance. They meet ASTM specifications and testing requirements for material quality.

Fittings for drinking water meet NSF/ANSI Standard 61.

Attach socket-connect ends to unthreaded pipe or another socket-connect fitting with a PVC primer and cement (also known as solvent weld).

Note: For fittings that are not rated for pressure, you can use the pressure rating of the plastic pipe as a reference. Threaded fittings are limited to 50% of the rated pressure of the pipe.

Warning: Never use plastic pipe fittings and pipe with compressed air or gas.

- For Use With: Drinking Water, Water

- Maximum Temperature: 140° F

- Specifications Met: ASTM D1784, NSF/ANSI 61

- Pipe Nipples and Pipe: Use Schedule 80 PVC Plastic

- Flanges: Use Class 150 PVC Plastic

Right-angle tees are also known as run tees.

| Pipe Size | Socket Depth | OD | ID | Wall Thick | Material | Color | Each | |

| 1/2 | 7/8" | 27/32" | 0.546" | 0.147" | PVC Plastic | Dark Gray | 00000000 | 00000 |

| 3/4 | 1" | 1 3/64" | 0.742" | 0.154" | PVC Plastic | Dark Gray | 00000000 | 0000 |

| 1 | 1 1/8" | 1 5/16" | 0.957" | 0.179" | PVC Plastic | Dark Gray | 00000000 | 0000 |

| 1 1/4 | 1 1/4" | 1 21/32" | 1.278" | 0.191" | PVC Plastic | Dark Gray | 00000000 | 00000 |

| 1 1/2 | 1 3/8" | 1 29/32" | 1.5" | 0.2" | PVC Plastic | Dark Gray | 00000000 | 00000 |

| 2 | 1 1/2" | 2 3/8" | 1.939" | 0.218" | PVC Plastic | Dark Gray | 00000000 | 00000 |

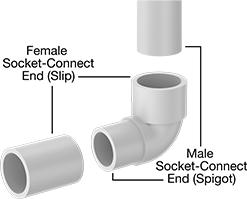

Standard-Wall Plastic Pipe Fittings for Water

Connect these fittings to Schedule 40 plastic pipe–they are the industry standard for residential and commercial low-pressure plumbing and water supply applications. They are plastic for good corrosion resistance.

Fittings for drinking water meet NSF/ANSI Standard 61.

Attach socket-connect ends to unthreaded pipe or another socket-connect fitting with a PVC primer and cement (also known as solvent weld).

Fittings that meet ASTM D1784, ASTM D1785, and ASTM D4066 adhere to specifications and testing requirements for material quality.

Note: For fittings that are not rated for pressure, you can use the pressure rating of the plastic pipe as a reference. Threaded fittings are limited to 50% of the rated pressure of the pipe.

Warning: Never use plastic pipe fittings and pipe with compressed air or gas.

- For Use With: Drinking Water, Water

- Maximum Temperature: 140° F

- Specifications Met: ASTM D1784, NSF/ANSI 61

- Pipe Nipples and Pipe: Use Schedule 40 PVC Plastic

- Flanges: Use Class 150 PVC Plastic

Right-angle tees are also known as run tees.

| Pipe Size | Socket Depth | OD | ID | Wall Thick. | Material | Color | Each | |

| 1/2 | 11/16" | 27/32" | 0.622" | 0.109" | PVC Plastic | White | 00000000 | 00000 |

| 3/4 | 23/32" | 1 3/64" | 0.824" | 0.113" | PVC Plastic | White | 00000000 | 0000 |

| 1 | 7/8" | 1 5/16" | 1.049" | 0.133" | PVC Plastic | White | 00000000 | 0000 |

| 1 1/2 | 1 3/32" | 1 29/32" | 1.61" | 0.145" | PVC Plastic | White | 00000000 | 00000 |

| 2 | 1 5/32" | 2 3/8" | 2.067" | 0.154" | PVC Plastic | White | 00000000 | 00000 |

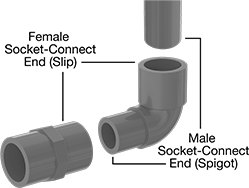

CPVC Pipe Fittings for Hot Water

Made of CPVC, these fittings can handle high temperatures. They have thick, strong walls to handle heavy duty industrial plumbing and water supply applications, such as water processing and waste water treatment. They also have good corrosion resistance. These fittings are comparable to Corzan. Some meet ASTM D1784 specifications and testing requirements for material quality.

Fittings for drinking water meet NSF/ANSI Standard 61.

