About Composites

More

About Plastic

More

Chemical-Resistant Slippery PTFE Film

PTFE has a naturally slippery surface that allows objects to easily slide across it. It resists most solvents and stands up to extreme temperatures. It’s also an excellent electrical insulator.

Film with a coarse texture masks scratches, scuffs, and fingerprints.

Film with a smooth texture is skived, so the edges may curl.

- Color: Semi-Clear White

- Temperature Range: -350° to 500° F

- Tensile Strength: 4,500 psi (Poor)

- Impact Strength: 3.5 ft.-lbs./in. (Good)

- Hardness: Durometer 46D-60D (Medium Soft)

- For Use Outdoors: Yes

- Specifications Met: FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 178.3297, UL 94 V-0

- Color: Semi-Clear White

- Max. Temperature: 250° F

- Tensile Strength: 4,500 psi (Poor)

- Impact Strength: 3.5 ft.-lbs./in. (Good)

- Hardness: Durometer 46D-60D (Medium Soft)

- For Use Outdoors: Yes

- Specifications Met: FDA Compliant 21 CFR 177.1550

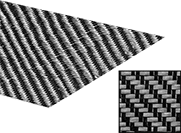

Composite Fabrics

Use these resin-free fabrics to reinforce or repair existing composites as well as create new composites. Mold custom-shaped composite parts by layering your choice of fabric with an epoxy. The epoxy (sold separately) is a two-part resin that begins to harden in 15 hours and reaches full strength in 4 days. Finished composite pieces withstand temperatures up to 250° or 350° F.

Fabrics with a plain, twill, or triaxial weave have fibers that are woven in alternating directions for uniform strength and rigidity in all directions. Easier to machine than fabrics with a unidirectional weave, their woven pattern holds the fibers together to limit splintering. Twill-weave fabrics are stronger than plain-weave fabrics. They’re also more flexible, making them easier to manipulate into complex shapes. They will not, however, retain their shape as well as plain-weave fabrics.

Fiberglass fabrics are strong and offer a little flex to finished custom composite parts.

Flame-Retardant Heavy Duty Heat-Shrink Film

Protect equipment exposed to flames and sparks. This film is often used on shipments staged in machine shops or construction sites where sparks may fly from welding and grinding. To meet NFPA 701 standards, this film self-extinguishes flames. It is also treated to prevent weakening and disintegrating from UV exposure, so your equipment will remain protected outdoors for up to a year. Shrink the film with a heat gun to create a formfitting barrier.

Eight times thicker than standard heat-shrink film, you can drag and shrink this film over corners of equipment without it tearing. It's large enough to cover forklifts, industrial compressors, or even a boat, but it's easy enough to trim down using a utility knife. This film comes folded on a roll for efficient storage.

Note: One mil equals 0.001".