Schedule 80 fittings have thick, strong walls for heavy duty, industrial applications.

Note: For fittings that are not rated for pressure, you can use the pressure rating of the plastic pipe as a reference. Threaded fittings are limited to 50% of the rated pressure of the pipe.

Warning: Never use plastic pipe fittings and pipe with compressed air or gas.

- For Use With: Acetic Acid (10%), Calcium Chloride, Deionized Water, Drinking Water, Hydrochloric Acid (25%), Phosphoric Acid (85%), Salt Water, Sodium Hydroxide (50%), Sulfuric Acid (75%), Water

- Maximum Temperature: 200° F

- Specifications Met: ASTM D1784, NSF/ANSI 61

- Pipe Nipples and Pipe: Use Schedule 80 CPVC Plastic

- Flanges: Use Class 150 CPVC Plastic

Attach socket-connect ends to unthreaded pipe or another socket-connect fitting with a CPVC primer and cement (also known as solvent weld).

Right-angle tees are also known as run tees.

| Pipe Size | Socket Depth | OD | ID | Wall Thick. | Material | Schedule | Color | Max. Pressure | Environment | Each | |

| 1/2 | 15/16", 1 3/32" | 27/32" | 0.546" | 0.147" | CPVC Plastic | 80 | Light Gray | Not Rated | Food Industry | 00000000 | 000000 |

| 3/4 | 1 1/32", 1" | 1 3/64" | 0.742" | 0.154" | CPVC Plastic | 80 | Light Gray | Not Rated | Food Industry | 00000000 | 00000 |

| 1 | 1 3/16", 1 3/16" | 1 5/16" | 0.957" | 0.179" | CPVC Plastic | 80 | Light Gray | Not Rated | Food Industry | 00000000 | 00000 |

| 1 1/4 | 1 1/4", 1 5/16" | 1 21/32" | 1.278" | 0.191" | CPVC Plastic | 80 | Light Gray | Not Rated | Food Industry | 00000000 | 00000 |

| 1 1/2 | 1 7/16", 1 7/16" | 1 29/32" | 1.5" | 0.2" | CPVC Plastic | 80 | Light Gray | Not Rated | Food Industry | 00000000 | 00000 |

| 2 | 1 1/2", 1 17/32" | 2 3/8" | 1.939" | 0.218" | CPVC Plastic | 80 | Light Gray | Not Rated | Food Industry | 00000000 | 00000 |

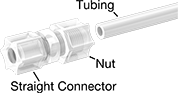

Plastic Compression Tube Fittings for Water

- Temperature Range: -40° to 200° F

- Tubing: Use with firm or hard (Durometer 1A-90A or Durometer OD-75D) nylon plastic or polypropylene plastic

Made of acetal, these compression fittings are lighter in weight than metal compression fittings and won’t absorb moisture when used in wet environments. Fittings include a nut with a built-in sleeve (ferrule), so there’s no need to remove the nut for assembly. The sleeve compresses the tubing as you tighten the nut, creating a strong seal. Fittings are also known as flareless fittings.

Tube supports (sold separately) are recommended if you want to use the fittings with soft nylon and polypropylene tubing to prevent the tube from collapsing.

Right-angle tees are also known as run tees.

| For Tube OD | Pipe Size | Material | Color | Max. Pressure | Each | |

NPT Threads | ||||||

|---|---|---|---|---|---|---|

| 1/4" | 1/4 | Acetal Plastic | White | 220 psi @ 72° F | 00000000 | 00000 |

| 5/16" | 1/4 | Acetal Plastic | White | 220 psi @ 72° F | 00000000 | 0000 |

| 3/8" | 1/4 | Acetal Plastic | White | 220 psi @ 72° F | 00000000 | 0000 |

| 3/8" | 3/8 | Acetal Plastic | White | 220 psi @ 72° F | 00000000 | 0000 |

| 1/2" | 3/8 | Acetal Plastic | White | 220 psi @ 72° F | 00000000 | 0000 |

| 1/2" | 1/2 | Acetal Plastic | White | 220 psi @ 72° F | 00000000 | 0000 |

| 5/8" | 1/2 | Acetal Plastic | White | 220 psi @ 72° F | 00000000 | 0000 |

| 3/4" | 1/2 | Acetal Plastic | White | 220 psi @ 72° F | 00000000 | 0000 |

| 3/4" | 3/4 | Acetal Plastic | White | 220 psi @ 72° F | 00000000 | 0000 |

| 7/8" | 3/4 | Acetal Plastic | White | 220 psi @ 72° F | 00000000 | 0000 |